Patents

Literature

140results about How to "Increase insensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bend insensitive single mode fiber

ActiveUS8750664B2Manufacturing toleranceReduce manufacturing costGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberAccess network

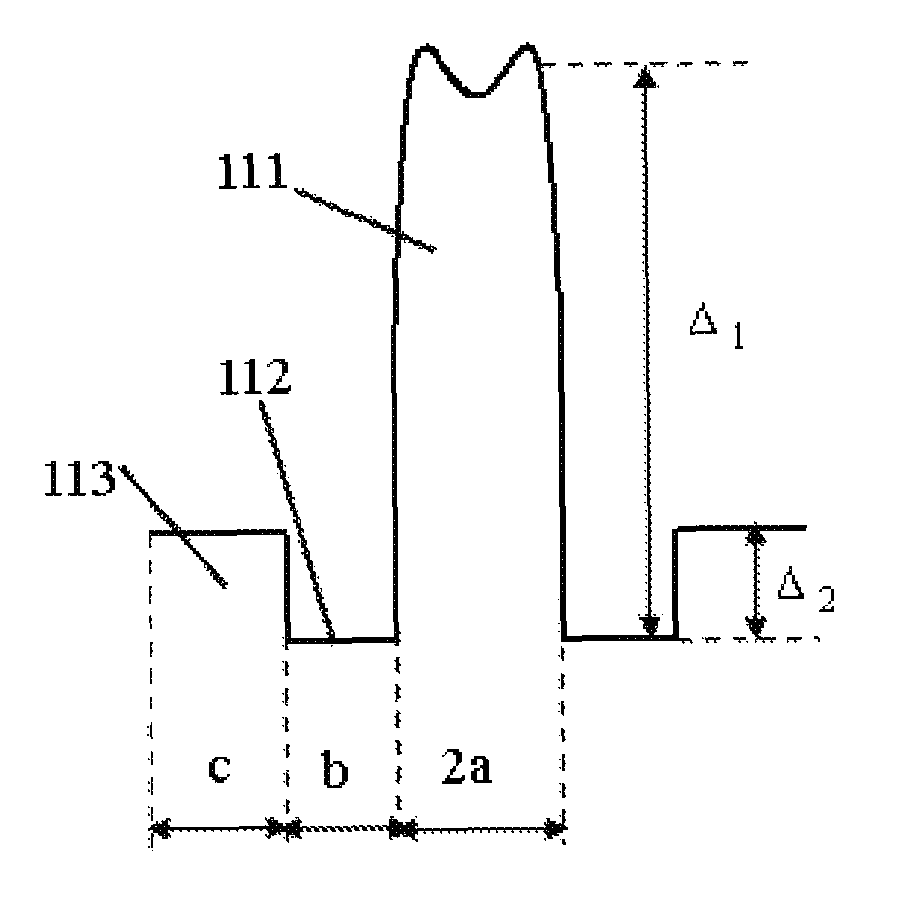

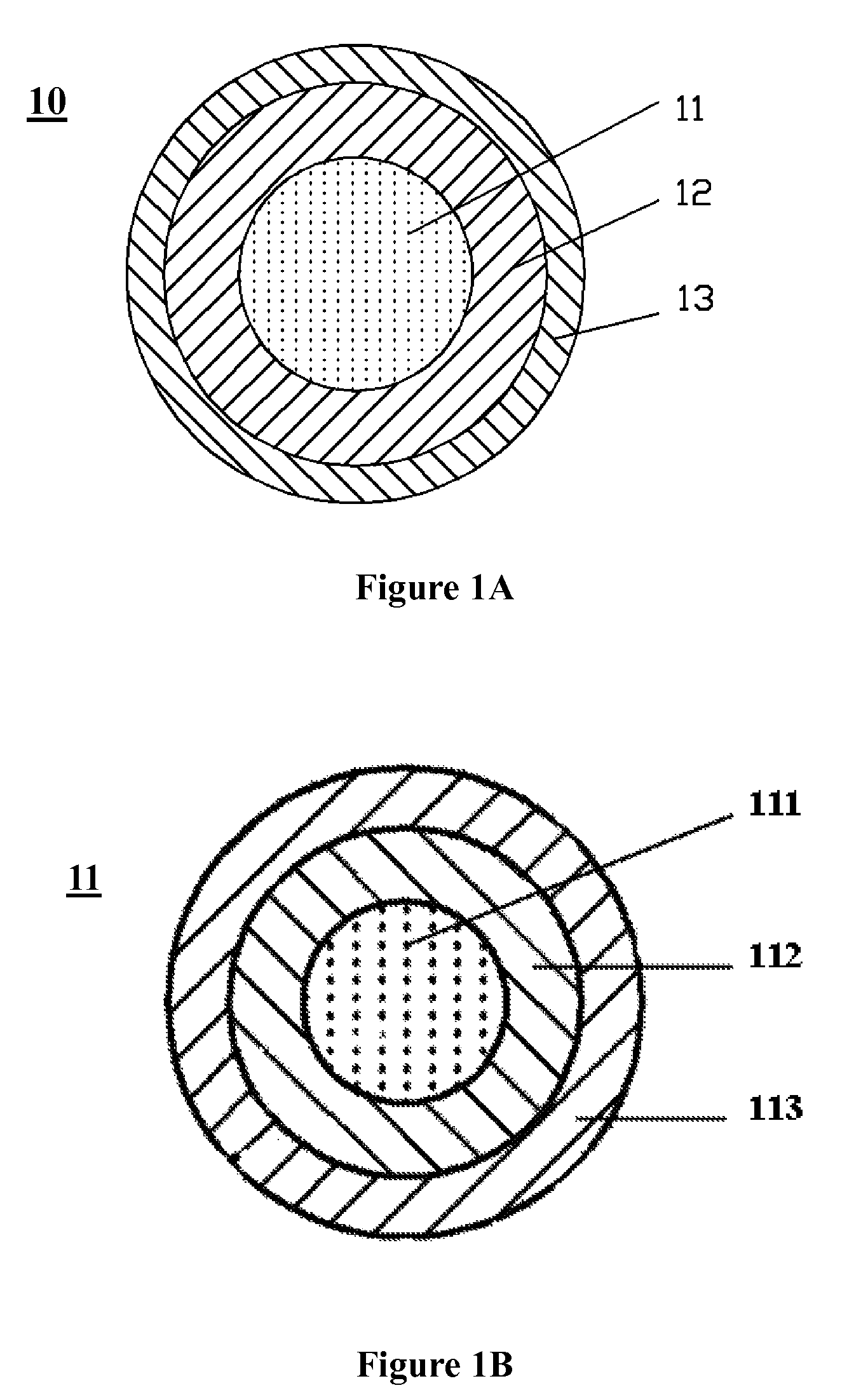

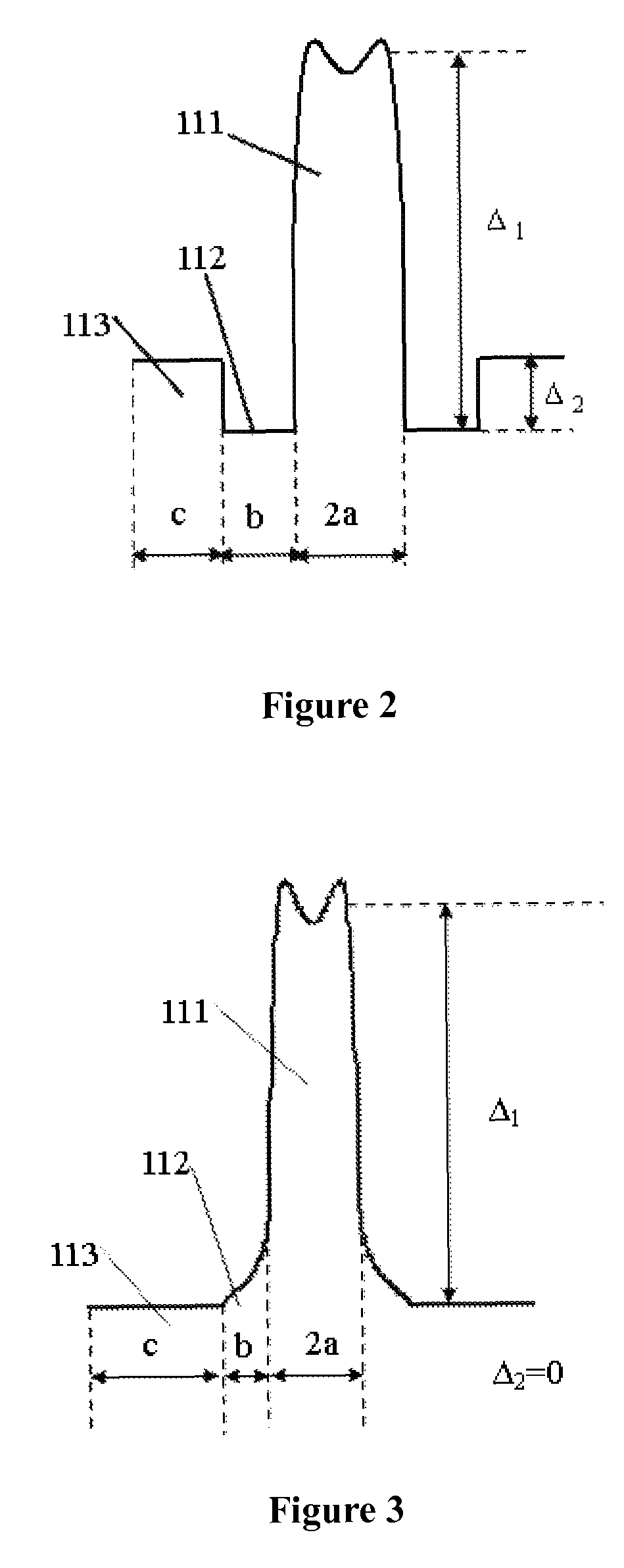

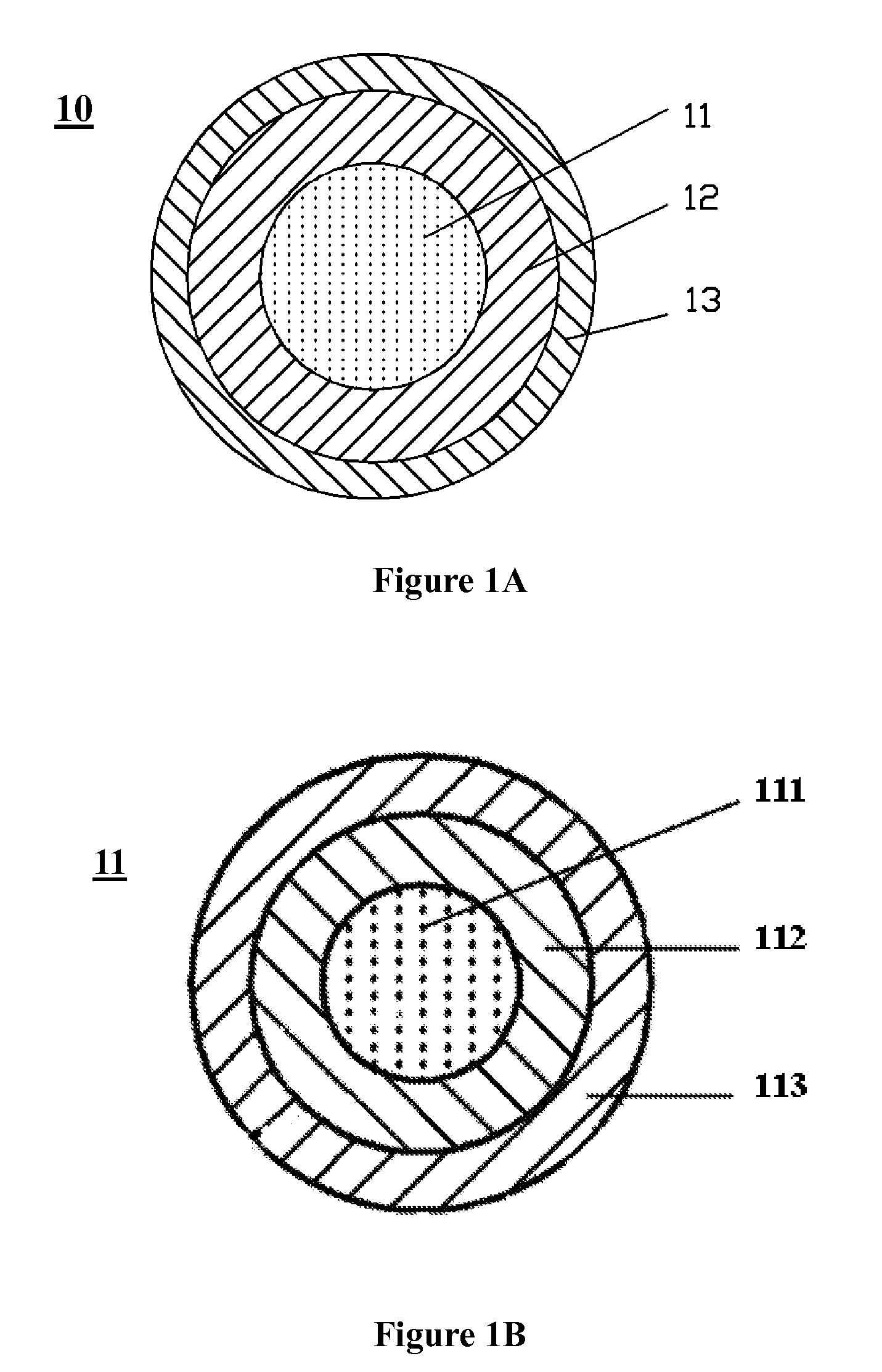

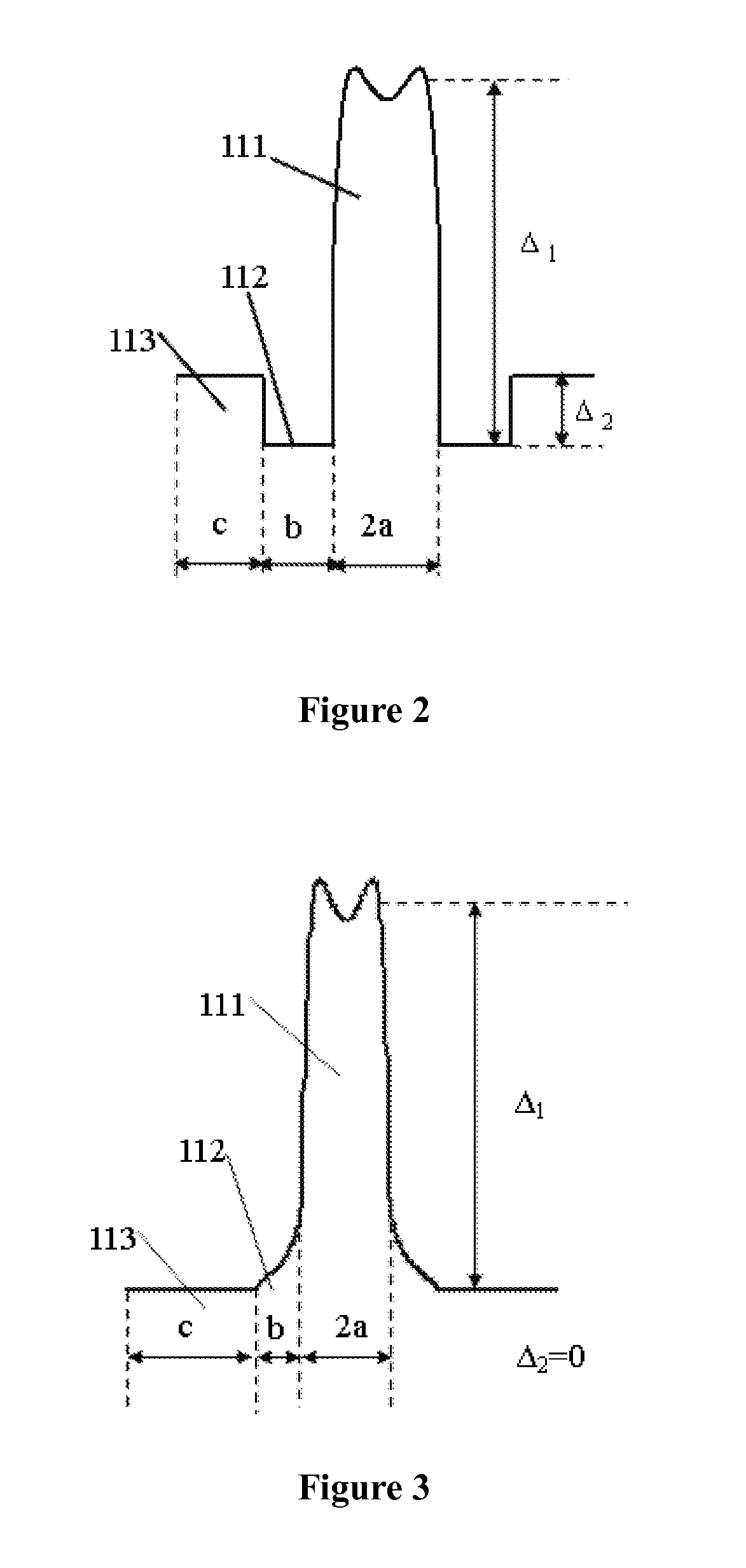

This invention discloses a bend insensitive single mode fiber, which is composed by a bare glass fiber with a round cross section and two resin protective layers with circular cross sections surrounding the outer of the bare glass fiber. It is characterized in that the bare glass fiber is composed by a core layer with a round cross section and two claddings with circular cross sections. The refractive index of the core layer is higher than the index of the two claddings and the refractive index difference between the core layer and the first cladding is larger than the difference between the first and second claddings. The second cladding is made of pure SiO2. The refractive index profile of the core layer follows a power function, and the refractive index profile of the two claddings follow a ladder-type distribution. The loss of the invented fiber is insensitive to the bending of the fiber, which meets the requirements of ITU.T G.657.A and G.657.B standards, respectively. It is applicable to the Fiber To The Home (FTTH) and other local area network and the access network systems.

Owner:FUTONG GROUP CO LTD

Composite refractory metal carbide coating on a substrate and method for making thereof

InactiveUS20050064247A1Improved corrosion resistance propertyIncreased emissivity insensitivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBeryllium carbideMagnesium

A composite coating for use on semi-conductor processing components, comprising a refractory metal carbide coating with its surface modified by at least one of: a) a carbon donor source for a stabilized stoichiometry, and b) a layer of nitride, carbonitride or oxynitride of elements selected from a group B, Al, Si, refractory metals, transition metals, rare earth metals which may or may not contain electrically conducting pattern, and wherein the metal carbide is selected from the group consisting of silicon carbide, tantalum carbide, titanium carbide, tungsten carbide, silicon oxycarbide, zirconium carbide, hafnium carbide, lanthanum carbide, vanadium carbide, niobium carbide, magnesium carbide, chromium carbide, molybdenum carbide, beryllium carbide and mixtures thereof. The composite coating is characterized as having an improved corrosion resistance property and little emissivity sensitivity to wavelengths used in optical pyrometry under the normal semi-conductor processing environments.

Owner:GENERAL ELECTRIC CO

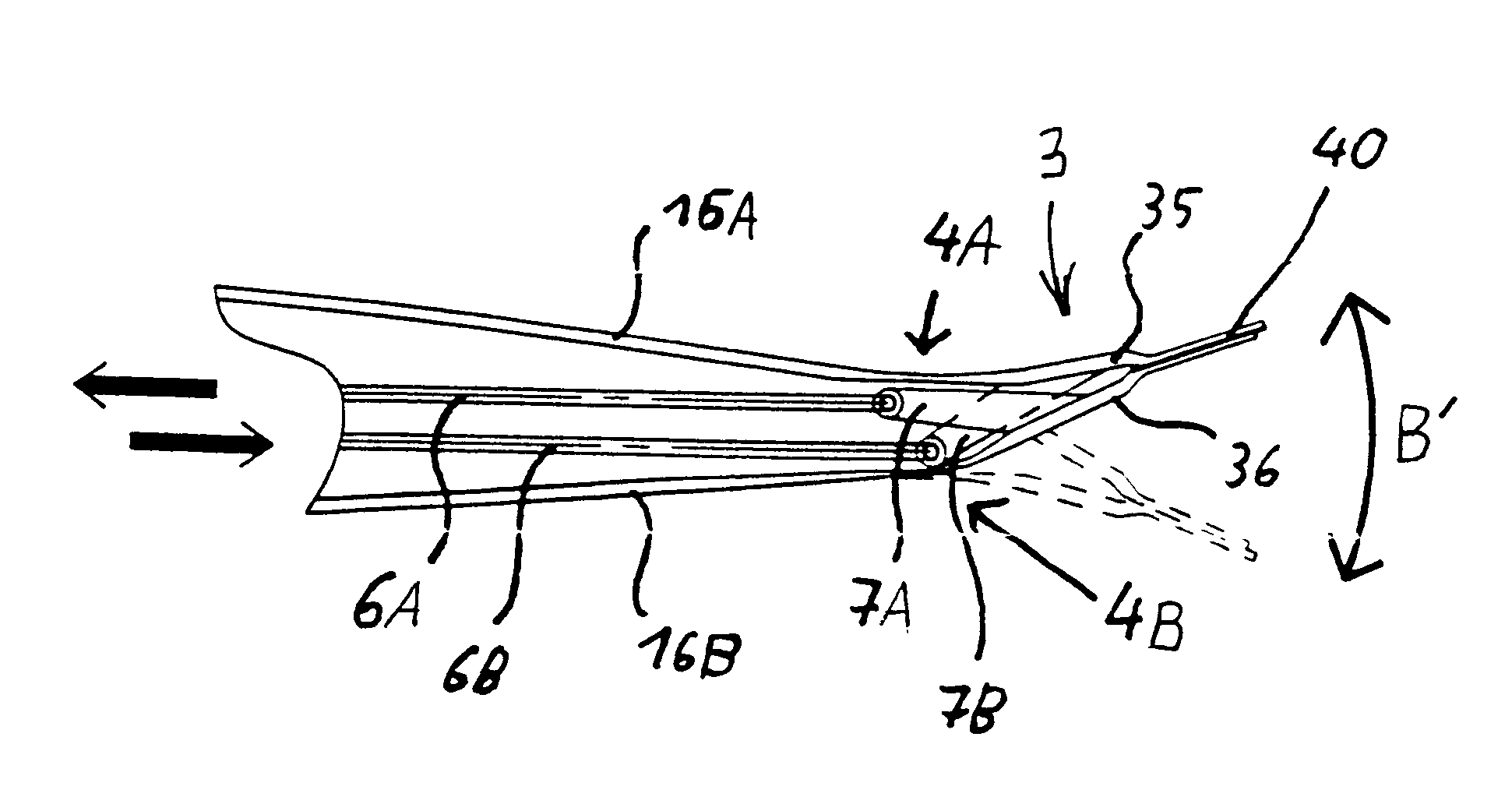

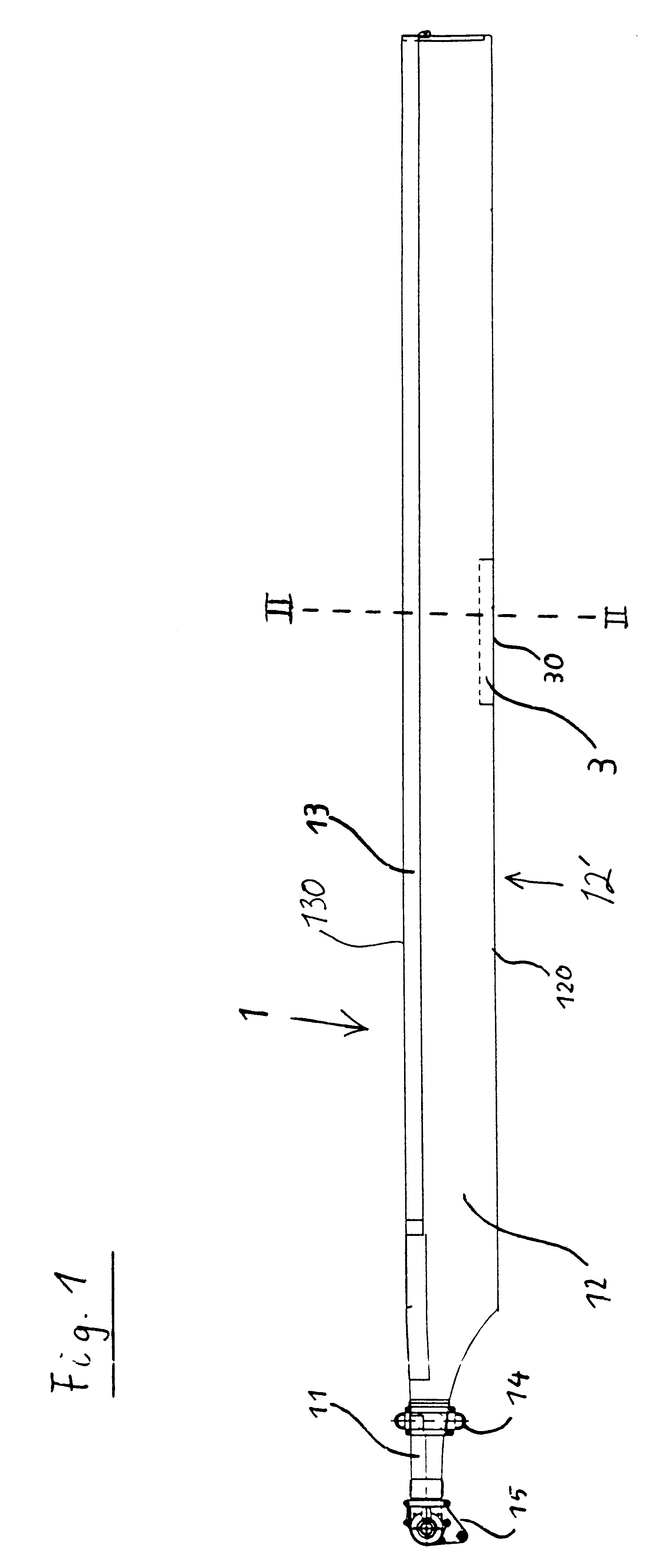

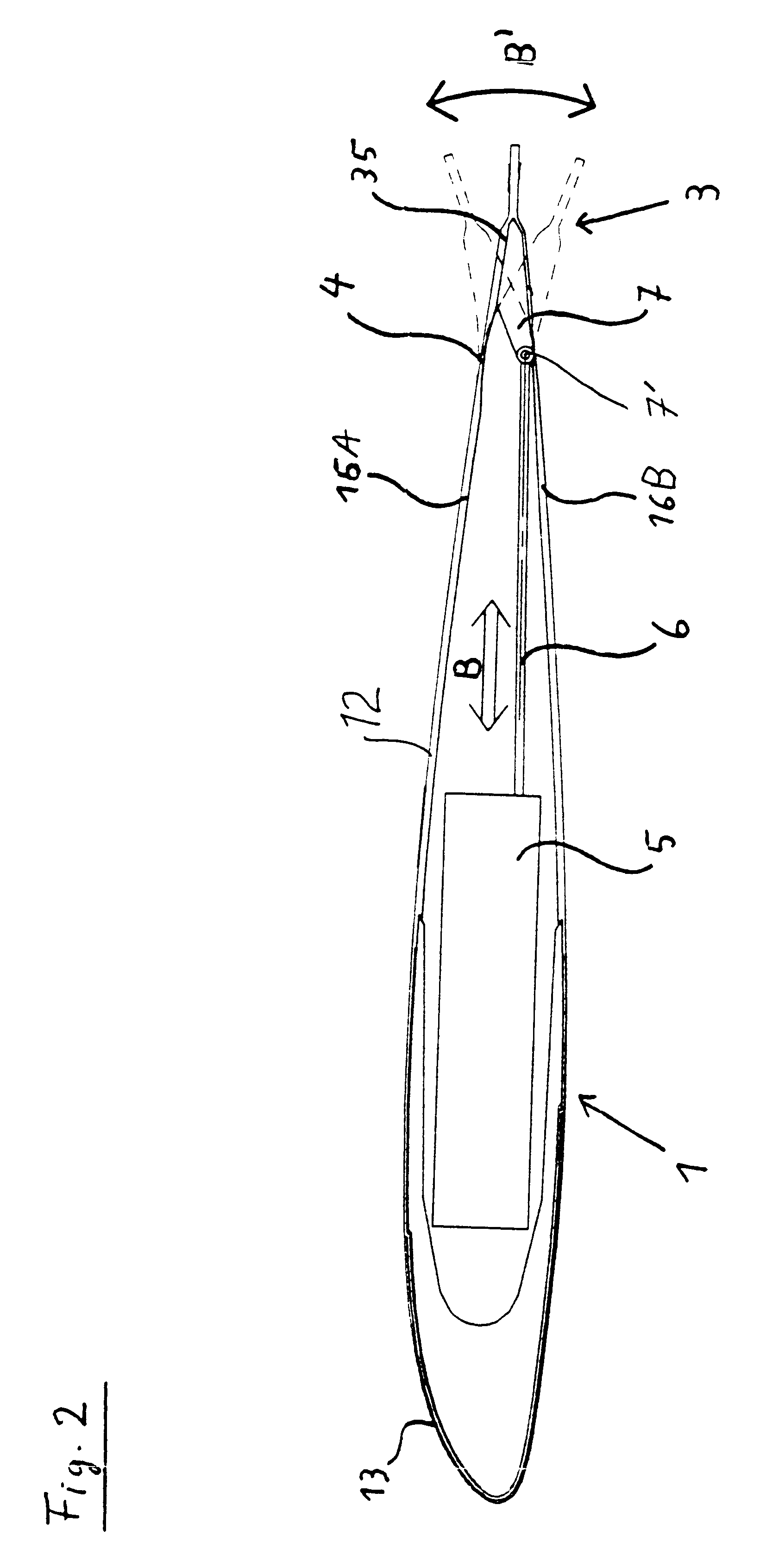

Helicopter rotor blade with a movable flap

InactiveUS6168379B1Durable and wear-resistant flexiblyImprove inspectionPropellersAircraft stabilisationPiezoelectric actuatorsFiber-reinforced composite

A helicopter rotor blade includes a main airfoil body (12) and a movable control flap (3) incorporated in the trailing edge profile of the airfoil body. The flap (3) is movably connected to the main airfoil body (12) by a flexibly bendable junction element (4), and is actuated by a piezoelectric actuator unit (5) via a push / pull rod (6) and a lever arm (7), whereby the control flap is deflected relative to the main airfoil body. The junction element (4) is preferably a continuous integral fiber-reinforced composite component having a flexible bending portion (42) with a reduced thickness in comparison to the adjoining portions, whereby the reinforcing fibers extend continuously through the joint in the direction of the connection between the main airfoil body and the flap.

Owner:AIRBUS HELICOPTERS DEUT GMBH

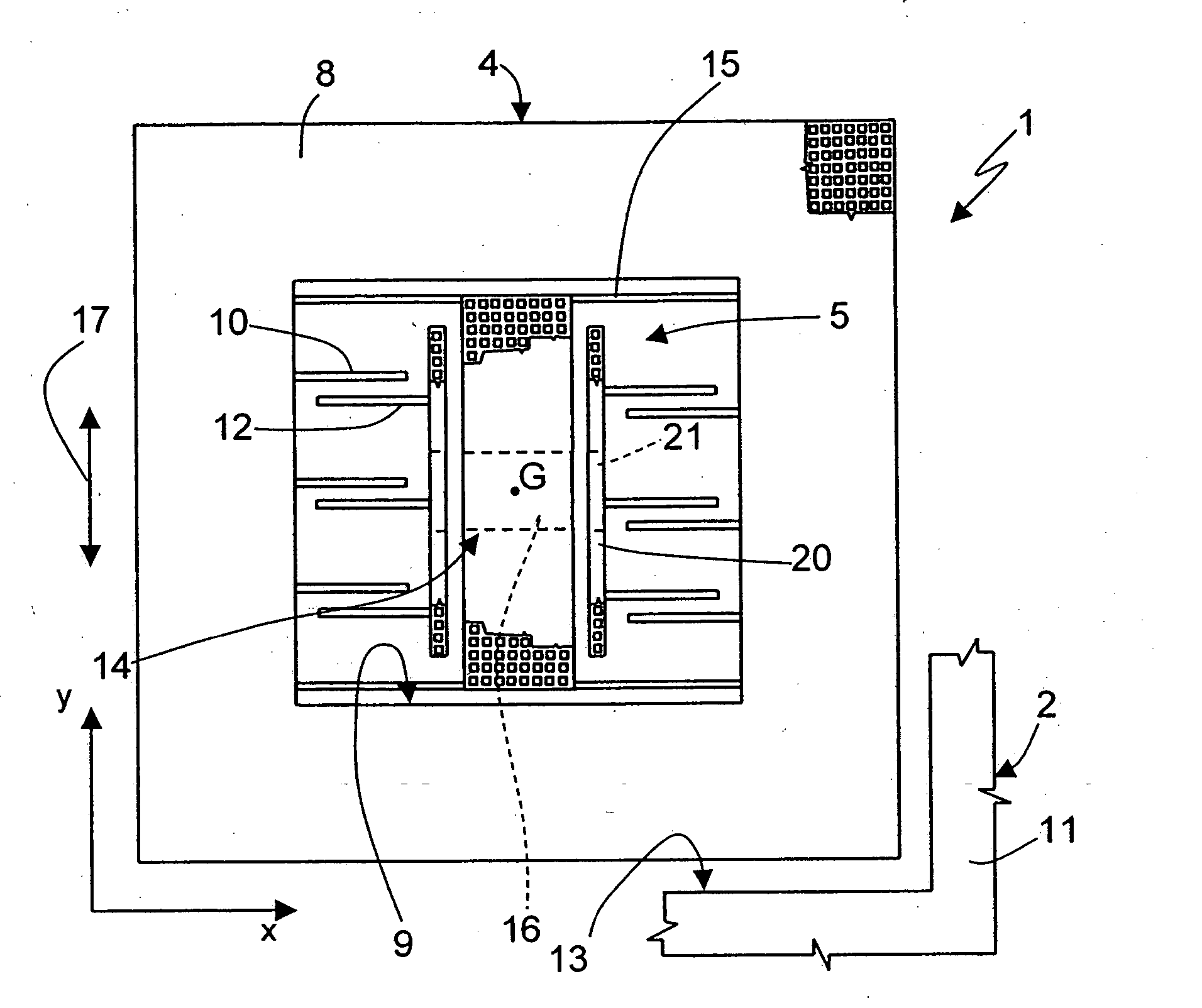

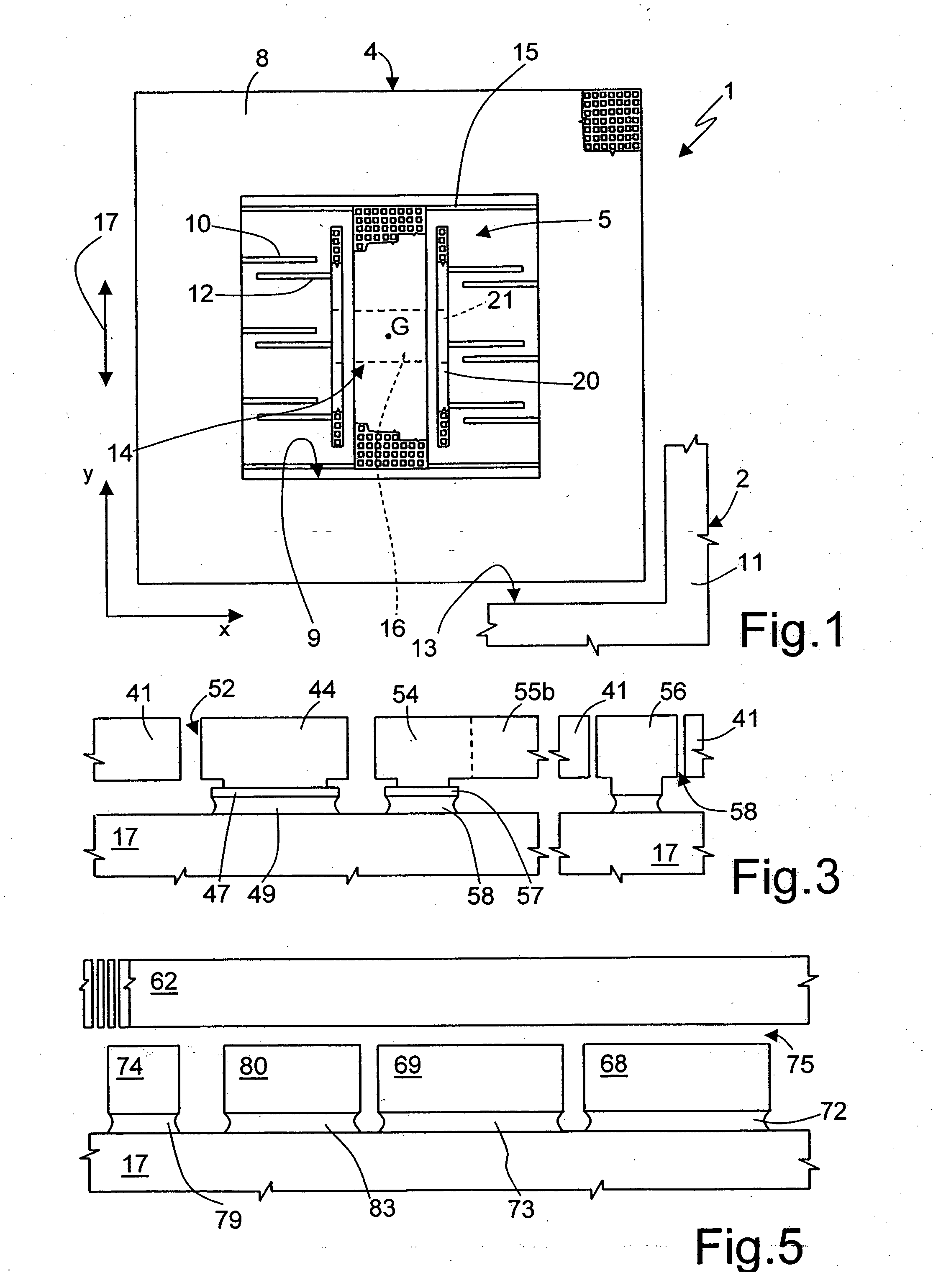

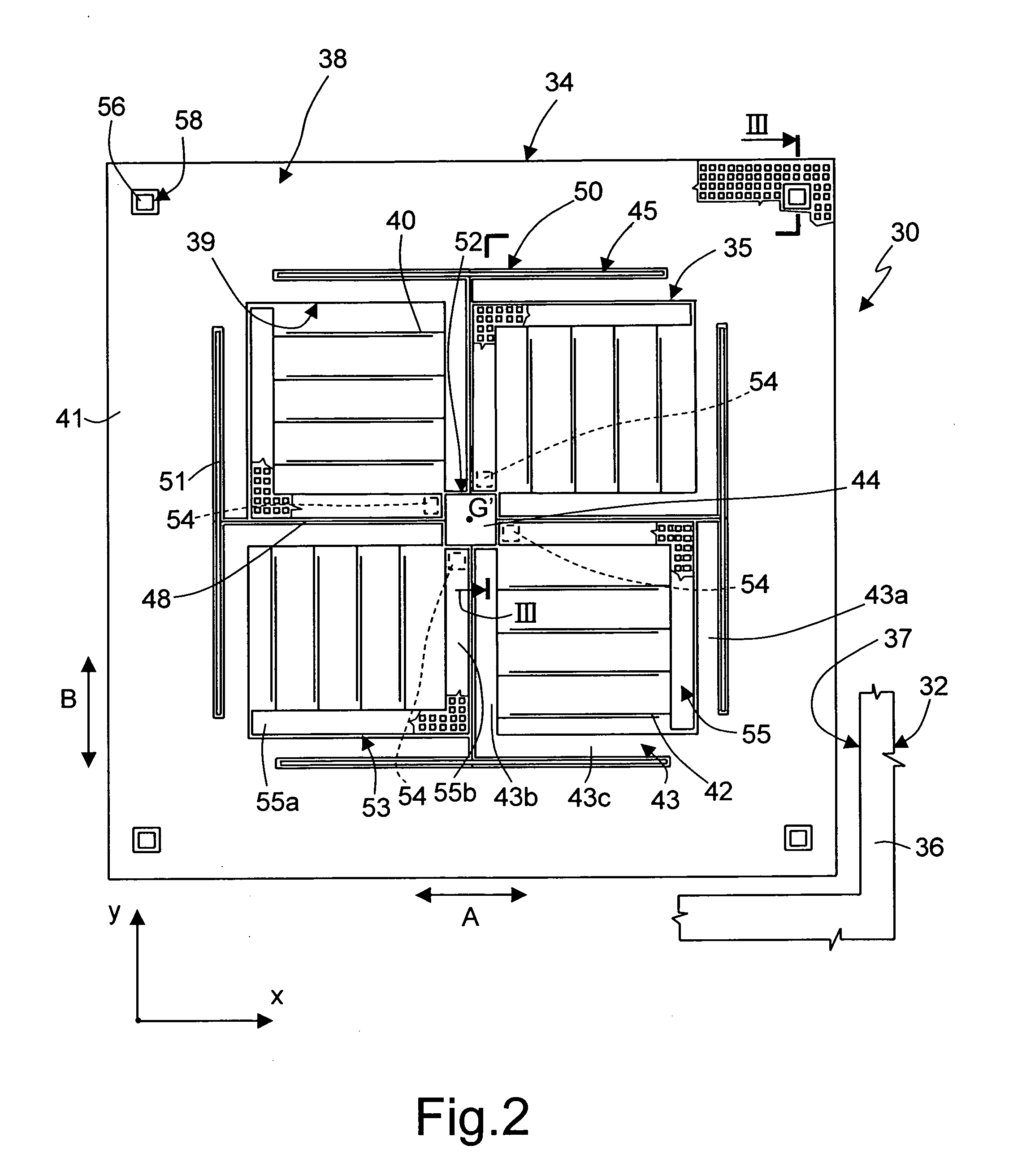

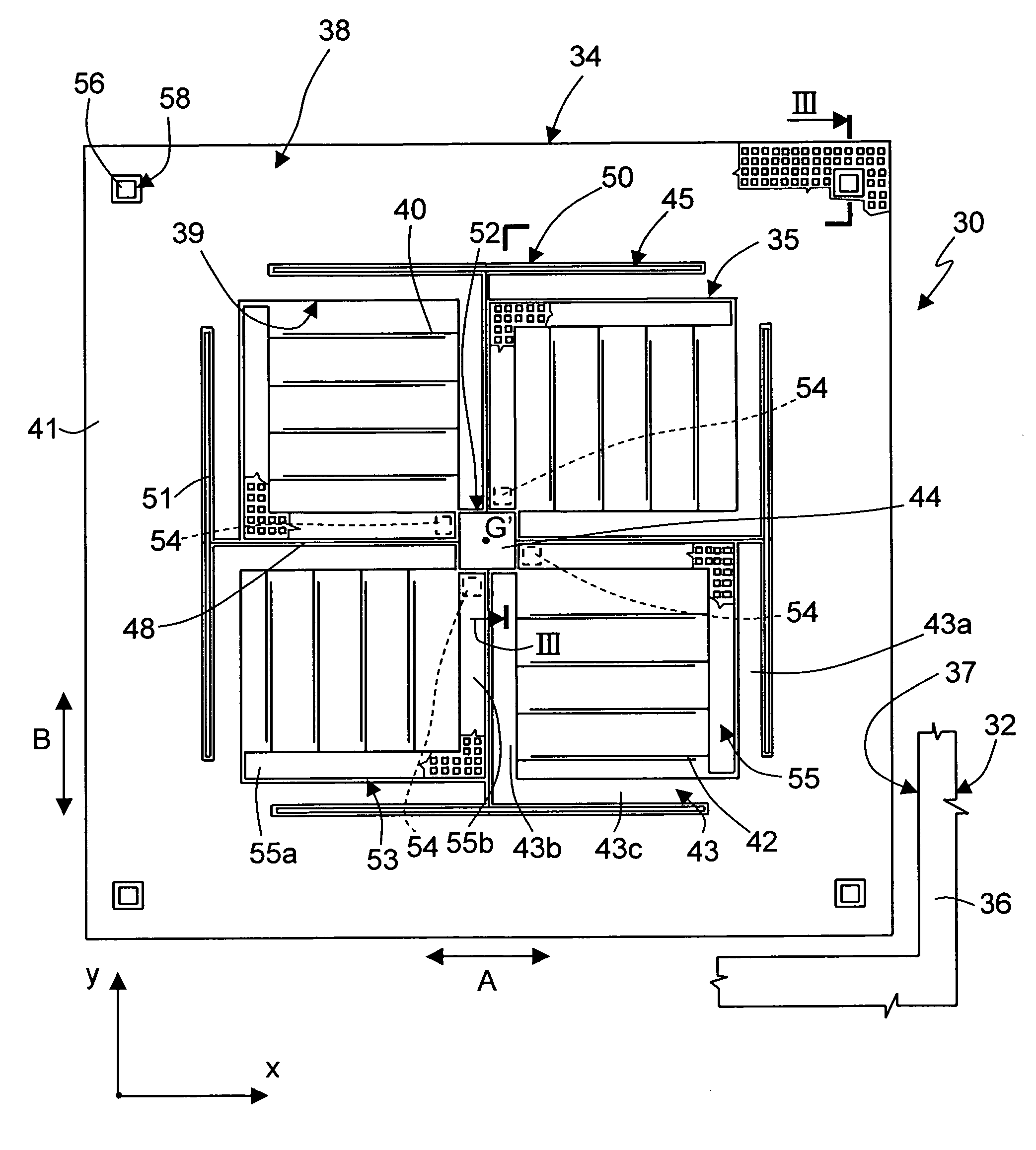

Micro-electromechanical structure with improved insensitivity to thermomechanical stresses induced by the package

ActiveUS20060032310A1Increase insensitivityAcceleration measurement using interia forcesSemiconductor/solid-state device detailsStress inducedEngineering

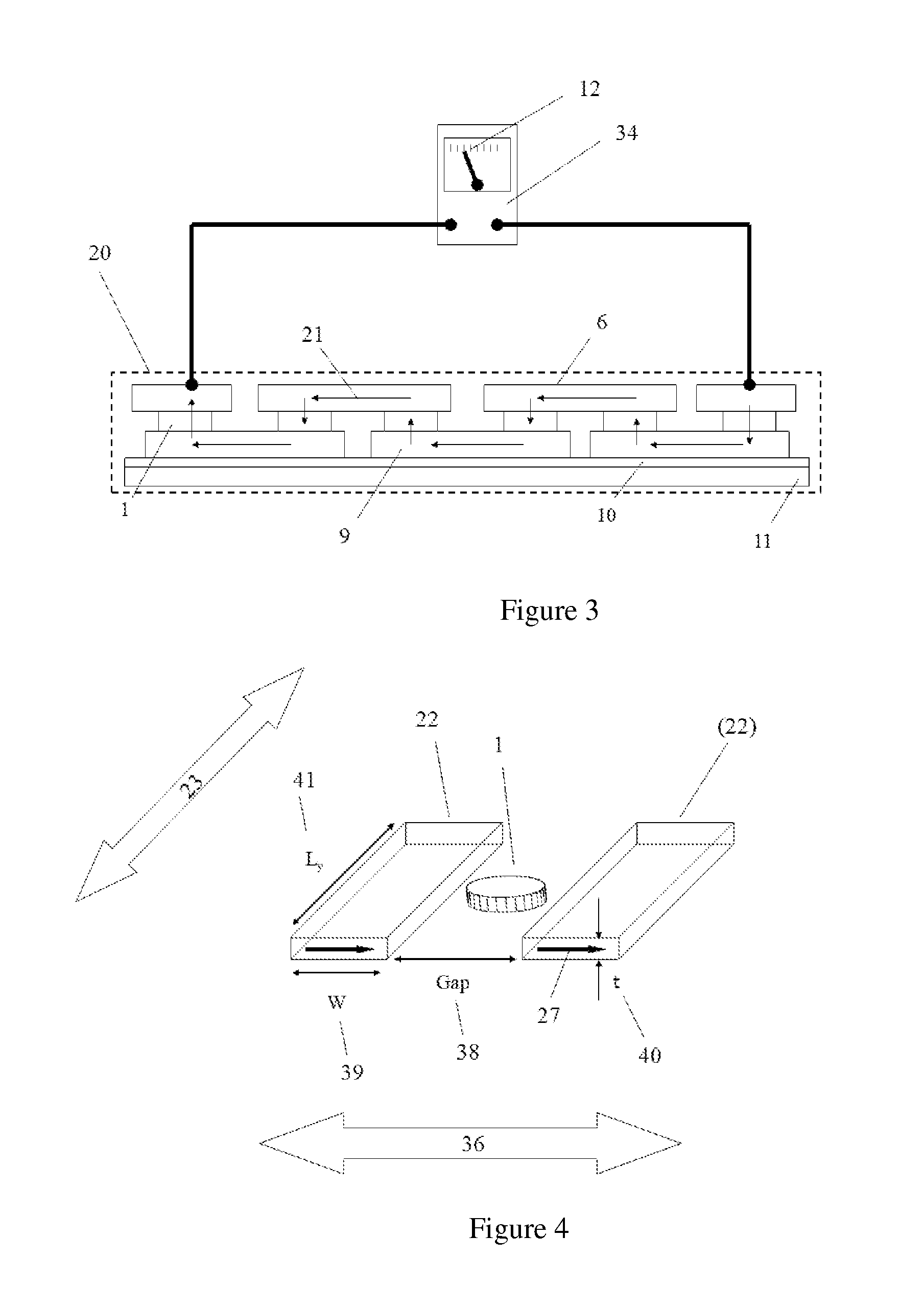

In a micro-electromechanical structure, a rotor has a centroidal axis and includes a suspended structure which carries mobile electrodes. A stator carries fixed electrodes facing the mobile electrodes. The suspended structure is connected to a rotor-anchoring region via elastic elements. The stator includes at least one stator element, which carries a plurality of fixed electrodes and is fixed to a stator-anchoring region. One of the rotor-anchoring regions and stator-anchoring regions extends along the centroidal axis and at least another of the rotor-anchoring regions and stator-anchoring regions extends in the proximity of the centroidal axis.

Owner:STMICROELECTRONICS SRL

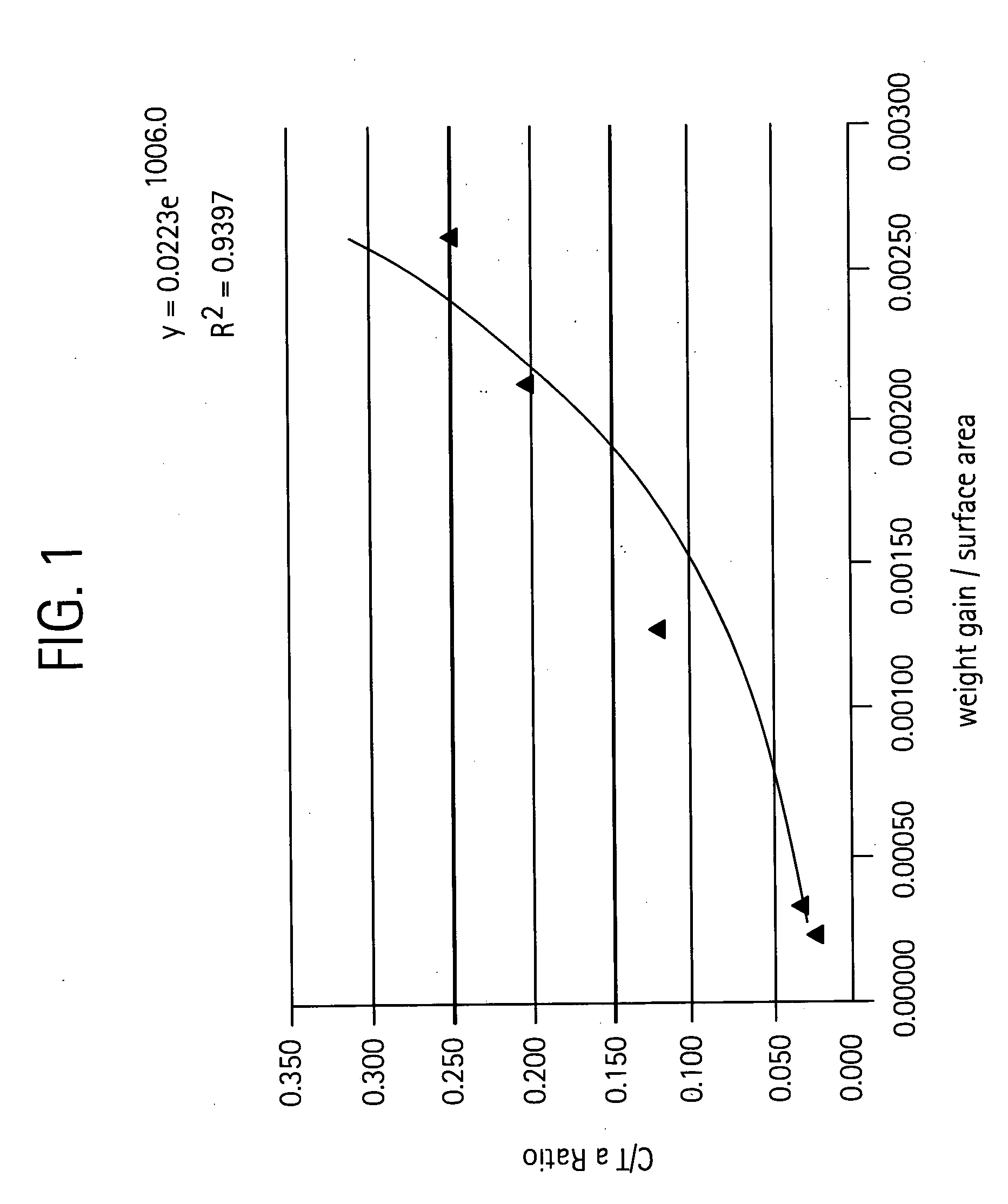

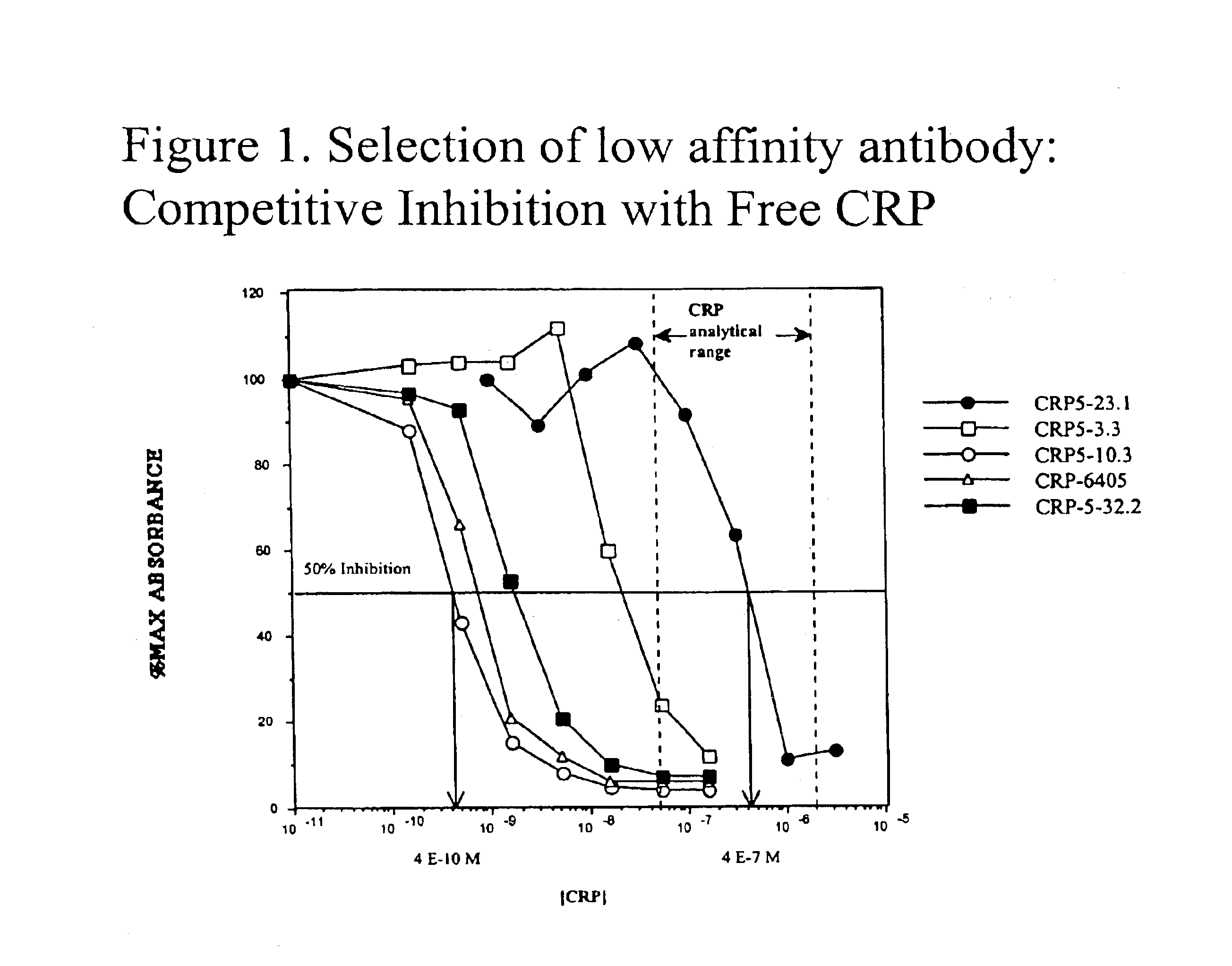

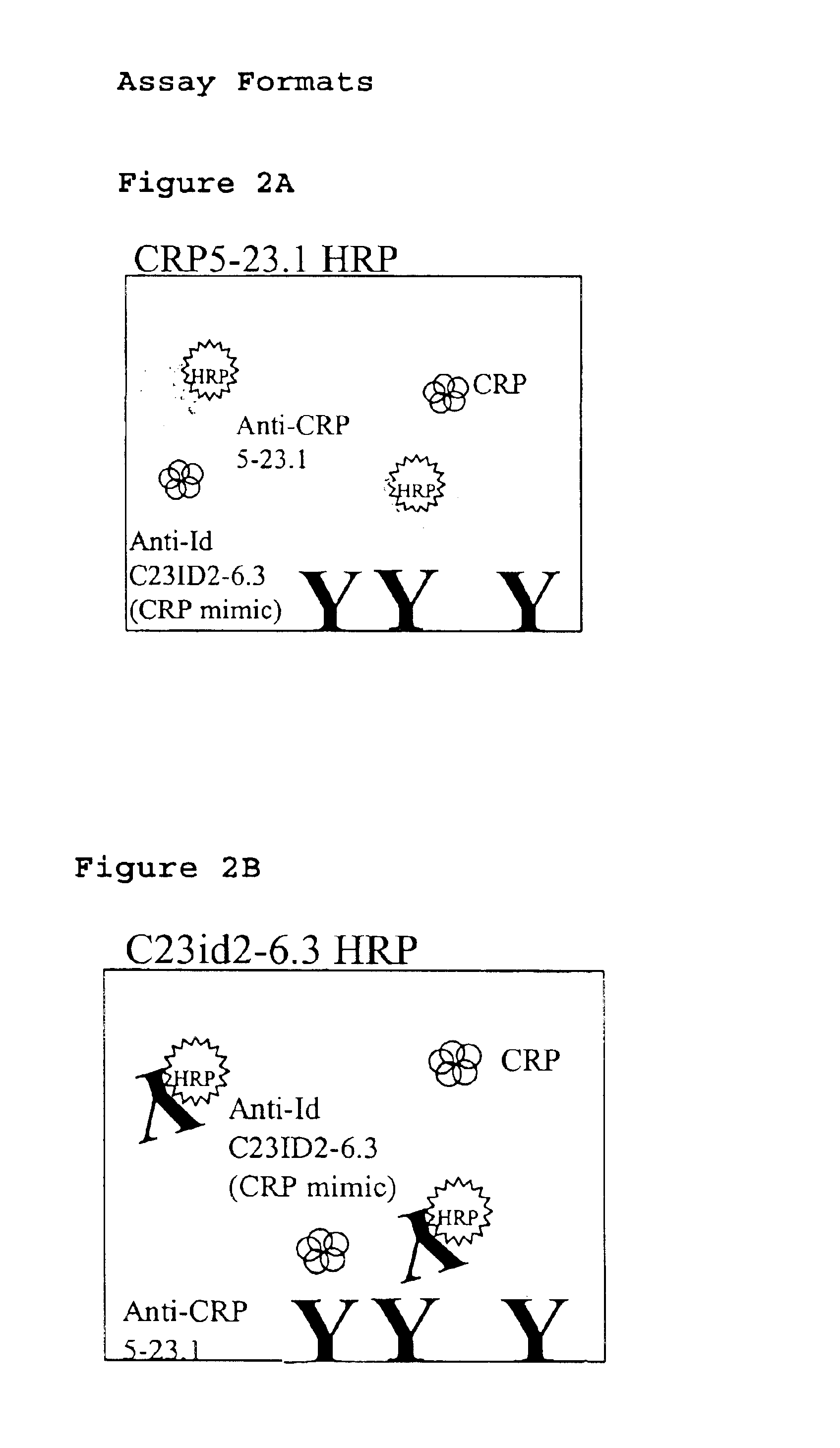

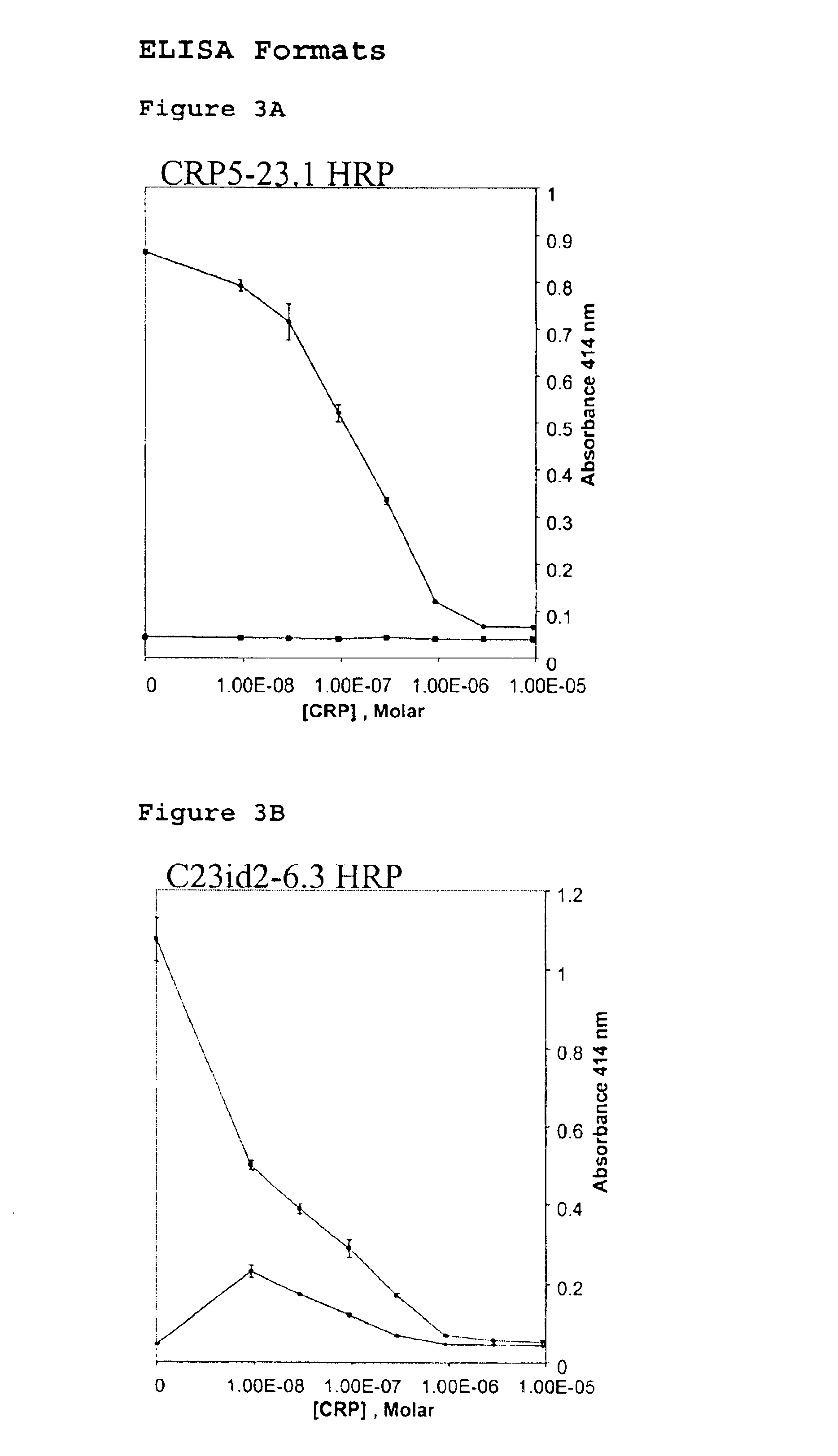

Immunoassay for C-reactive protein

InactiveUS6838250B2High affinityWeak affinityAnimal cellsImmunoglobulins against animals/humansLow affinityAntigen

The present invention relates to new CRP immunoassay compositions. The compositions include a low affinity anti-human CRP monoclonal antibody, and an antiidiotypic antibody raised against it. The invention further provides a method for obtaining antiidiotypic monoclonal antibody populations directed to an antibody that is specific for a high concentration, high molecular weight target antigen.

Owner:ORTHO-CLINICAL DIAGNOSTICS

Micro-electromechanical structure with improved insensitivity to thermomechanical stresses induced by the package

ActiveUS7322242B2Increase insensitivityAcceleration measurement using interia forcesSemiconductor/solid-state device detailsStress inducedEngineering

In a micro-electromechanical structure, a rotor has a centroidal axis and includes a suspended structure which carries mobile electrodes. A stator carries fixed electrodes facing the mobile electrodes. The suspended structure is connected to a rotor-anchoring region via elastic elements. The stator includes at least one stator element, which carries a plurality of fixed electrodes and is fixed to a stator-anchoring region. One of the rotor-anchoring regions and stator-anchoring regions extends along the centroidal axis and at least another of the rotor-anchoring regions and stator-anchoring regions extends in the proximity of the centroidal axis.

Owner:STMICROELECTRONICS SRL

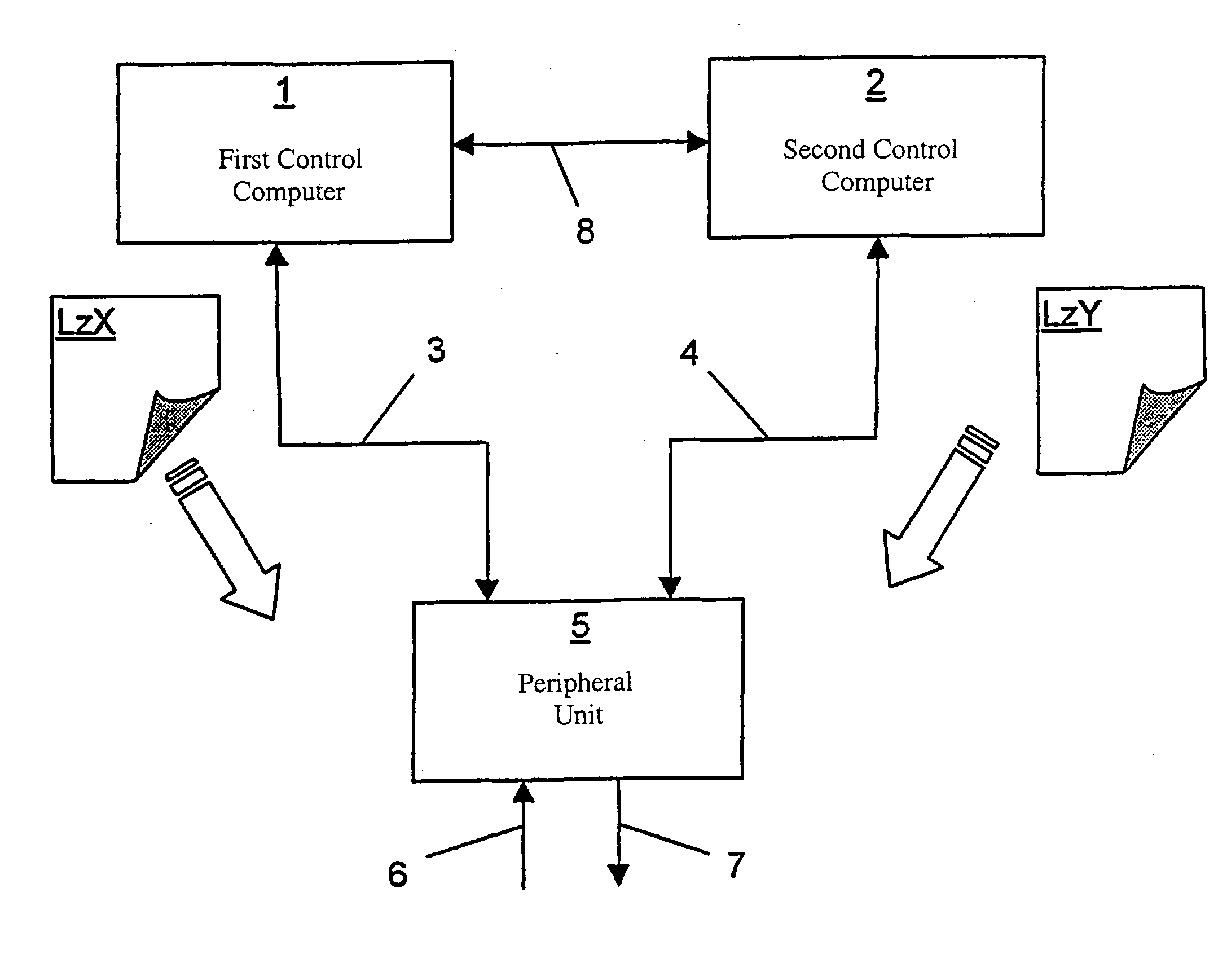

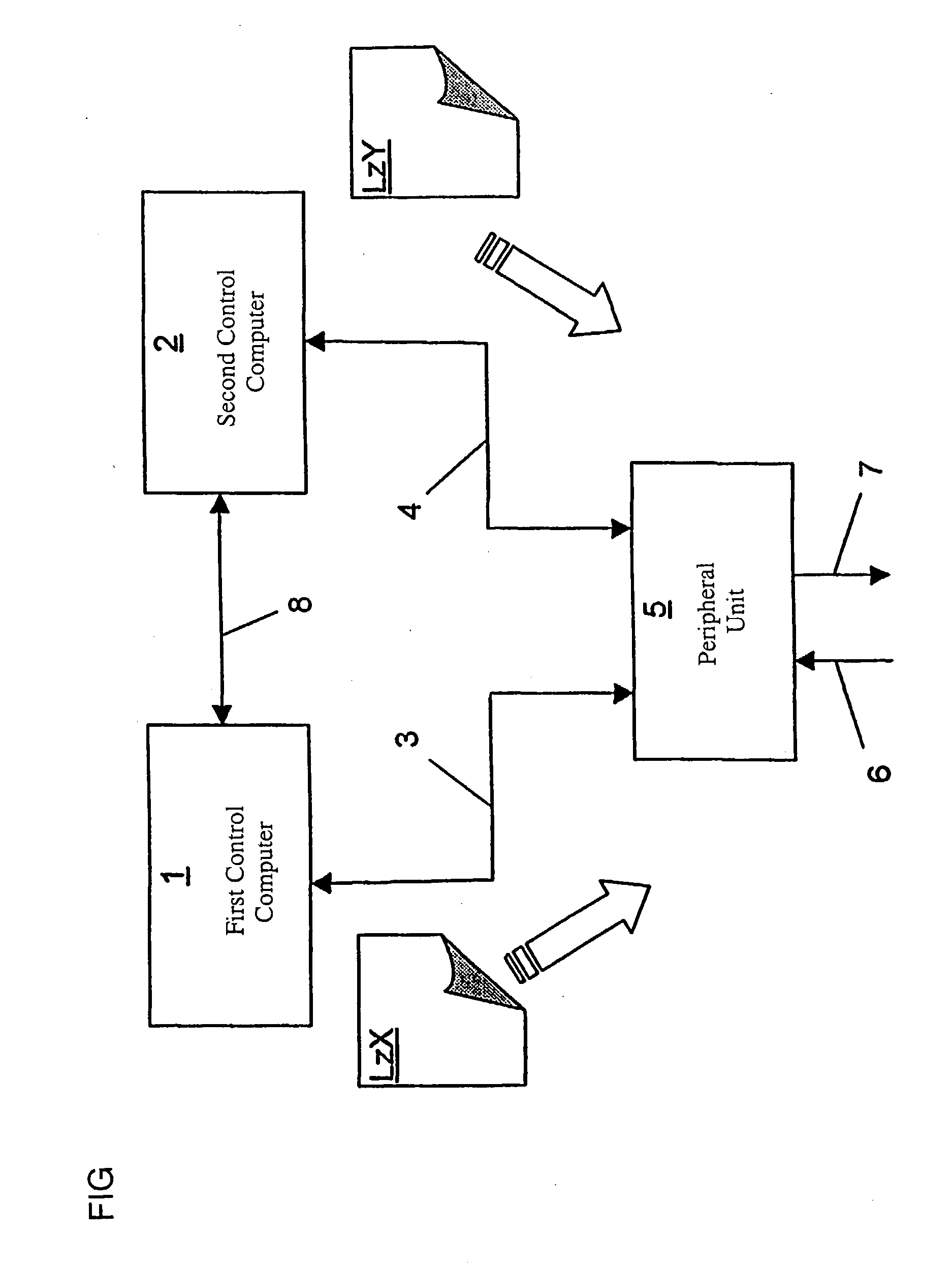

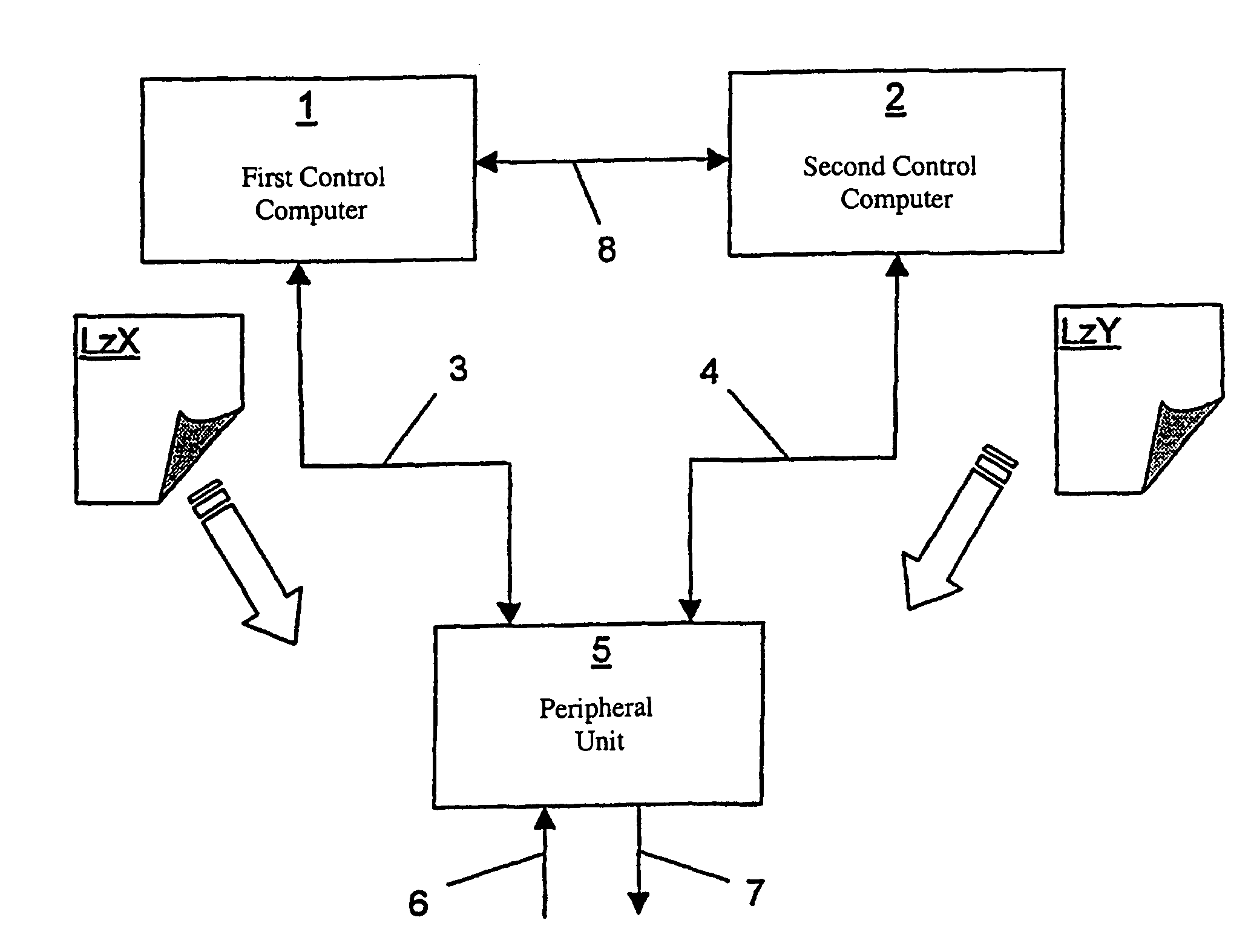

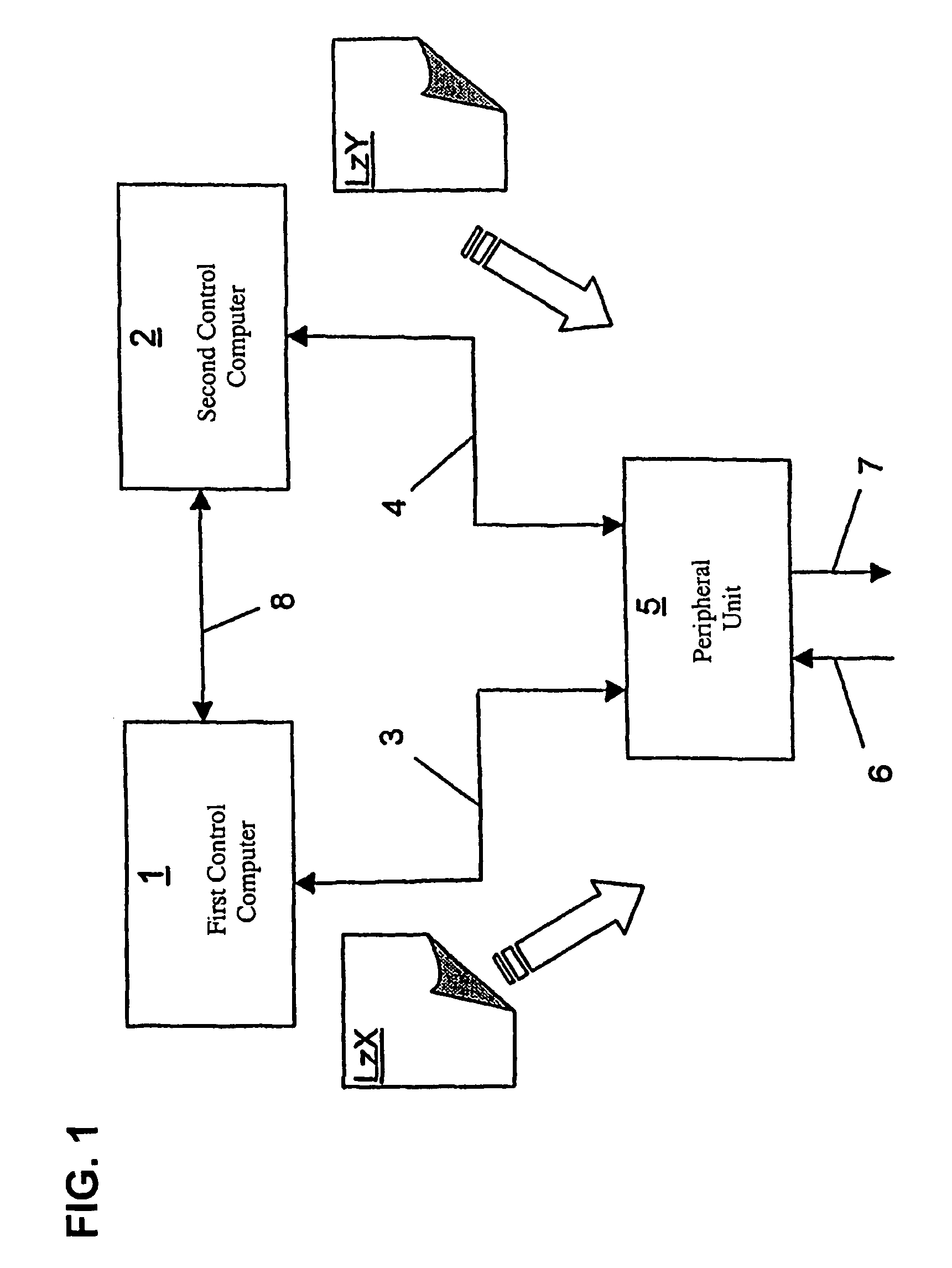

Redundant control system and control computer and peripheral unit for a control system of this type

InactiveUS20030140270A1Easy constructionPromote conversionReliability increasing modificationsError preventionControl system

A redundant control system having at least a first and a second control computer (1,2) and at least one peripheral unit (5) that is connected to the control computers (1,2) by a bus system (3,4). Both control computers transmit cyclically changing signs of life (LzX, LzY) to the peripheral unit (5), which checks whether a change in the signs life has taken place within a given time period and which switches to the other control computer for executing the control tasks if the change in the sign of life is not timely received.

Owner:SIEMENS AG

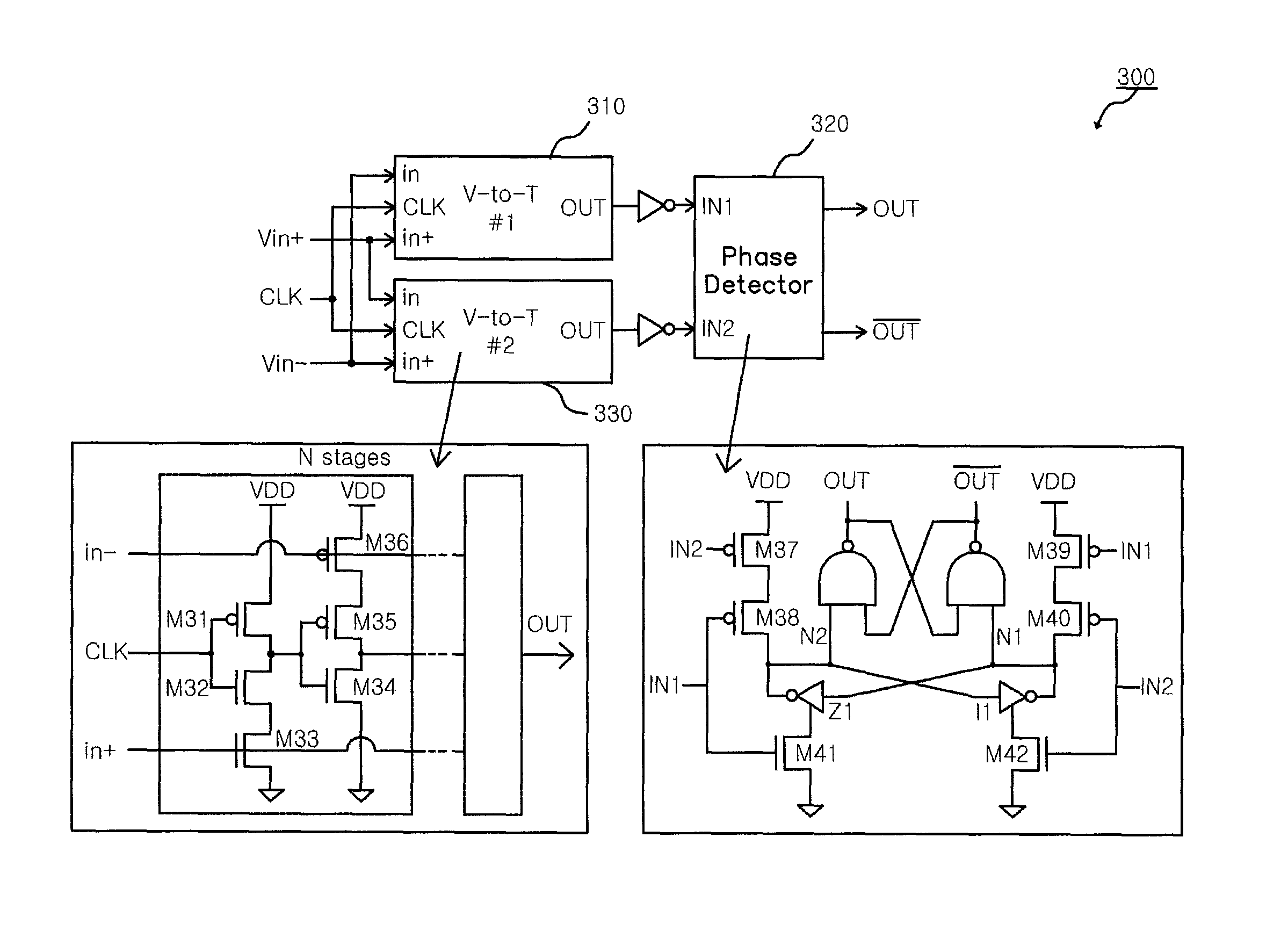

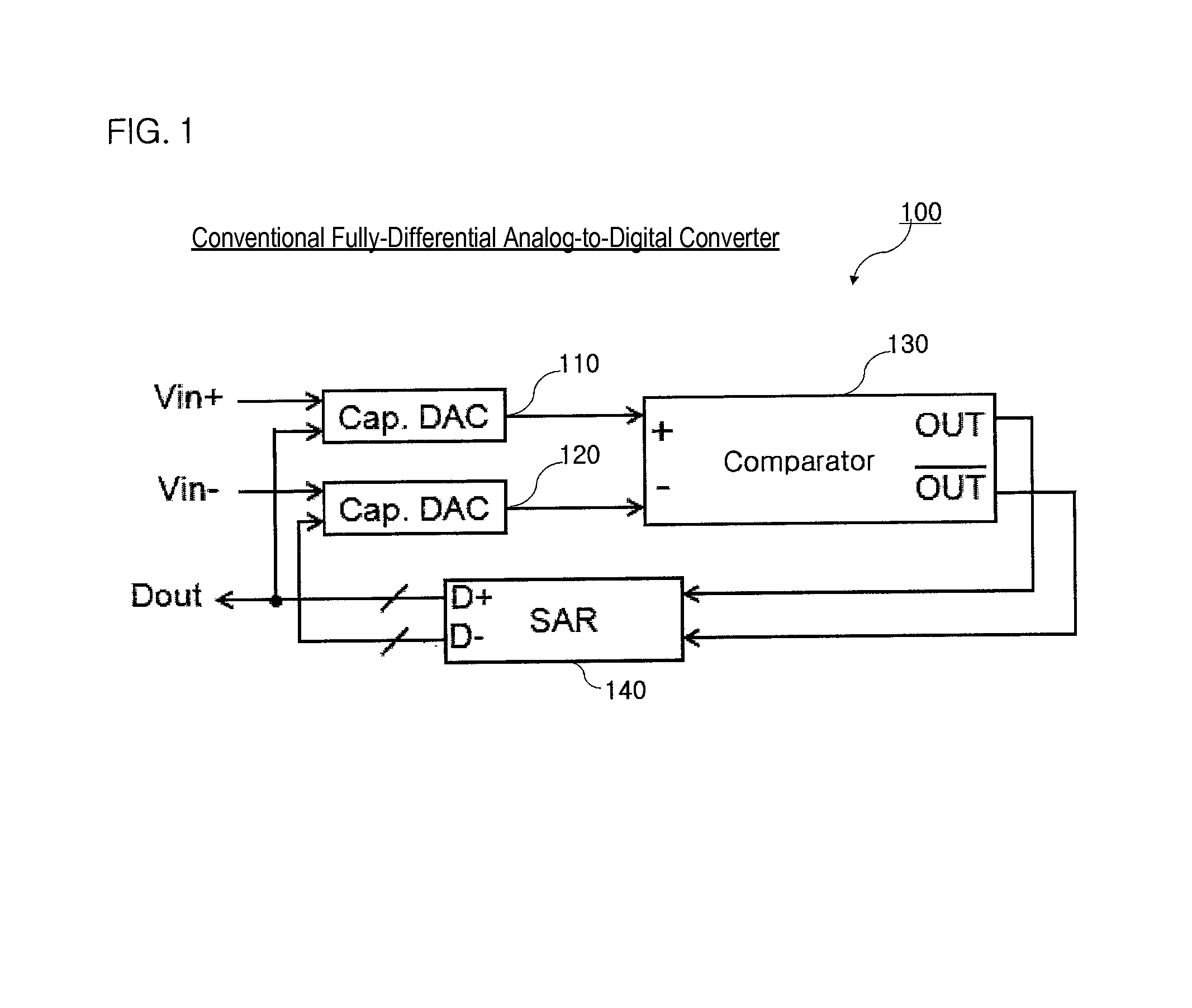

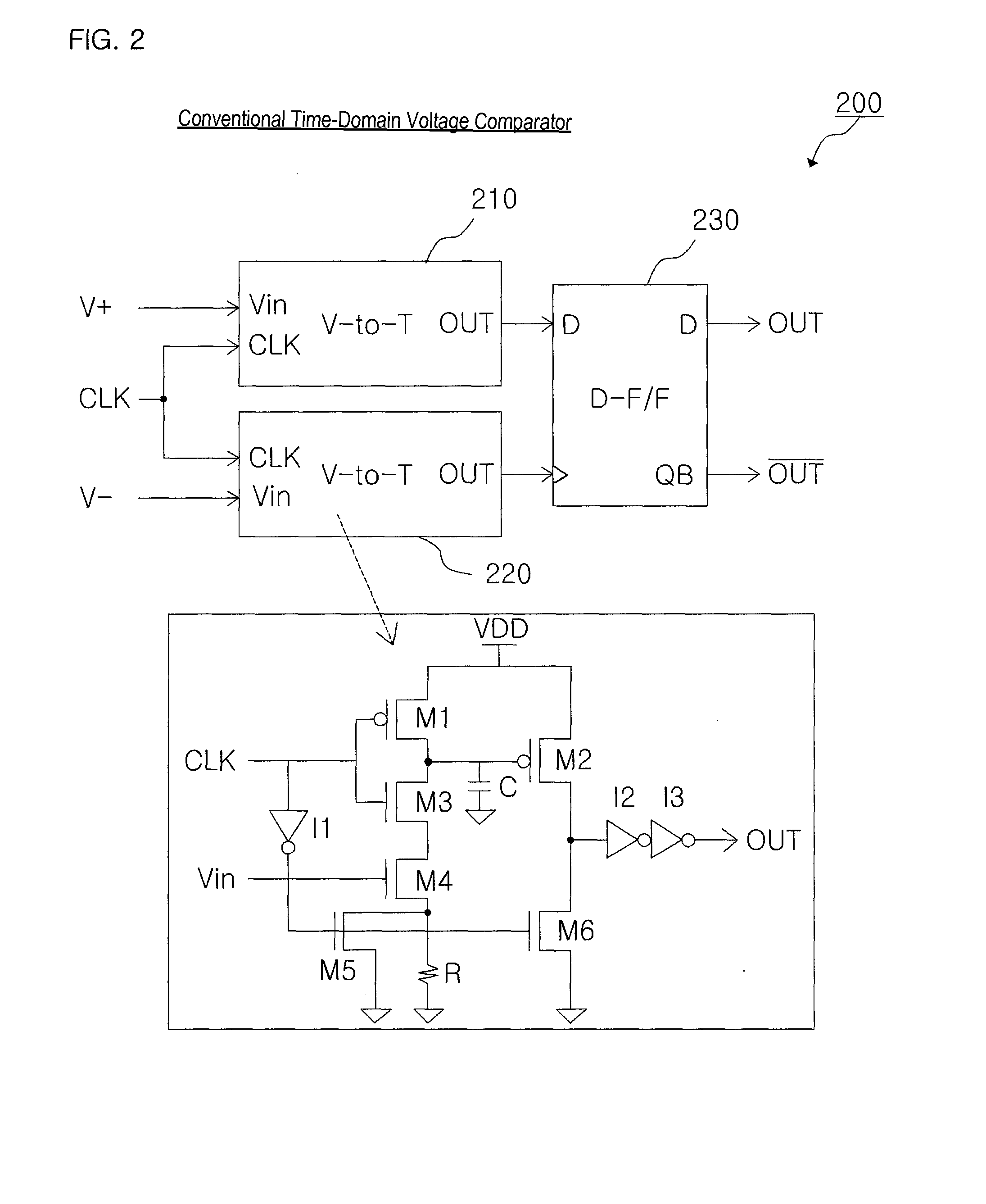

Time-domain voltage comparator for analog-to-digital converter

InactiveUS8373444B2Increase insensitivityOffset is decreasedElectric signal transmission systemsMeasurement using ac-dc conversionTime informationTime domain

A time-domain voltage comparator for an analog-to-digital converter includes a first voltage-to-time converter configured to be connected in series with at least one time delay cell and convert an input voltage into time information; a second voltage-to-time converter configured to be connected in series with at least one time delay cell and convert an input voltage into time information; and a phase comparator configured to determine a difference between times outputted from the first voltage-to-time converter and the second voltage-to-time converter.

Owner:POSTECH ACAD IND FOUND

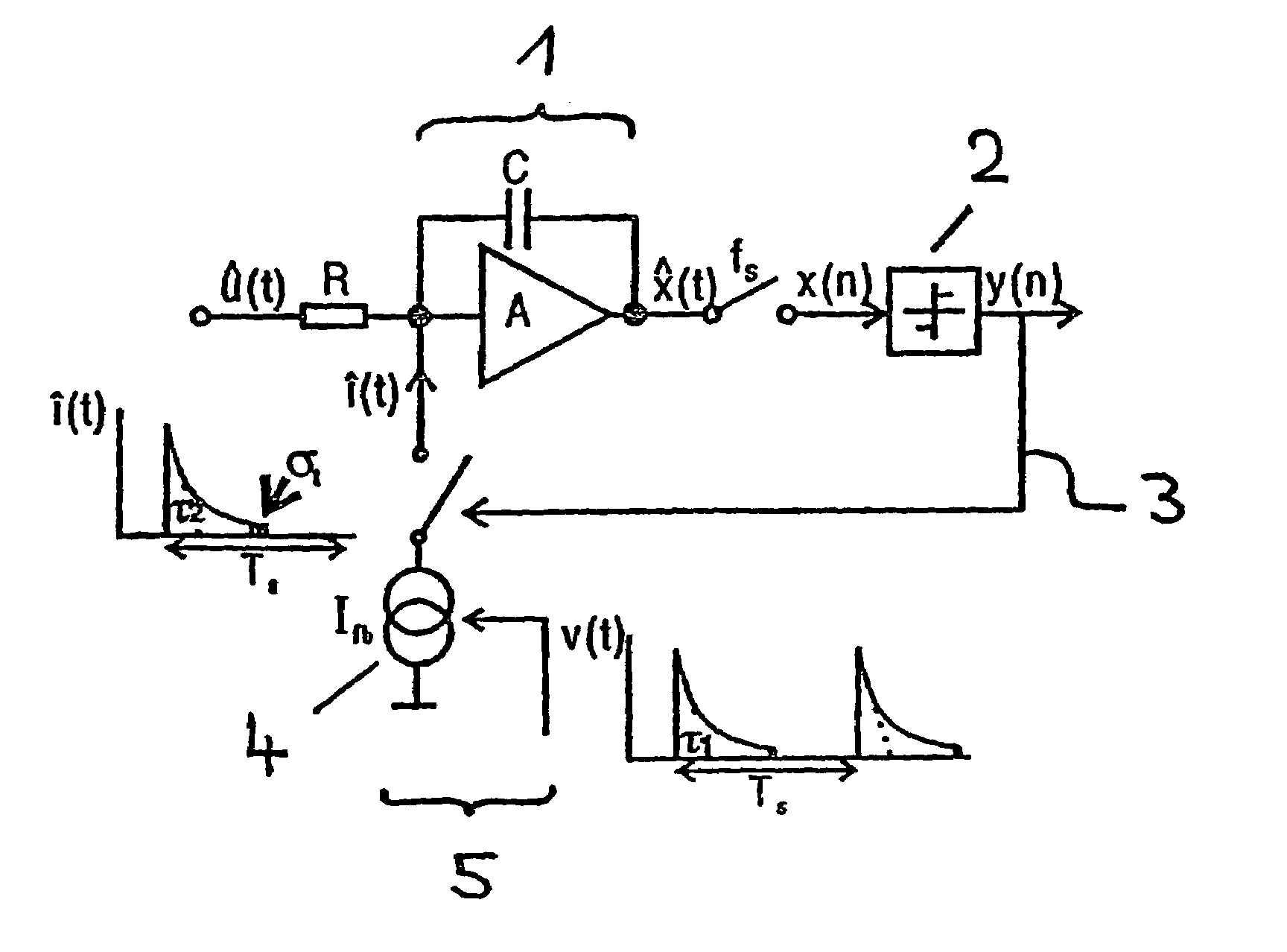

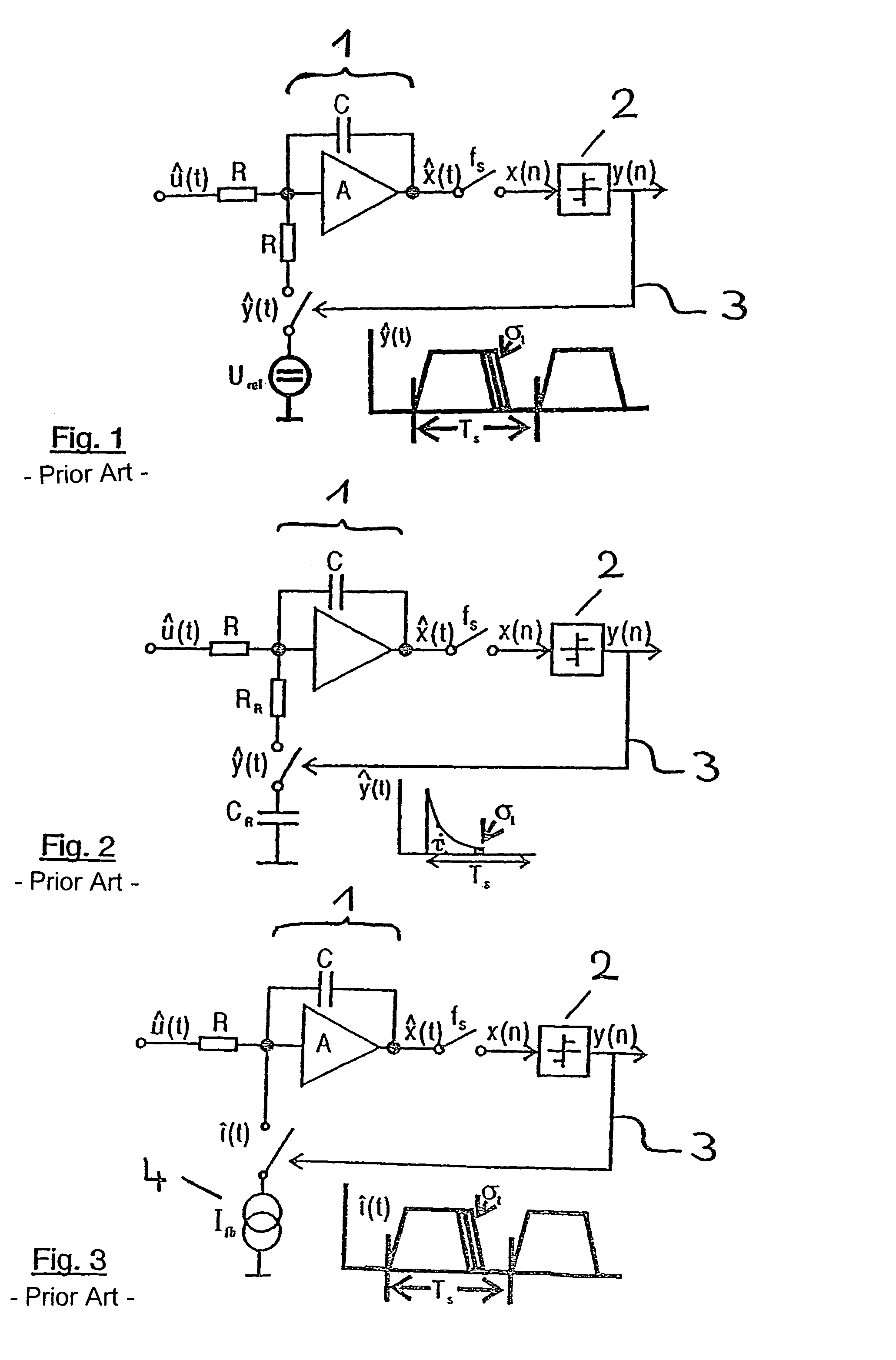

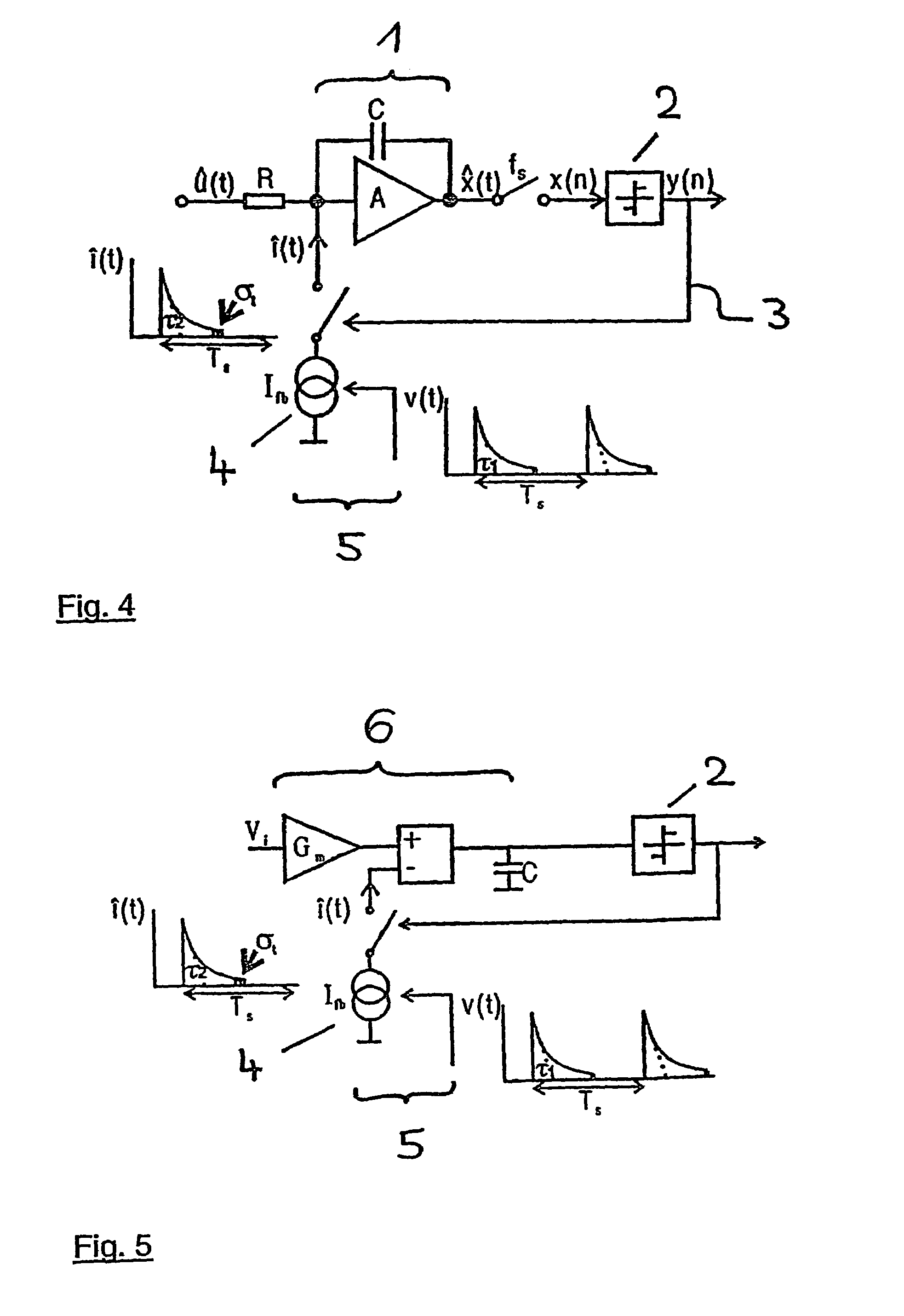

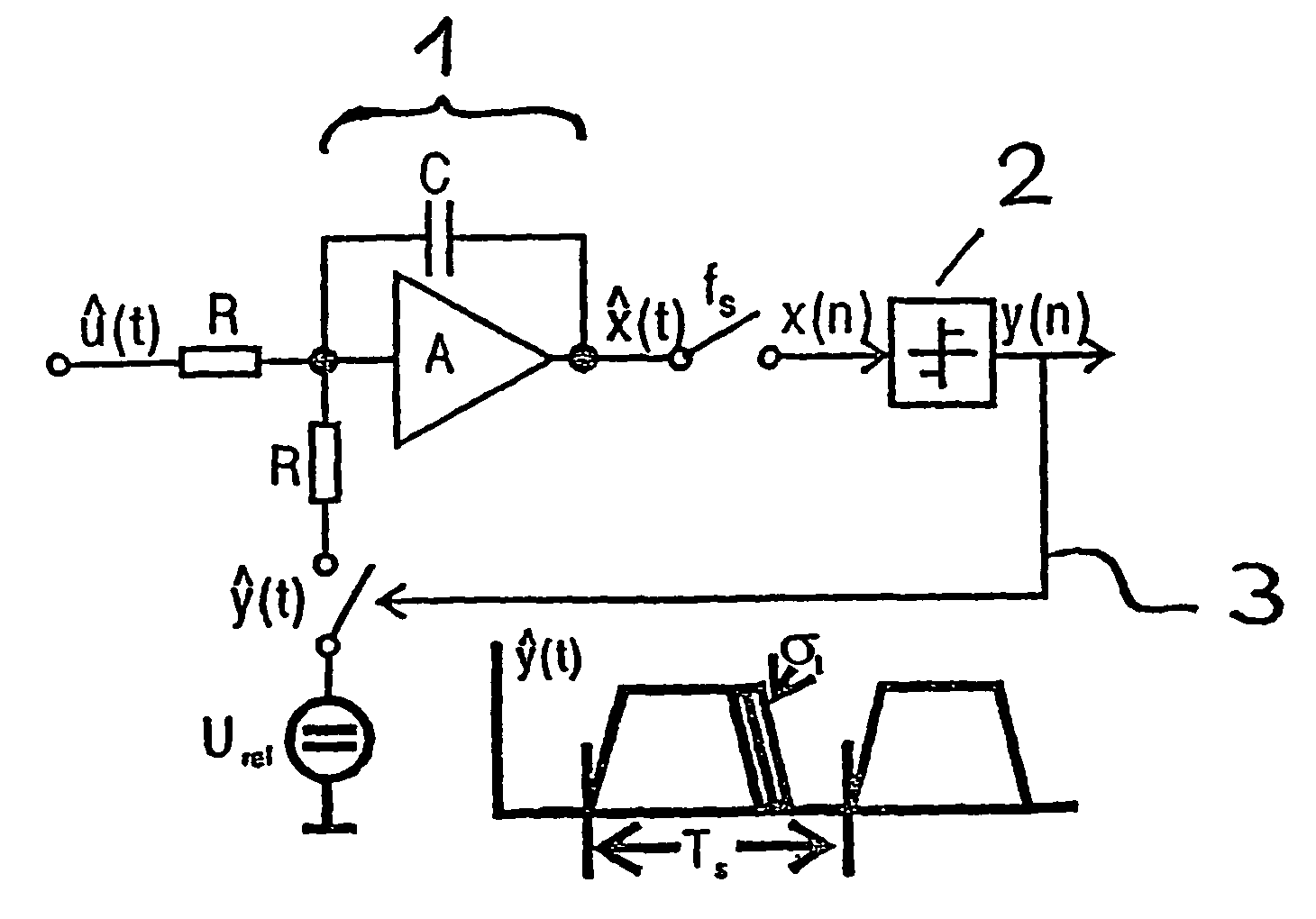

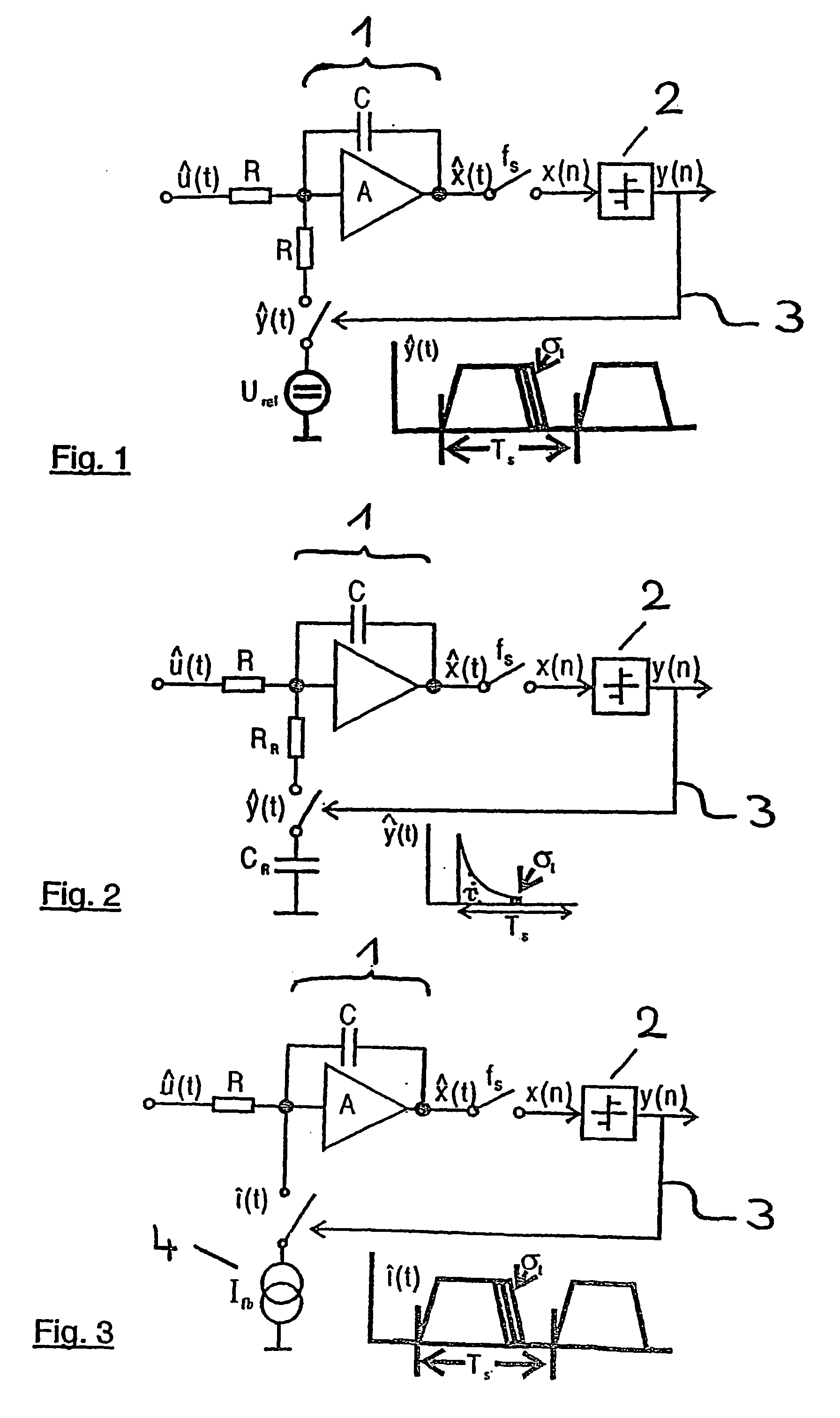

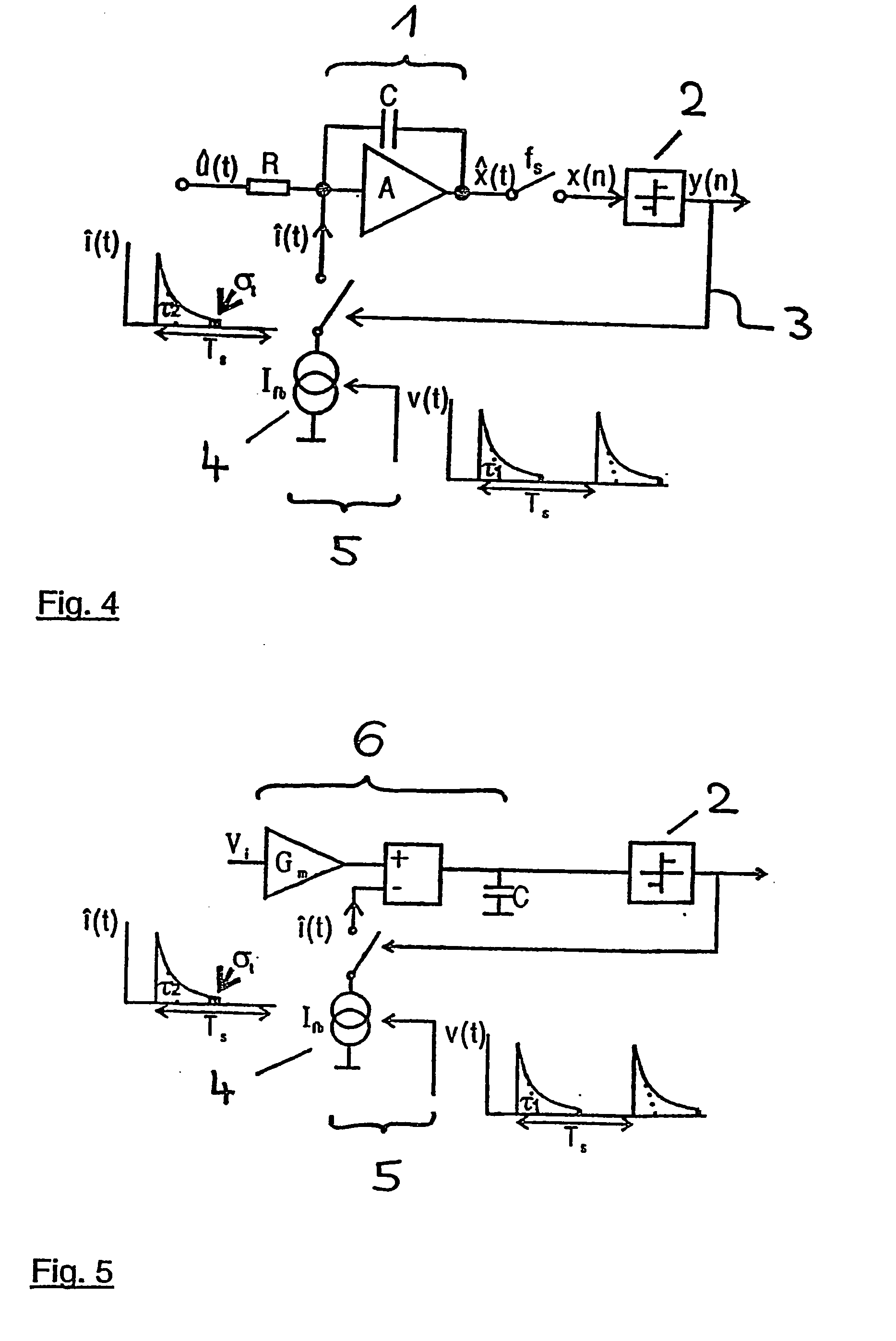

Controlled current source; in particular for digital/analogue converters in continuous-time sigma/delta modulators

InactiveUS7151474B2Reduce sensitivity to clock jitterIncrease insensitivityAnalogue/digital conversionElectric signal transmission systemsControl theoryCurrent source

The present invention relates to a controlled current source having a control input, in particular for digital / analogue converters in continuous-time sigma / delta modulators, having a current source (4) with a control input which generates an output current dependent on a control voltage applied to the control input, and having a controller (7) for converting a clock signal into a voltage signal, with the controller (7) being connected to the current source (4) in such a manner that the voltage signal is applied as a control voltage to the control input of the current source (4). The controller is designed to is designed to convert the clock signal into a voltage signal which has within a clock duration a reproducible curve ending with a falling flank. Using the present controlled current source in a digital / analogue converter in a feedback branch of a continuous-time sigma / delta modulator permits realizing a sigma / delta modulator which is essentially insensitive to clock jitter.

Owner:INTEL CORP

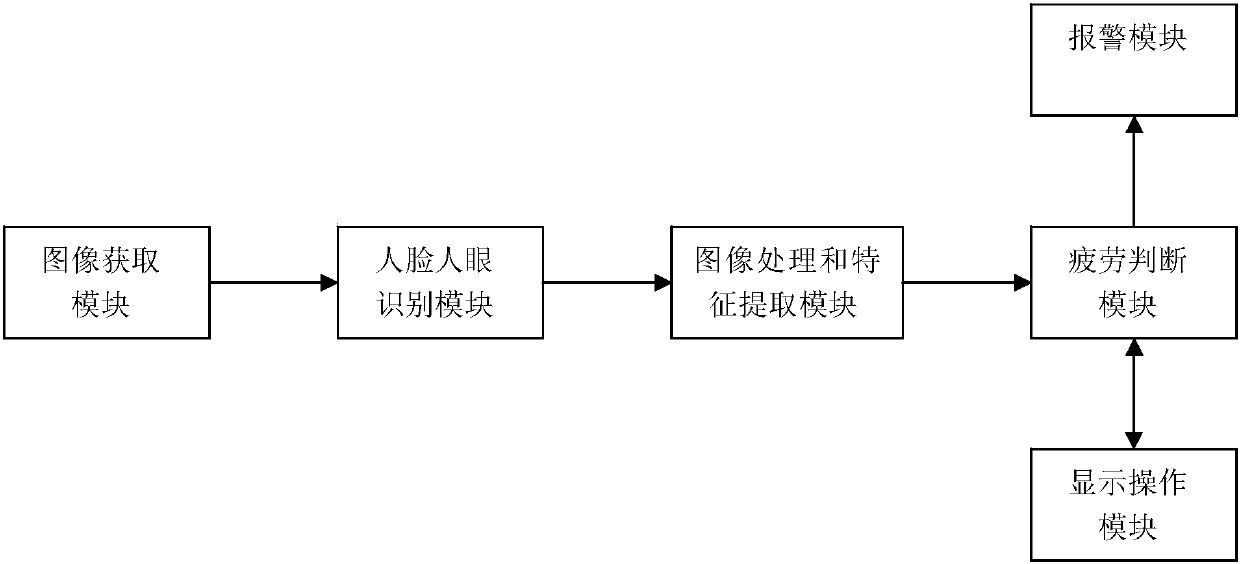

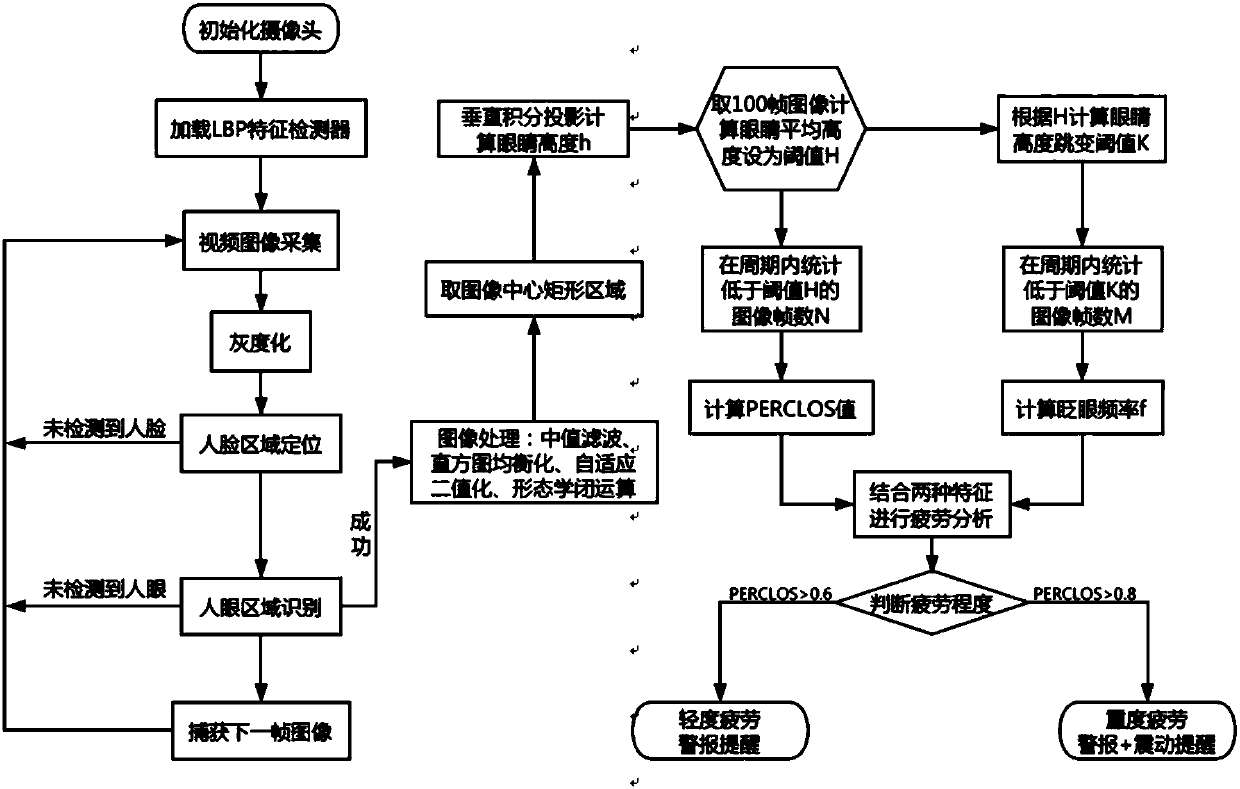

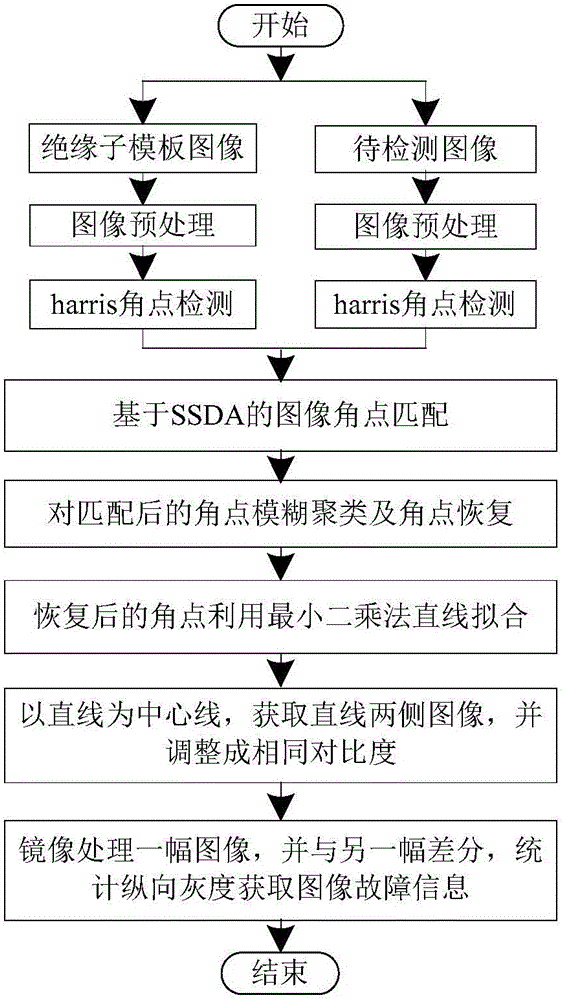

Fatigue driving detection device and detection method based on machine vision human eye recognition

InactiveCN107595307ASolve invisibleSolve the low-light environment imaging problemDiagnostic recording/measuringSensorsBlink frequencyMachine vision

The invention discloses a fatigue driving detection method based on machine vision human eye recognition. The detection method includes the steps: capturing a human face in a captured image, and tracking and positioning human eyes in real time to obtain a human eye image; processing the human eye image; extracting eye characteristics of a human eye area-of-interest; acquiring human eye characteristics in a waking state, fusing the characteristics according to the acquired human eye height characteristics and human eye blinking frequency characteristics, and judging degree of fatigue; giving analarm for the degree of fatigue. The eye characteristics include the human eye height characteristics and the human eye blinking frequency characteristics. By extracting the eye characteristics of auser, PERCLOS in a detection cycle is calculated and then compared with set PERCLOS, different degrees of fatigue are distinguished according to comparison results, and the user is reminded of two different degrees of fatigue including slight fatigue and severe fatigue. The invention further discloses a fatigue driving detection device based on machine vision human eye recognition.

Owner:HUNAN UNIV OF SCI & TECH

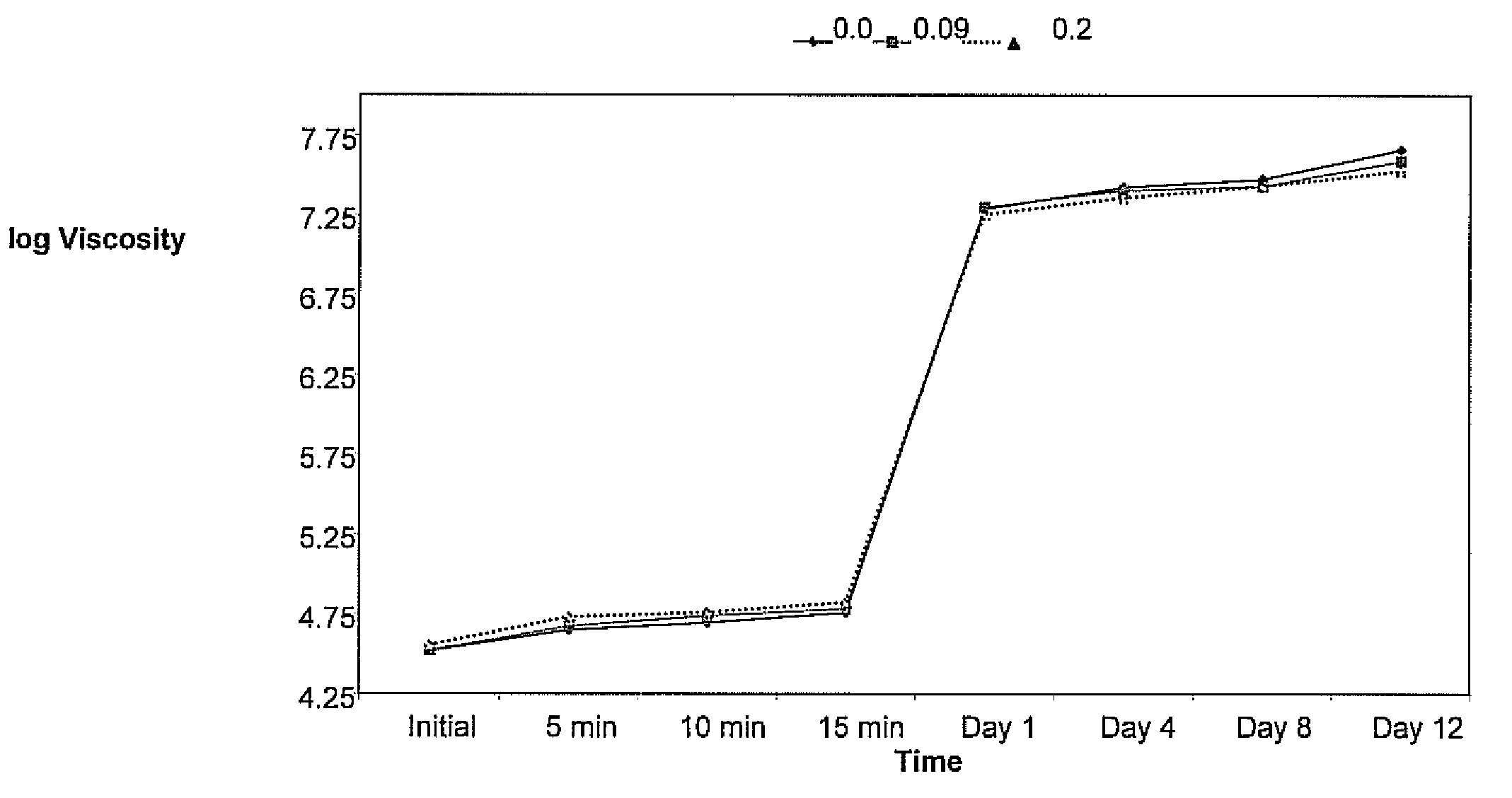

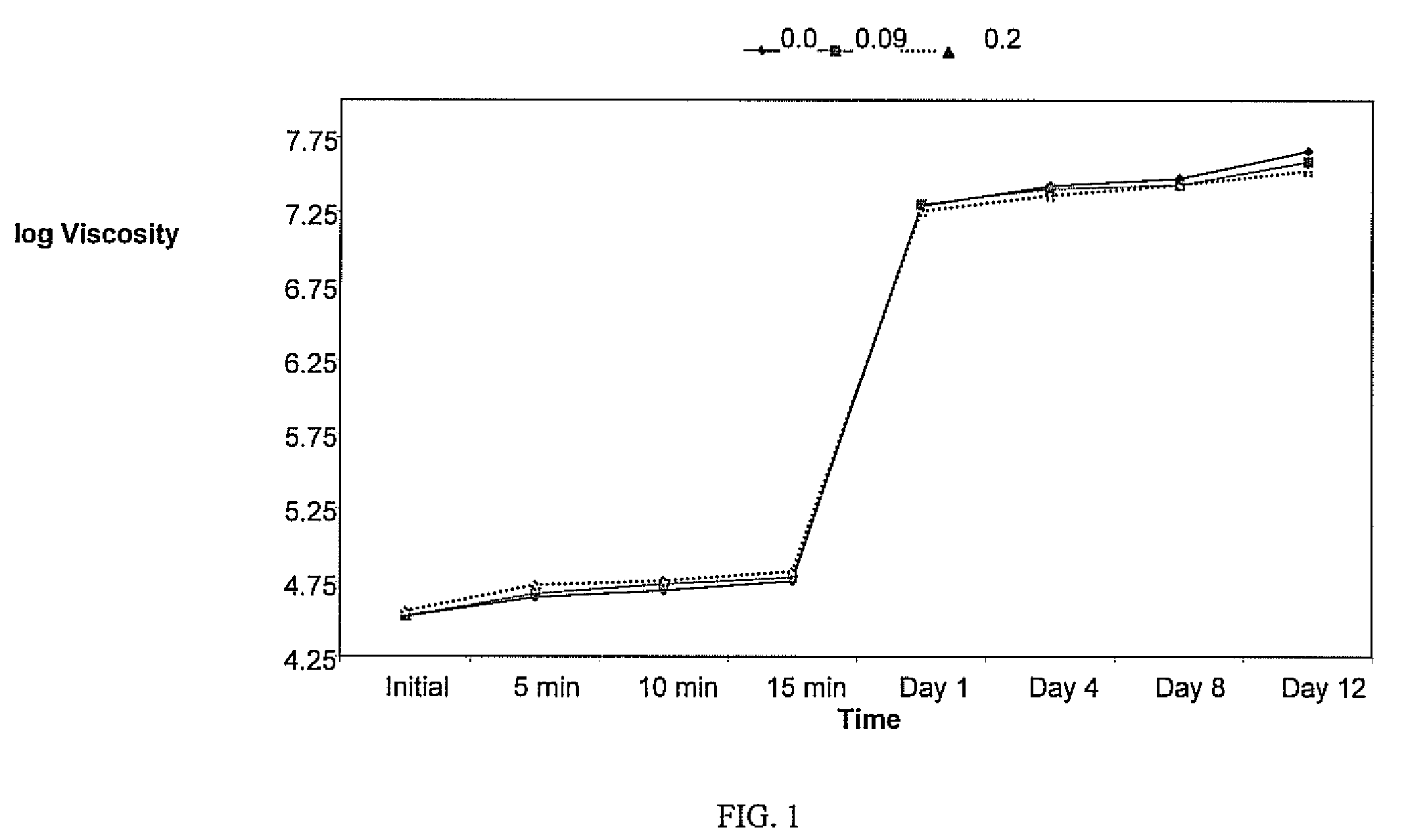

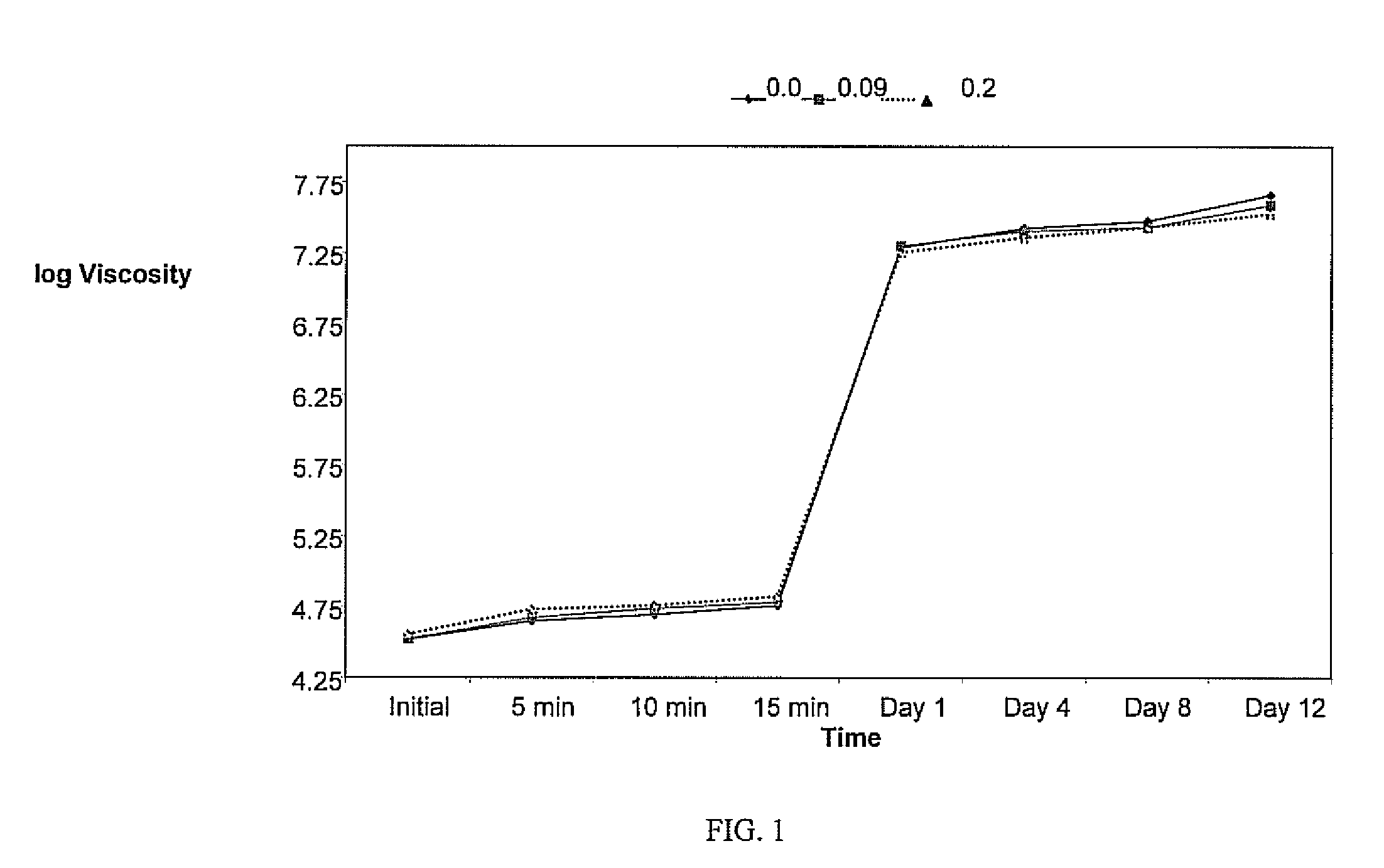

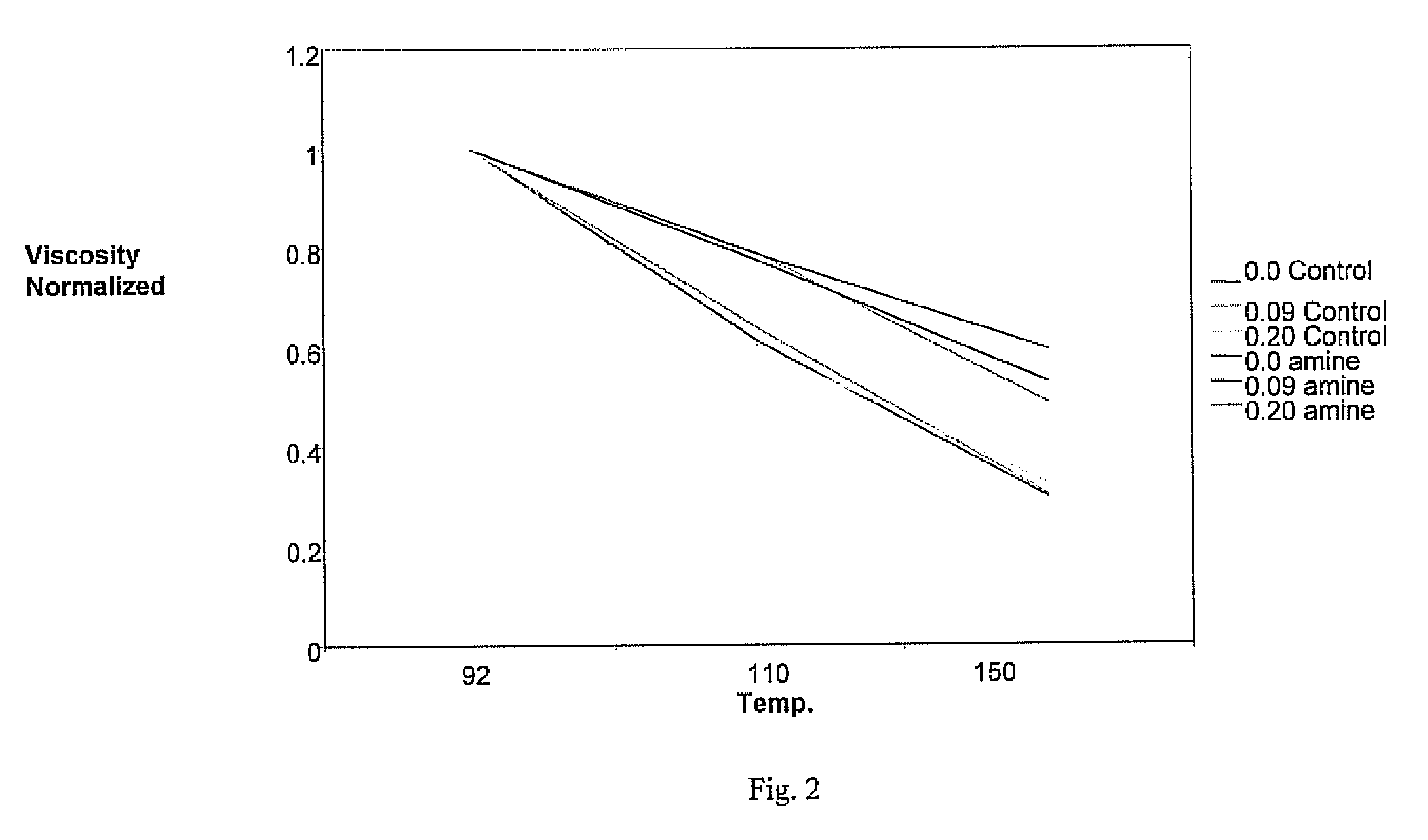

Polymeric thickener for molding compounds

A molding composition is provided that includes a thermoset cross-linkable polymeric resin, a fibrous filler and a thickener system. The thickener system includes an amine and an isocyanate that are reactive to form a polyurea. The polyurea is operative to thicken the molding composition formulation prior to polymeric resin thermoset with superior properties relative to conventional thickener systems. A molded article produced from a cross-linked thermoset polymeric resin containing fibrous filler and a polyurea present from 1 to 5 total weight percent of the article either forms an interpenetrating network between the resin and the polyurea or the resin and polyurea crosslink upon resin thermoset to further strengthen the resulting article. An alkali earth oxide or hydroxide simultaneously thickens through interaction with carboxylate functionality of the cross-linkable resin to provide a superior viscosity build and humidity tolerance.

Owner:TEIJIN AUTOMOTIVE TECH INC

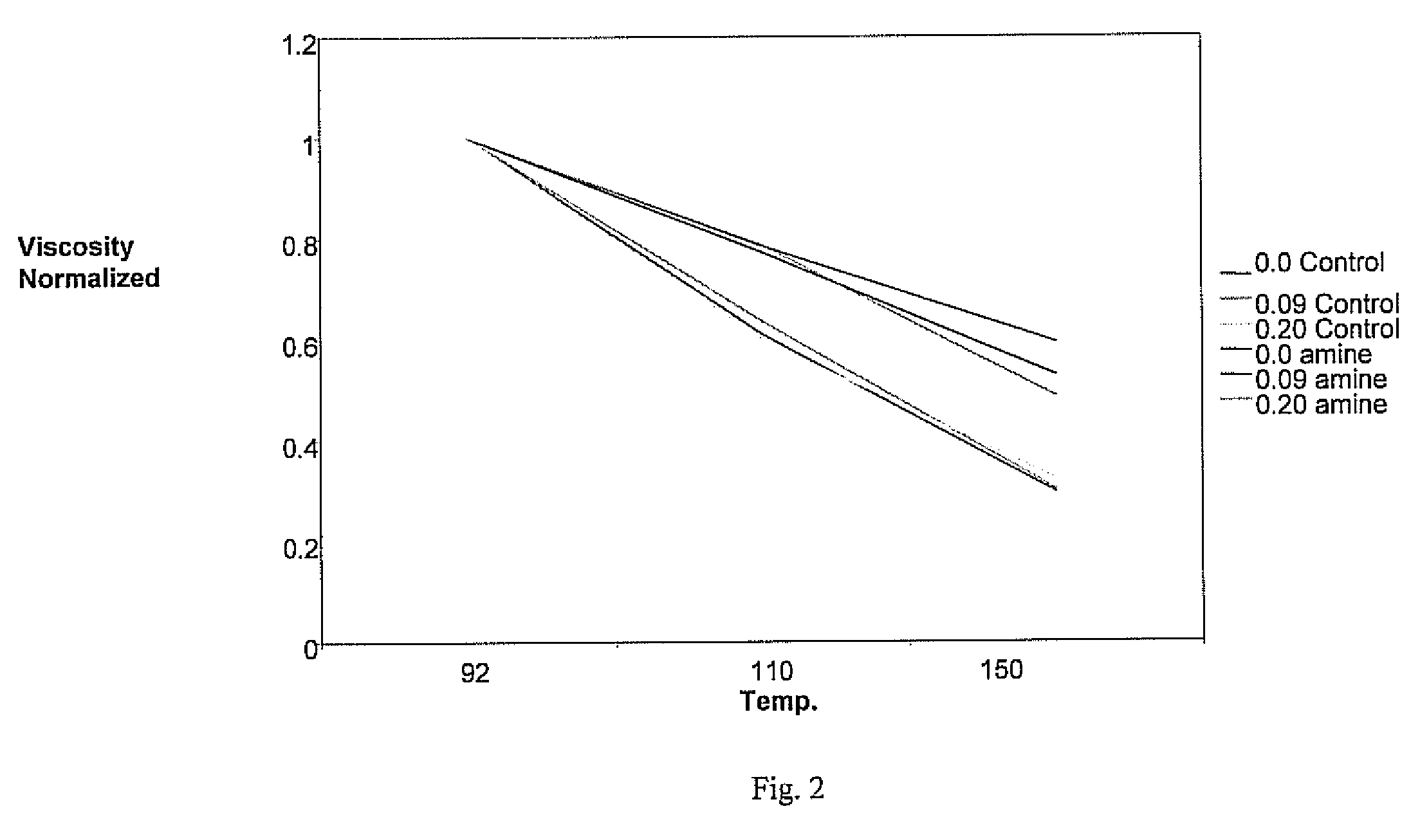

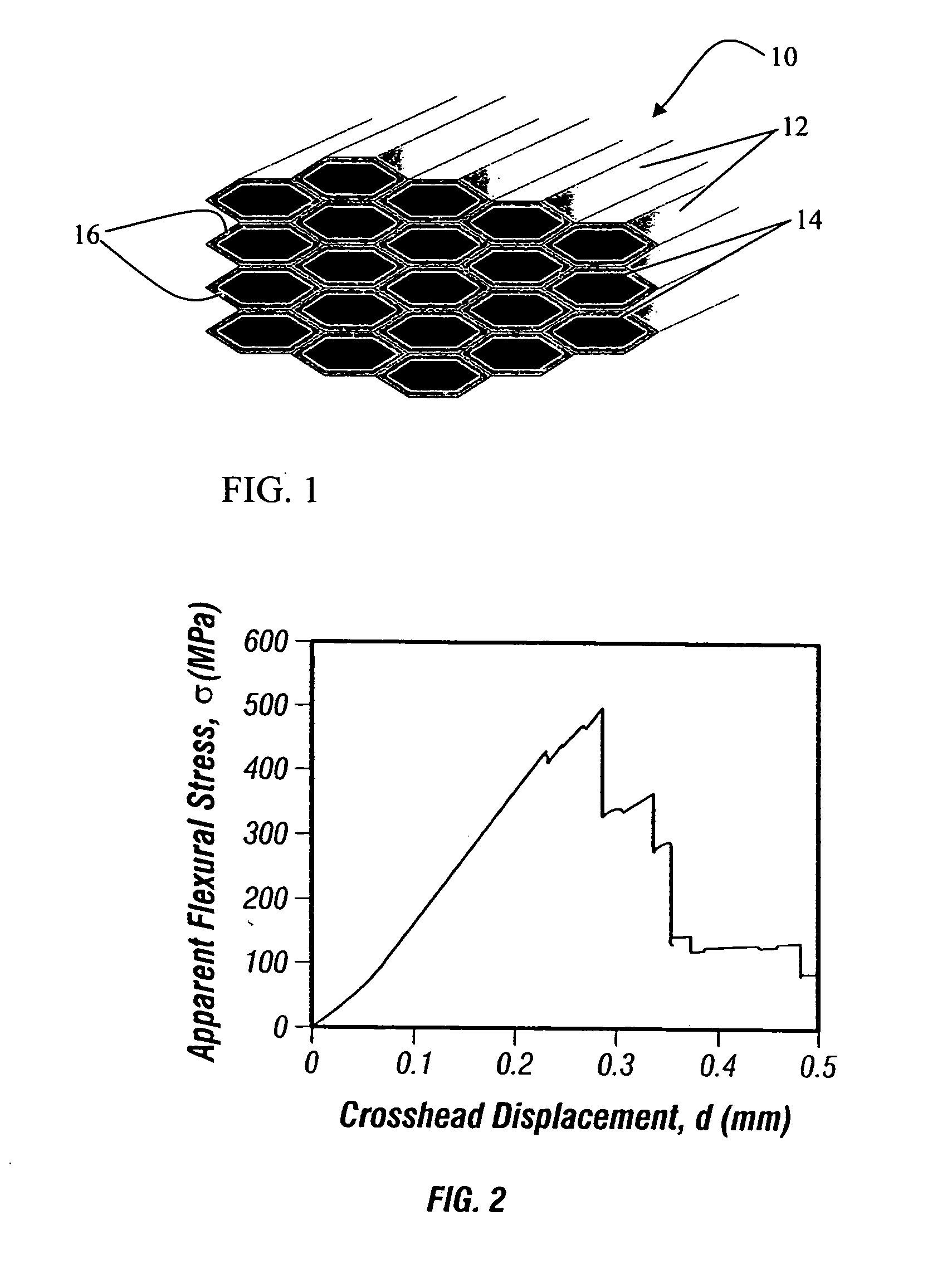

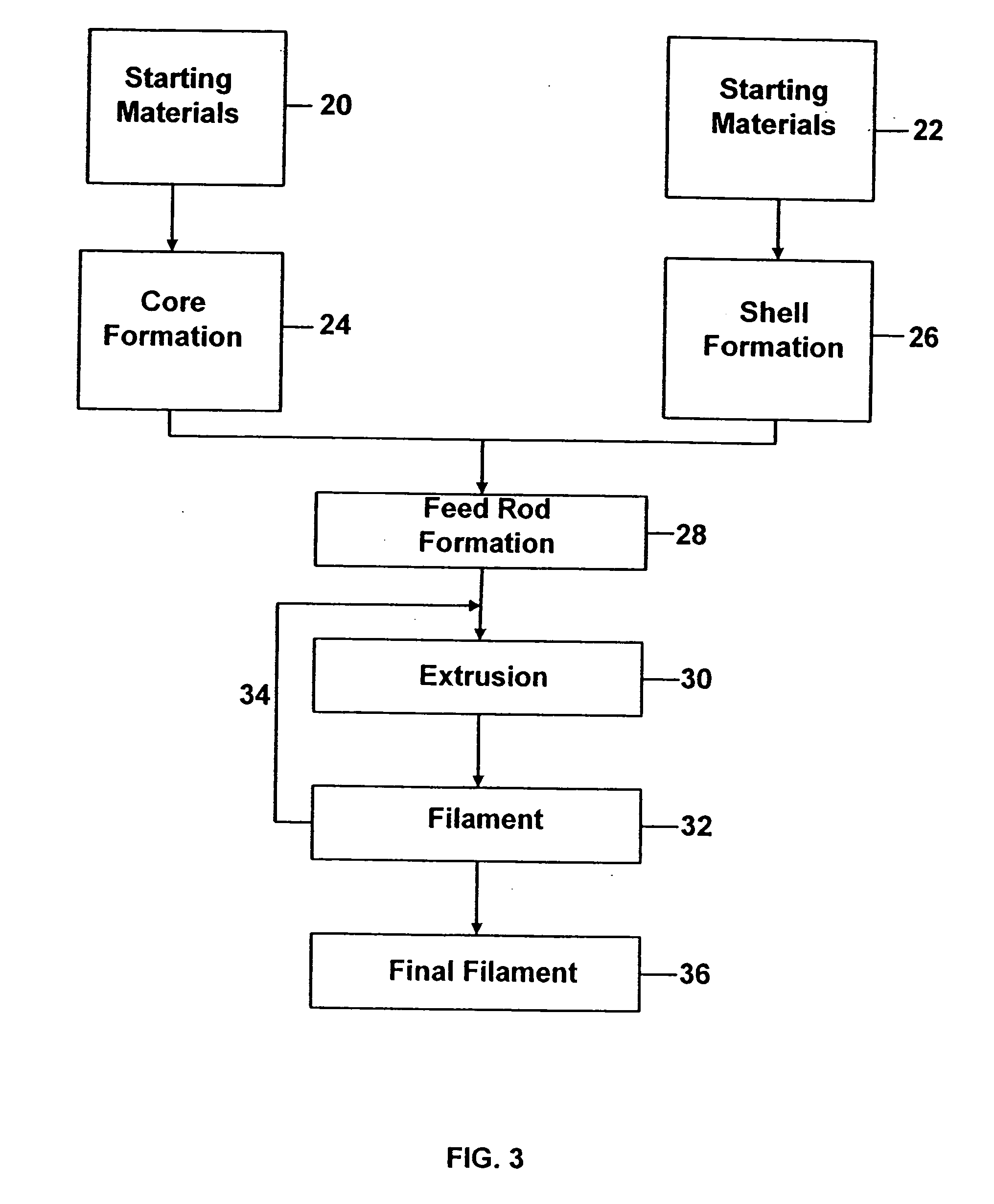

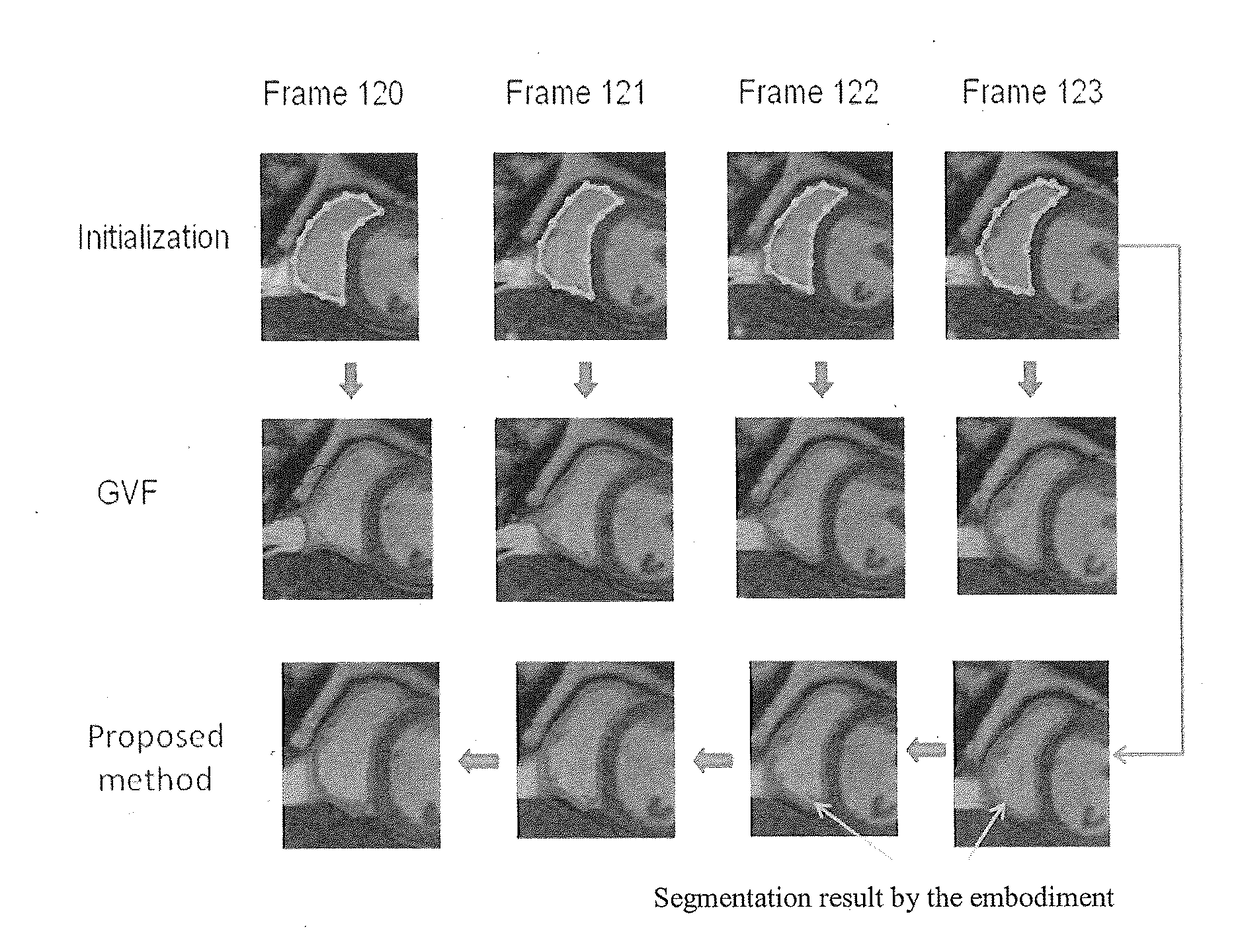

Aligned composite structures for mitigation of impact damage and resistance to wear in dynamic environments

InactiveUS20060091580A1Improve mechanical propertiesIncrease insensitivityNatural cellulose pulp/paperFilament/thread formingFiberDamage tolerance

Fibrous monolith composites having architectures that provide increased flaw insensitivity, improved hardness, wear resistance and damage tolerance and methods of manufacture thereof are provided for use in dynamic environments to mitigate impact damage and increase wear resistance.

Owner:ADVANCED CERAMICS

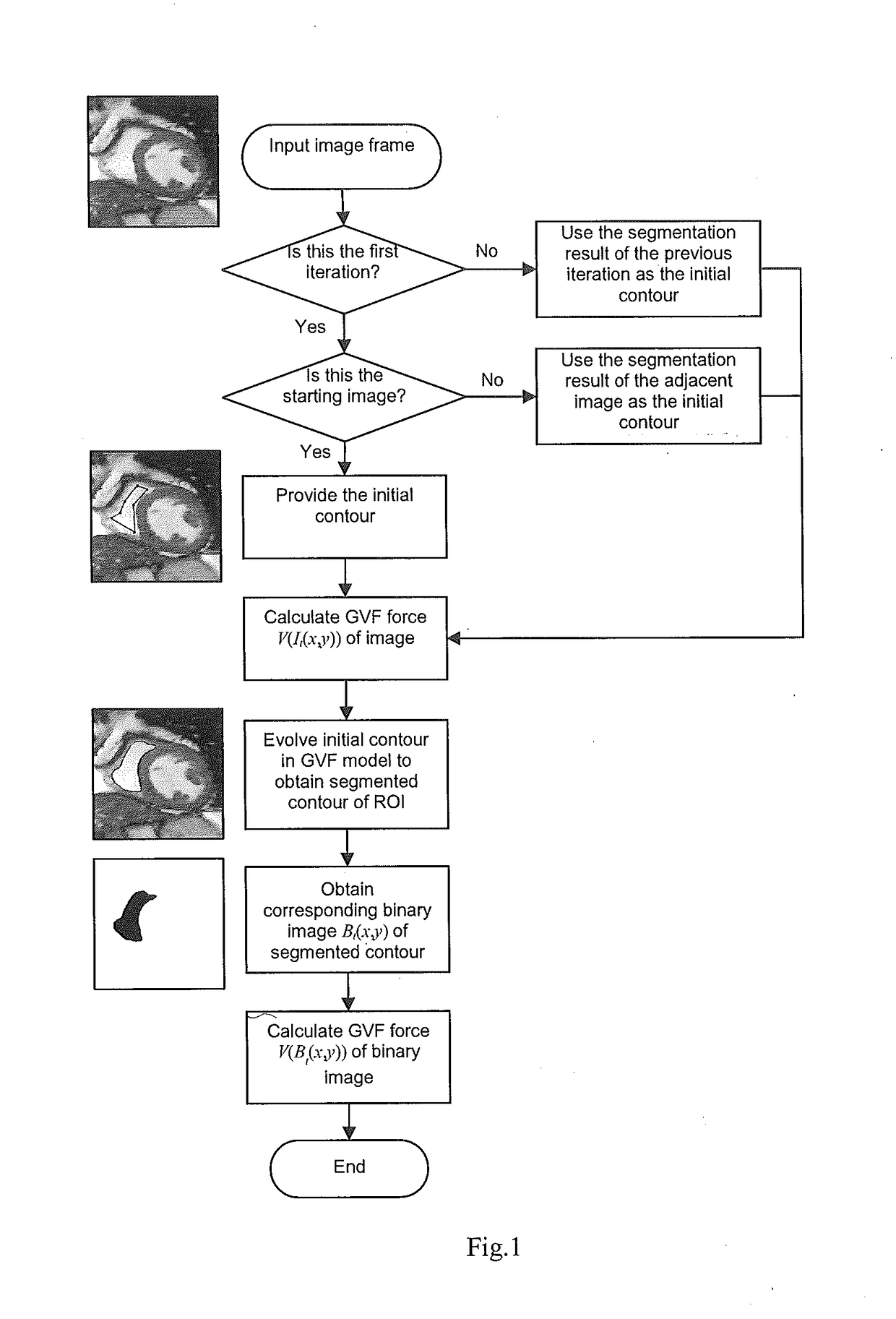

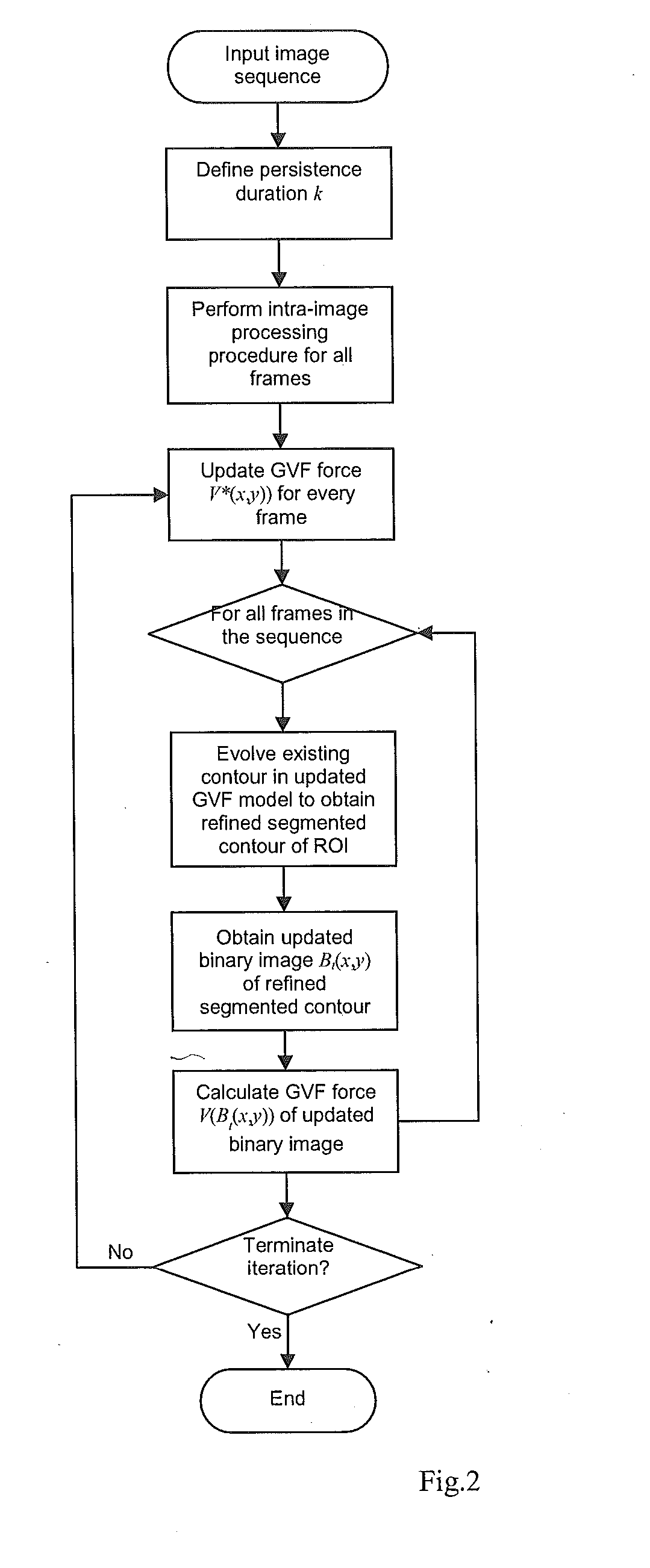

Segmentation of cardiac magnetic resonance (CMR) images using a memory persistence approach

InactiveUS20170109878A1Increase flexibilityAccurate segmentationImage enhancementImage analysisAnatomical structuresCluster algorithm

A method is proposed for identifying an anatomical structure within a spatial-temporal image (i.e. a series of frames captured as respective times). A current frame of spatial-temporal medical image is processed using information from one or more previous and / or subsequent temporal frames, to aid in the segmentation of an object or a region of interest (ROI) in a current frame. The invention is applicable to both two- and three-dimensional spatial-temporal images (i.e., 2D+time or 3D+time), and in particular to cardiac magnetic resonance (CMR images). An initialisation process for this method segments the left ventricle (LV) in a CMR image by a fuzzy c-means (FCM) clustering algorithm which employs a circular shape function as part of the definition of the dissimilarity measure.

Owner:AGENCY FOR SCI TECH & RES +1

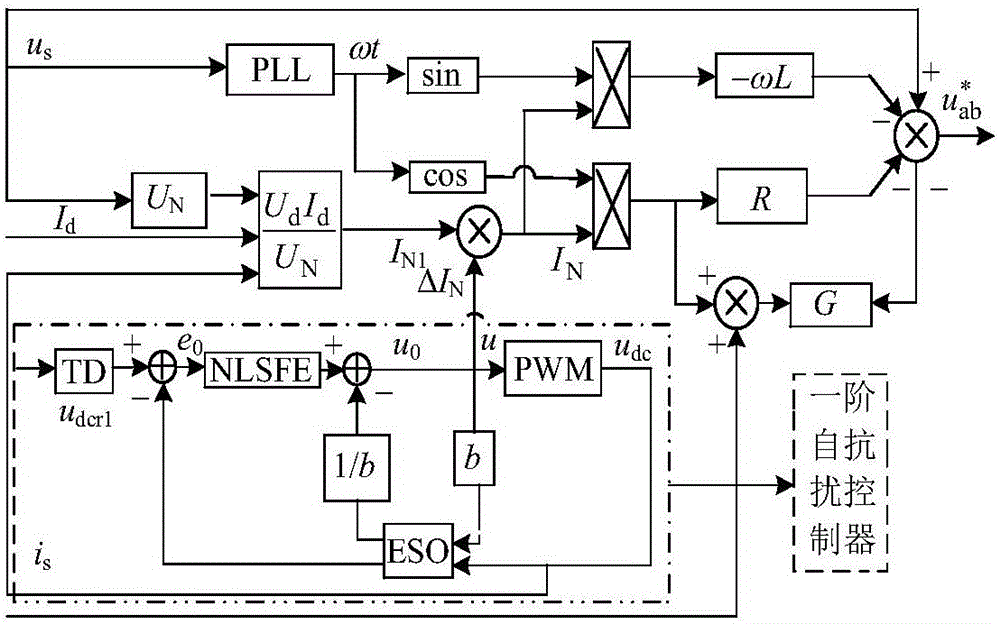

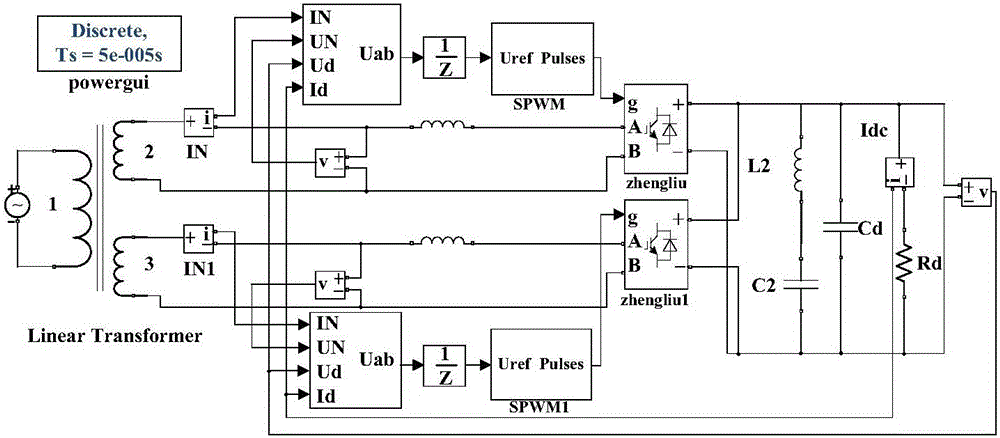

Active-disturbance-rejection control-based high-speed railway traction network low-frequency oscillation suppression method

InactiveCN105119307ASimple control structureImprove robustnessPower oscillations reduction/preventionDifferentiatorInput control

The invention discloses an active-disturbance-rejection control-based high-speed railway traction network low-frequency oscillation suppression method. According to the method, a nonlinear active-disturbance-rejection controller is adopted for a motor train unit converter which is a strong-coupling nonlinear system; the nonlinear active-disturbance-rejection controller includes a tracking differentiator (TD), an extended state observer (ESO) and nonlinear state error feedback control laws (NLSEF); and the method is realized based on transient direct current control strategies of the active-disturbance-rejection controller. The method can be implemented with easiness; the functionality function of an active-disturbance-rejection control module is written according to the state space model of a rectifier; as for the tracking differentiator, a direct current link voltage value u<dcr> is set, when input signals change, a transition process is arranged, so that no overshoot tracking input signals do not exist in output in a limited time period; as for the extended state observer, middle direct-current voltage output u<dc> and input control quantity u are made to track the state and disturbance of a converter; and the disturbance is dynamically compensated, and error feedback control quantity u<0> is calculated. With the above method provided by the above technical schemes of the invention adopted, high robustness and excellent control quality of the controller can be realized, and the stability of a control system can be improved, and the problem of motor train unit-traction network electric quantity low-frequency oscillation can be solved with low cost.

Owner:SOUTHWEST JIAOTONG UNIV

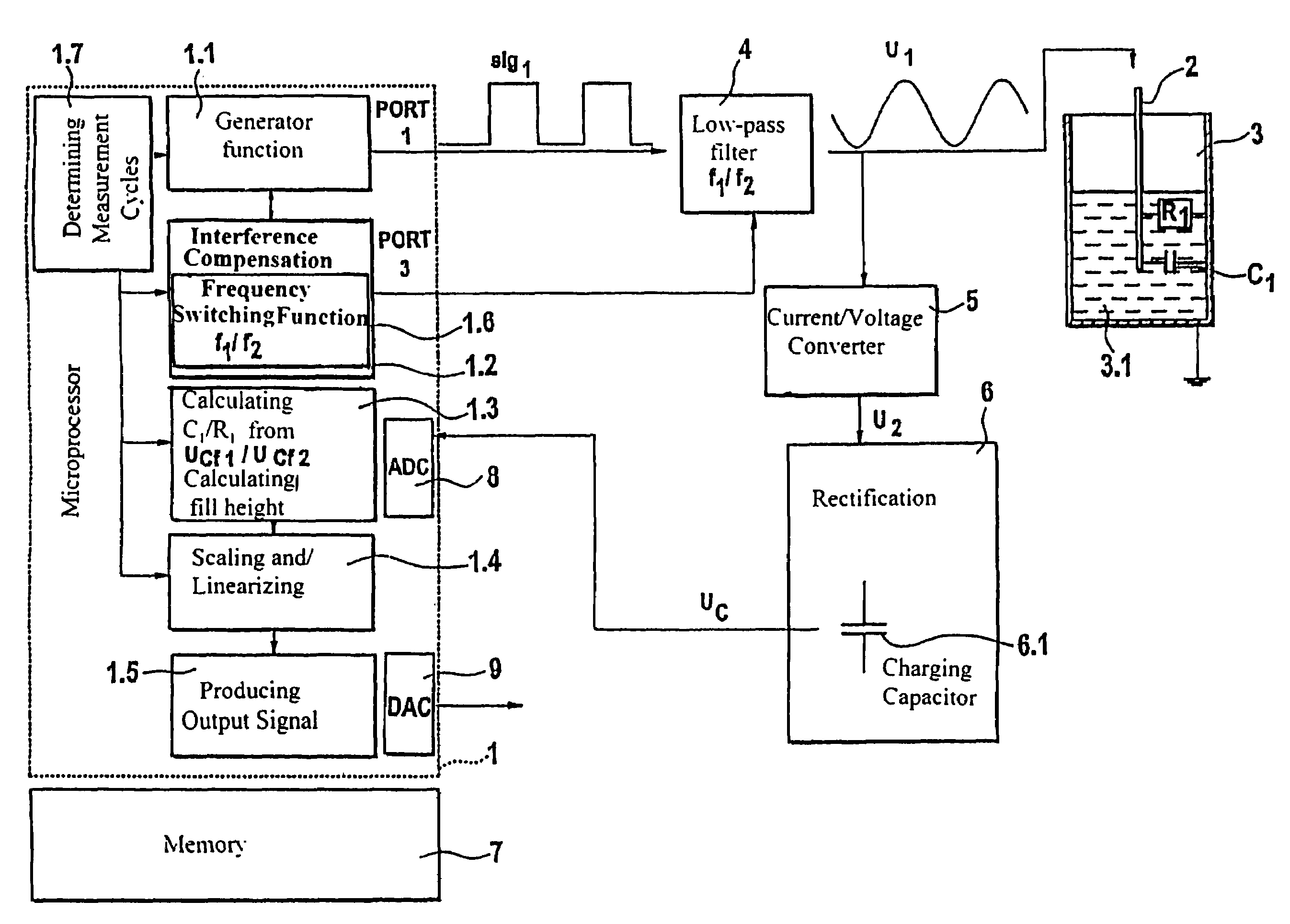

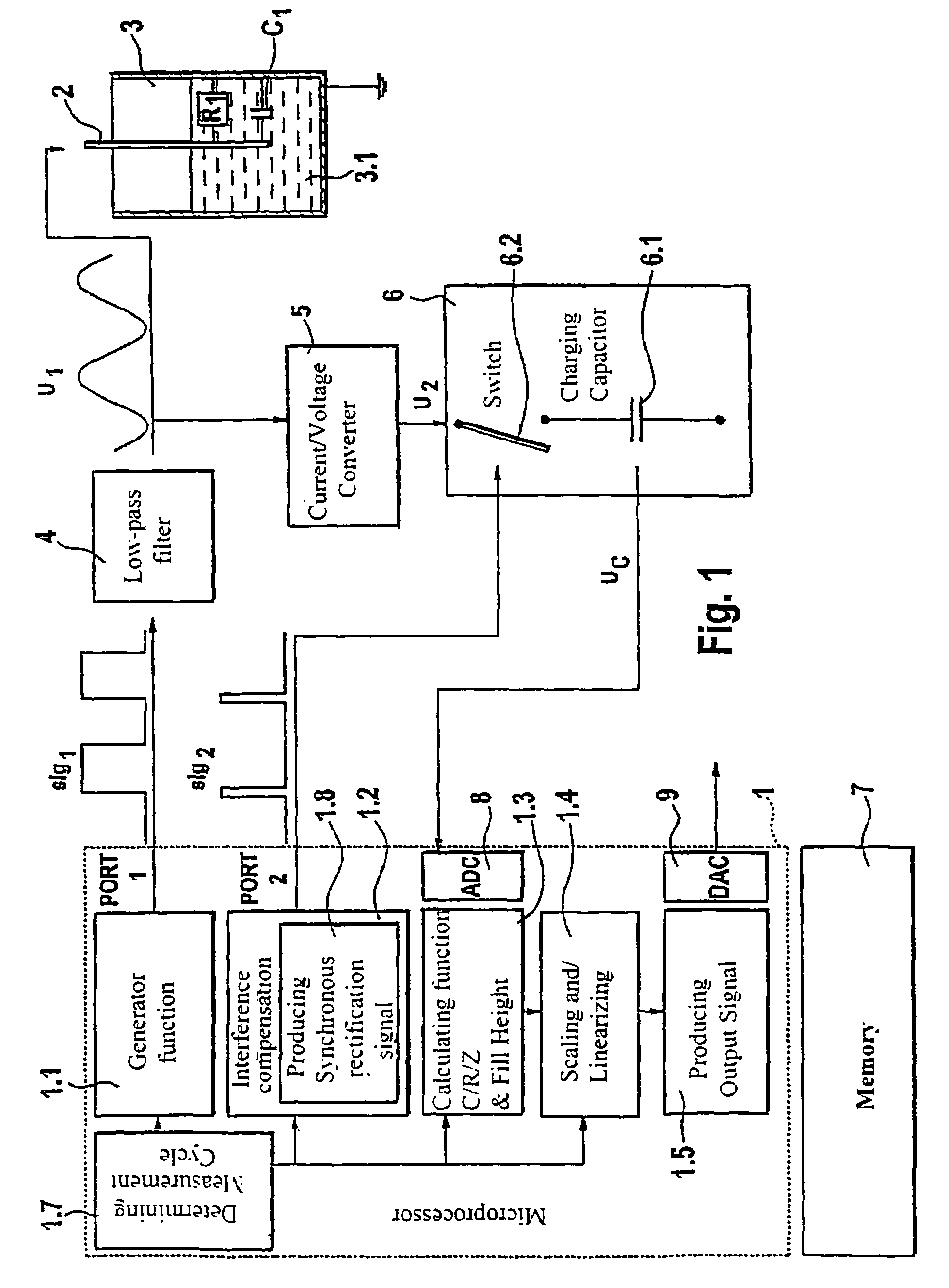

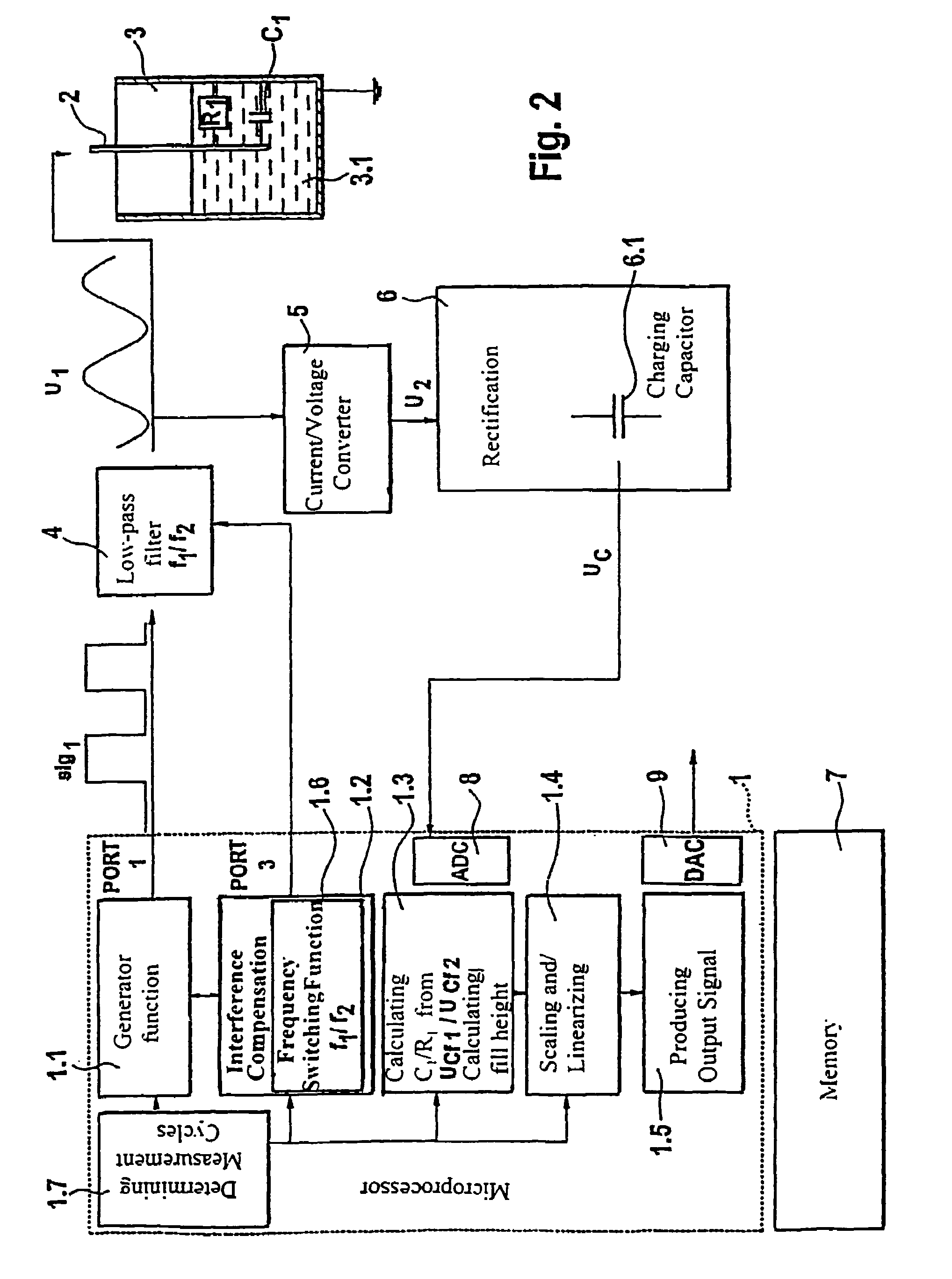

Electronic field device with a sensor unit for capacitive level measurement in a container

InactiveUS7415366B2Easy to adaptCompensation is simpleResistance/reactance/impedenceCurrent/voltage measurementCapacitanceEngineering

A field device electronics with a sensor unit for capacitive fill level measurements in a container, wherein the field device electronics is connected over appropriate signal paths with the sensor unit, wherein the field device electronics produces a voltage signal for driving the sensor unit and receives and evaluates a measurement current from the sensor unit. According to the invention, an analog / digital converter digitizing the analog measurement current, a microprocessor and a memory unit are present, wherein the microprocessor utilizes predetermined program routines to perform the production of the voltage signal and the evaluation of the measurement current and a compensation of interference parameters and a determination of the parameters of the sensor-container arrangement which are to be determined, with the associated programs being stored in the memory unit.

Owner:EHNDRESS KHAUZER GMBKH KO KG

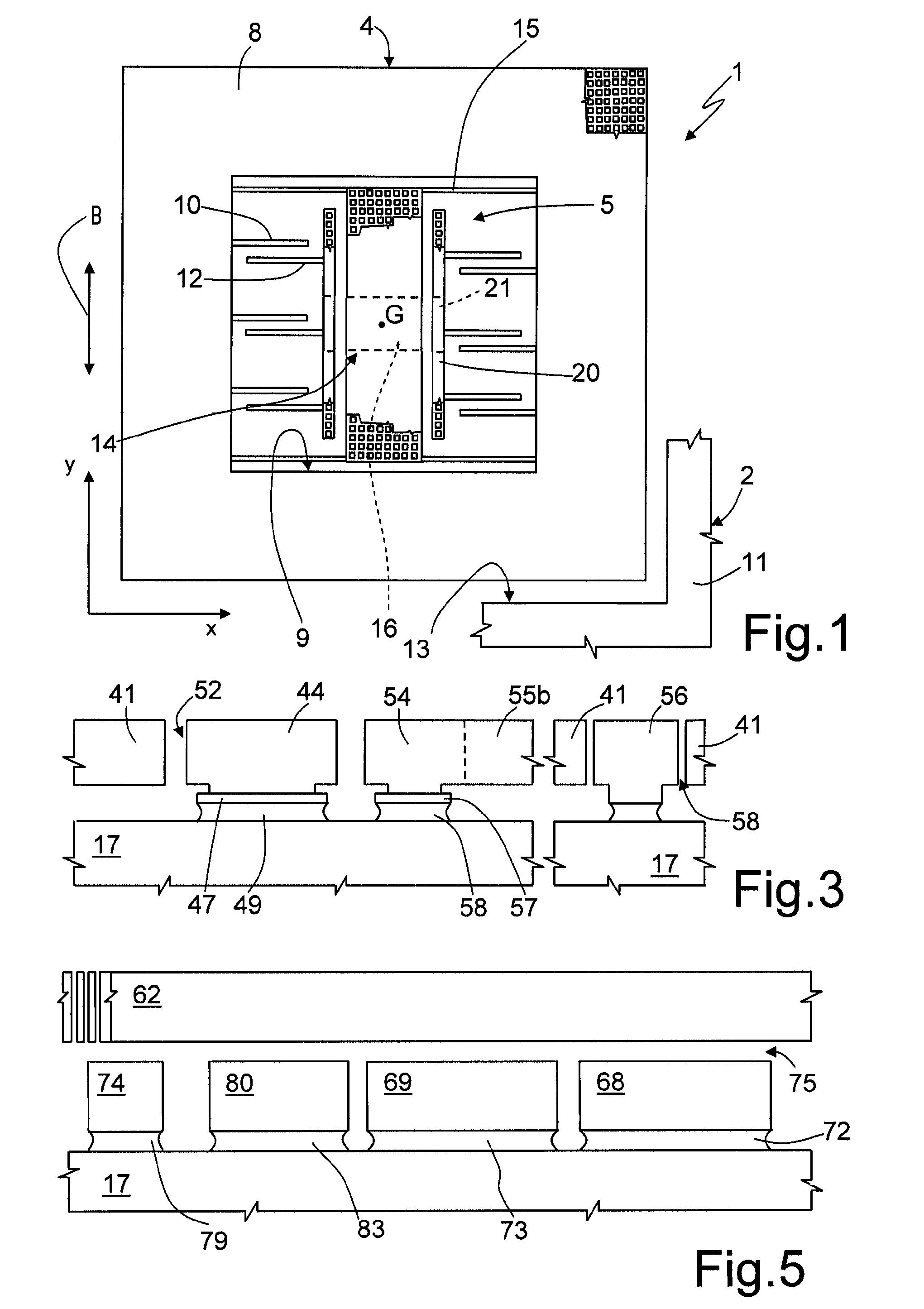

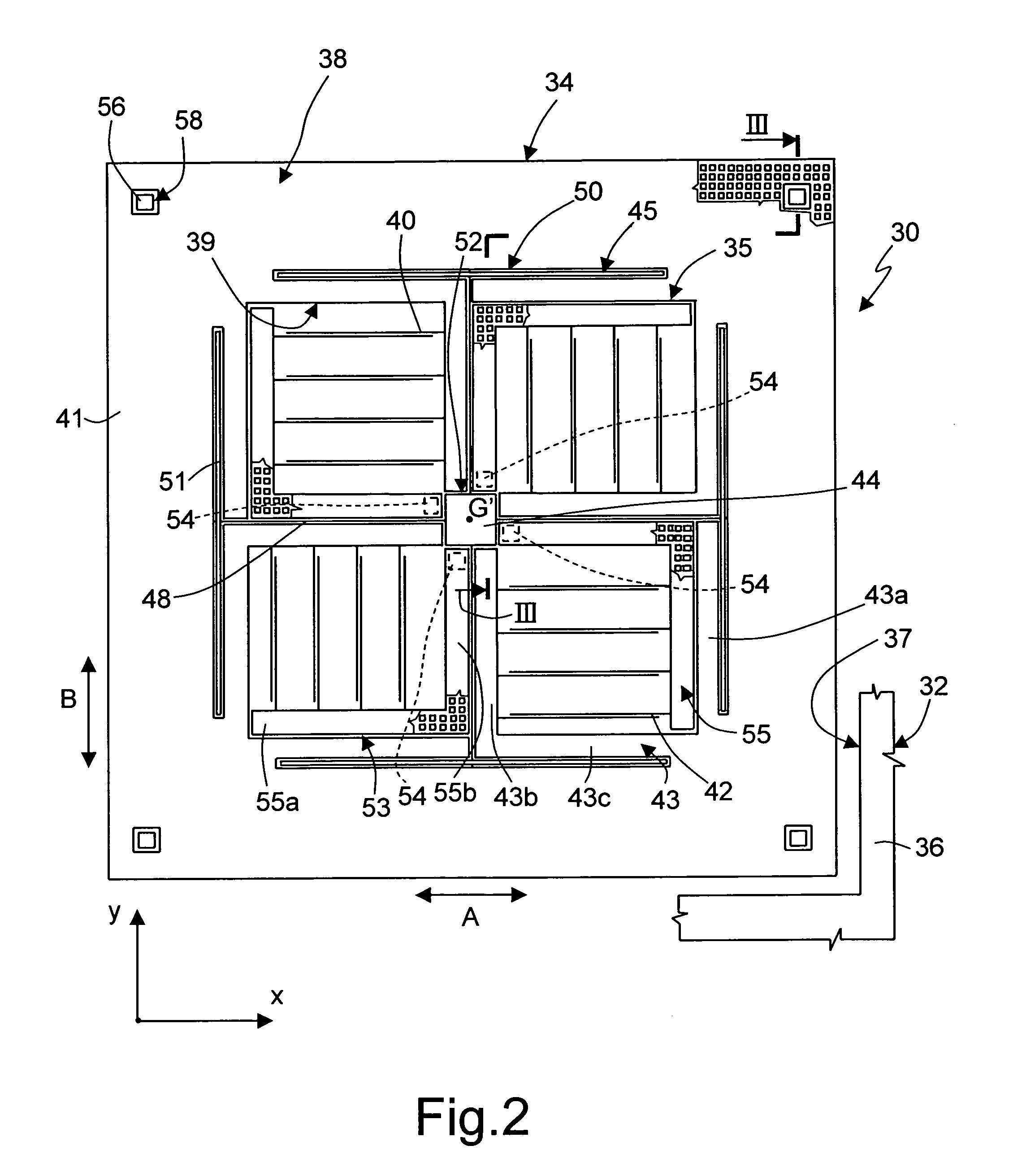

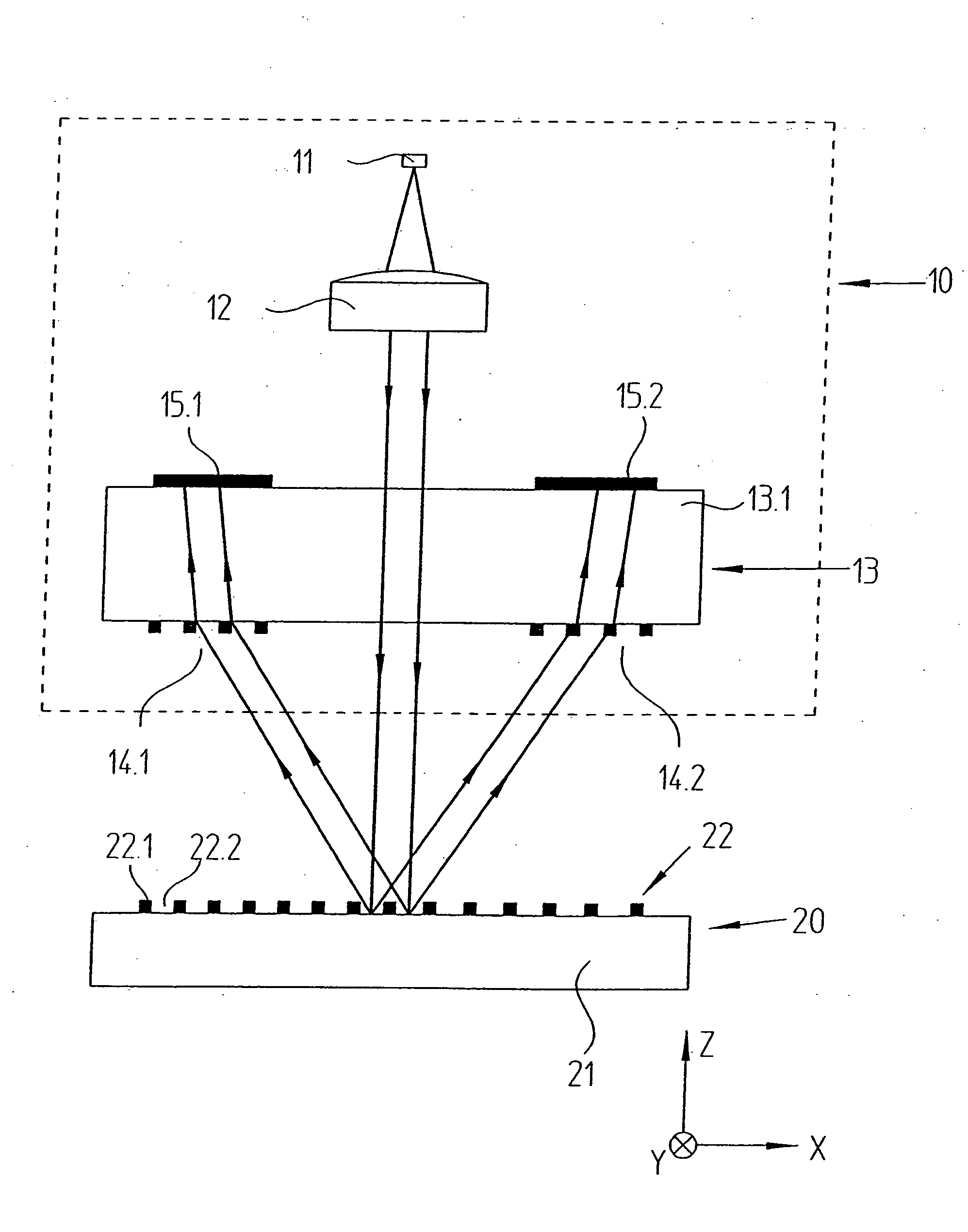

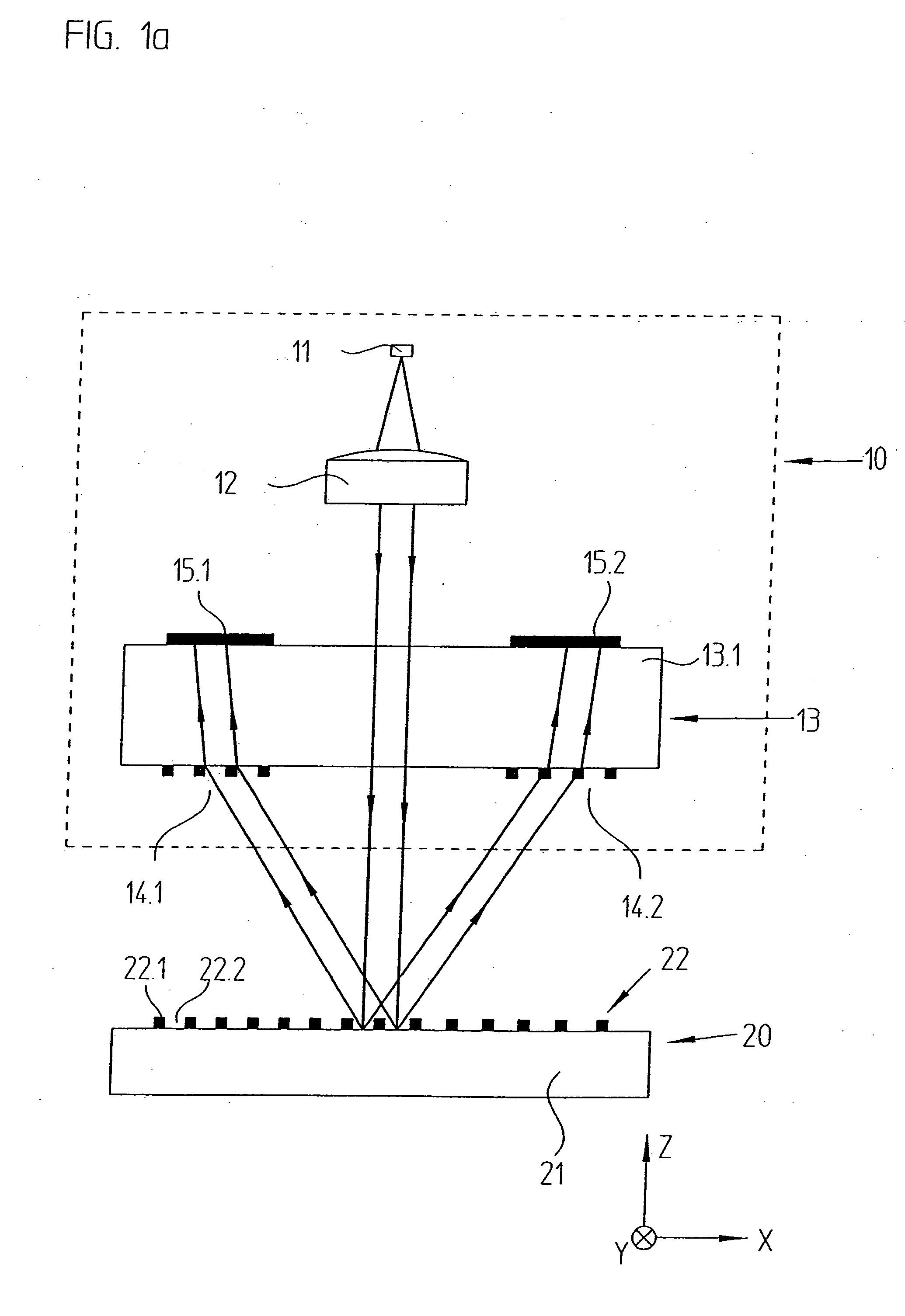

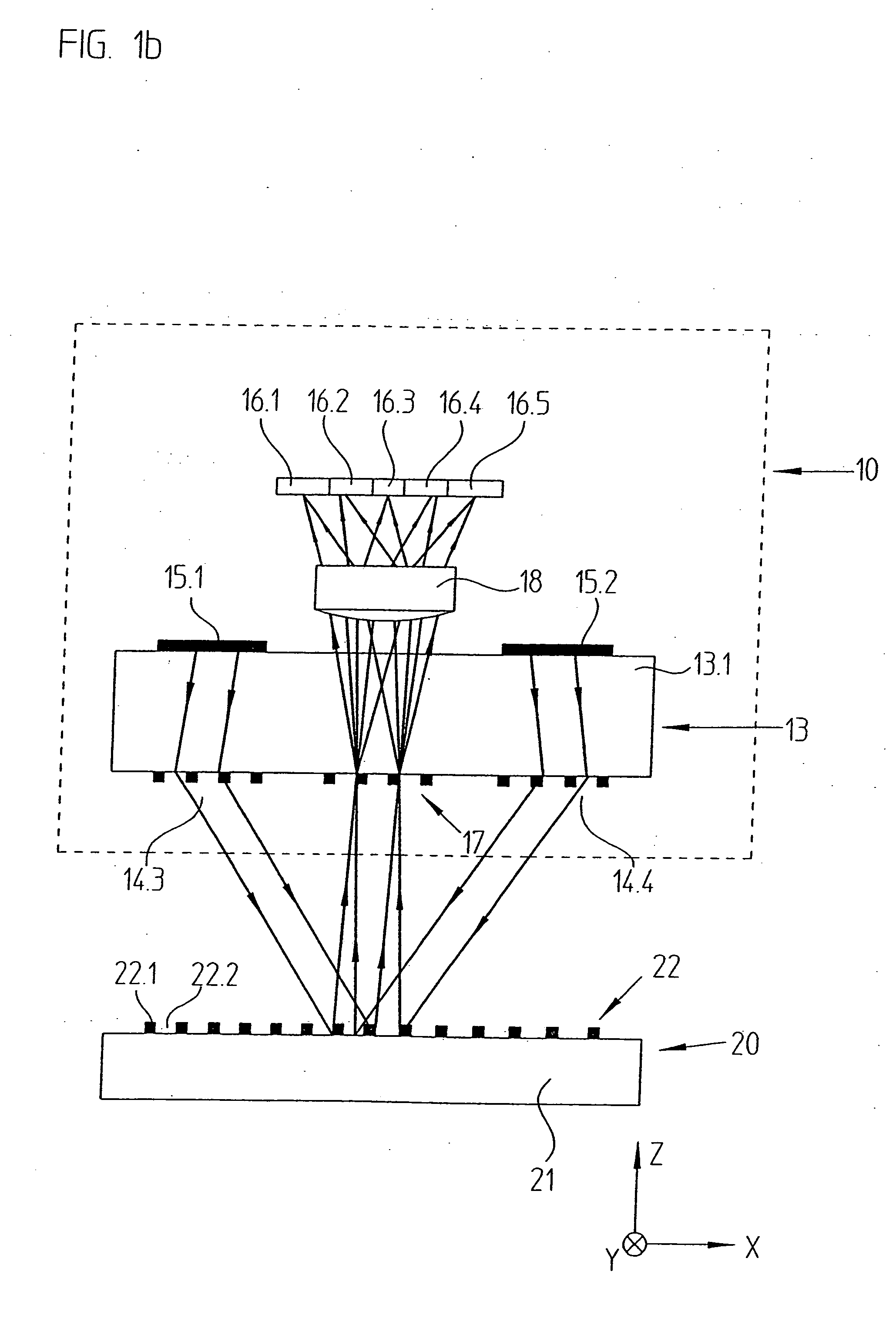

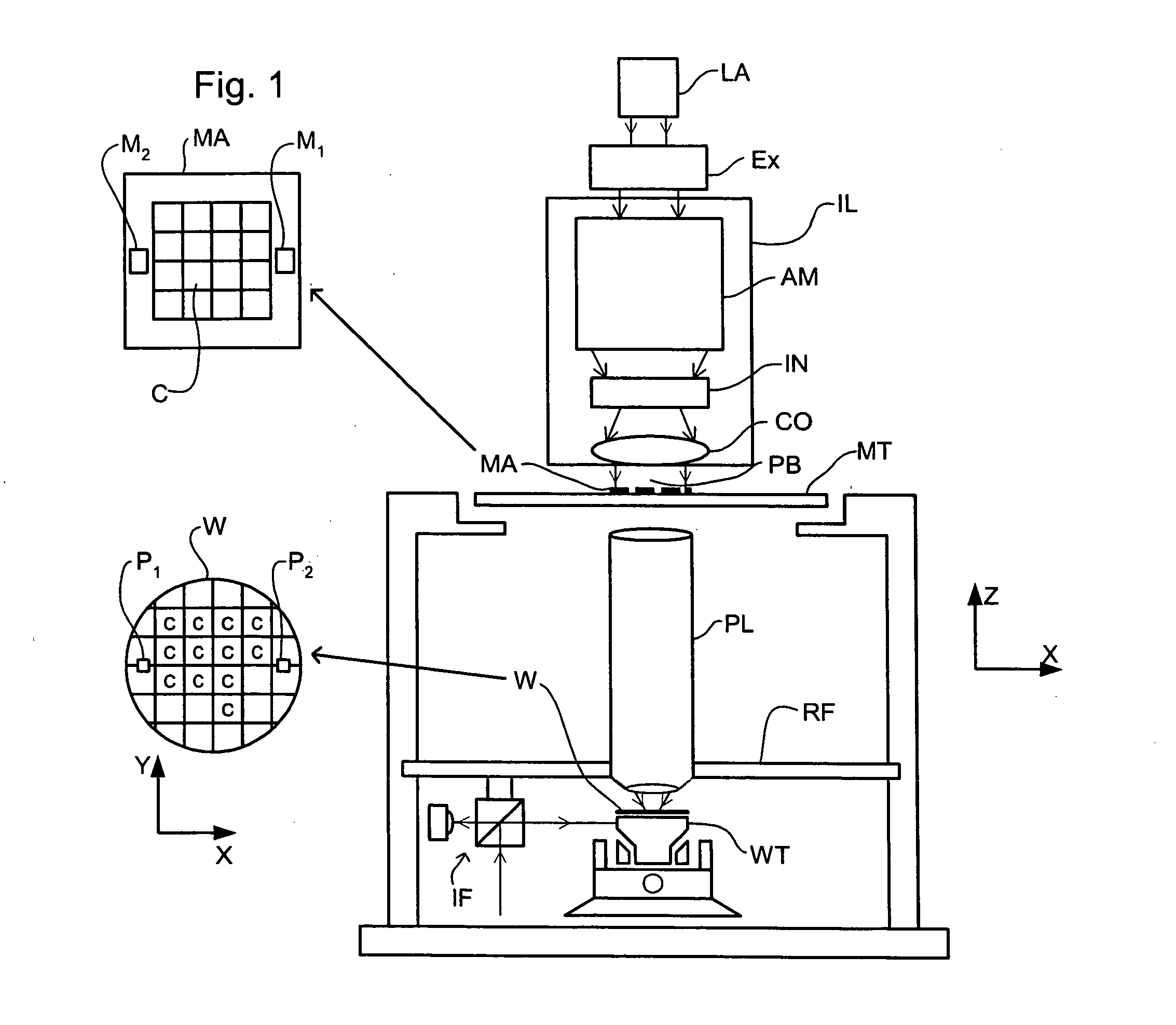

Optical position measuring arrangement

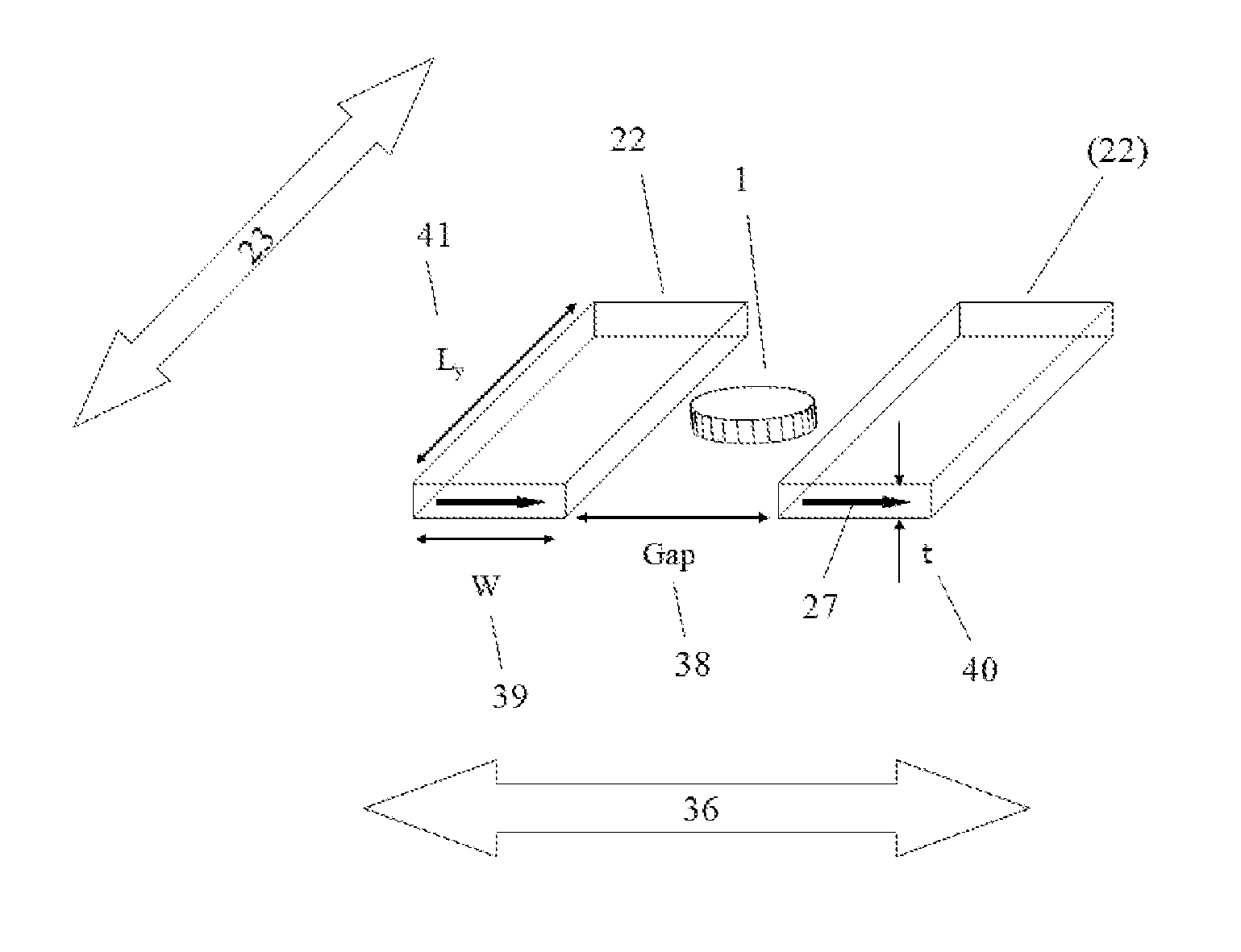

ActiveUS20090195792A1Improve efficiencyIncrease insensitivityUsing optical meansConverting sensor output opticallyPhase shiftedLight beam

An optical position measuring arrangement for the generation of n>1 phase-shifted incremental signals characterizing relative positions of two objects which are movable with respect to each other along a measuring direction. The optical position measuring arrangement includes a light source that emits bundles of beams, a measurement grating, a plurality of optional gratings and a scanning unit. The scanning unit includes a scanning grating arranged in a scanning plane, wherein the scanning grating includes a plurality of blocks arranged periodically along the measuring direction with a scanning grating periodicity TPAG equaling a fringe pattern periodicity TPS, and each block includes n grating sections (n=1, 2, 3, . . . ) of a width bx=TPAG / n, exclusively arranged along the measuring direction, and each of the n grating sections has a periodic grating structure, which causes a deflection of the bundles of beams propagated through each of the n grating sections in several spatial directions, in which resulting spatial directions of the n grating sections in a block differ. The scanning unit further includes a plurality of detector elements arranged downstream of the scanning grating, wherein the detector elements are arranged in the spatial directions in the detector plane, and wherein the detector plane is located in an area in which the bundles of beams coming from the scanning grating are completely spatially separated. The fringe pattern having a periodicity TPS is formed in the scanning plane by an interaction of the bundles of beams emitted by the light source with the measurement grating and the further optional gratings.

Owner:DR JOHANNES HEIDENHAIN GMBH

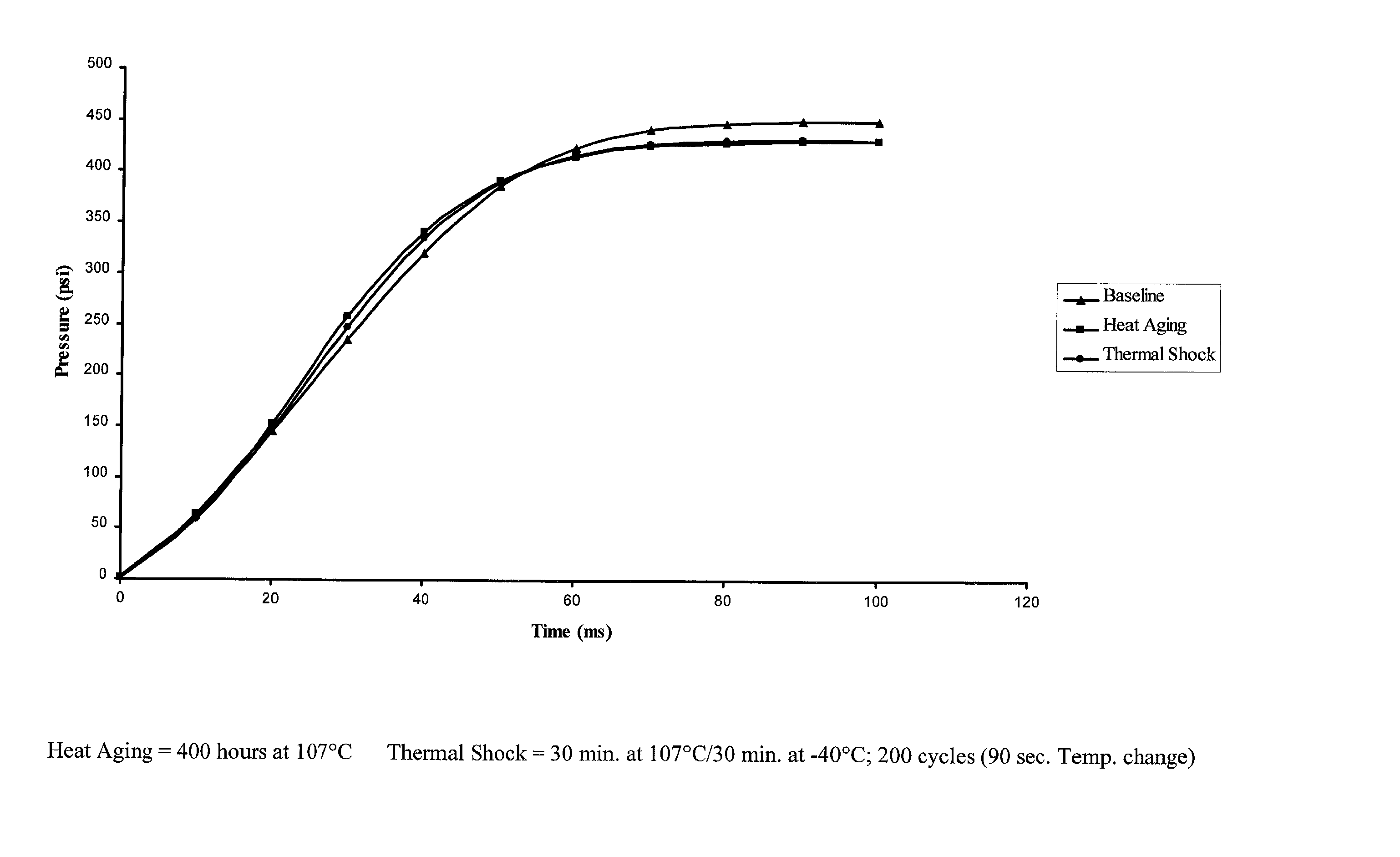

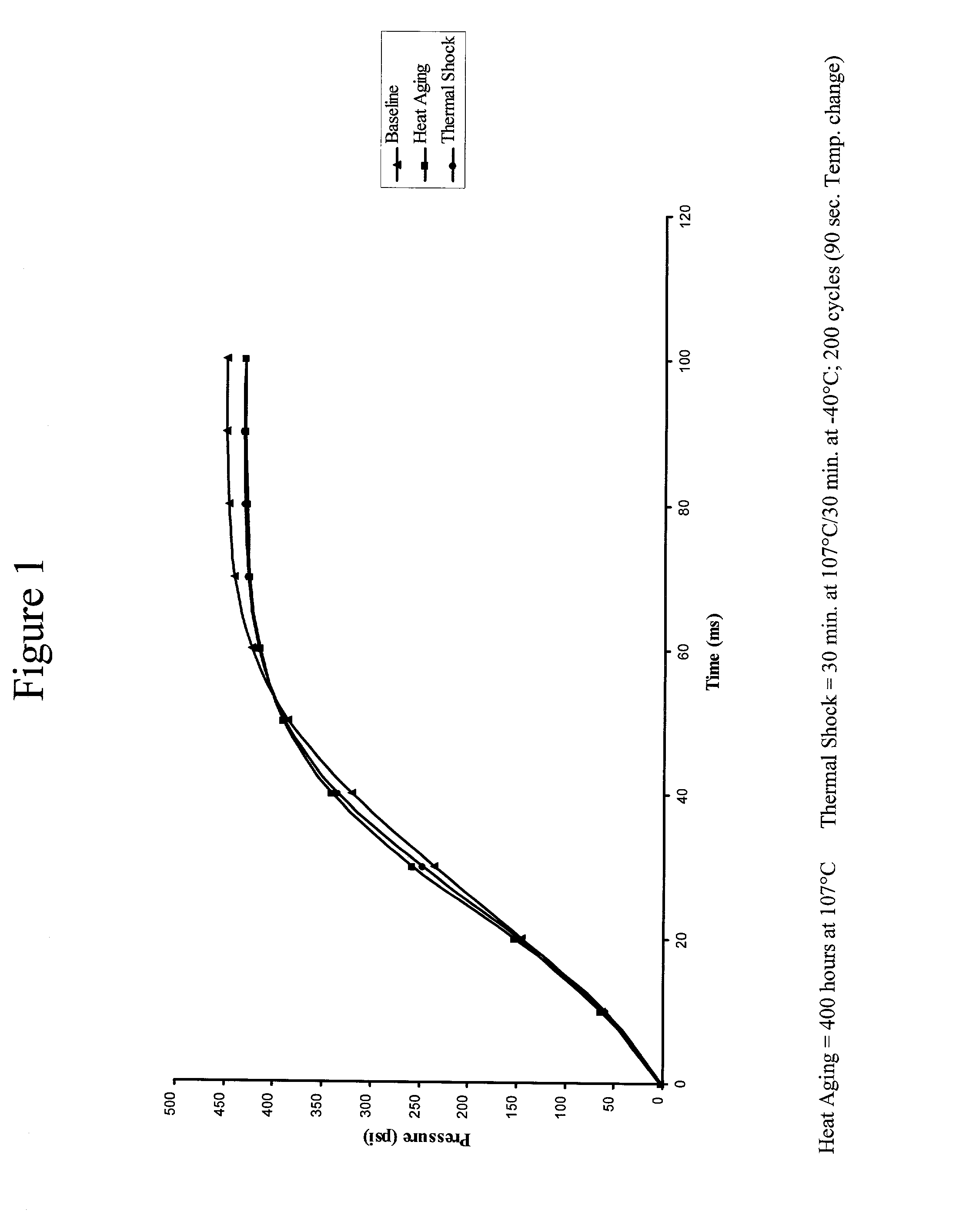

Airbag propellant

InactiveUS20020144759A1Extended shelf lifeIncrease resistanceNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPressure gas generationHigh resistanceAirbag

The present invention is a propellant used to inflate an airbag in vehicle safety systems comprising from about 70 weight percent to about 82 weight percent Cyclotrimethylenetrinitramine (RDX), from about 10 weight percent to about 15 weight percent of a polymer binder, from about 6 weight percent to about 9 weight percent of an inert plasticizer, from about 2 weight percent to about 4 weight percent of Hydroxypropyl Cellulose, from about 0.5 weight percent to about 1 weight percent of a polymeric processing aid; and, from about 0.3 weight percent to about 0.5 weight percent of a material that acts as a stabilizer and anti-oxidant. The present invention is designed to have a long shelf life, high resistance to performance degradation after thermal aging testing and excellent physical properties such as excellent strength, insensitivity, and safety.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

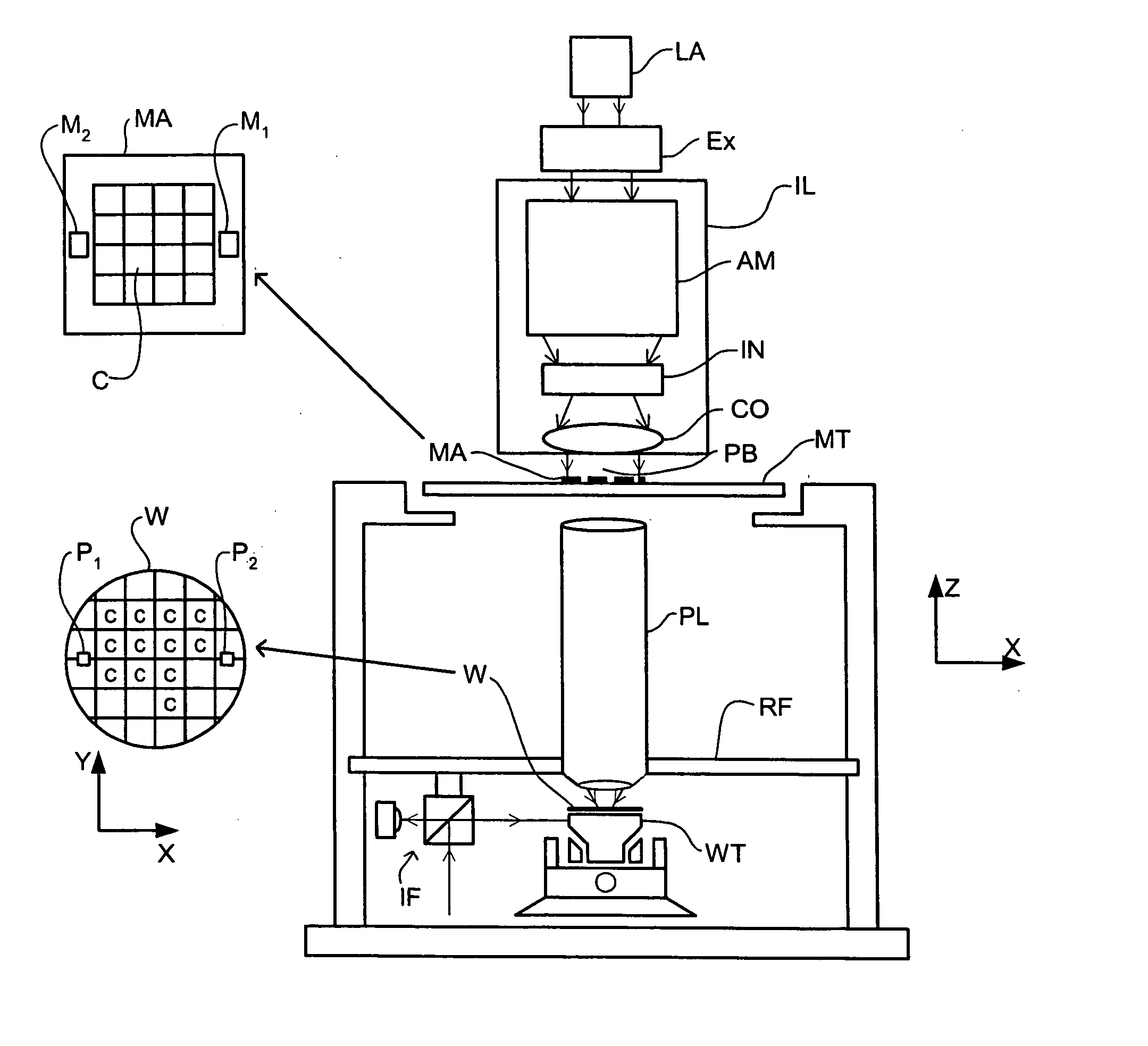

Lithographic apparatus and device manufacturing method

InactiveUS20050012915A1Effectively averages outReduce the impactSemiconductor/solid-state device manufacturingUsing optical meansPhase gratingBroadband

An off-axis alignment system in a lithographic projection apparatus uses broadband radiation to illuminate a phase grating on the wafer. The broadband radiation source may include fluorescent materials, e.g. Yag:Ce or ND:Yag crystals illuminated by excitation light.

Owner:ASML NETHERLANDS BV

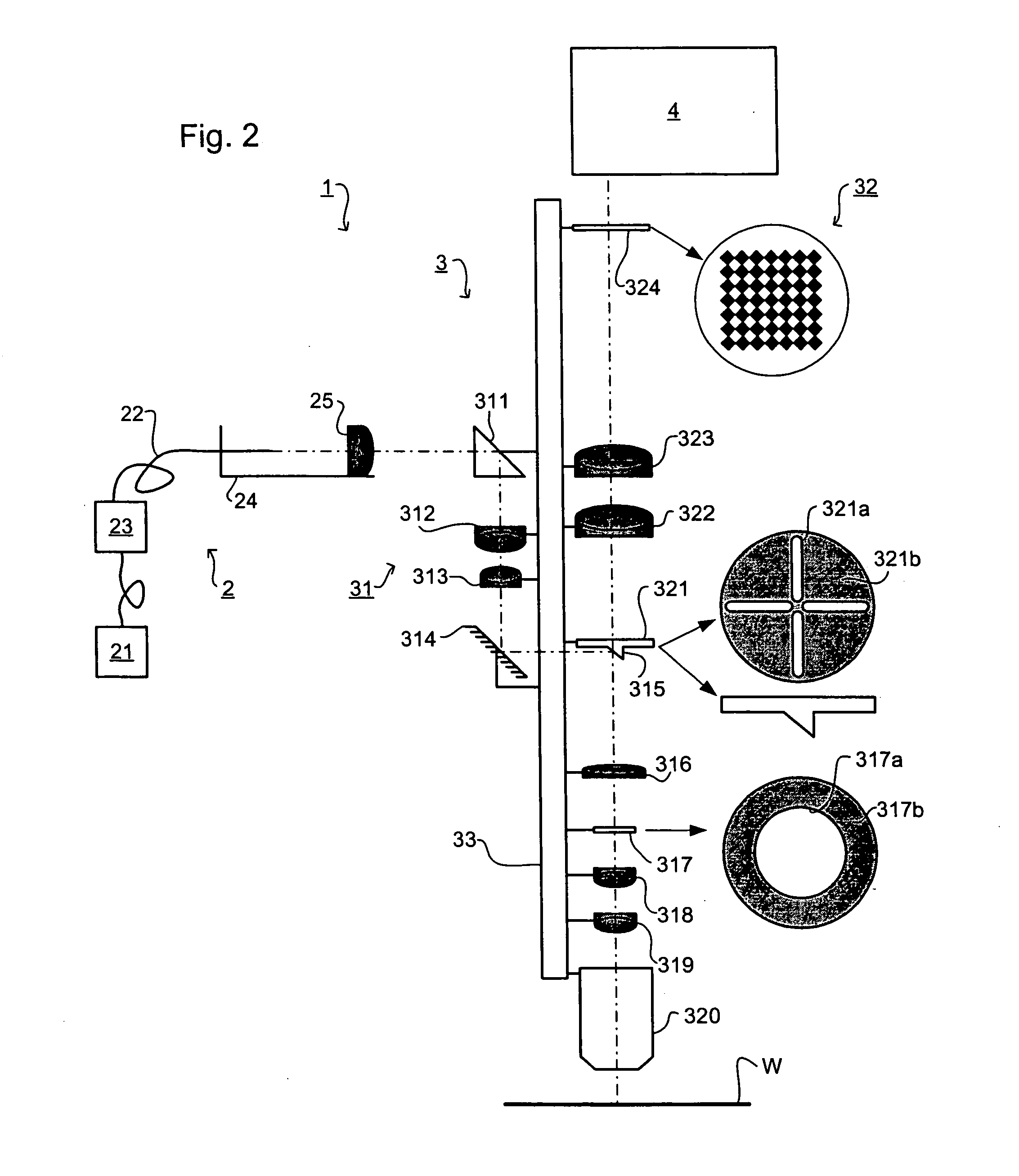

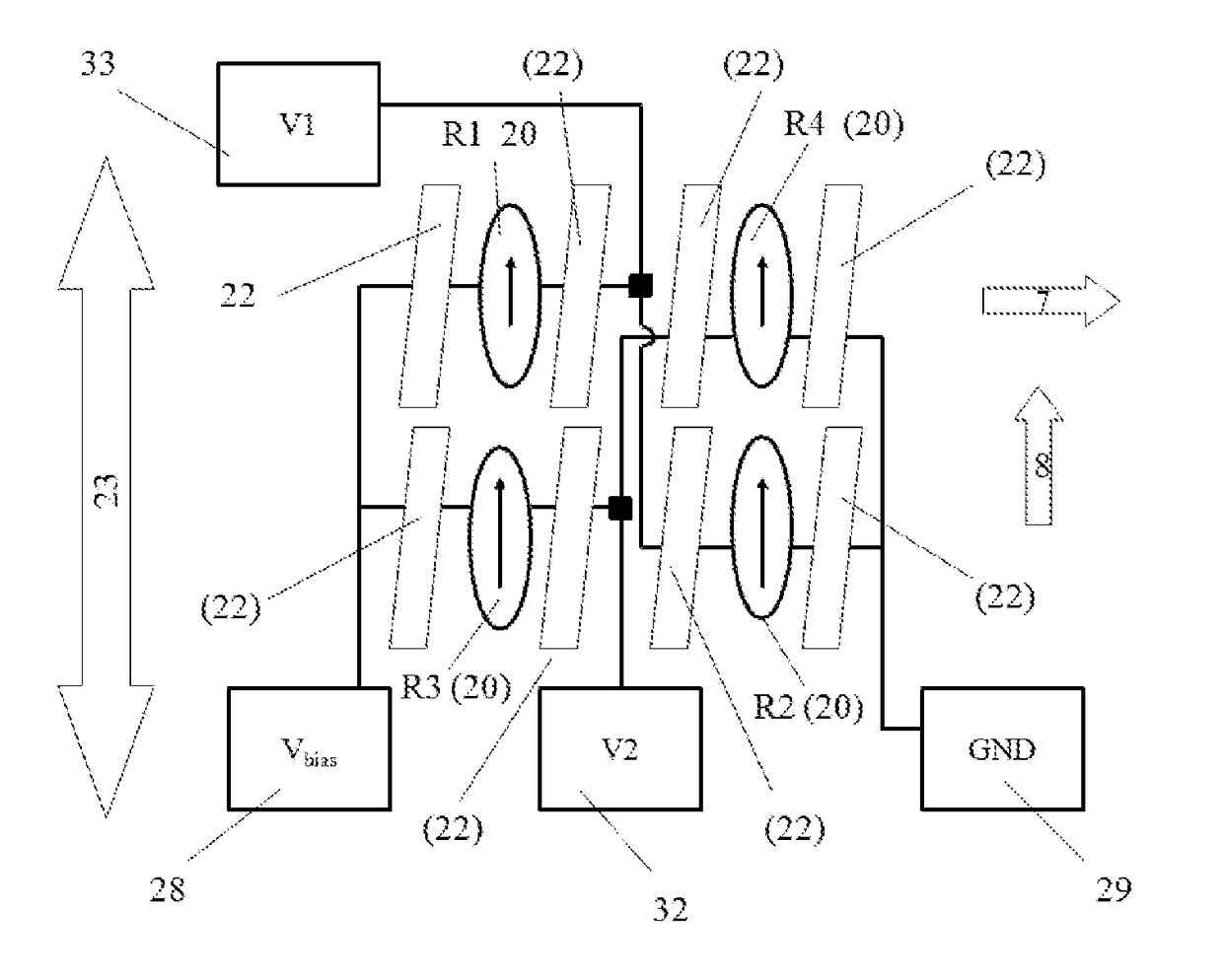

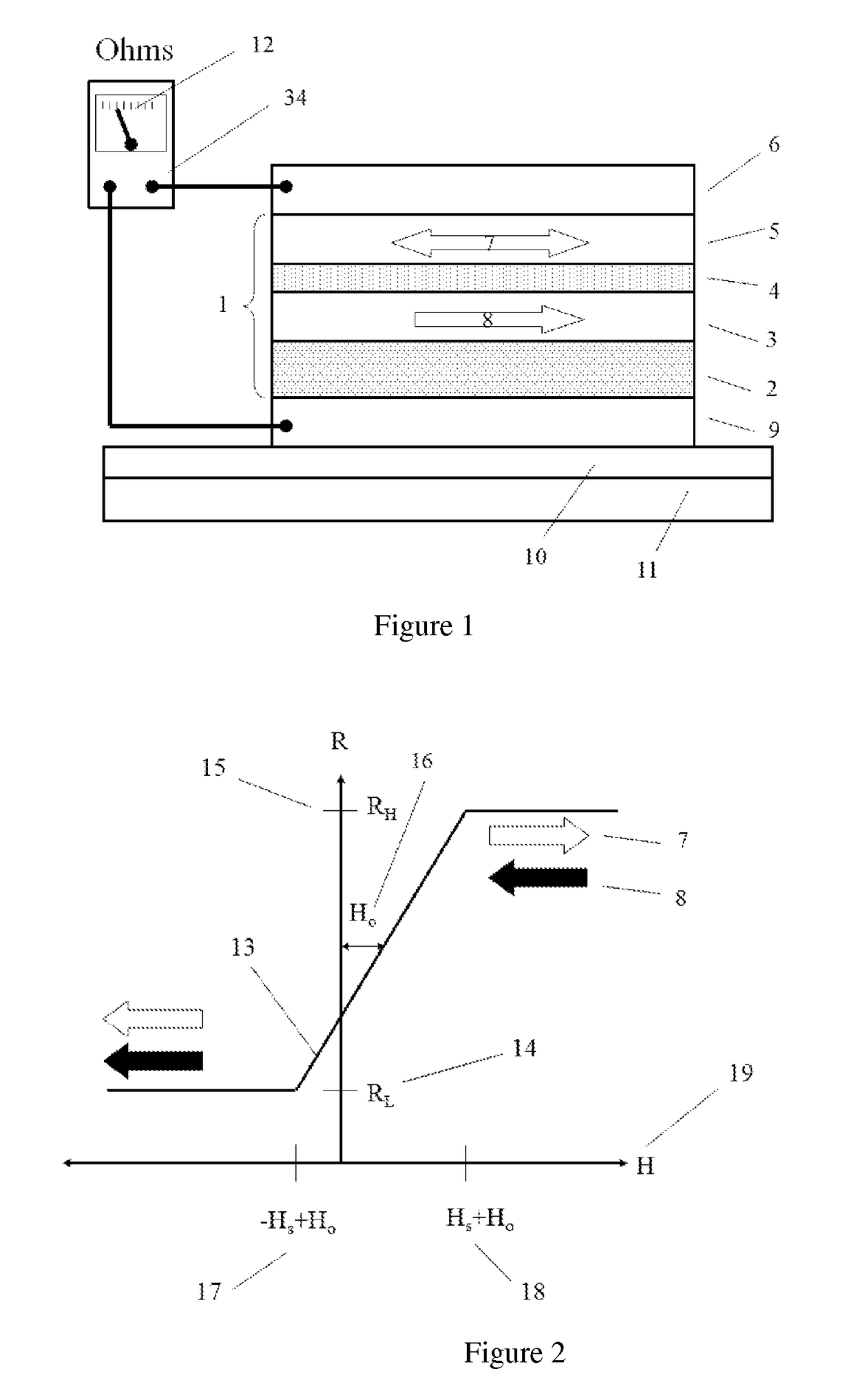

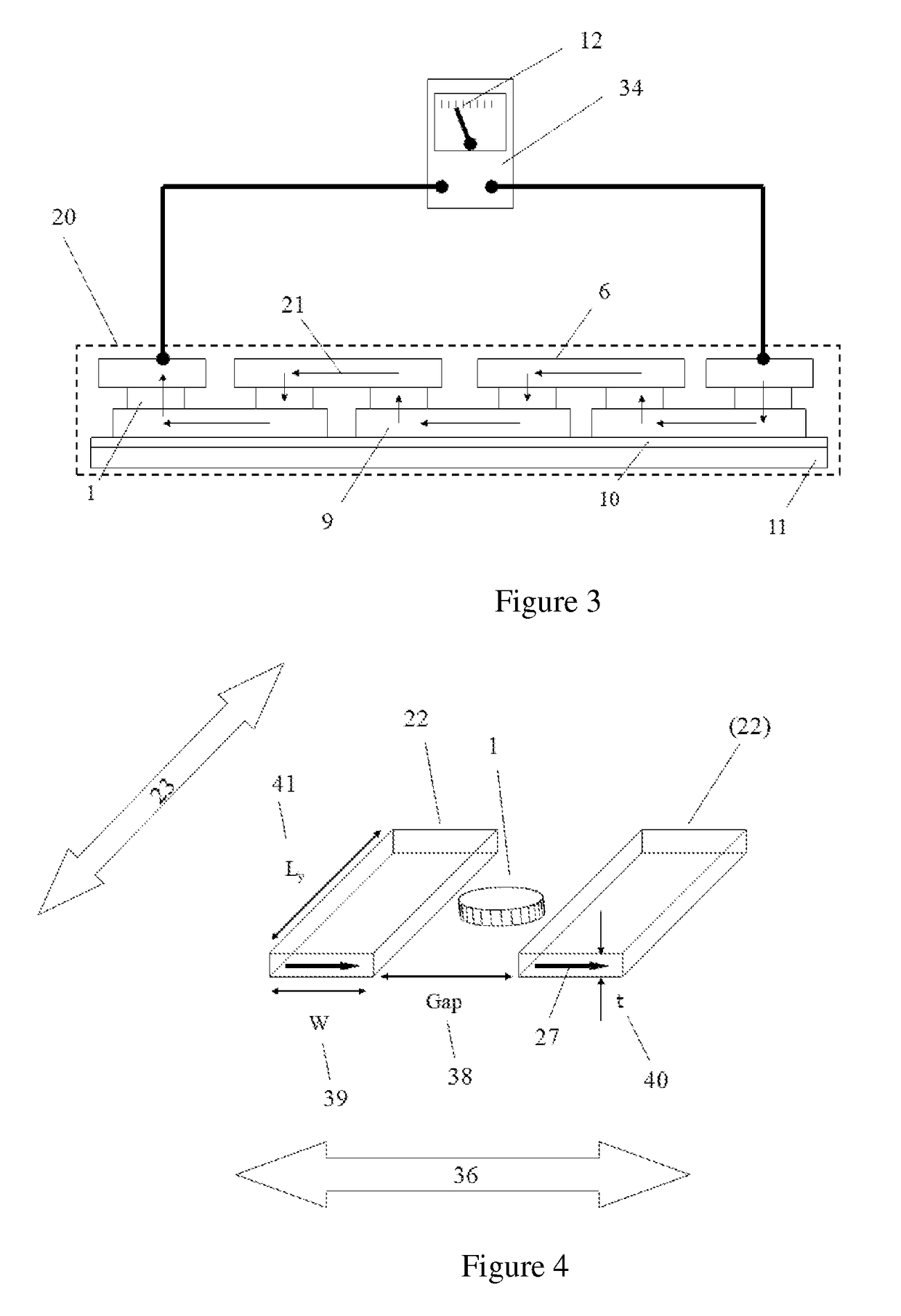

Magnetoresistive magnetic field gradient sensor

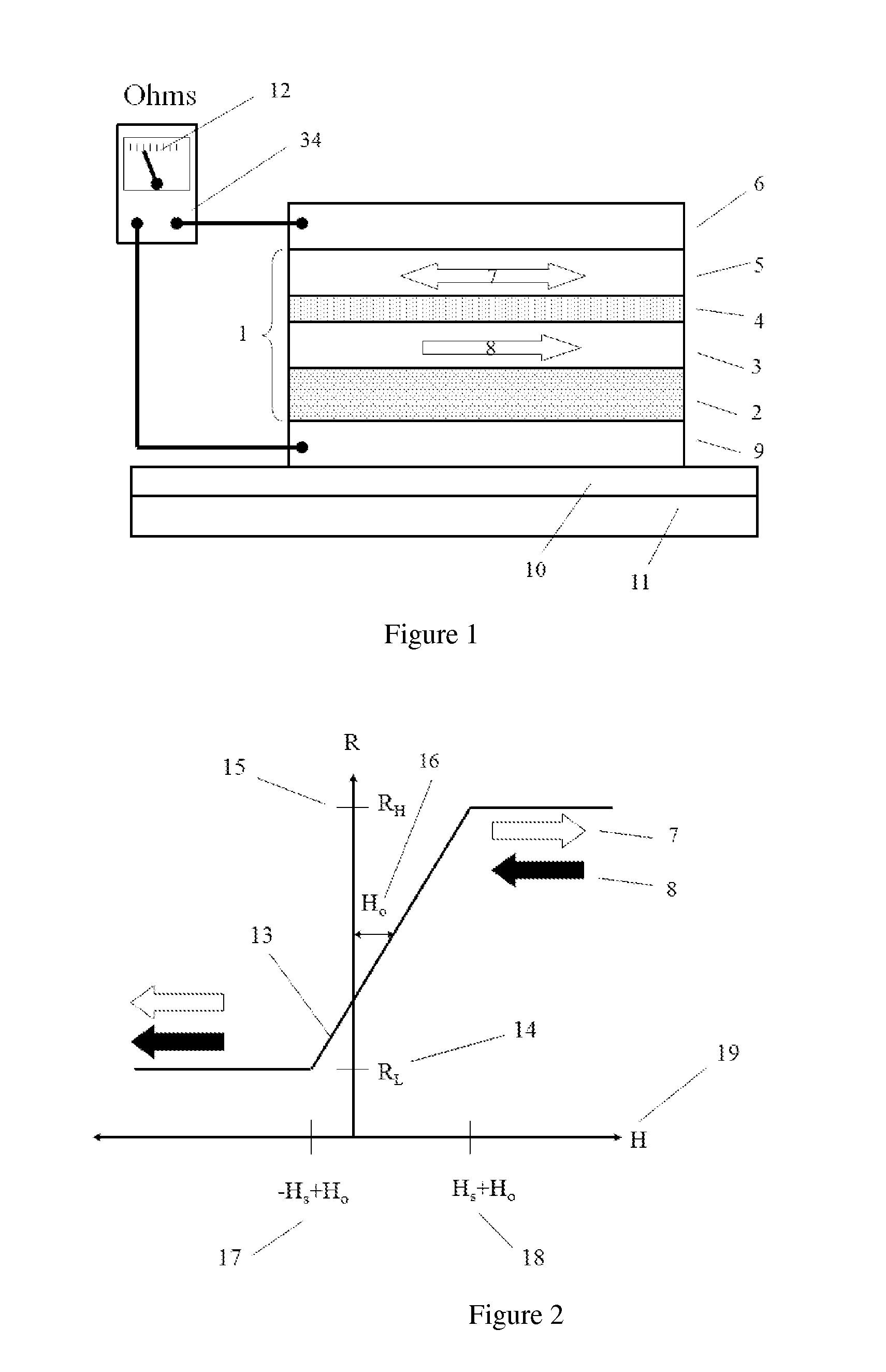

ActiveUS9678178B2High sensitivityWide linear rangeMagnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesMagnetic field gradientBias field

Disclosed is a magnetoresistive magnetic field gradient sensor, comprising a substrate, a magnetoresistive bridge and a permanent magnet respectively disposed on the substrate; the magnetoresistive bridge comprises two or more magnetoresistive arms; each magnetoresistive arm consists of one or more magnetoresistive elements; each magnetoresistive element is provided with a magnetic pinning layer; the magnetic pinning layers of all the magnetoresistive elements have the same magnetic moment direction; the permanent magnet is disposed adjacent to each magnetoresistive arm to provide a bias field, and to zero the offset of the response curve of the magnetoresistive element; the magnetoresistive gradiometer includes wire bonding pads that can be electrically interconnected using wire bonding to an ASIC or to the lead frame of a semiconductor chip package.

Owner:MULTIDIMENSION TECH CO LTD

Redundant control system and control computer and peripheral unit for a control system of this type

InactiveUS7120820B2Easy constructionPromote conversionComputer controlError detection/correctionControl systemEngineering

A redundant control system having at least a first and a second control computer (1,2) and at least one peripheral unit (5) that is connected to the control computers (1,2) by a bus system (3,4). Both control computers transmit cyclically changing signs of life (LzX, LzY) to the peripheral unit (5), which checks whether a change in the signs life has taken place within a given time period and which switches to the other control computer for executing the control tasks if the change in the sign of life is not timely received.

Owner:SIEMENS AG

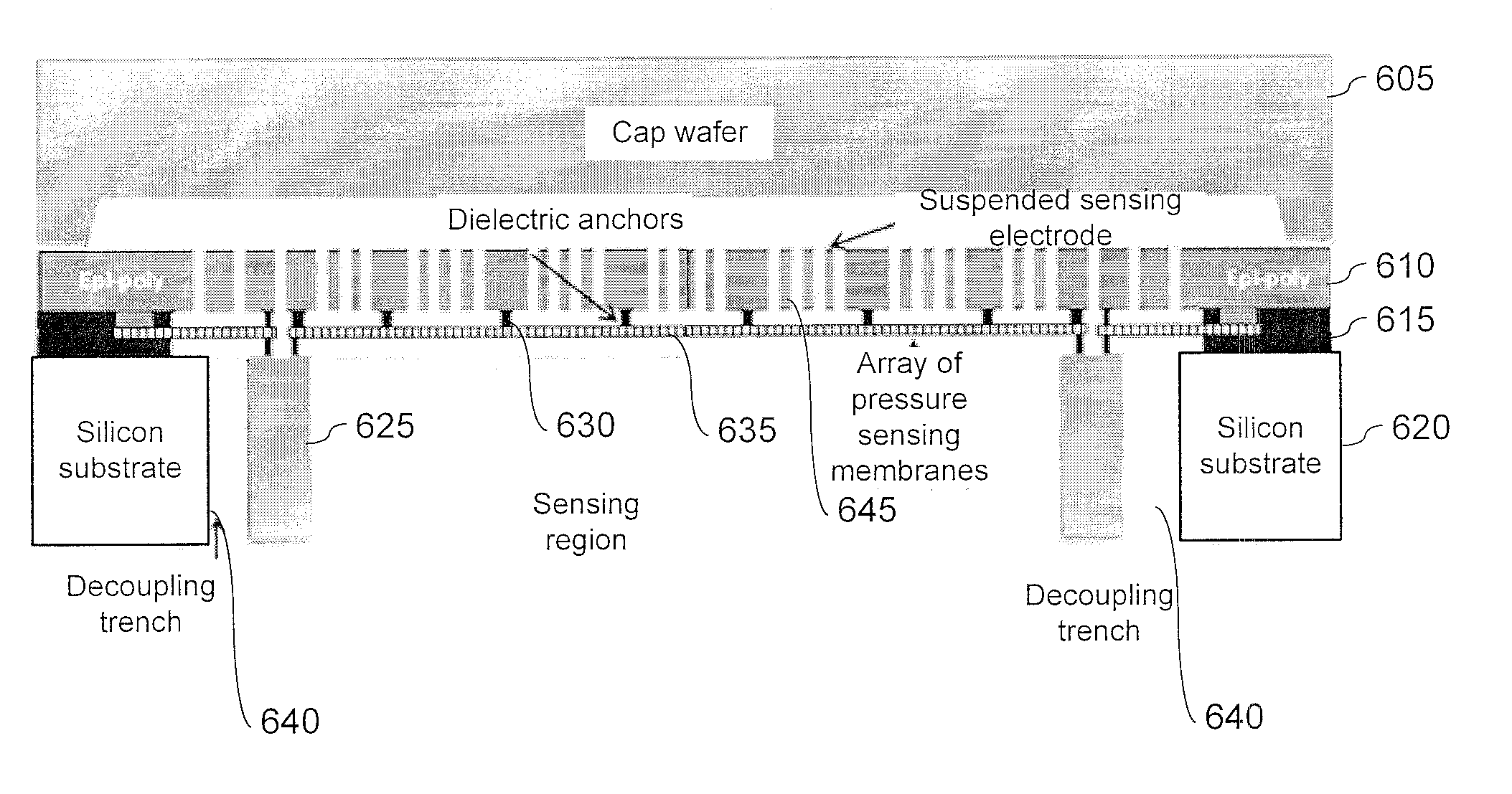

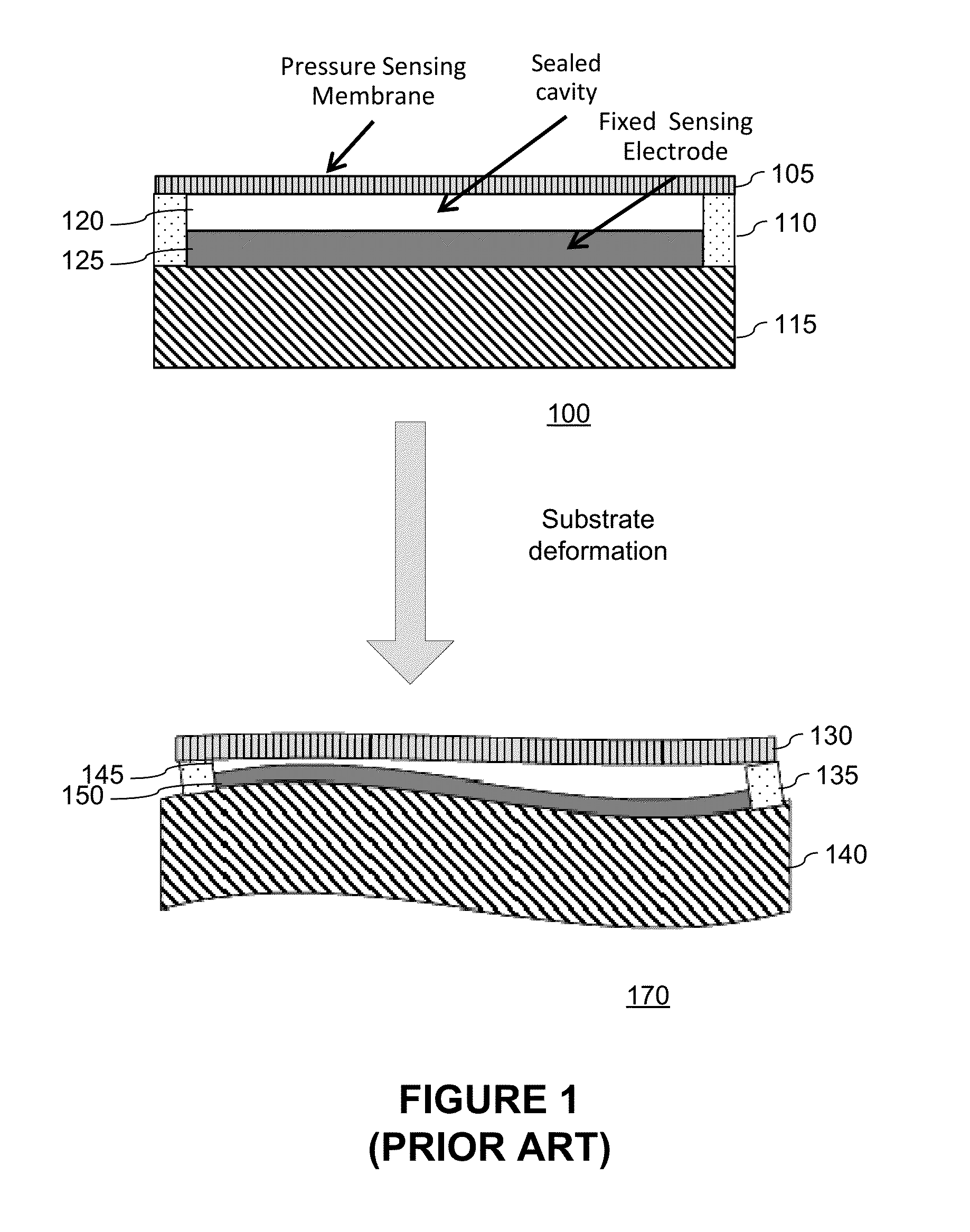

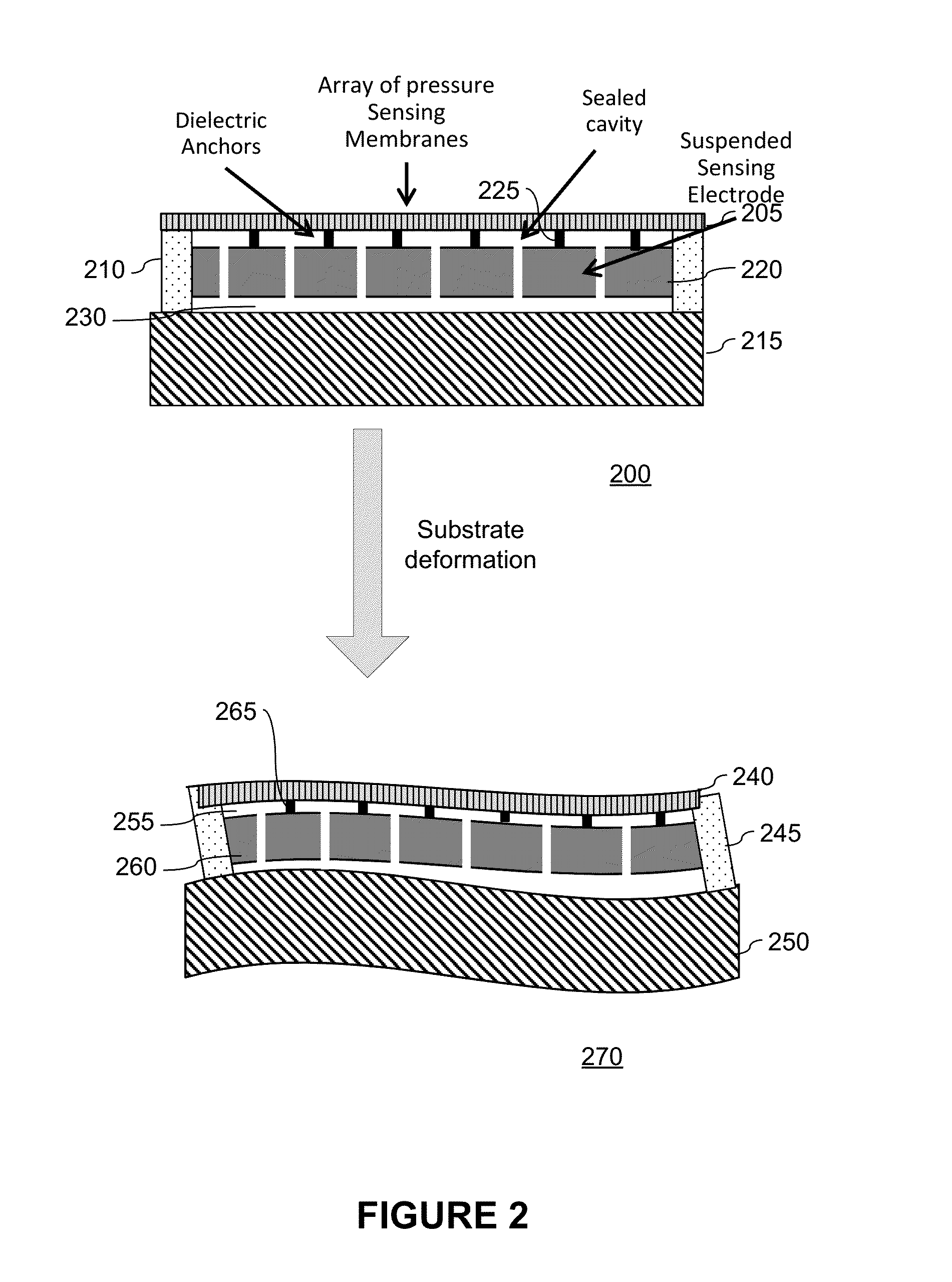

MEMS pressure sensor with improved insensitivity to thermo-mechanical stress

ActiveUS20150274505A1Improve performanceIncrease insensitivityDecorative surface effectsFluid pressure measurement by electric/magnetic elementsMems pressure sensorRelative precision

This invention relates generally to semiconductor manufacturing and packaging and more specifically to semiconductor manufacturing in MEMS (Microelectromechanical systems) inertial sensing products. Embodiments of the present invention improve pressure sensor performance (e.g., absolute and relative accuracy) by increasing pressure insensitivity to changes in thermo-mechanical stress. The pressure insensitivity can be achieved by using the array of pressure sensing membranes, suspended sensing electrodes, and dielectric anchors.

Owner:HANKING ELECTRONICS LTD

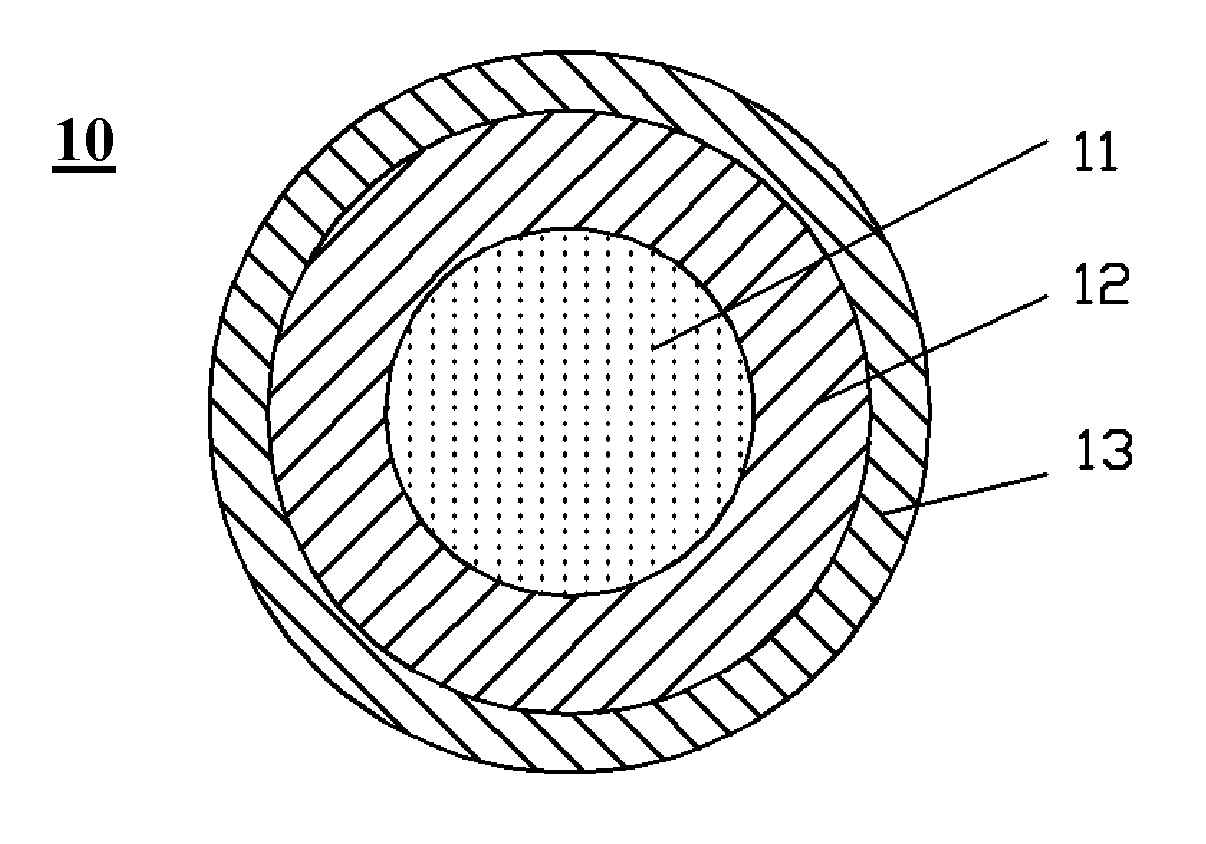

Bend Insensitive Single Mode Fiber

ActiveUS20110142404A1Relaxed manufacturing toleranceReduce manufacturing costGlass optical fibreOptical fibre with multilayer core/claddingAccess networkGlass fiber

This invention discloses a bend insensitive single mode fiber, which is composed by a bare glass fiber with a round cross section and two resin protective layers with circular cross sections surrounding the outer of the bare glass fiber. It is characterized in that the bare glass fiber is composed by a core layer with a round cross section and two claddings with circular cross sections. The refractive index of the core layer is higher than the index of the two claddings and the refractive index difference between the core layer and the first cladding is larger than the difference between the first and second claddings. The second cladding is made of pure SiO2. The refractive index profile of the core layer follows a power function, and the refractive index profile of the two claddings follow a ladder-type distribution. The loss of the invented fiber is insensitive to the bending of the fiber, which meets the requirements of ITU.T G.657.A and G.657.B standards, respectively. It is applicable to the Fiber To The Home (FTTH) and other local area network and the access network systems.

Owner:FUTONG GROUP CO LTD

Magnetoresistive magnetic field gradient sensor

ActiveUS20150130455A1High sensitivityWide linear rangeReference comparisonMagnetic gradient measurementsMagnetic field gradientSemiconductor chip

Disclosed is a magnetoresistive magnetic field gradient sensor, comprising a substrate, a magnetoresistive bridge and a permanent magnet respectively disposed on the substrate; the magnetoresistive bridge comprises two or more magnetoresistive arms; each magnetoresistive arm consists of one or more magnetoresistive elements; each magnetoresistive element is provided with a magnetic pinning layer; the magnetic pinning layers of all the magnetoresistive elements have the same magnetic moment direction; the permanent magnet is disposed adjacent to each magnetoresistive arm to provide a bias field, and to zero the offset of the response curve of the magnetoresistive element; the magnetoresistive gradiometer includes wire bonding pads that can be electrically interconnected using wire bonding to an ASIC or to the lead frame of a semiconductor chip package.

Owner:MULTIDIMENSION TECH CO LTD

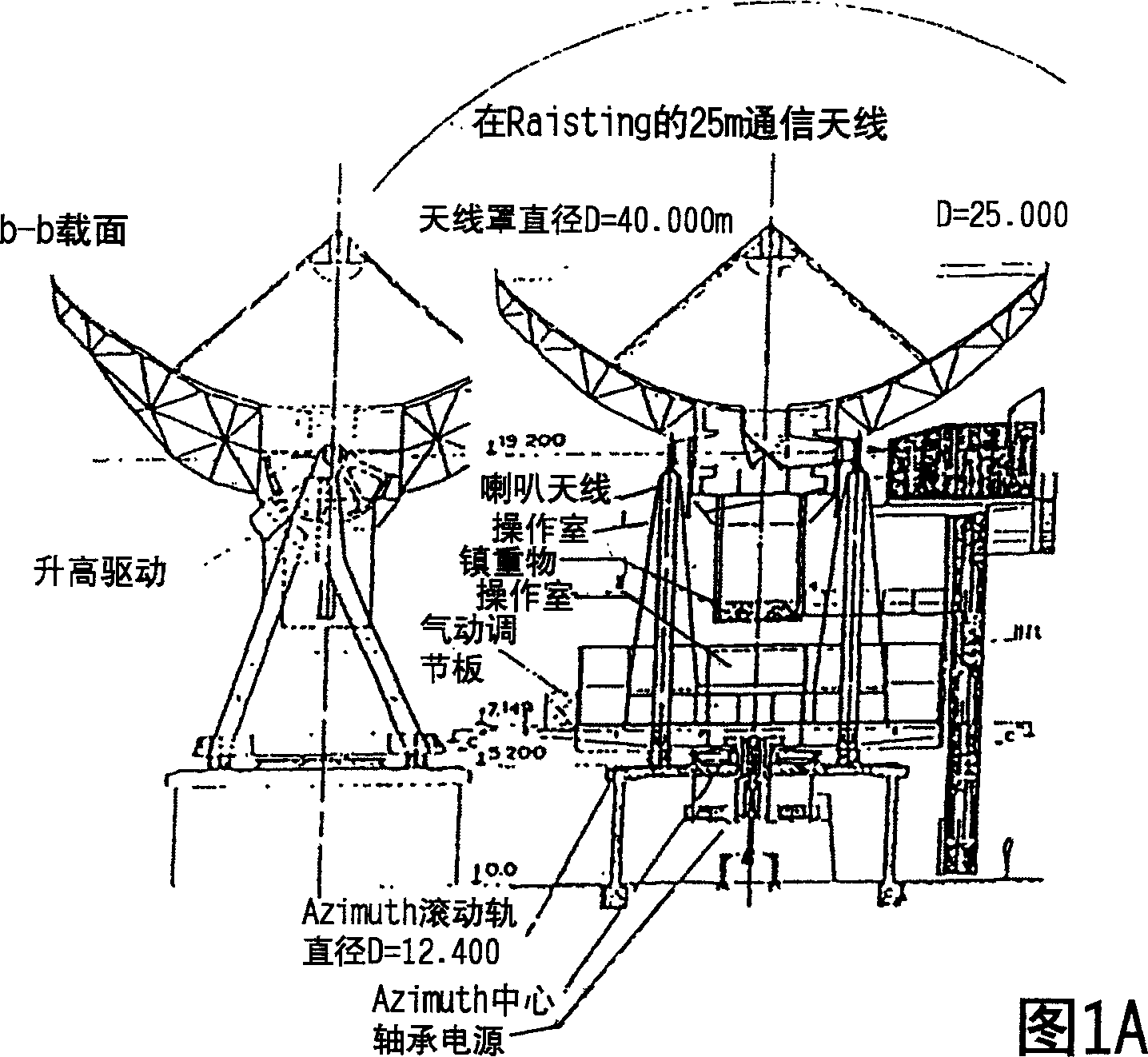

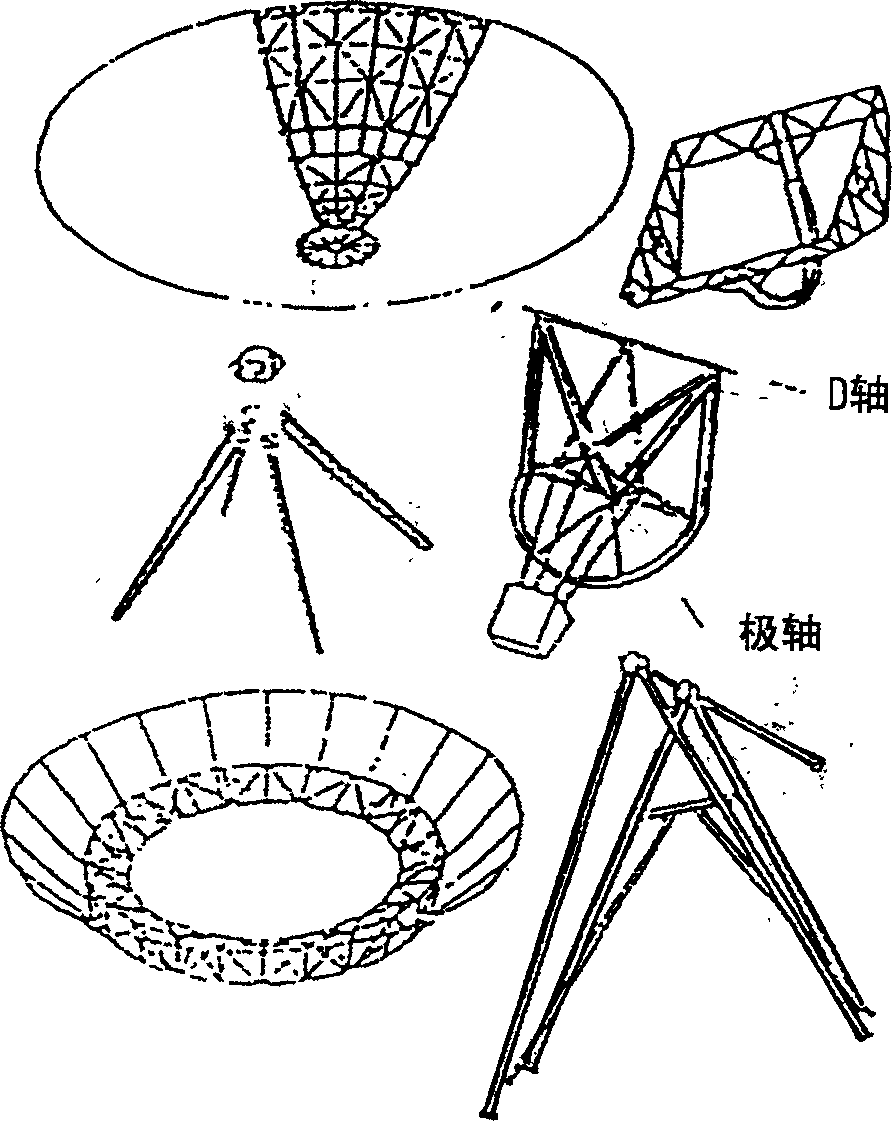

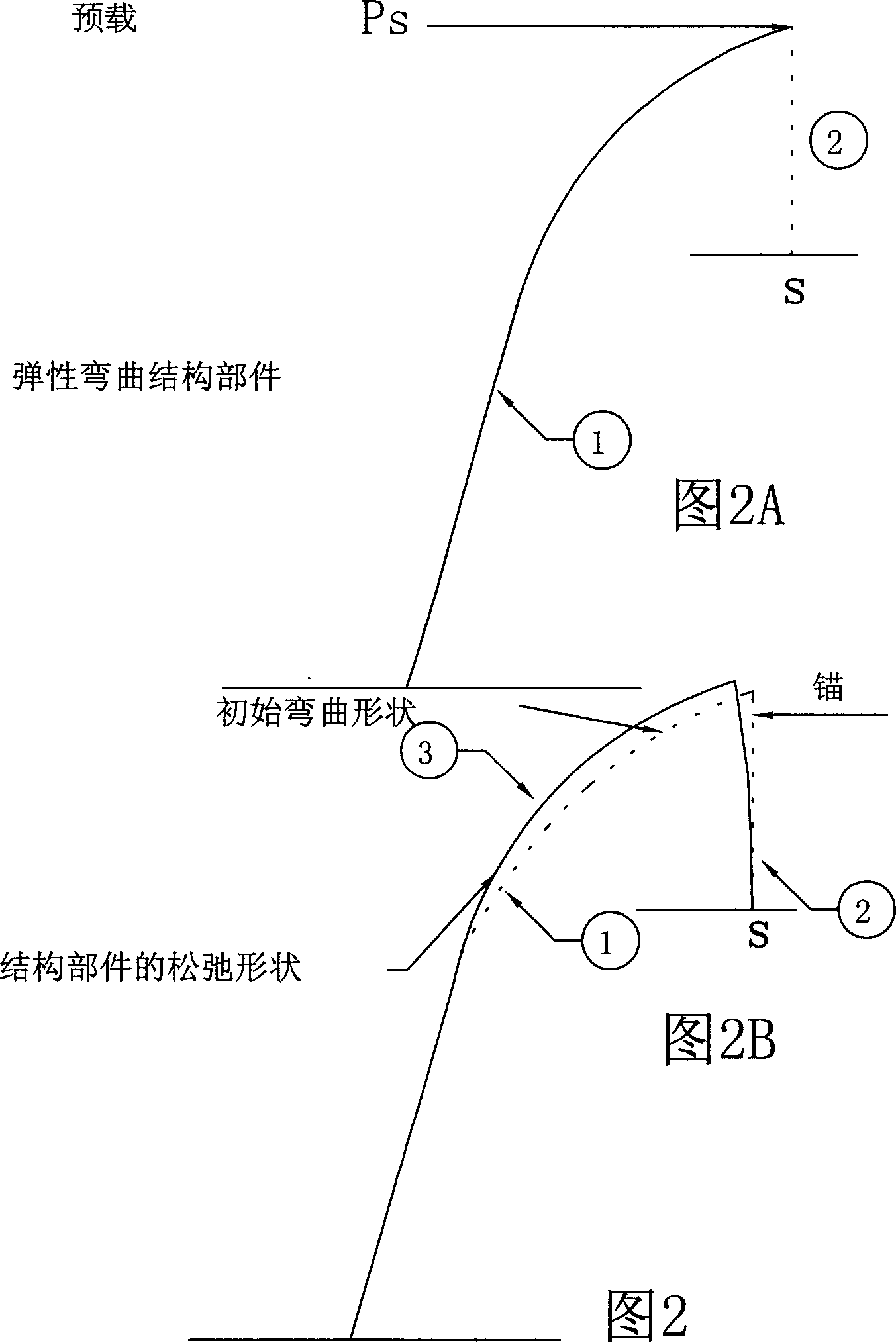

Preloaded parabolic dish antenna and method of making it

InactiveCN1444781AAvoid bouncingReduce weightVibration dampingWind-induced force reductionEngineeringStraight pull

The parabolic reflector antenna, by preloading its radially circumferentially placed straight support members to support its reflective surface, makes it significantly lighter and also plays a role in its installation. The support structure for the preloaded parabolic reflector antenna consists of a central hub, an assembly of an appropriate number of resiliently curved radial structural members, an equal number of straight structural members connected to the tips of the radial members at the outer rim of the parabolic antenna, and circumferentially located The straight brace components in the middle position are all tensioned to the specified prestress value when there is no wind load. The outermost rim part located at the periphery of the parabolic antenna forms the opening of the parabolic antenna. Fixing the radial part at an appropriate inclination angle and position at the hub, applying a force with a normal component at its tip to elastically bend the radial part with a curvature approximately the same as the parabolic curvature between the hub and the peripheral rim point, so that the supporting member Has a parabolic shape.

Owner:塔塔基础研究院

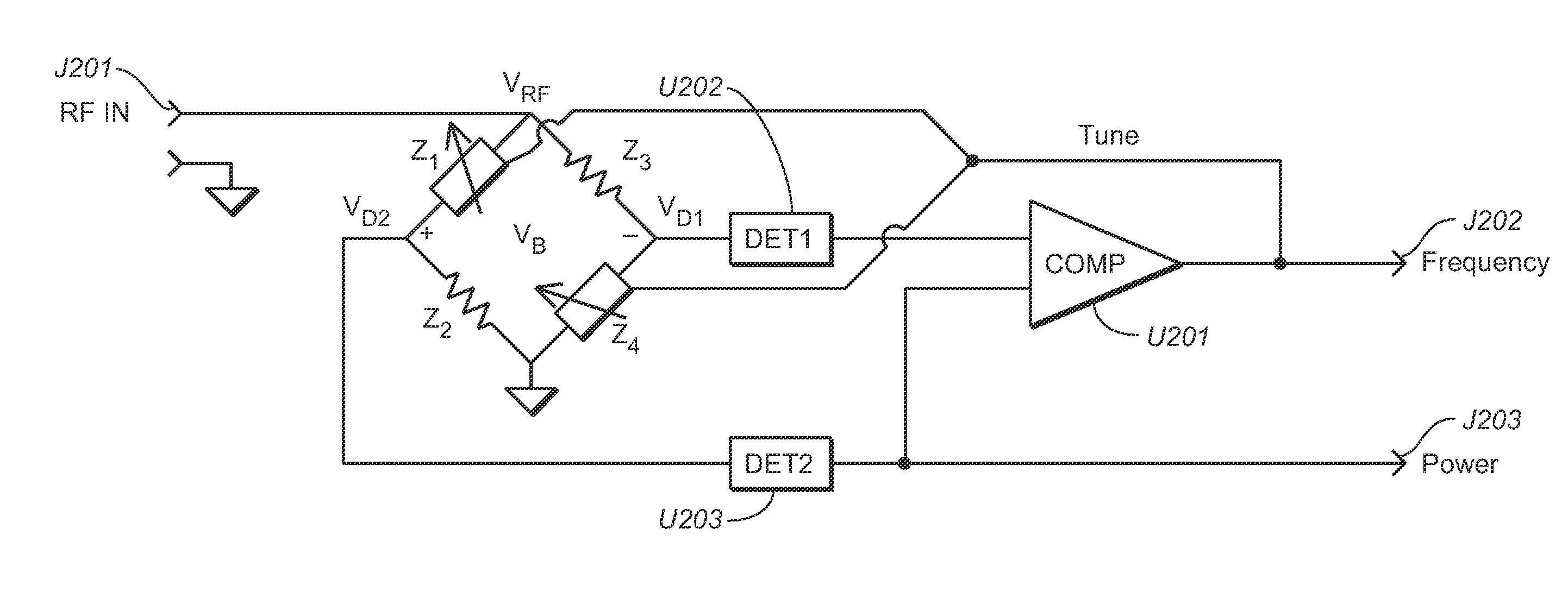

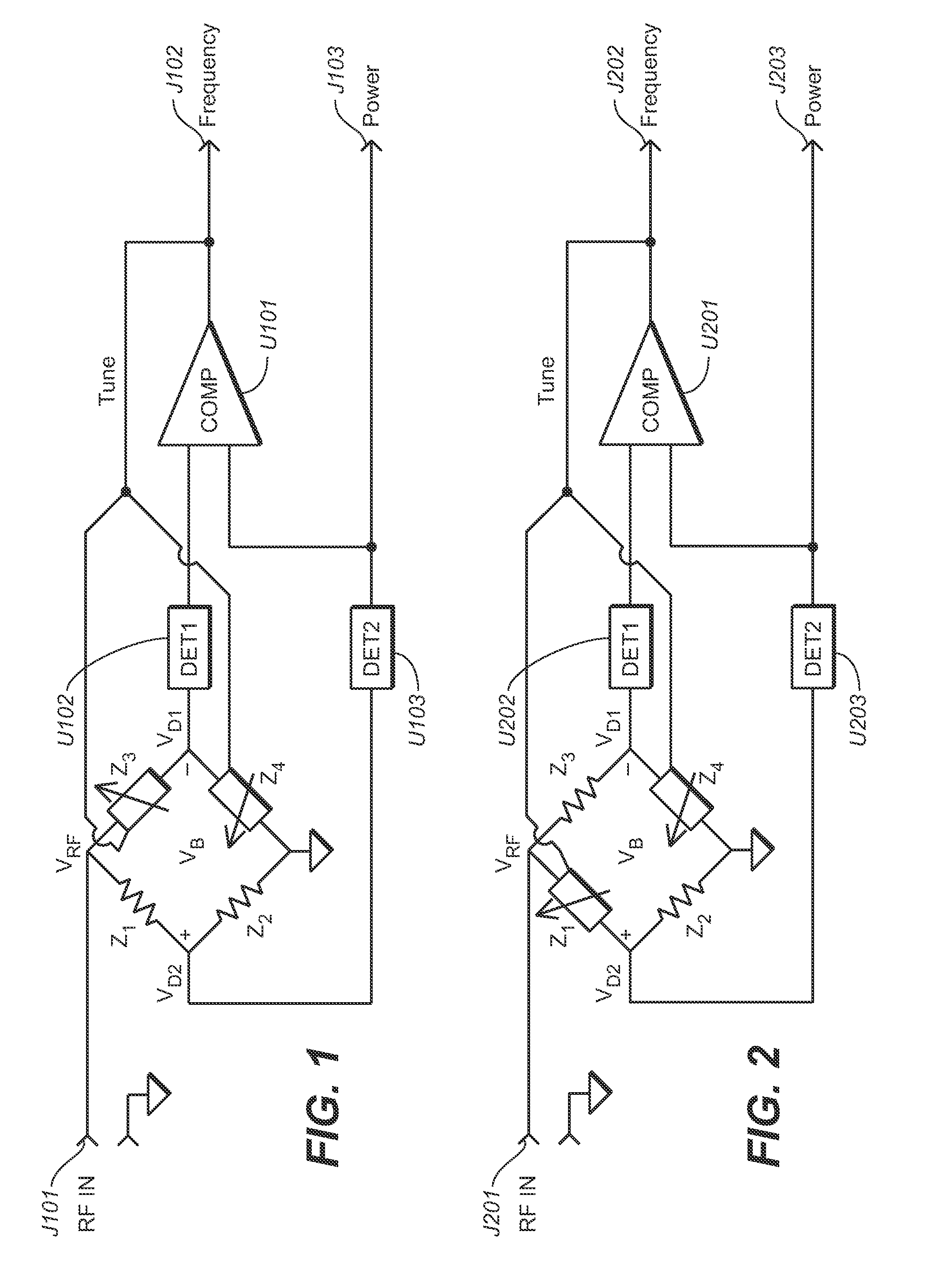

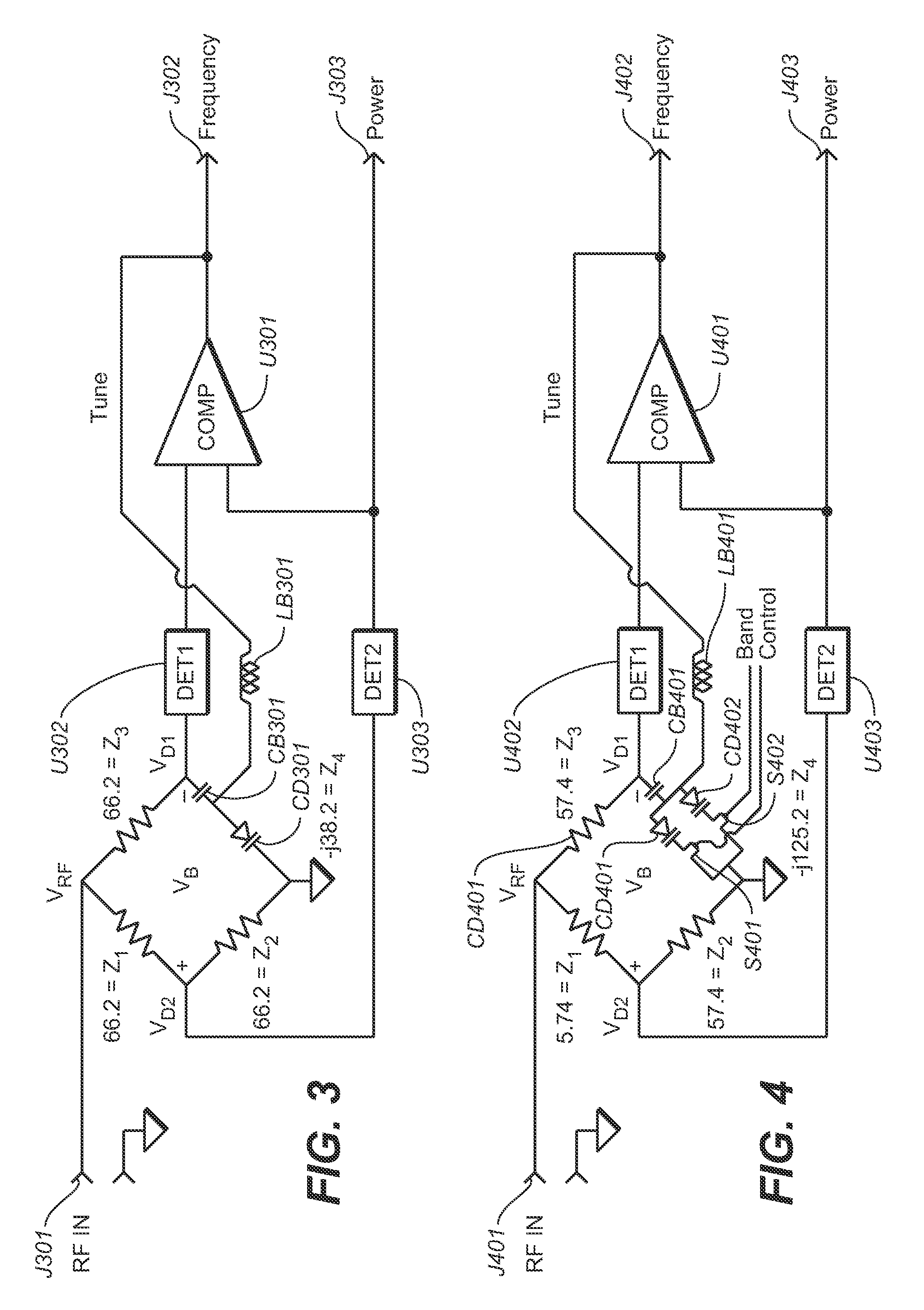

Self-balancing frequency determining bridge

ActiveUS20100007331A1Improve matchIncrease insensitivityResistance/reactance/impedenceAc/dc measuring bridgesEngineeringDynamic range

A self-balancing Wheatstone bridge that provides frequency and power information. The frequency information obtained can be applied to correct the power measurement to provide excellent match, excellent frequency insensitivity, good dynamic range, good frequency range, and adequate frequency accuracy. The system is highly responsive, simple, and cost effective.

Owner:LADYBUG TECH

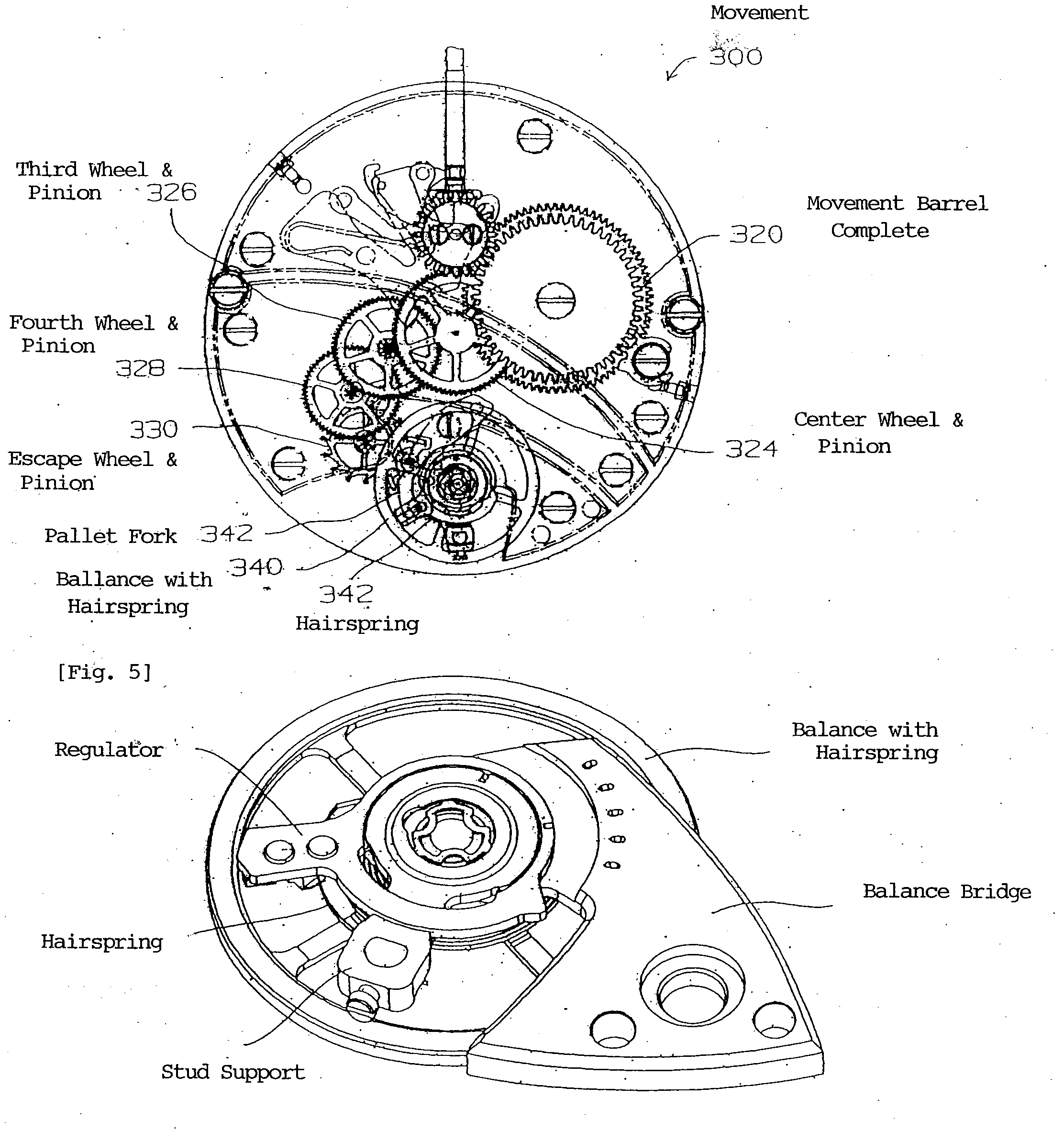

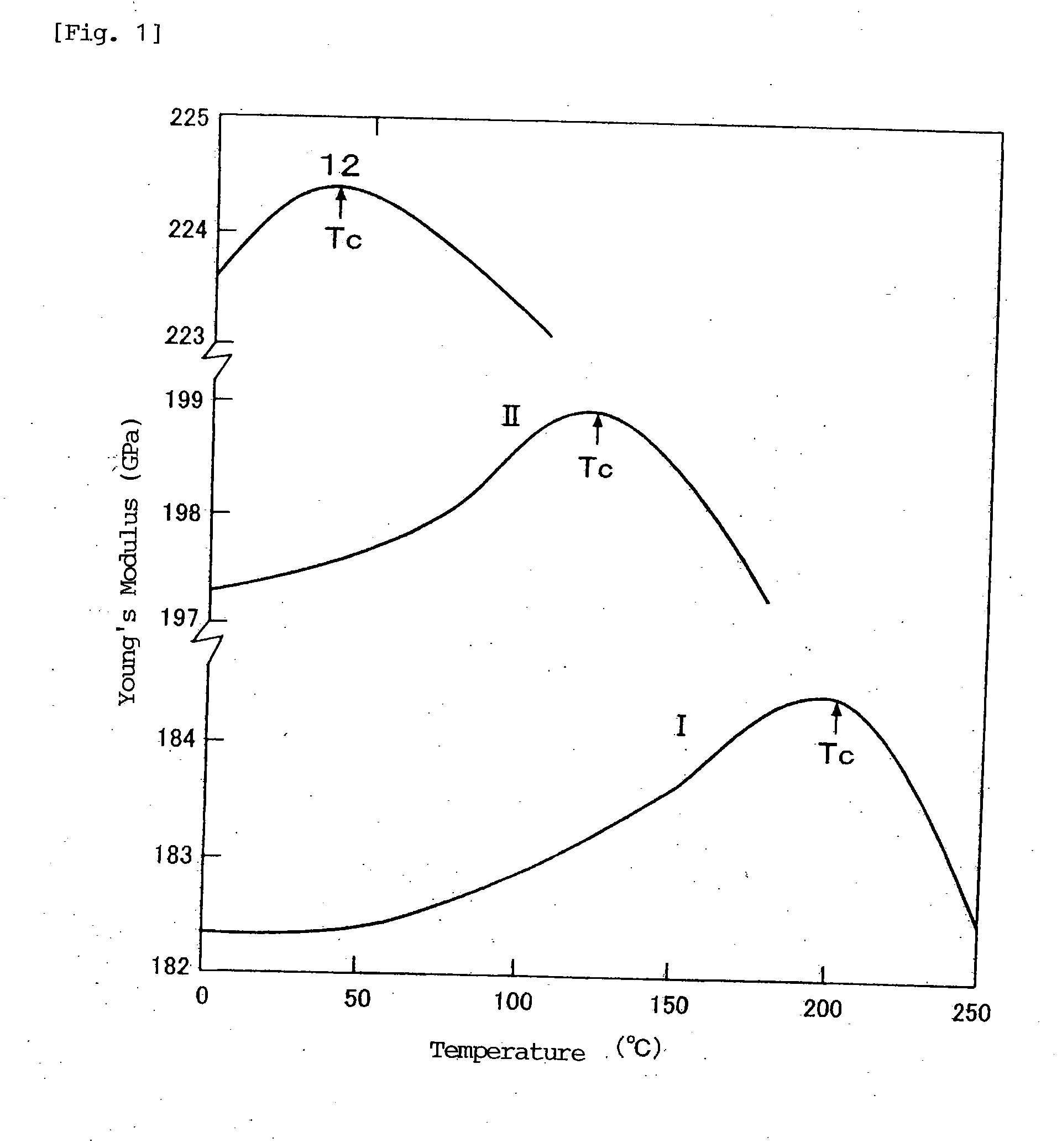

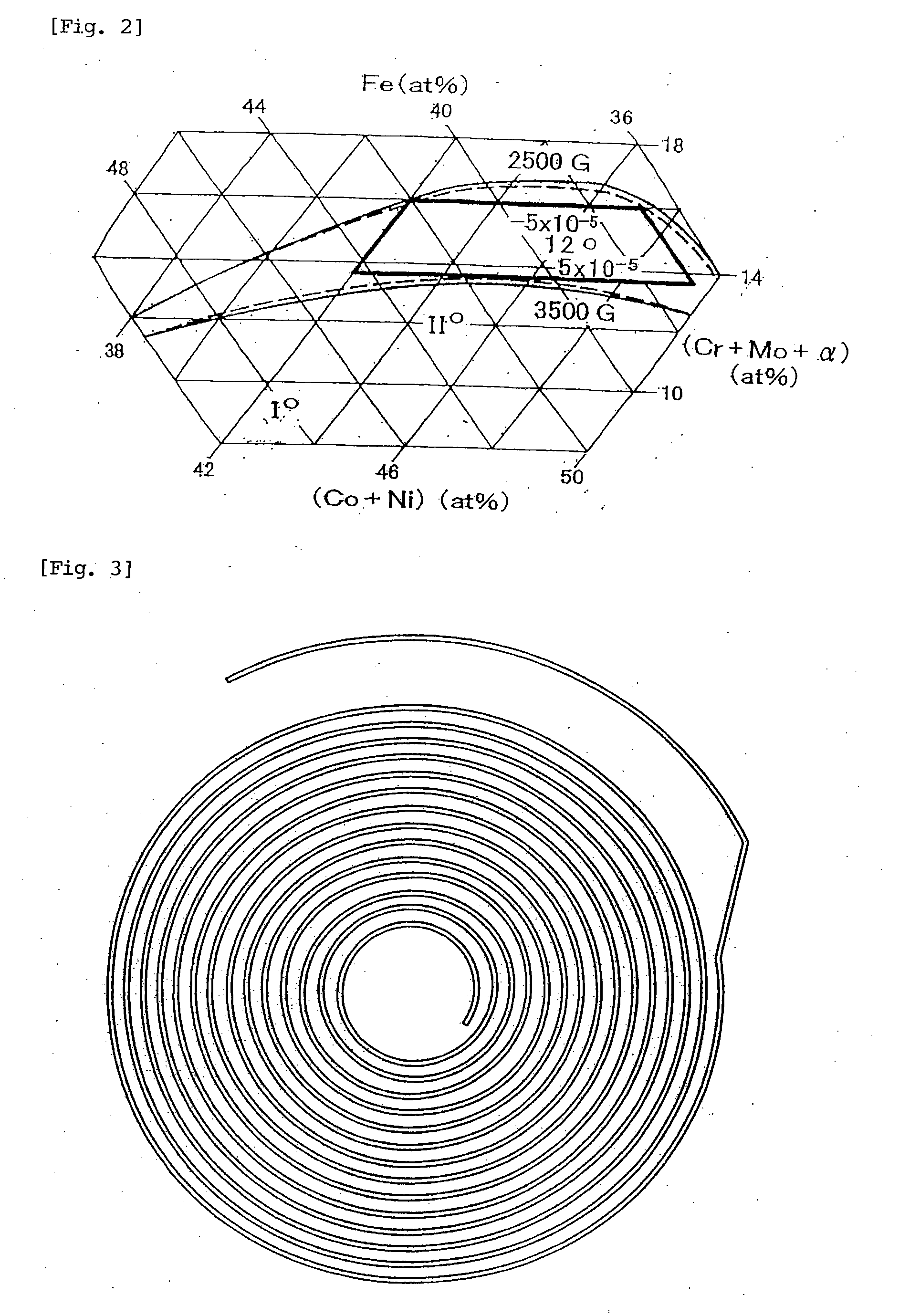

Magnetically insensitive, highly hard and constant-modulus alloy, and its production method, as well as hair spring, mechanical driving apparatus and watch and clock

ActiveUS20110286312A1Weakly magneticHigh Young 's modulusFrequency stabilisation mechanismFurnace typesWire rodYoung's modulus

[Task] A constant-modulus alloy, which has a low saturation magnetic flux density to provide weakly magnetic properties, a high Young's modulus, a low temperature coefficient of Young's modulus, and high hardness, is provided. A hairspring, a mechanical driving apparatus and a watch and clock, in which the alloy is used, are provided.[Means for Solution]The alloy consists essentially of, by atomic weight ratio, 20 to 40% Co and 7 to 22% Ni, with the total of Co and Ni being 42.0 to 49.5%, 5 to 13% Cr and 1 to 6% Mo, with the total of Cr and Mo being 13.5 to 16.0%, and with the balance being essentially Fe (with the proviso that Fe is present in an amount of 37% or more) and inevitable impurities. The alloy is heated to a temperature of 1100 degrees C. or higher and lower than the melting point, followed by cooling. The alloy is subsequently subjected to repeated wiredrawing and intermediate annealing at 800 to 950 degrees C., thereby forming a wire at a working ratio of 90% or more. The resultant wire has a fiber structure having a <111> fiber axis. The wire is subsequently cold rolled at a rolling reduction of 20% or more, thereby obtaining a sheet, followed by heating the sheet at a temperature of 580 to 700 degrees C. The obtained magnetically insensitive, highly hard, constant modulus alloy has a {110}<111> texture. 2500 to 3500 G of saturation flux density, (−5˜+5)×10−5 degrees C−1 of temperature coefficient of Young's modulus as measured at 0 to 40 degrees C., and 350 to 550 of Vickers hardness

Owner:RESEARCH INSTITUTE FOR ELECTROMAGNETIC MATERIALS +1

Polymeric thickener for molding compounds

A molding composition is provided that includes a thermoset cross-linkable polymeric resin, a fibrous filler and a thickener system. The thickener system includes an amine and an isocyanate that are reactive to form a polyurea. The polyurea is operative to thicken the molding composition formulation prior to polymeric resin thermoset with superior properties relative to conventional thickener systems. A molded article produced from a cross-linked thermoset polymeric resin containing fibrous filler and a polyurea present from 1 to 5 total weight percent of the article either forms an interpenetrating network between the resin and the polyurea or the resin and polyurea crosslink upon resin thermoset to further strengthen the resulting article. An alkali earth oxide or hydroxide simultaneously thickens through interaction with carboxylate functionality of the cross-linkable resin to provide a superior viscosity build and humidity tolerance.

Owner:TEIJIN AUTOMOTIVE TECH INC

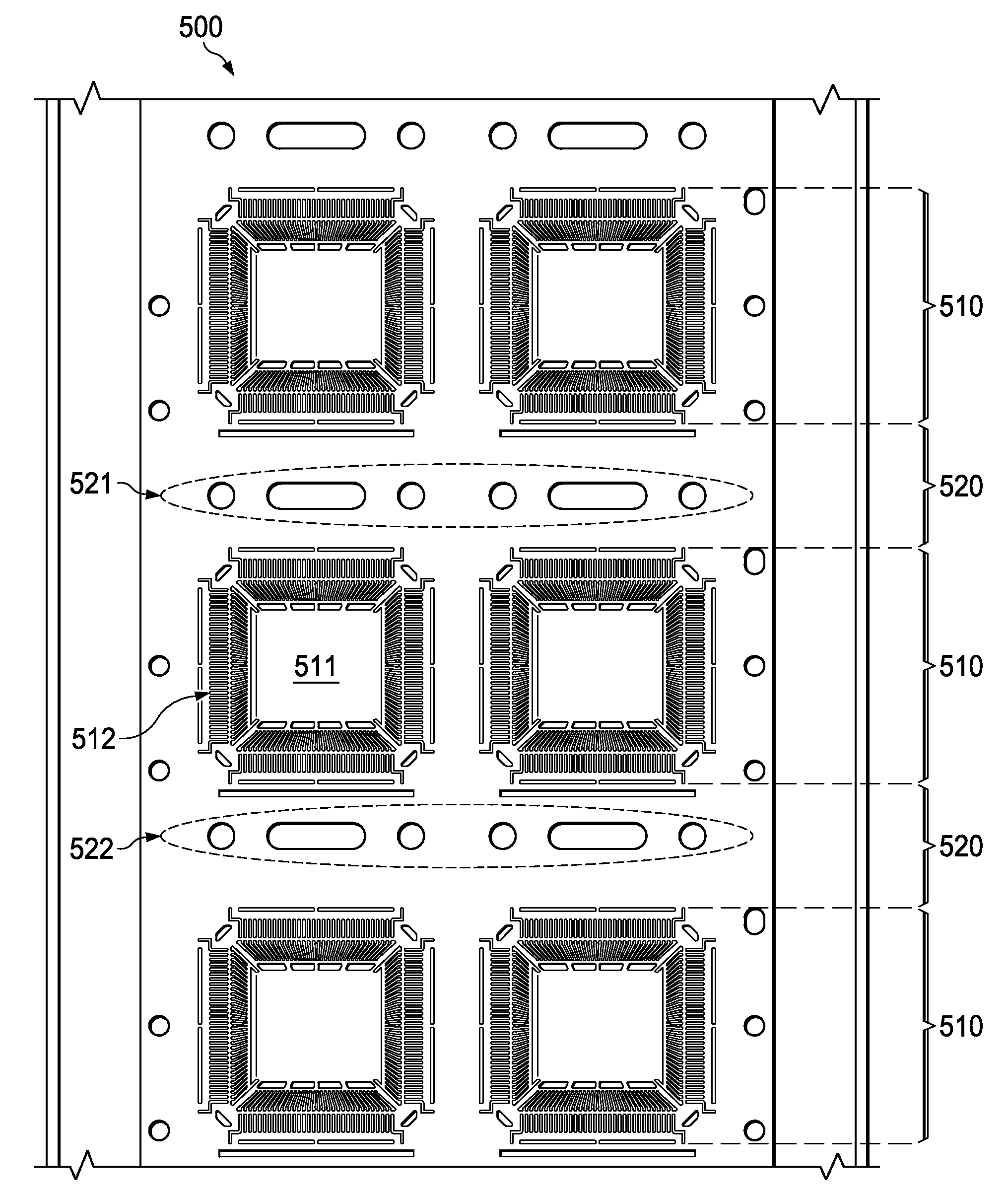

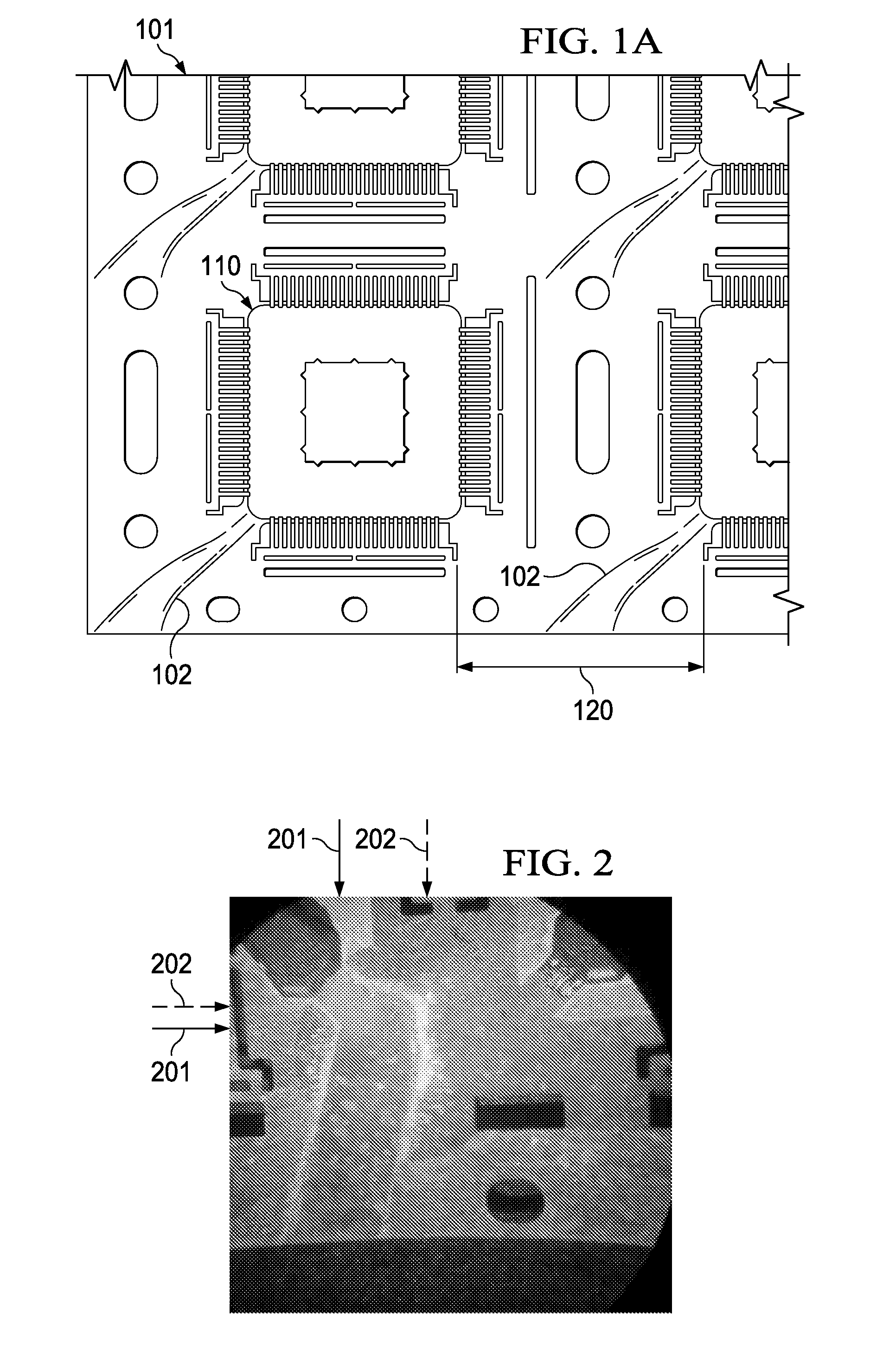

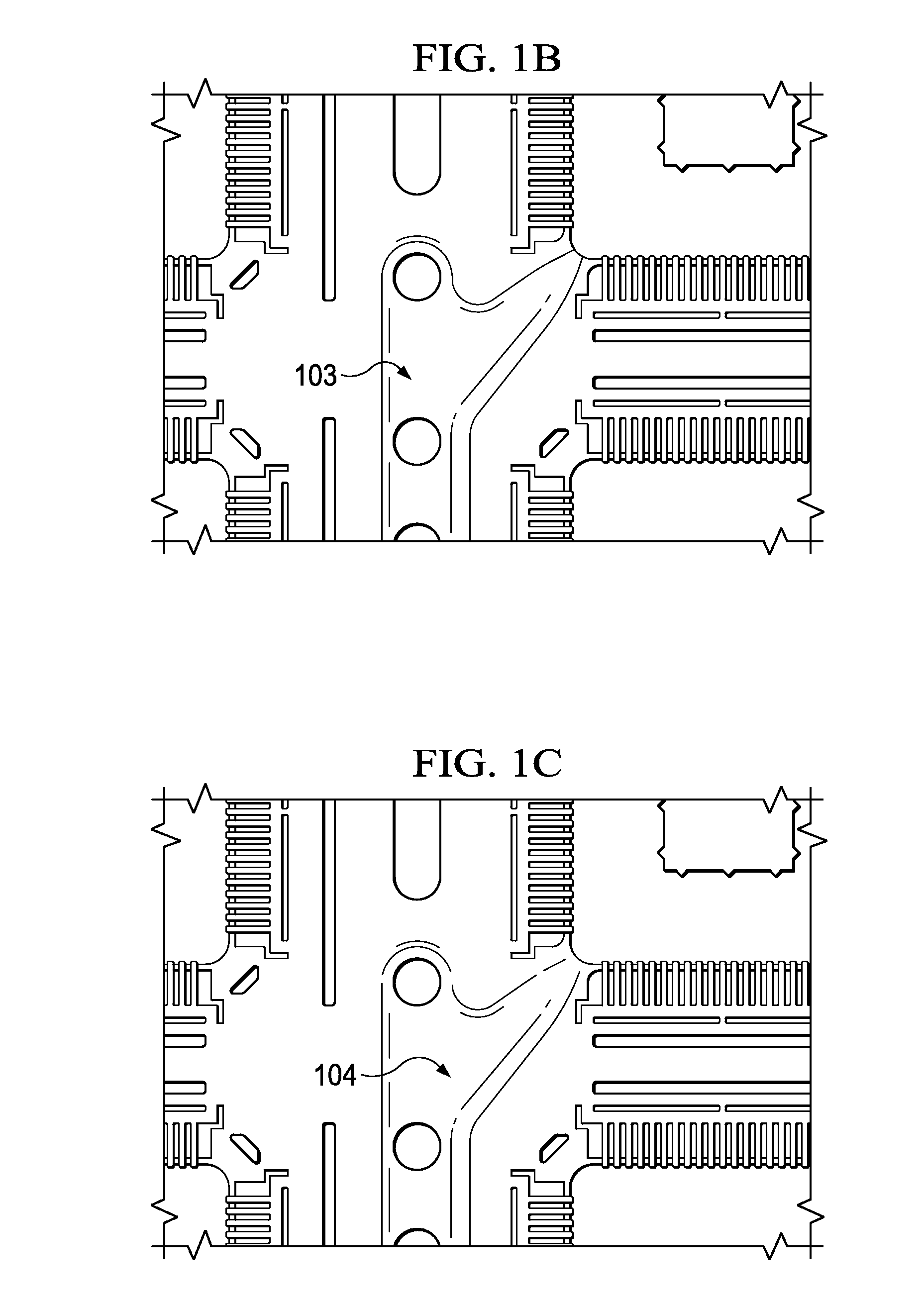

Leadframe having selective planishing

ActiveUS20130292811A1Increase insensitivityReduce manufacturing costLine/current collector detailsSemiconductor/solid-state device detailsRough surfaceSemiconductor chip

A metal leadframe strip (500) for semiconductor devices is described. The leadframe strip has a plurality of sites (510) for assembling semiconductor chips. The sites alternate with zones (520) for connecting the leadframe to molding compound runners. The sites (510) have mechanically rough and optically matte surfaces (511, 512). The zones (520) have at least portions with mechanically flattened and optically shiny metal surfaces (521, 522). The flattened surface portions transition into the rough surface portions by a step.

Owner:TEXAS INSTR INC

Controlled power source, in particular for a digital analogue converter in continuous time sigma delta modulators

InactiveUS20060055580A1Reduce sensitivity to clock jitterIncrease insensitivityAnalogue/digital conversionElectric signal transmission systemsControl powerControl theory

The present invention relates to a controlled current source having a control input, in particular for digital / analogue converters in continuous-time sigma / delta modulators, having a current source ( 4 ) with a control input which generates an output current dependent on a control voltage applied to the control input, and having a controller ( 7 ) for converting a clock signal into a voltage signal, with the controller ( 7 ) being connected to the current source ( 4 ) in such a manner that the voltage signal is applied as a control voltage to the control input of the current source ( 4 ). The controller is designed to is designed to convert the clock signal into a voltage signal which has within a clock duration a reproducible curve ending with a falling flank. Using the present controlled current source in a digital / analogue converter in a feedback branch of a continuous-time sigma / delta modulator permits realizing a sigma / delta modulator which is essentially insensitive to clock jitter.

Owner:INTEL CORP

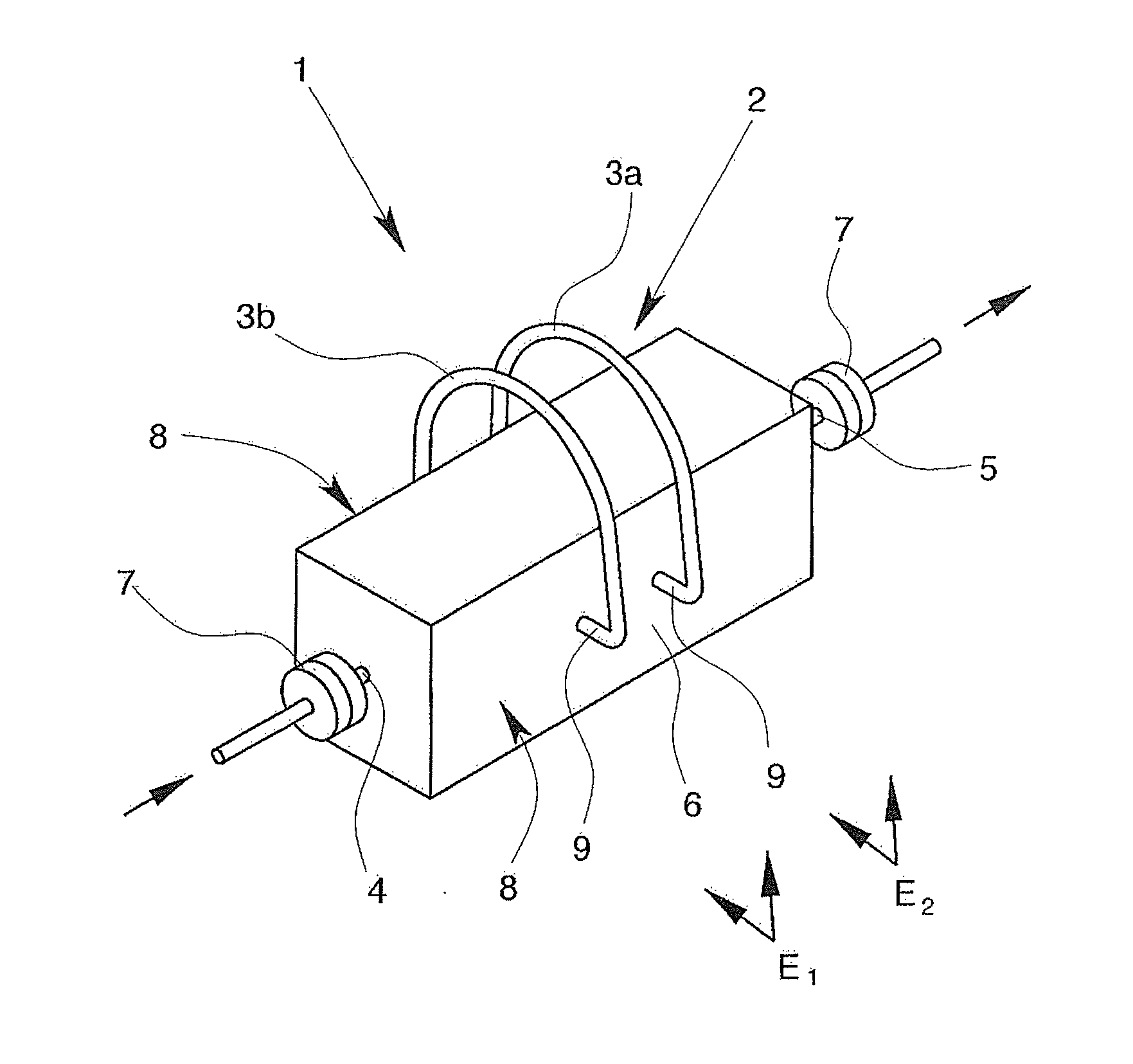

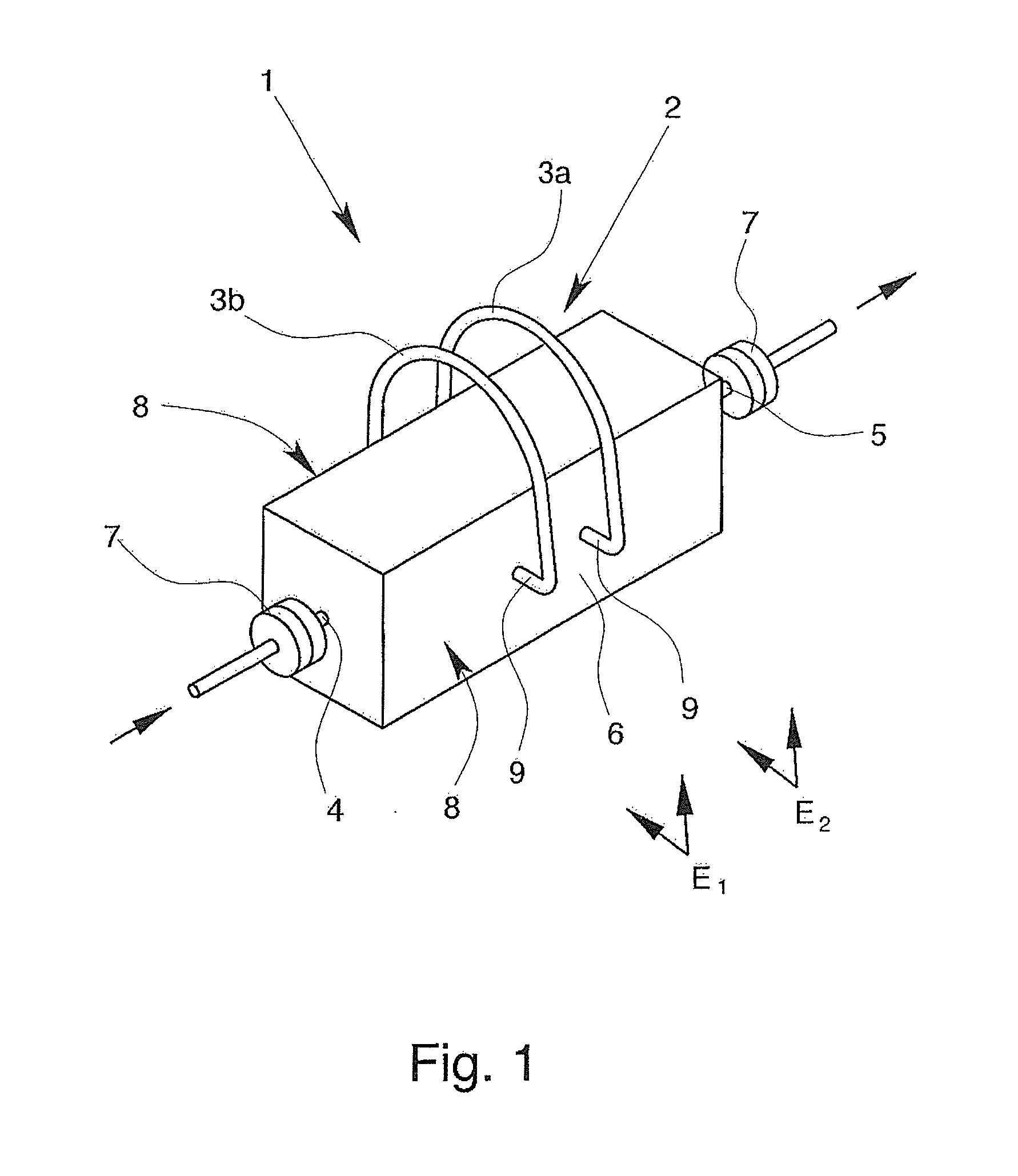

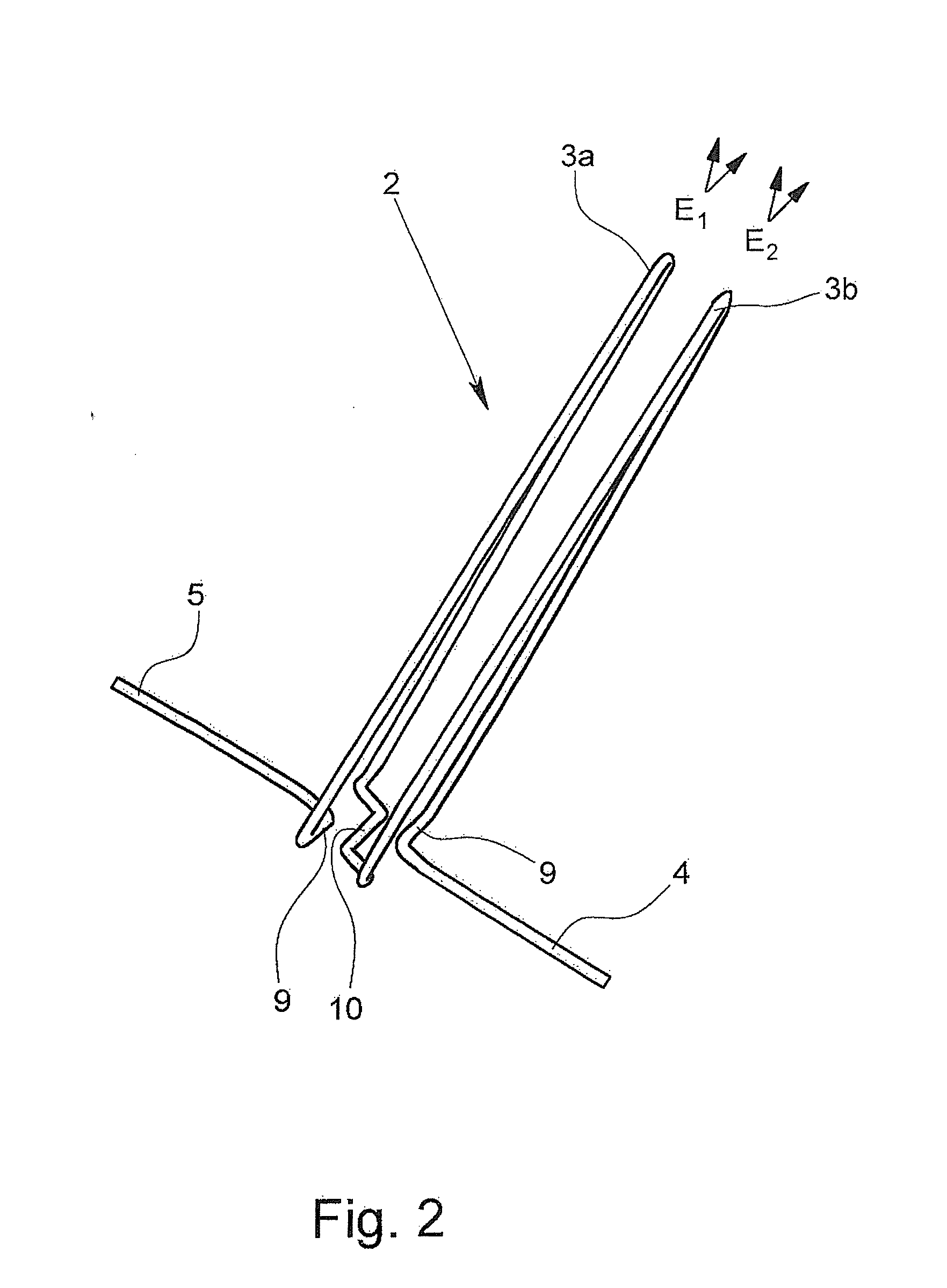

Coriolis mass flowmeter

ActiveUS20130042701A1Increase insensitivitySmall flow rateVolume meteringDirect mass flowmetersEngineeringParallel plane

A Coriolis mass flowmeter with at least one measurement tube (2) for forming a flow channel, at least one vibration generator and at least one vibration pick-up, the measurement tube (2) having one inlet end (4), two vibration sections (3a, 3b) and one outlet end (5) and being bent at least in sections such that two U-shaped or V-shaped vibration sections (3a, 3b) which run in essentially parallel planes are formed, and the vibration sections (3a, 3b) can be excited to vibrations by the vibration generator. The flow channel, except for the inlet end (4), the vibration sections (3a, 3b) and the outlet end (5), runs within a solid base (6).

Owner:KRONE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com