Metal liner clamping hoop

A technology of metal gaskets and clamps, applied in the direction of pipe brackets, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as cable stringing out, bending breaks, etc., to prevent stringing and damping Good, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

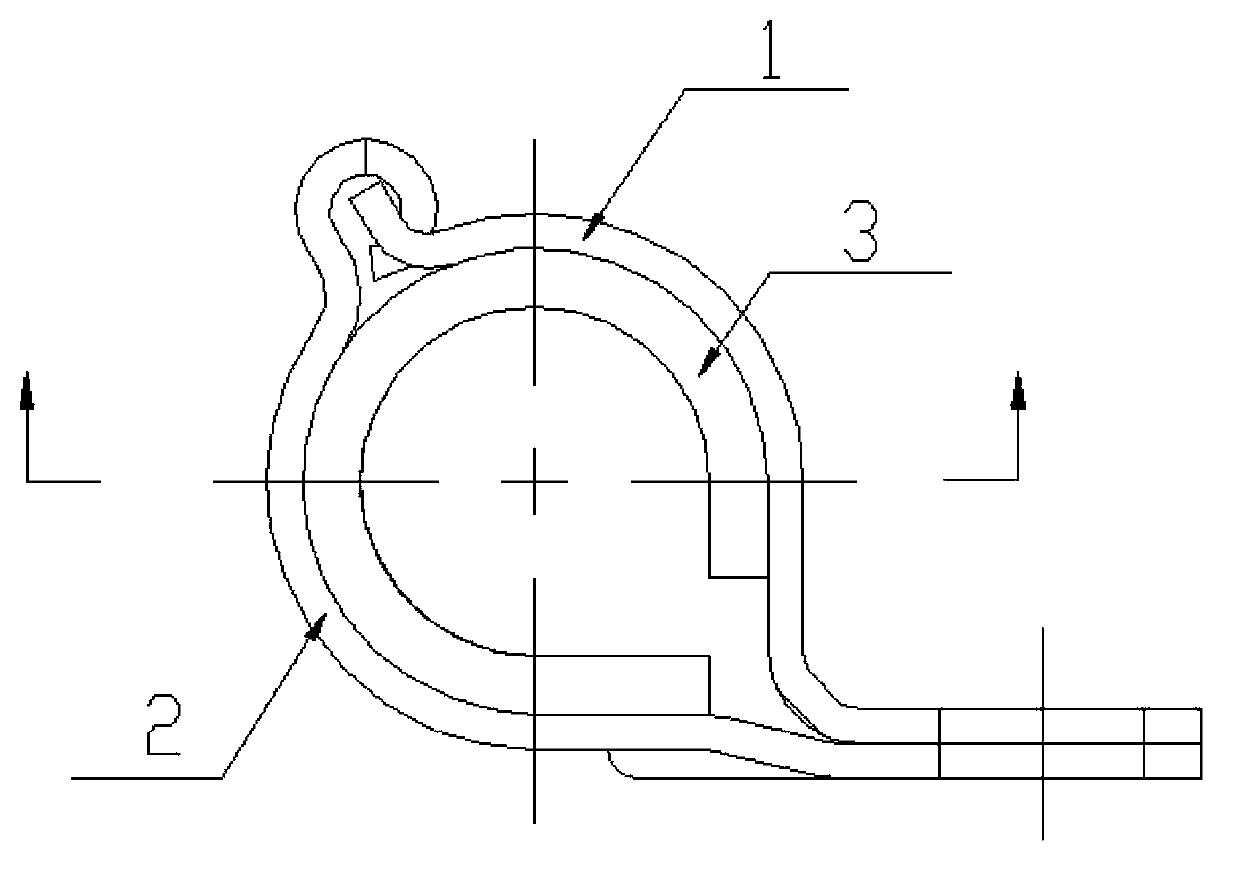

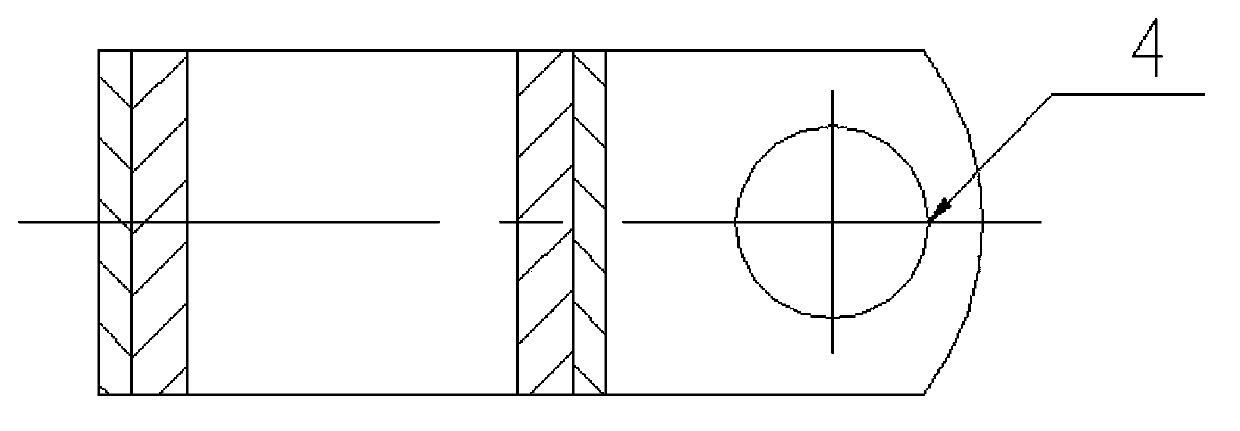

[0011] Such as figure 1 and figure 2 As shown, a metal liner clip includes: a right clip 1, a left clip 2, a gasket 3, a round hole 4 and a square hole; the upper ends of the right clip 1 and the left clip 2 are bent The spot welding is fixedly connected together, and the connection is very firm. The tail end of the right clip 1 is provided with a round hole 4, and the tail end of the left clip 2 is provided with a square hole. The tail ends of the right clip 1 and the left clip 2 pass through the bolts. The round hole 4 is connected and fixed with the square hole, which is convenient to form a complete arc when closing, and the ring is closed to close. This structure has a large clamping force, which reduces the frequency of relative displacement between the clamp, the cable and the pipeline, and prevents serial movement.

[0012] The liner 3 is a metal liner, and the metal liner has good high temperature resistance; it has the characteristics of light weight, good vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com