Water pump comprehensive automatic test system

A technology of comprehensive automation and test system, applied in the field of comprehensive automatic test system of water pump, can solve the problems of large human factors in worker operation, affecting test efficiency, test result error, etc., to improve test efficiency and detection accuracy, and low skill requirements , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

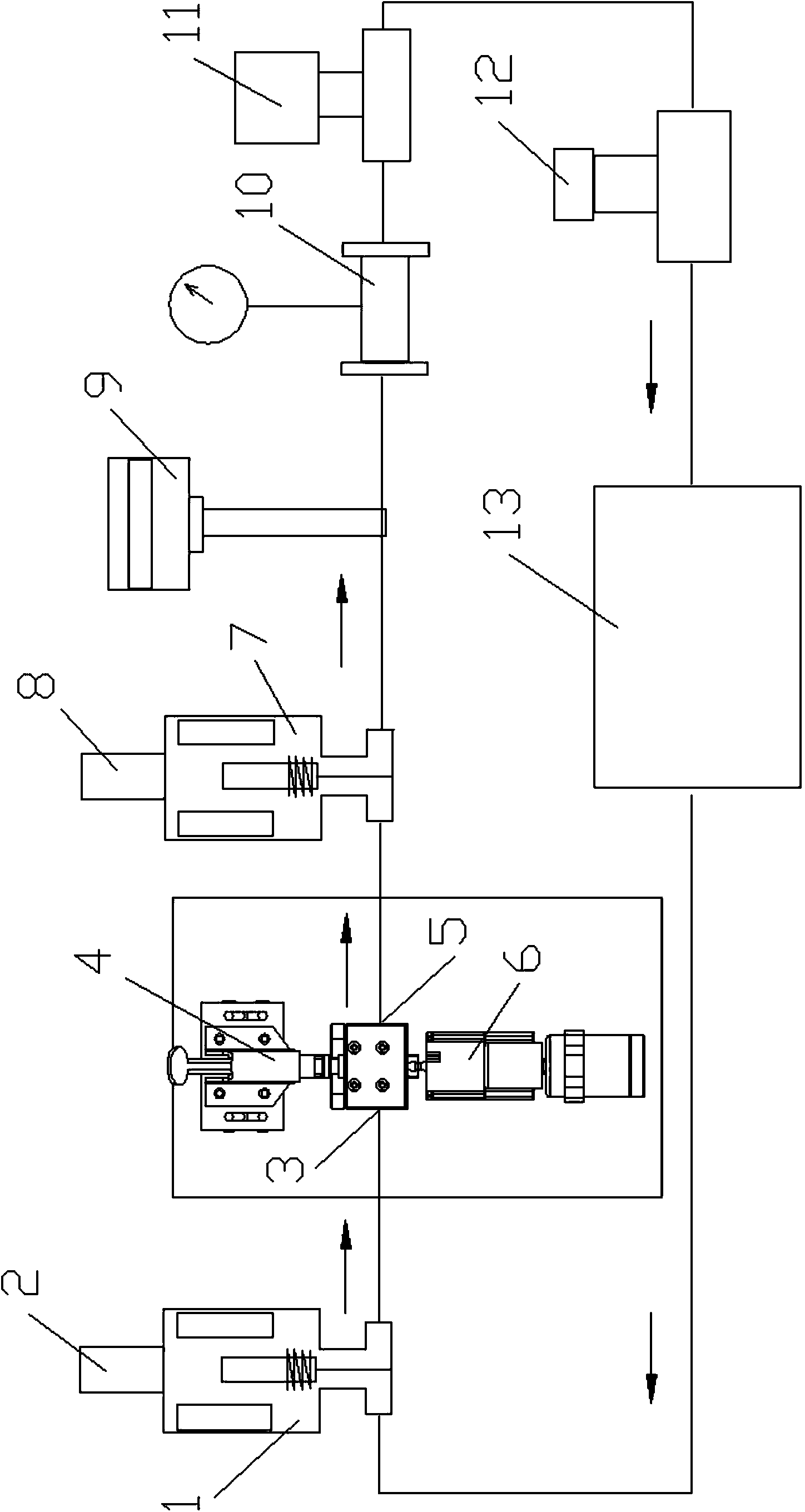

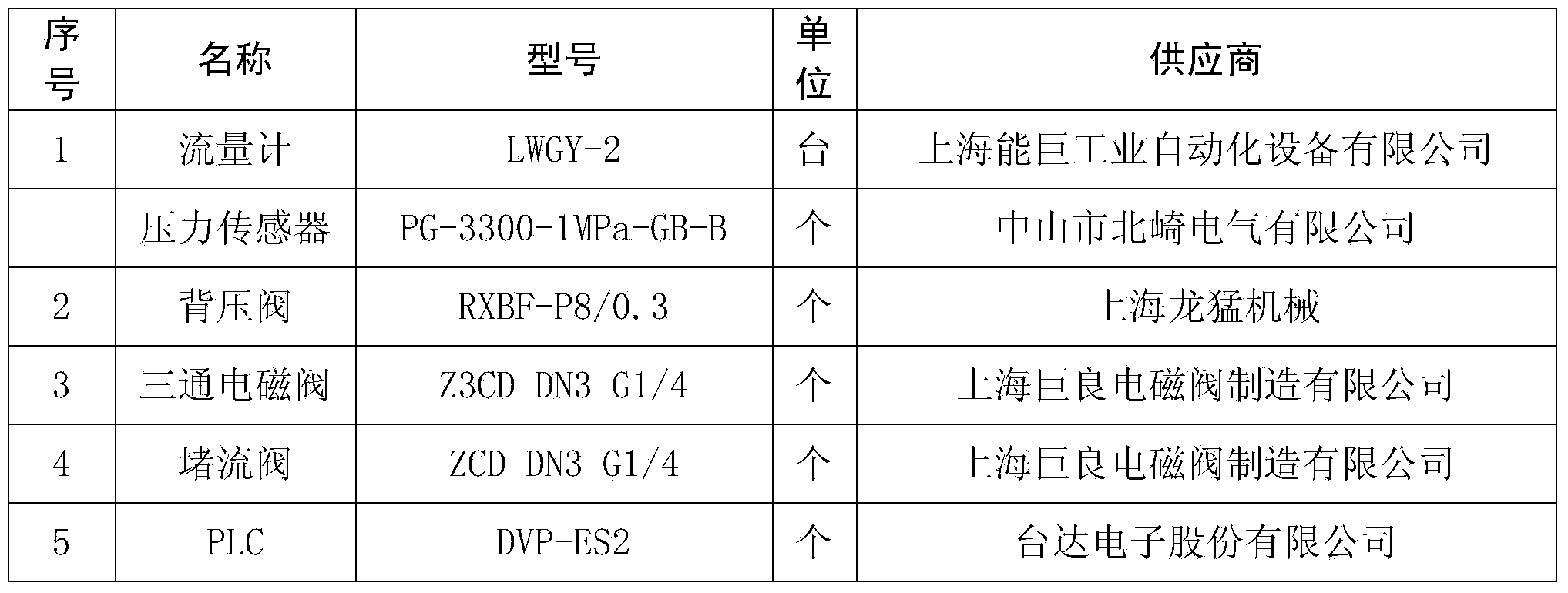

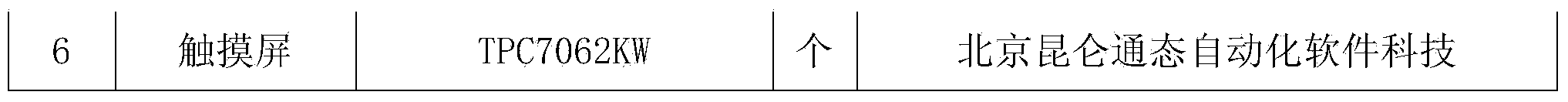

[0016] Such as figure 1 , a comprehensive automatic test system for water pumps, including a water inlet three-way solenoid valve 1, a water pump comprehensive test quick-install fixture 4, a water pump to be tested 6, a water outlet three-way solenoid valve 7, a flow sensor 10, a blocking valve 11, a back Pressure regulating valve 12 and circulating pool 13, the water outlet of the three-way solenoid valve 1 at the water inlet is connected to the water pump comprehensive test quick-install fixture 4, the water pump comprehensive test quick-install fixture water inlet 3, and the water outlet is connected to the water pump comprehensive test quick-install fixture The water pump comprehensive test of 4, the water outlet 5 of the quick-installation fixture is connected to the water inlet of the three-way solenoid valve 7 at the water outlet, and the water outlet of the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com