Oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity

A technology with strong inhibition and lubricity, applied in the field of drilling fluids, it can solve the problems of weak plugging ability of shale micro-fractures, and the lubricity cannot fully meet the construction requirements, and achieves low cost, strong plugging ability and good plugging ability. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

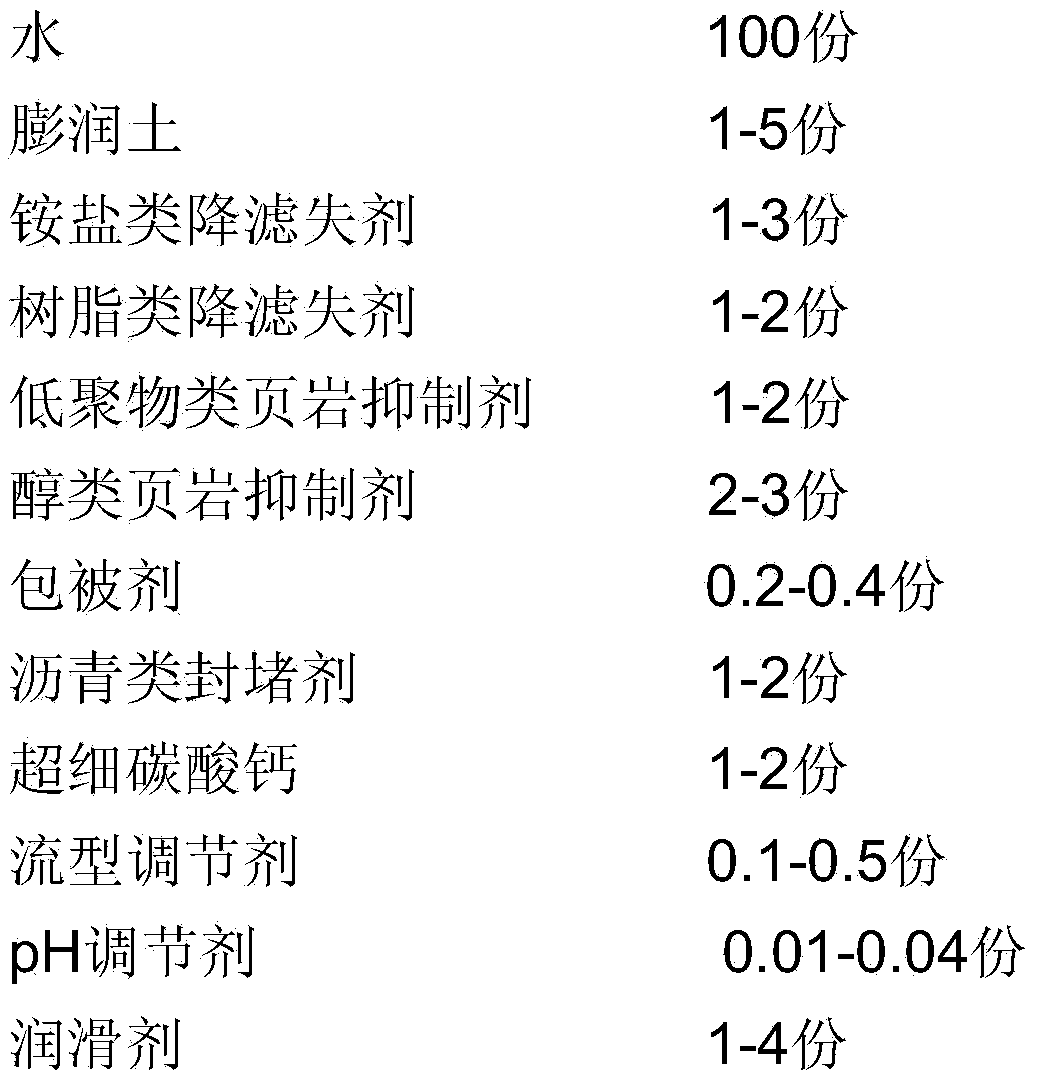

[0024] Measure 5 parts of 400mL water, start the stirrer, add 0.12g of pH regulator potassium hydroxide, and then add 16g of bentonite powder. After prehydration for 24 hours, add 8g of hydrolyzed polyacrylonitrile- Compound ammonium salt, 4g lignite resin, 8g oligomer shale inhibitor, 12g polyethylene glycol, 1.2g coating agent PAC-141, 8g sulfonated pitch, 8g compounded ultrafine calcium carbonate, 1.2g High-viscosity polyanionic cellulose, 12g compounded lubricant. Each treatment agent should be stirred at intervals and fully for 10 minutes before adding the treatment agent. After the treatment agent is added, stir at 3000rpm for 30 minutes.

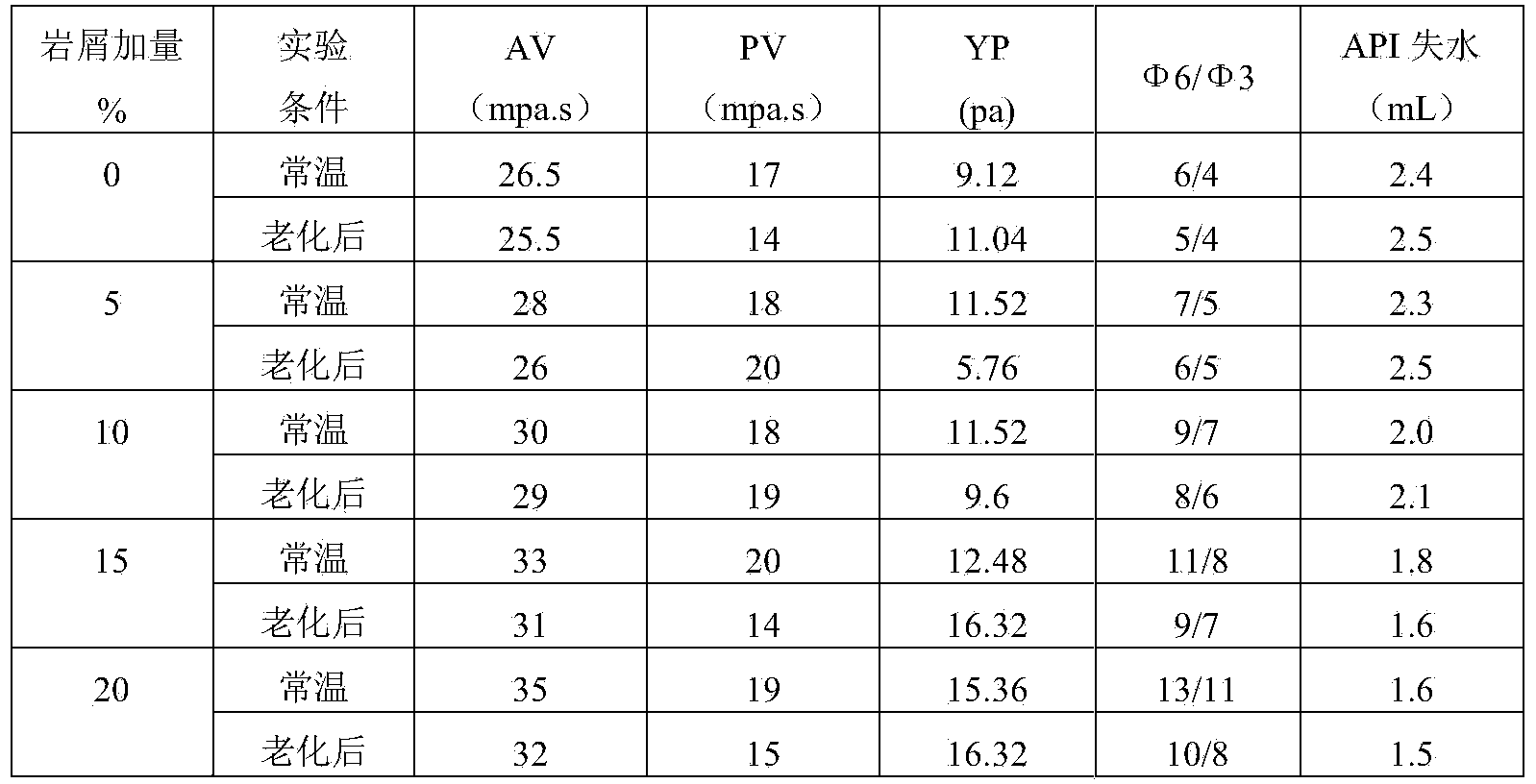

[0025] Dry and crush the shale cuttings that are easy to hydrate and disperse, pass through a 100-mesh sieve, add the cuttings at 0%, 5%, 10%, 15%, and 20%, add the cuttings to the prepared drilling fluid, and measure The performance before and after aging at 150°C, the results are shown in Table 1.

[0026] Table 1 Drilling fluid p...

Embodiment 2

[0031] Prepare the imitation oil-based drilling fluid in the room according to the steps: Measure 400mL of water, turn on the mixer, add 0.12g of pH regulator potassium hydroxide, then add 16g of bentonite powder, pre-hydrate for 24 hours, and stir at low speed Add 8g of hydrolyzed polyacrylonitrile-compound ammonium salt, 4g of lignite resin, 8g of oligomer shale inhibitor, 12g of polyethylene glycol, 1.2g of coating agent PAC-141, 8g of sulfonated pitch, and 8g of compounded Ultrafine calcium carbonate, 1.2g high-viscosity polyanionic cellulose, and 12g compounded lubricant. Each treatment agent should be stirred at intervals and fully for 10 minutes before adding the treatment agent. After the treatment agent is added, stir at 3000rpm for 30 minutes.

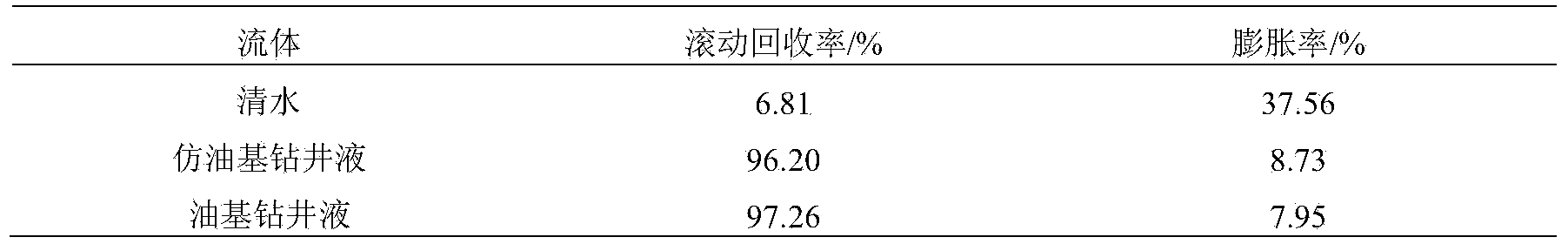

[0032] Prepare one portion of oil-based drilling fluid according to the oil-based drilling fluid formula (the oil-water ratio is 80:20).

[0033] Select mud shale cuttings that are easily hydrated and dispersed, crush them i...

Embodiment 3

[0039]Prepare the imitation oil-based drilling fluid in the room according to the steps: Measure 400mL of water, turn on the mixer, add 0.12g of pH regulator potassium hydroxide, then add 16g of bentonite powder, pre-hydrate for 24 hours, and stir at low speed Add 8g of hydrolyzed polyacrylonitrile-compound ammonium salt, 4g of lignite resin, 8g of oligomer shale inhibitor, 12g of polyethylene glycol, 1.2g of coating agent PAC-141, 8g of sulfonated pitch, and 8g of compounded Ultrafine calcium carbonate, 1.2g flow regulator high-viscosity polyanionic cellulose, 12g compounded lubricant. Each treatment agent should be stirred at intervals and fully for 10 minutes before adding the treatment agent. After the treatment agent is added, stir at 3000rpm for 30 minutes.

[0040] Prepare one portion of oil-based drilling fluid according to the oil-based drilling fluid formula (the oil-water ratio is 80:20).

[0041] The lubricity and mud cake adhesion coefficient of the two drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com