Preloaded parabolic dish antenna and method of making it

A technology of reflector antenna and parabolic cylinder, which is applied in the direction of antenna, wind load reduction, electrical components, etc., and can solve problems such as labor consumption, increased weight of structural components, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

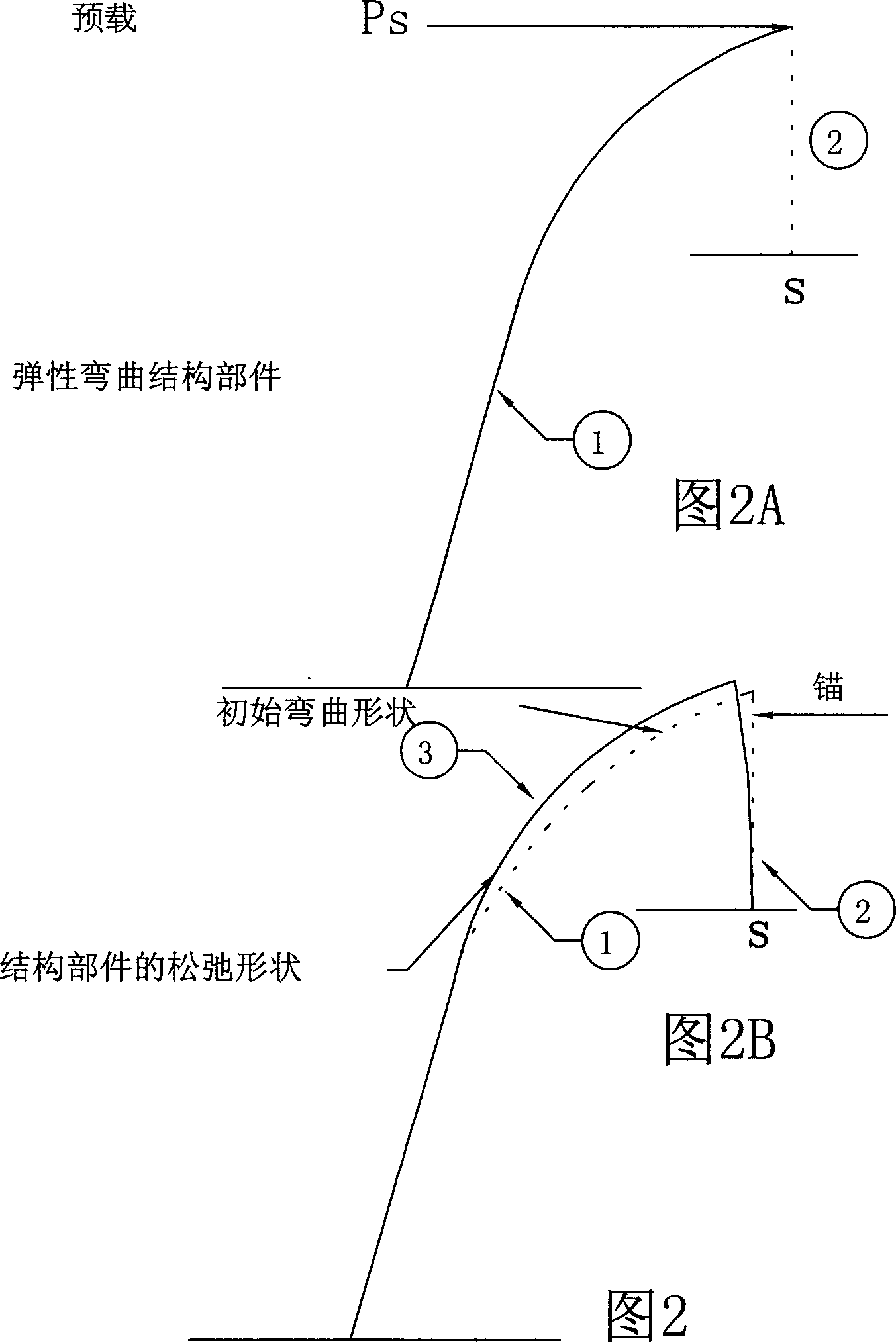

[0091] The curvature of the radial elements requiring elastic bending can be made to approximate the same as the parabolic curvature of the parabolic antenna in many ways, for example, (a) by fixing the straight radial elements at the appropriate location at the central hub and at an angle of inclination relative to the central hub , then the normal component exerts force at their tips to achieve the desired curvature, and then rigidly connects them to the rim parts forming an approximately circular (regular polygonal) circumferential ring; (b) first, the radial parts are lightly Gently bend to a relatively large radius of curvature, then fix them at the appropriate inclination angle and position of the central hub, and then apply force at their tips with the normal component used to achieve the desired curvature; (c) first use the appropriate The tensioning means elastically bends the radial members from the hub to the intermediate ring formed by the bracing members and from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com