A method of outsourcing waterproof construction that penetrates metal roof panel components

A construction method and metal house technology, applied in the direction of building structure, roof insulation materials, building materials, etc., can solve the problems of small waterproof structure rigidity, waterproof material damage, etc., to avoid pulling damage and increase the overall rigidity , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] The invention discloses an outsourcing waterproof construction method for penetrating metal roof components, comprising the following steps:

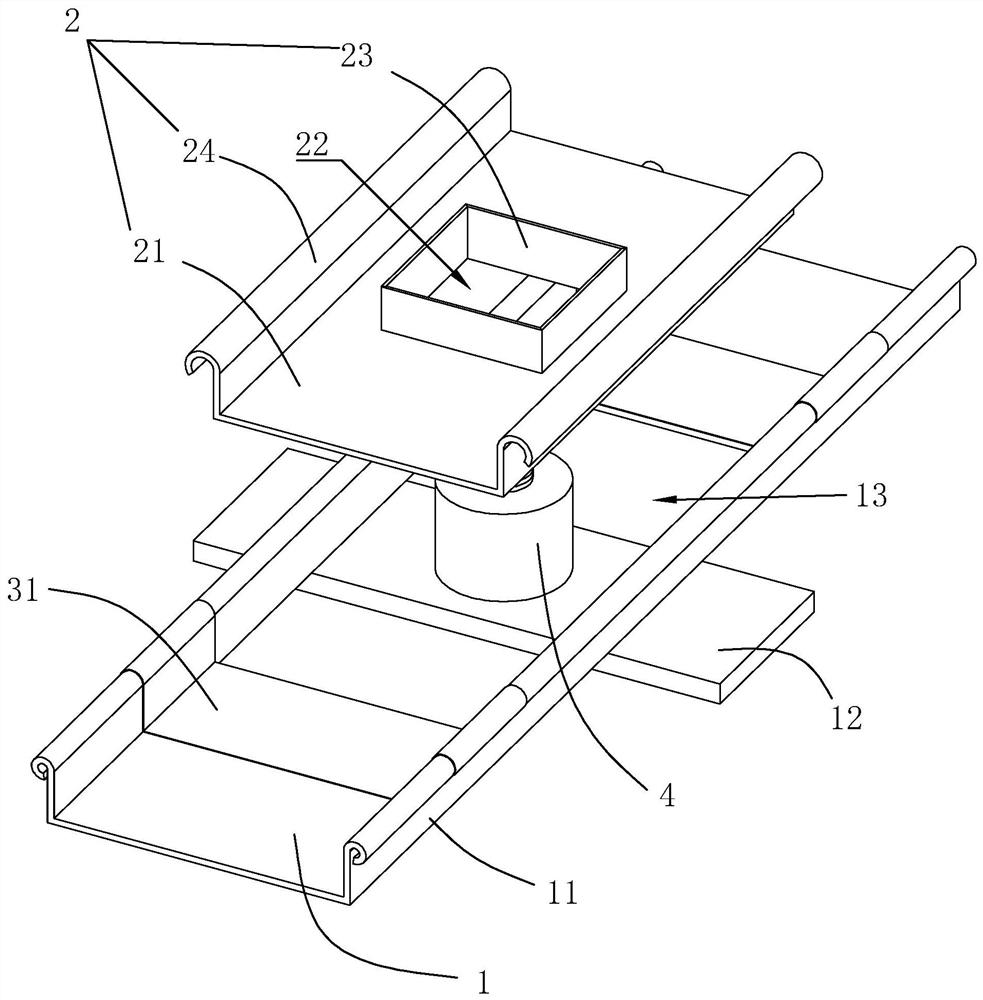

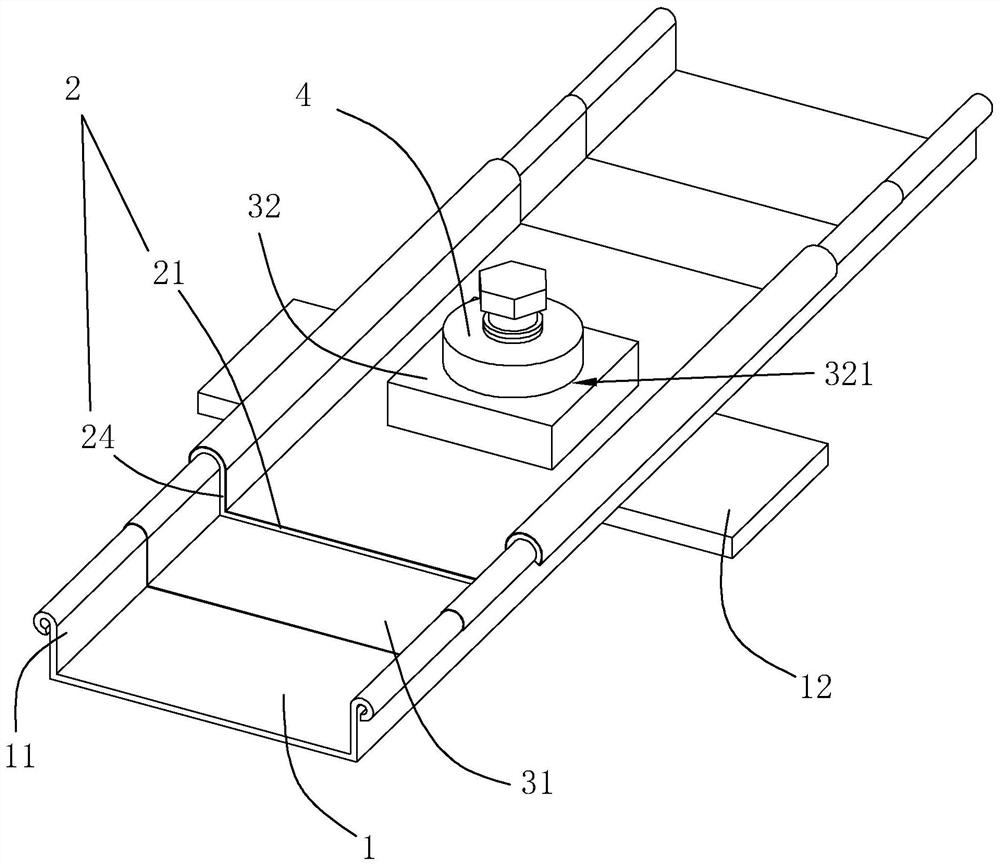

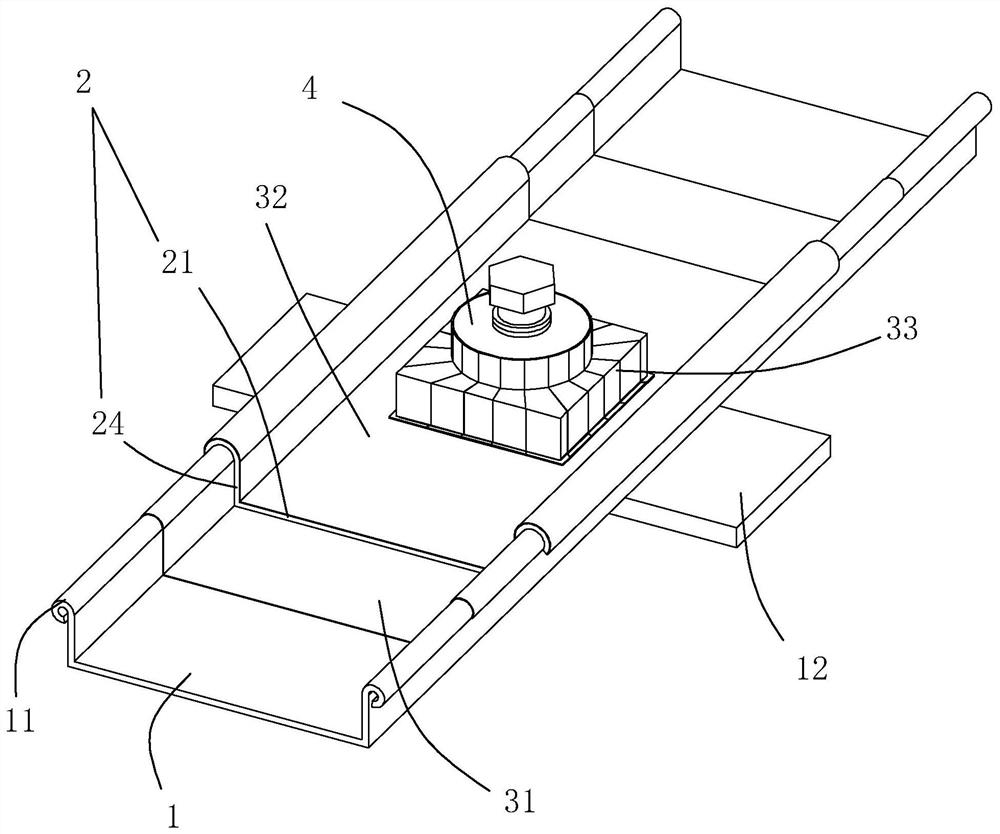

[0044] Such as figure 1 As shown, step 1: prefabricate the water-stop cover 2; the water-stop cover 2 includes a substrate 21 with an area larger than that of the hole 13 of the roof panel 1, and the middle section of the substrate 21 is provided with a through hole 22 for passing through the metal roof panel member 4. , the substrate 21 is fixed with a frame body 23 whose shape matches the through hole 22 at the through hole 22, and the top end of the frame body 23 protrudes from the upper surface of the substrate 21;

[0045] Step 2: Carry out basic treatment on the roof panel 1, polish the burrs on the edge of the hole 13, and remove the dust accumulated on the roof panel 1; Step 1 and Step 2 can be performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com