Composite retaining pile structure

A kind of enclosure pile, composite technology, applied in the direction of foundation structure engineering, sheet pile wall, coastline protection, etc., can solve the problem of lack of T-shaped piles, stability needs to be strengthened, etc., to improve strength and stability, fast sealing connection , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

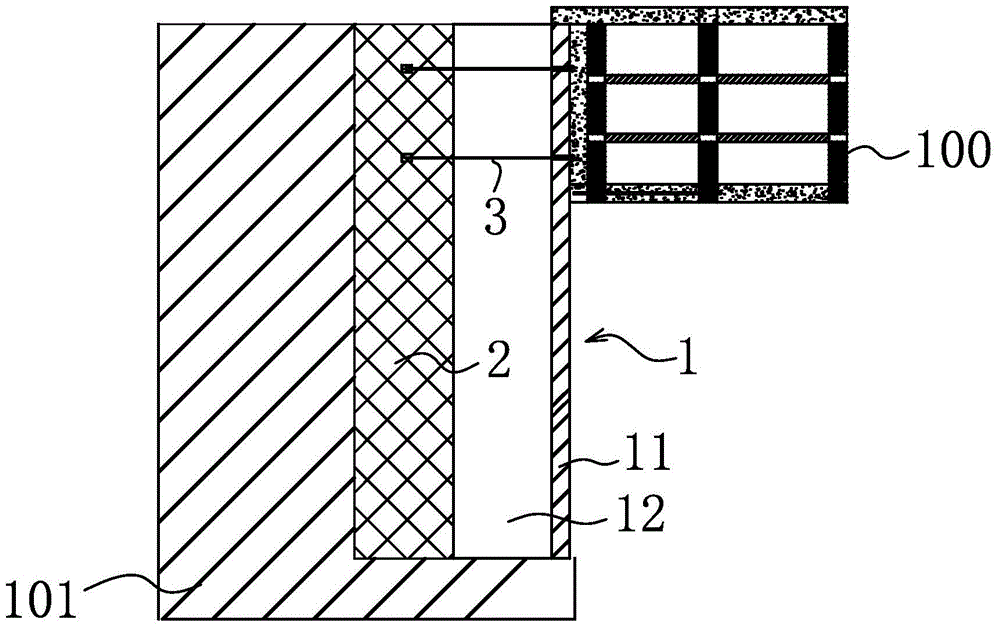

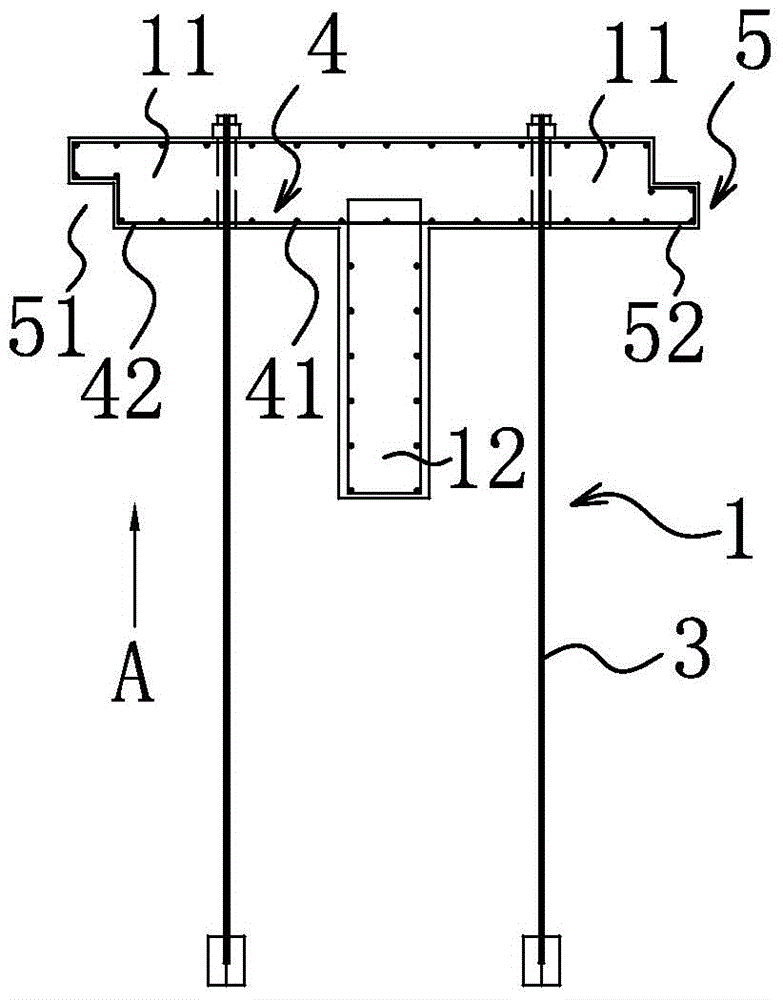

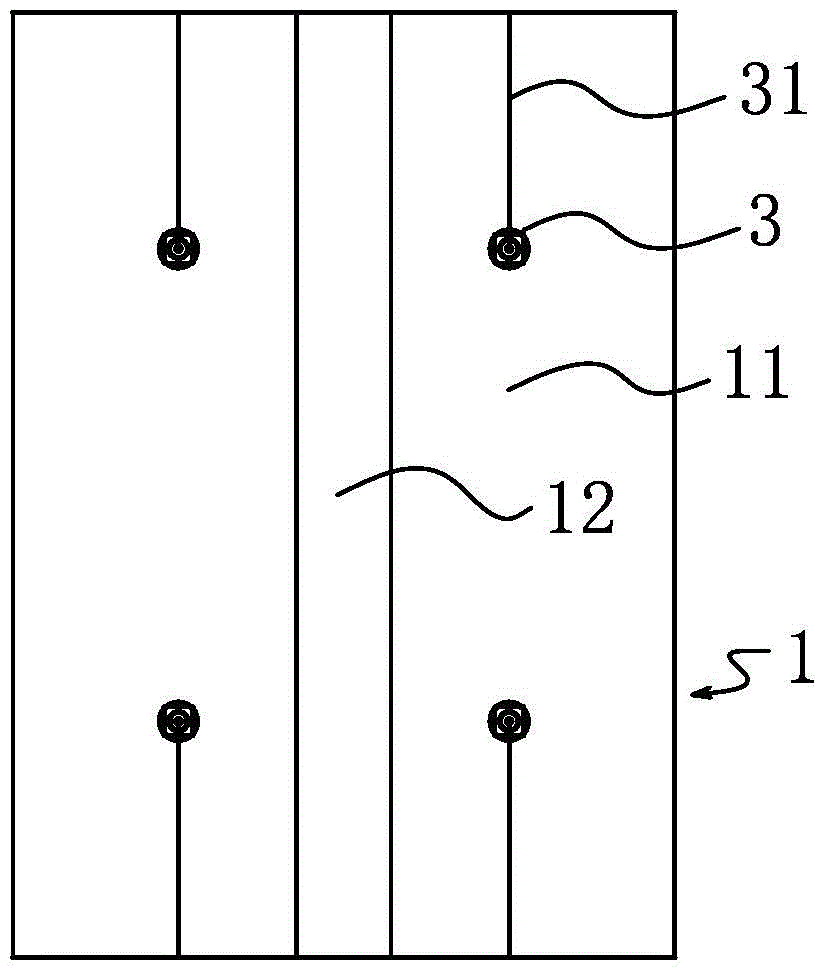

[0033] Such as figure 1 As shown, a compound enclosure pile structure includes a T-shaped pile 1 with a T-shaped cross section, and a composite pile 2 whose axis line is parallel to the T-shaped pile 1. The T-shaped pile 1 is provided with A number of anchor rods 3, and one end of the anchor rod 3 is fixedly connected to the T-shaped pile 1, and the other end is inserted into the composite pile 2 to form a fixed connection with the composite pile 2, such as figure 2 As shown, the T-shaped pile 1 includes a transverse plate 11 and a longitudinal plate 12 connected to each other. Such as image 3 As shown, there are several anchor rods 3 located on both sides of the longitudinal plate 12 , preferably, the anchor rods 3 located on both sides of the longitudinal plate 12 are evenly distributed. In order to strengthen the fixing effect of the anchor rod 3 , a connecting rod 31 parallel to the axis of the transverse plate 11 is fixed inside the transverse plate 11 , and the conne...

Embodiment 2

[0040] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as Figure 7 and Figure 11As shown, the concave-convex connection mechanism 5 includes connecting blocks 53 respectively arranged on both sides of the transverse plate 11 , and the two connecting blocks 53 are centrally symmetrical along the axis of the transverse plate 11 . The connection block 53 has a concave hole 54 and a protrusion 55, and the protrusion 55 is matched with the concave hole 54, and the protrusion 55 on one connection block 53 can be inserted into the concave hole 54 on the other connection block 53 Therefore, two adjacent T-shaped piles 1 can be clamped and fitted. Figure 7 The connecting block 53 in the middle is a hook type, which is convenient and firm to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com