Lifting device for lifting tapered instrument compartment

An instrument cabin and cone-shaped technology, applied in the field of spreaders, can solve the problems of in- and out-of-field maintenance affecting the assembly of production lines, difficult hoisting of cone-shaped instrument cabins, and inability to complete hoisting, etc. The effect of low hoisting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

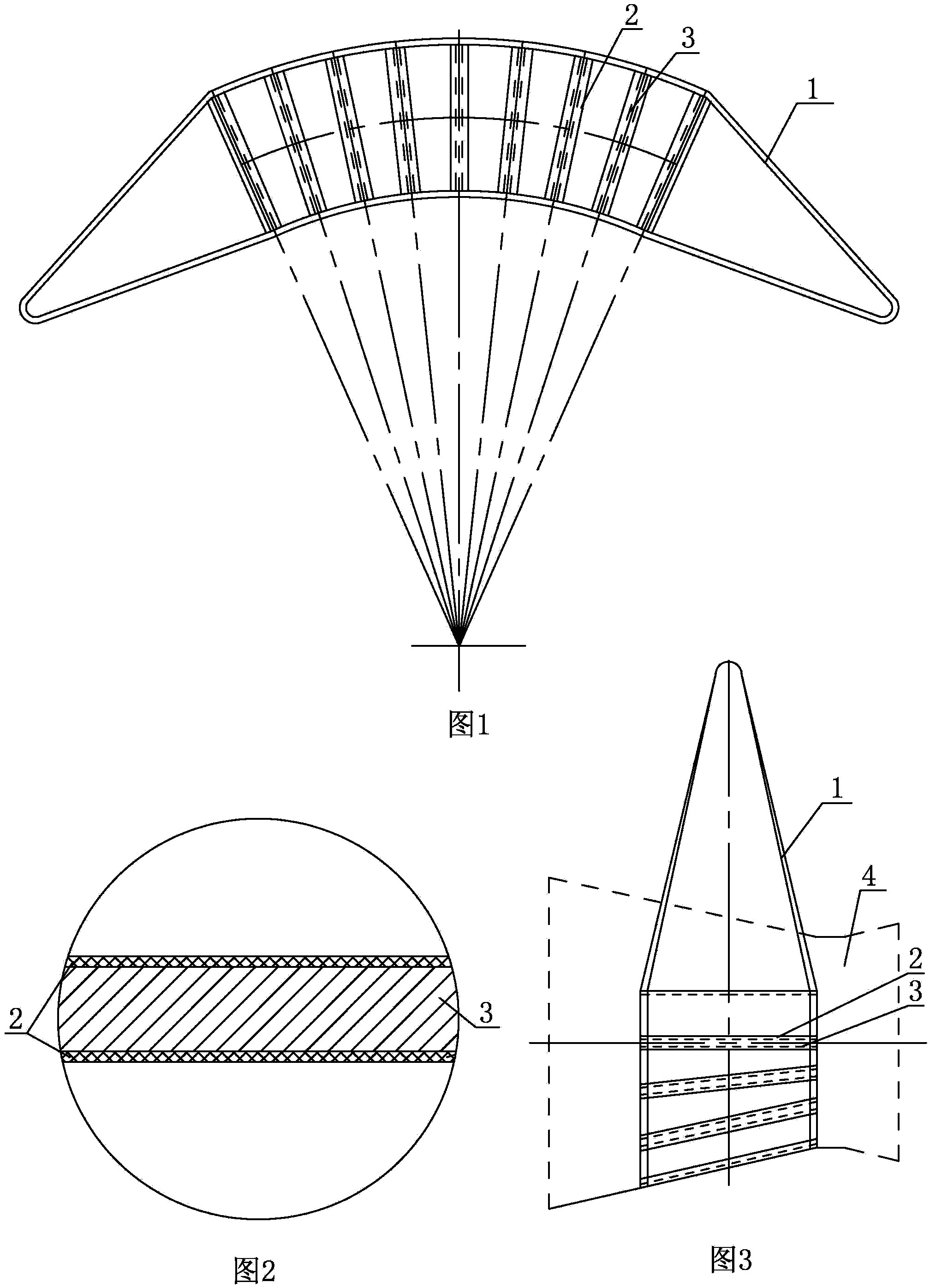

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Illustrate, the suspender of a kind of hoisting conical body instrument cabin of the present embodiment comprises flexible annular sling 1, a plurality of shawls 2 and the stainless steel plate 3 that is consistent with shawl 2 quantity, and described stainless steel plate 3 is cuboid, flexible annular A plurality of stainless steel plates 3 are arranged between the suspenders 1, and the connecting segment at the center of the two wide sides of each stainless steel plate 3 has an extension line, and a plurality of extension lines meet at one point, and the shawl 2 wraps the stainless steel plates 3, and the shawl 2 is connected with the flexible ring sling 1 as a whole.

[0008] The connecting line of the centers of the two wide sides of each stainless steel plate 3 in this embodiment has an extension line, and a plurality of extension lines meeting at one point means that the centerlines in the length directi...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and image 3 Note that the flexible endless sling 1 in this embodiment is a flexible endless sling made of vinylon, polyester or nylon. With such setting, the strength is high, and the load carried is large, which meets the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 1-Figure 3 Note that the thickness of the stainless steel plate 3 of this embodiment is 2mm-4mm. Such arrangement can meet the hoisting requirements of conical instrument cabins of different weights and sizes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com