A quick plug-in water feeder and its construction method

A water feeder and mandrel technology, which is applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of low loading and unloading efficiency, low drilling efficiency, etc., achieve compact size, improve drilling efficiency, The effect of a quick seal connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

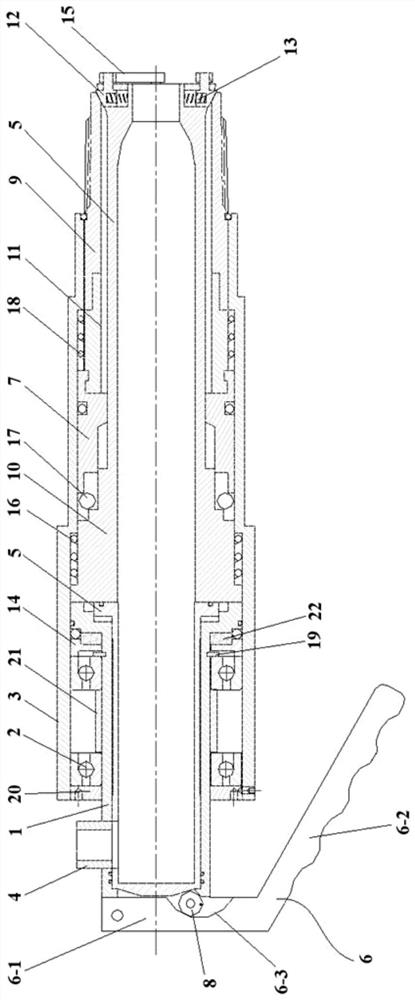

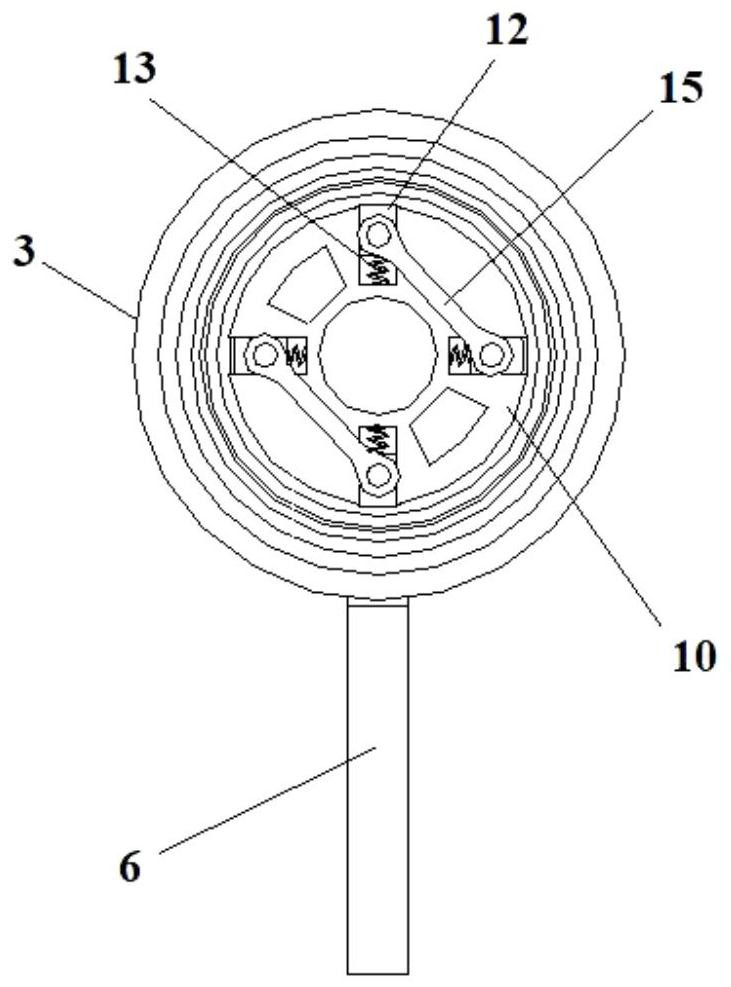

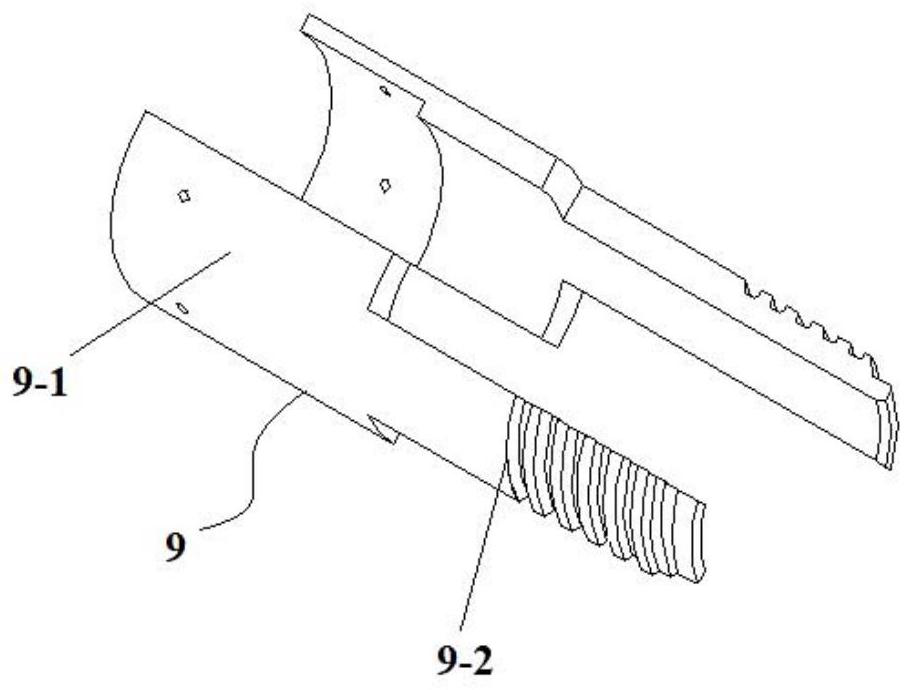

[0044] Such as Figures 1 to 3As shown, this embodiment provides a quick-plug water feeder, including a mandrel 1, a bearing 2 and a bearing sleeve 3 arranged coaxially from the inside to the outside in sequence, and a high-pressure water interface is installed on the side wall of the mandrel 1 4; It also includes a force transmission hollow shaft 5 coaxially tightly fitted in the mandrel 1 and capable of moving axially, with one end closed and the other end open; the high-pressure water interface 4 is sealed and connected to the force transmission hollow shaft 5, which is used for the force transmission hollow shaft 5. High-pressure water is passed into the shaft 5; the closed end of the force transmission hollow shaft 5 is flush with one end of the mandrel 1, and a pressure handle 6 and a rolling body 8 located between the pressure handle 6 and the closed end are provided, and the force transmission hollow shaft 5 The open end of the shaft is flush with the other end of the ...

Embodiment 2

[0052] This embodiment also provides a construction method for a quick-plug water feeder, including the following steps:

[0053] Step 1: Press the pressure handle first, the pressure handle rotates around the hinge shaft, the rolling body contacts the closed-end circular platform structure of the force transmission hollow shaft, and under the action of the pressure handle, the power transmission hollow shaft moves axially and pushes the core rod , The annular piston and the jaws both move axially, compressing the second spring and the third spring, and the moving speed of the core rod is greater than the moving speed of the jaws, so that the wedge-shaped outer wall of the piston block is away from the wedge-shaped surface of the claw piece, and the first spring resets , the claw shrinks, and the elastic piece of the claw is inserted into the internal thread of the drill pipe;

[0054] Step 2: Loosen the pressing handle again, under the reset action of the second spring and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com