A high-precision integrated circuit chip packaging device and its packaging process

An integrated circuit and chip packaging technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of low chip bonding stability, increased manufacturing costs, no seismic performance and high heat dissipation, etc. The effect of light curing efficiency, improving packaging efficiency and shortening light curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

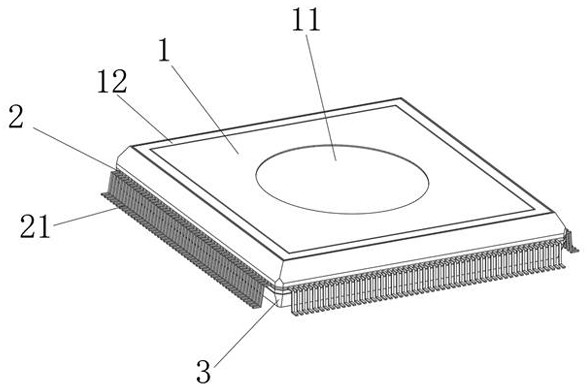

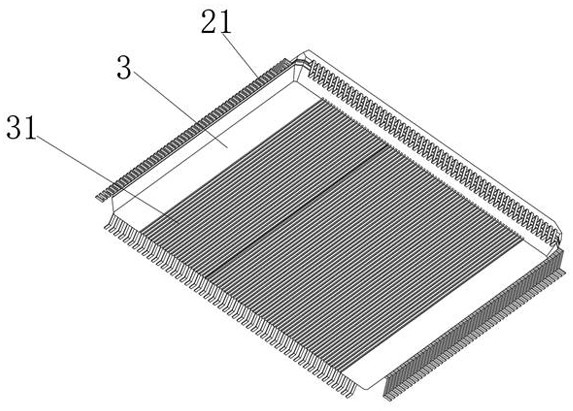

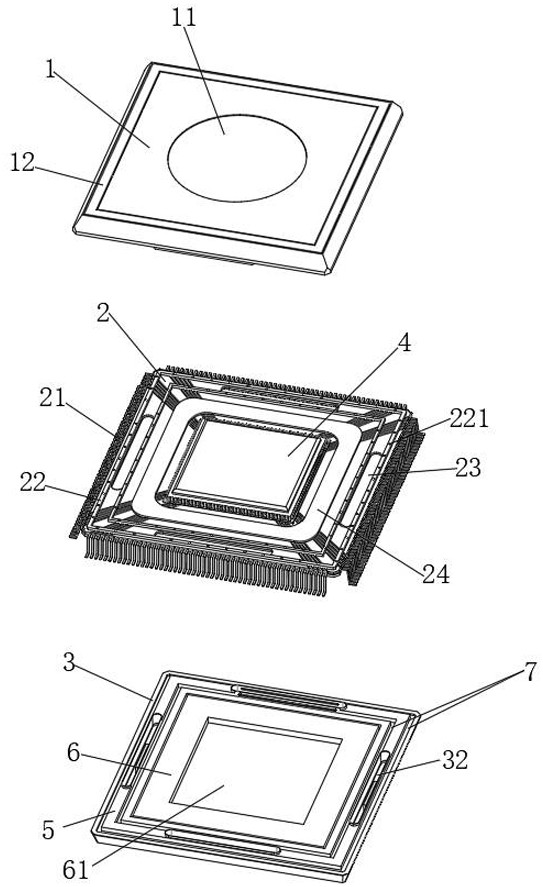

[0045] see Figure 1-Figure 10 , a high-precision integrated circuit chip packaging device, including an upper case 1, a lower case 3 and a liner 2, a chip 4 is fixed on the liner 2, and the opposite sides of the upper case 1 and the lower case 3 are A second light guide frame 5 is provided, the inside and outside of the frame of the second light guide frame 5 are provided with gluing grooves 7, and the second light guide frame 5 of the upper housing 1 is provided with a mating block 13, four mating blocks 13 The blocks 13 are equally arranged at equal angles, the top of the matching block 13 extends through the upper casing 1 and is fixed with the first light guide frame 12, and the second light guiding frame 5 of the lower casing 3 is provided with a matching The mating groove 32 that matches the block 13 is provided with an elastic capsule 14 in the mating block 13, and the elastic capsule 14 is saturated and filled with light-curing glue 9, and the bottom of the elastic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com