A leak-proof electric contact water level gauge

A technology of water level gauge and electric contact, which is applied in the direction of liquid level indicator for physical variable measurement, etc. It can solve problems such as loosening, production stop, medium overflow, etc., and achieve the effect of speeding up installation, fast sealing connection, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

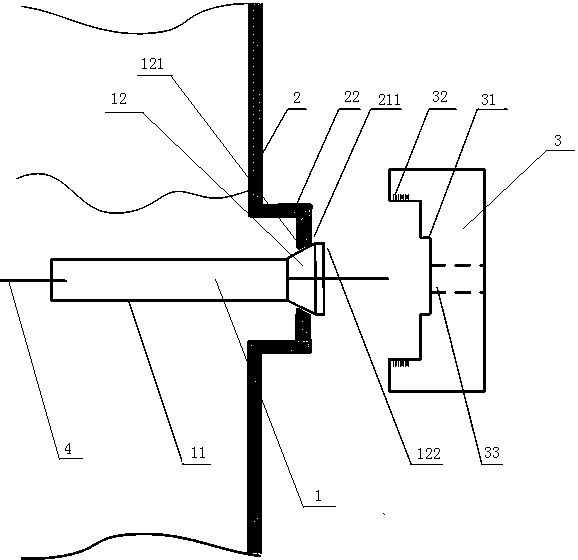

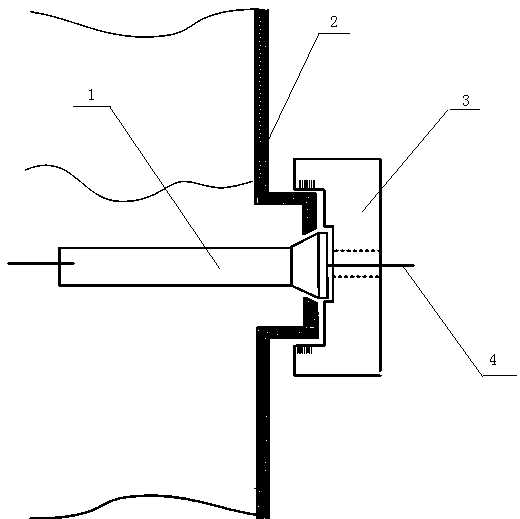

[0024] Such as Figures 1 to 2 Shown is an embodiment of a leakage-proof electric contact water level gauge of the present invention. The electric contact water level gauge includes a water level gauge main body 1, an installation cylinder 2, and a compression end cover 3, and the water level gauge main body 1 is installed in the installation cylinder 2 , the compression end cover 3 is tightly pressed on the end of the water level gauge main body 1, the electric contact water level gauge also includes a detection structure 4 for detection, and the installation cylinder 2 is provided with a first installation hole 21 for the installation of the water level gauge main body 1, The first installation hole 21 is provided with a first inclined side structure 211; the main body of the water level gauge 1 includes a detection part 11 and an installation part 12 connected to each other, and the installation part 12 is provided with a second inclined side that fits with the first incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com