Quick connector device

A joint device and fast technology, applied in the direction of fixing device, rod connection, connecting member, etc., can solve the problems of long connecting rod or wrench of clamping device, strict diameter requirements of clamped parts, and difficulty in manufacturing internal racks, etc. To achieve the effect of wide size requirements, wide size range, avoid damage to the hose and long operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

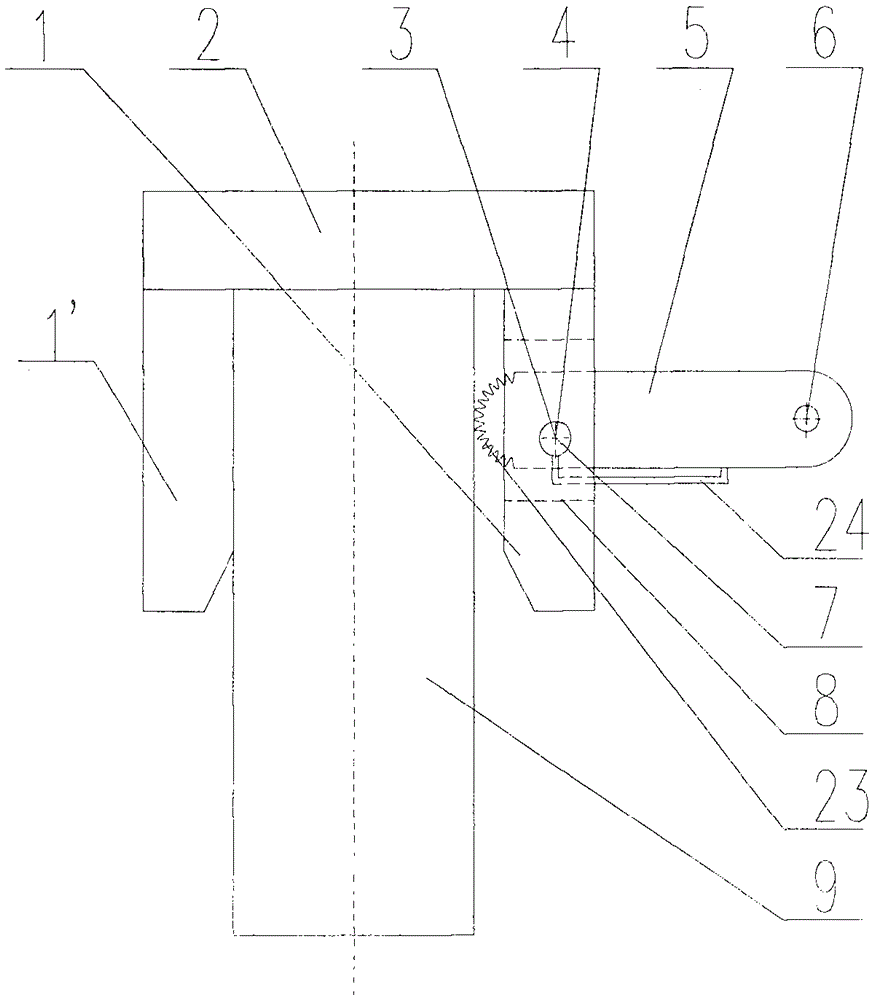

[0063] Example 1 The clamping jacket is an inverted U-shaped structure and a quick clamping release device with a clamping rod on one side

[0064] A quick clamping and releasing device, including an inverted U-shaped clamping jacket composed of two parallel vertical plates 1, 1' and a top plate 2 vertically fixed together above it, a clamping rod 5 and a clamping Tight bar 5 is connected together with clamping outer hinge shaft 3 of clamping outer cover, as figure 1 As shown; a vertical plate 1 of the inverted U-shaped groove clamping jacket is provided with a circular through hole 4, and the circular through hole 4 is parallel to the top plate 2 of the inverted U-shaped jacket and another vertical wall parallel to it. Plate 1'. A square or rectangular hole 8 is formed symmetrically or not completely symmetrically to the axis of the circular through hole 4 on the vertical plate 1 having the circular through hole 4 . One end on the clamping rod 5, that is, the clamping end, ...

Embodiment 2

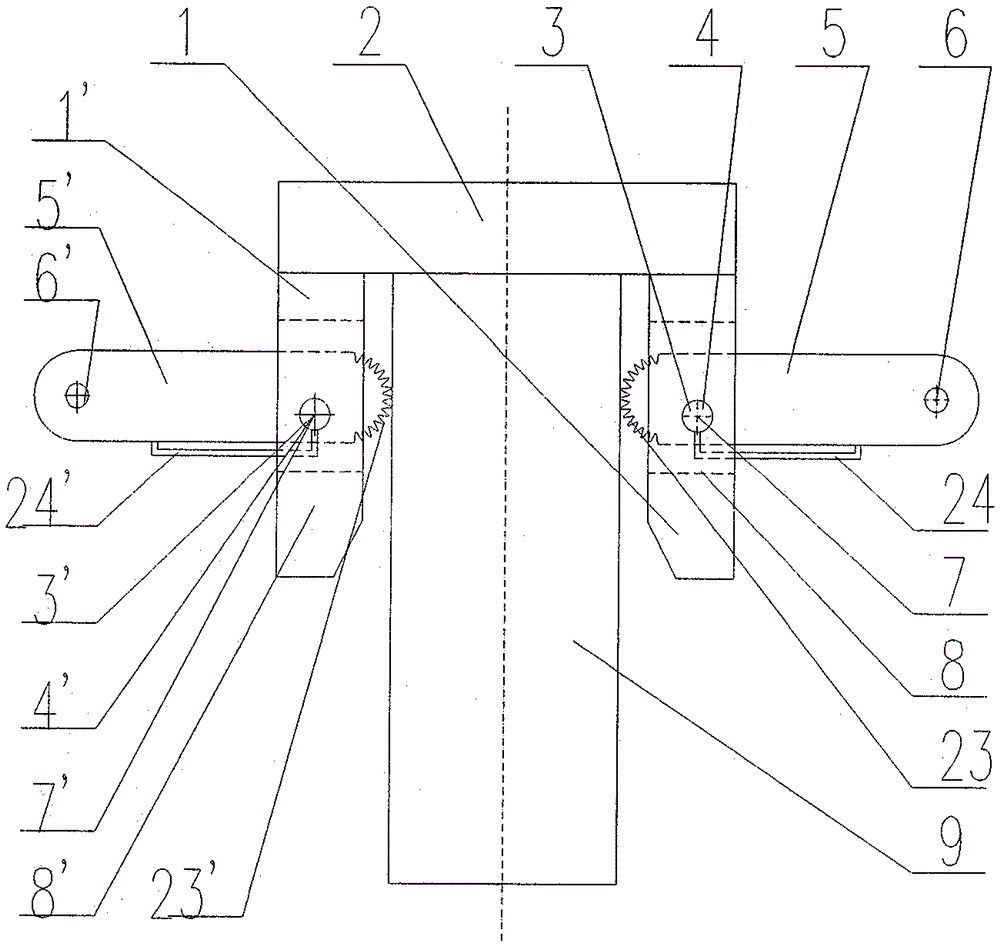

[0066] Example 2 The quick clamping and releasing device with the clamping jacket having an inverted U-shaped structure and clamping rods on both sides

[0067] Such as figure 2 As shown, in order to achieve clamping in a wider size range or to achieve the purpose of flexible operation, it is characterized in that the other vertical plate 1' is symmetrically opened with square or rectangular holes 8', and in this vertical plate 1' A circular through hole 4' is symmetrically opened on the top. Clamping rods 5' and hinge shafts 3' of the same size are installed symmetrically. A shaft hole 7' and a coupling hole 6' parallel to each other are respectively provided on the clamping end and the force application end of the clamping rod 5'. The simultaneous rotation of the two clamping rods 5 and 5' can allow a wider size range of the clamped object 9 under the condition of constant clamping force.

[0068] In order to enable the quick clamp release device to enter the clamped pie...

Embodiment 3

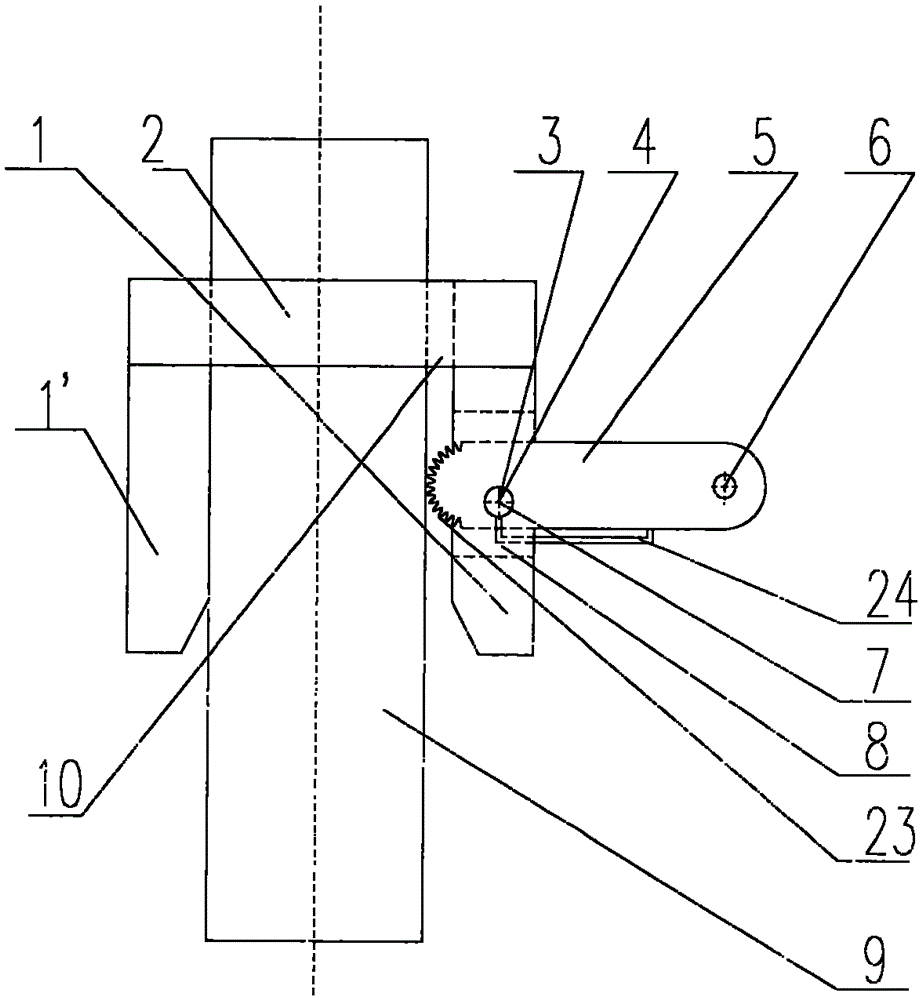

[0070] Embodiment 3 That is, on the basis of Embodiment 1, the quick clamping and releasing device with a hole in the top plate

[0071] Such as image 3 As shown, for cylindrical objects, due to the needs of some occasions, on the basis of the above-mentioned scheme, the top plate 2 of the clamping sleeve is opened at a position between the two vertical plates and perpendicular to the top plate 2. A circular hole 10 with a parallel spacing not smaller than the two vertical plates 1 and 1 ′, the circular hole 10 is a through hole coaxial with the clamping jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com