Mute barbell roller bearing

A technology of roller bearings and cylindrical roller bearings, which is applied in the direction of roller bearings, bearing components, shafts and bearings, etc., can solve the problem of insurmountable retention of the edge of the roller run, large axial momentum of a single roller, and unsuitable Discharge of impurities in lubricating oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

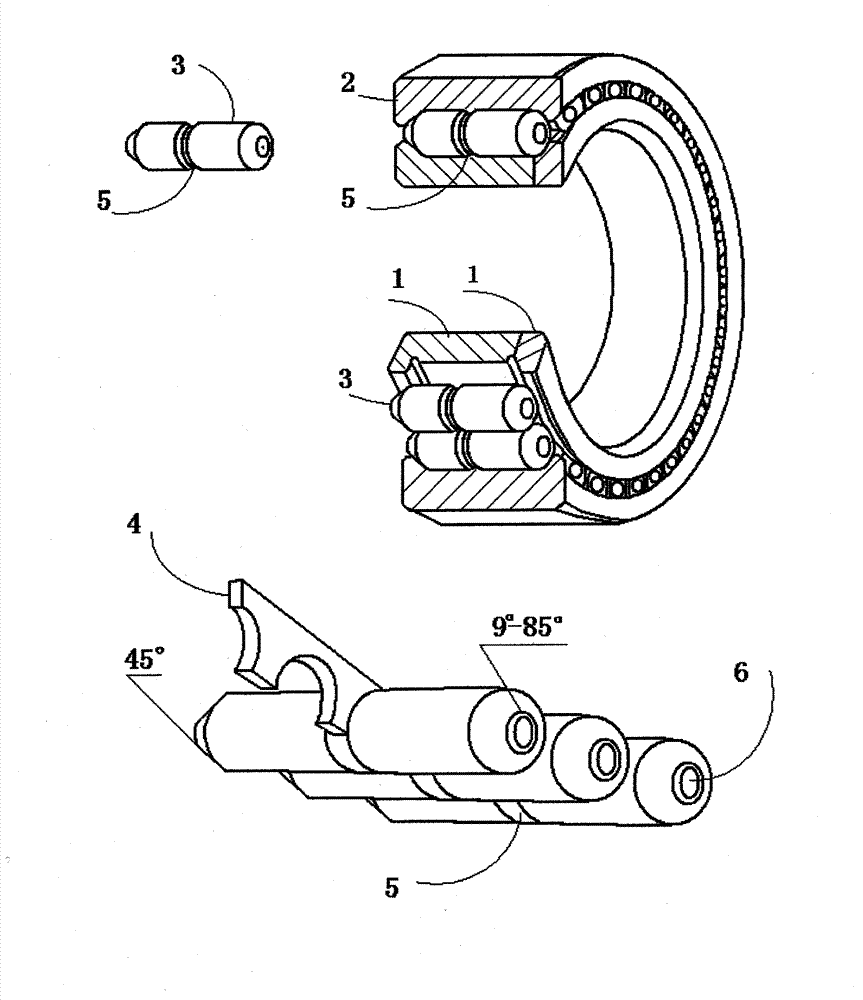

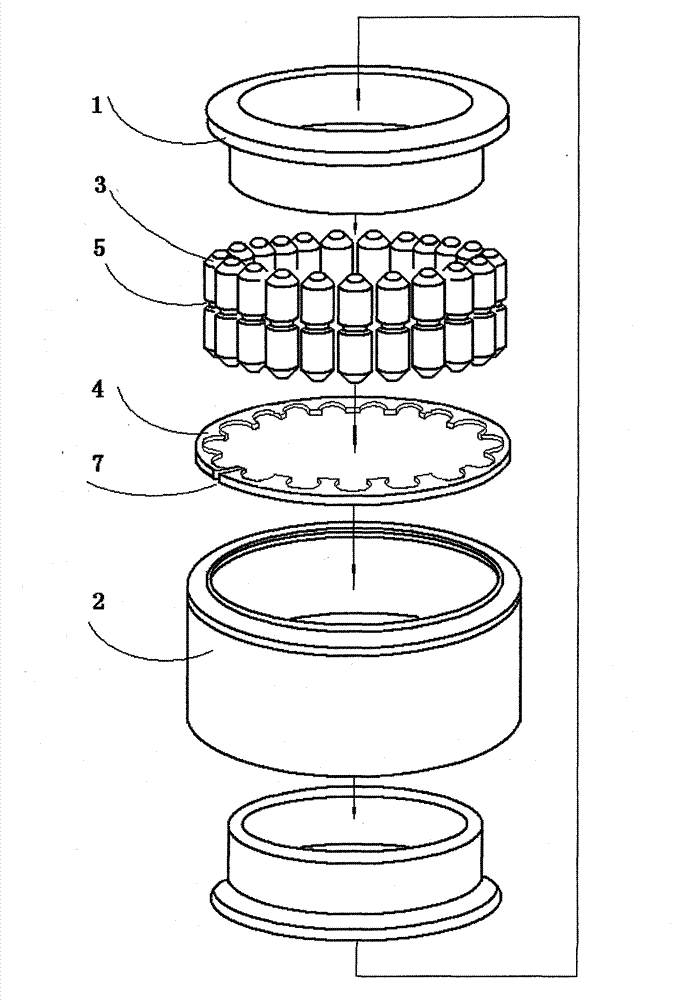

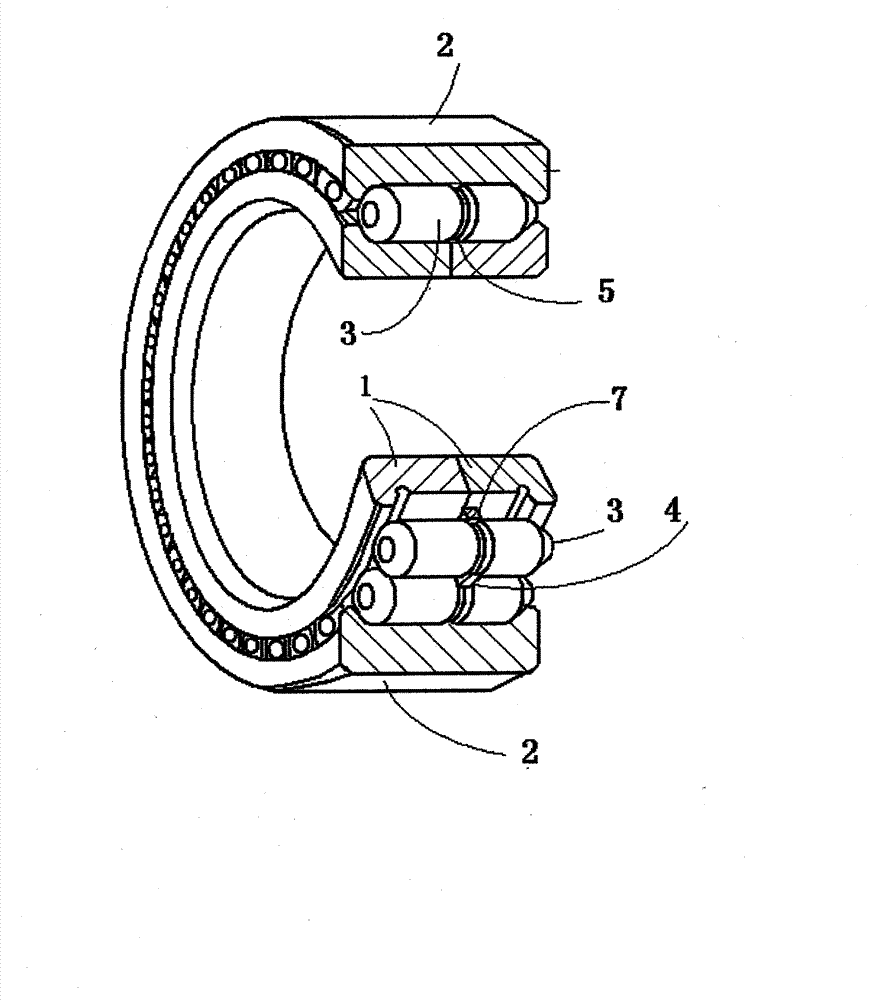

[0010] A specific embodiment of a practical and innovative silent barbell roller bearing, such as Figure 2 Shown; on the raceway surface of the inner circle of the outer circle 2, install the invisible spring cage 4 with inner teeth, and then insert the barbell rollers 3 one by one in the tooth openings until they are full; then separate the two pieces The internal ferrule 1 is respectively inserted into the inner holes of a row of barbell rollers 3 from both sides, and is on the same horizontal plane as the outer ferrule 2 to realize Figure 3 A silent barbell roller bearing was born.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com