Wood-type golf club head

a golf club head and wood-type technology, applied in the field of wood-type golf club heads, can solve the problems of too high spin rate, and achieve the effect of preventing effective errors in hitting the ball and high resistance to slippag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

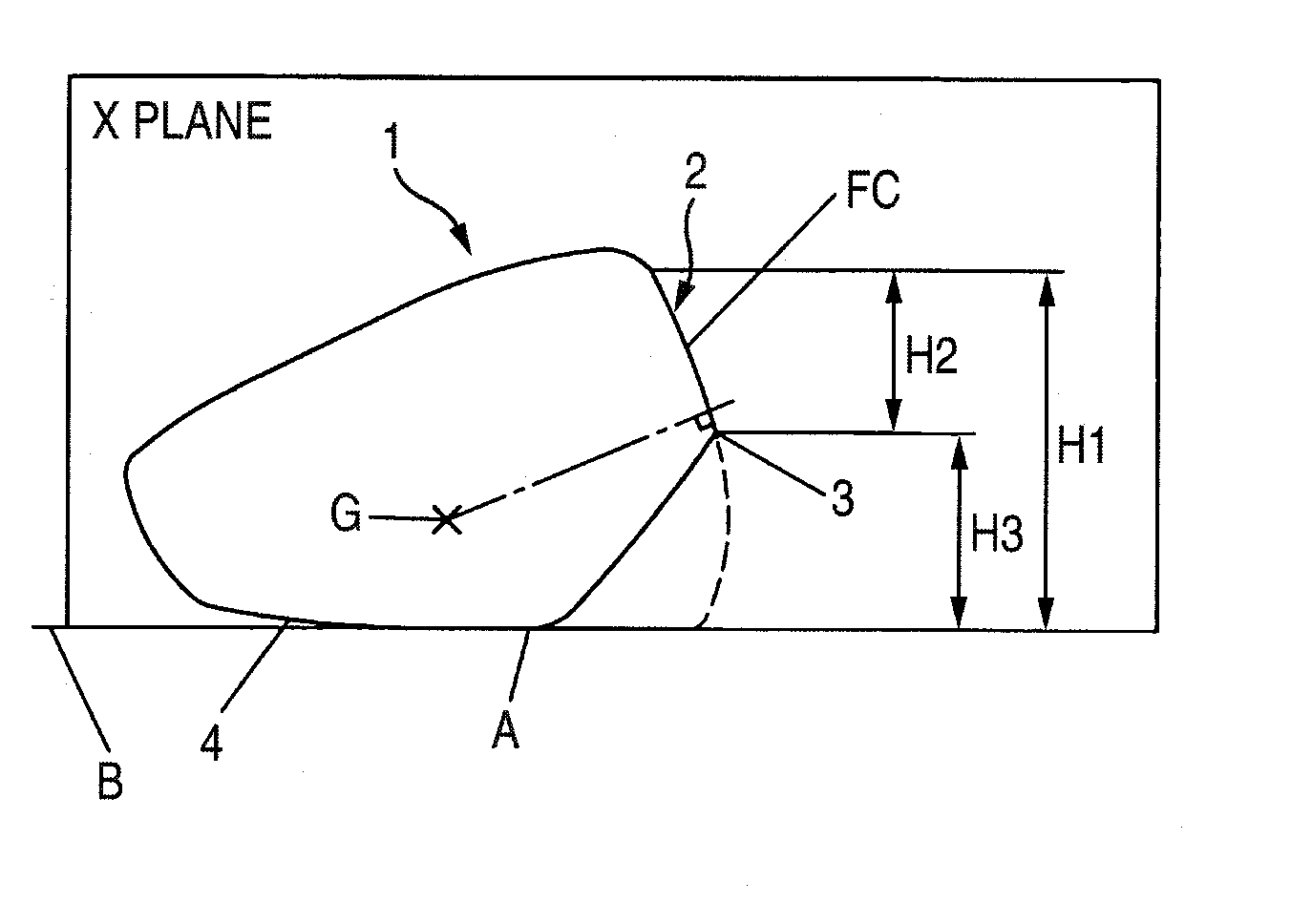

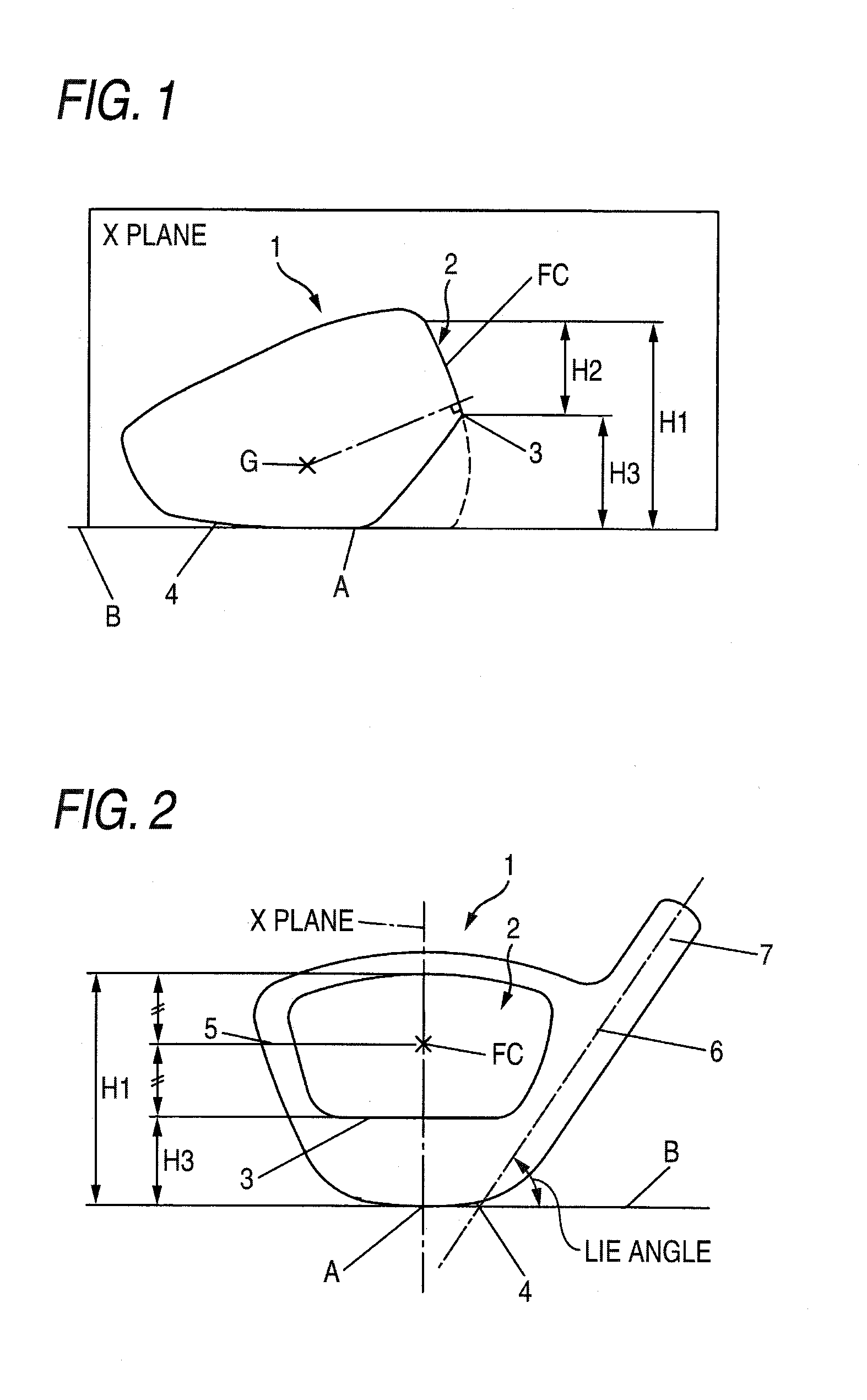

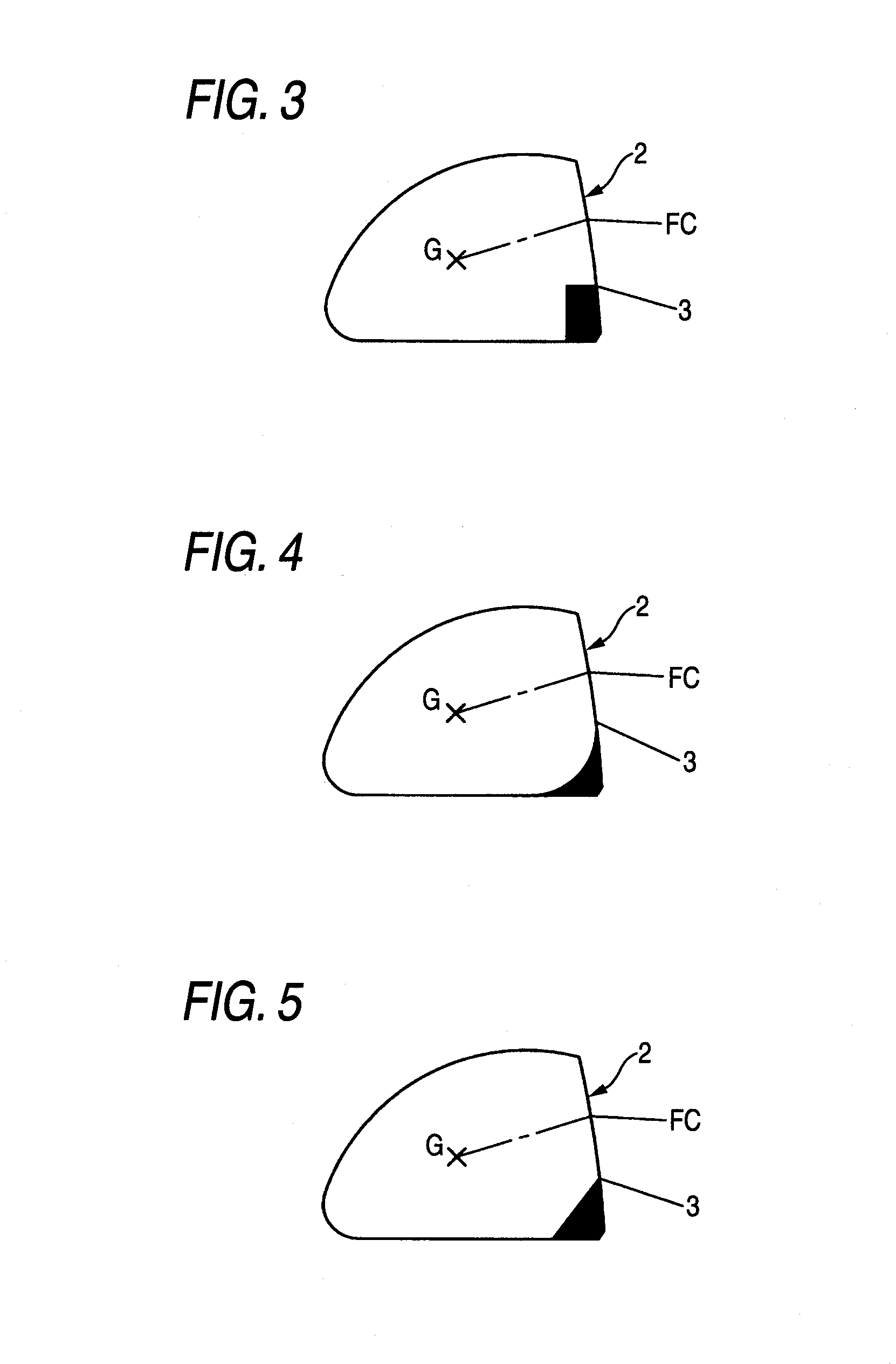

[0028]FIG. 1 shows a lateral view of a head body 1, and FIG. 2 shows a front view of the head body 1, with a leading edge 3 formed to be located at a higher position compared with a normal head. In FIG. 1 and FIG. 2, there is shown a state in which the head body 1 is set on a horizontal plane B at predetermined lie angle and loft angle. When the head body 1 is set in this manner, a face center FC is set at the midpoint between an upper edge and a lower edge (leading edge 3) of a face 2, which intersect a vertical plane X (shown as an “X plane” in the diagrams) passing through a ground point A between a sole 4 and the horizontal plane B and extending from the rear of the head in a target line direction serving as a target. A height measured from this ground point A to the upper edge of the face 2 is referred to as a face height H1. Further, a height measured from the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com