Tunnel multichannel rapid grouting joint device and tunnel grouting system

A grouting joint and multi-channel technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of quality and safety hazards, time-consuming, lengthened bolt grouting process time, etc., to avoid safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

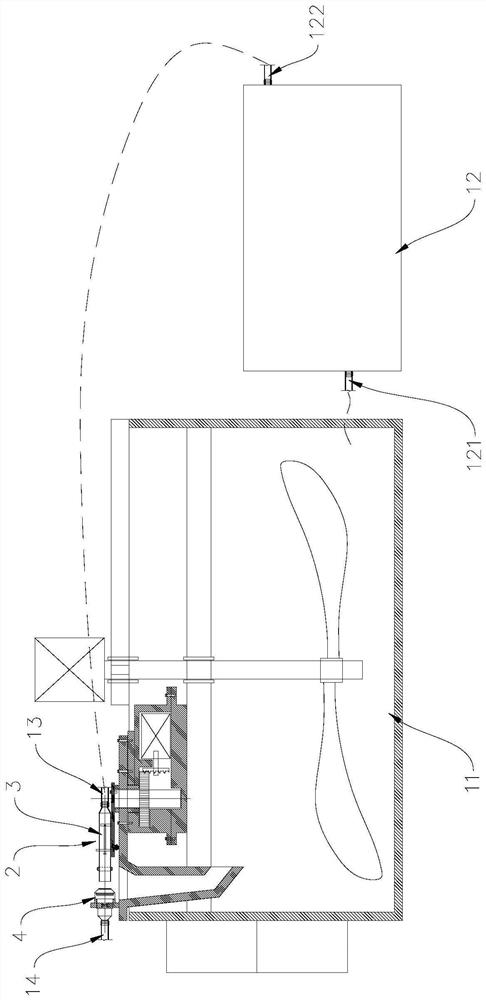

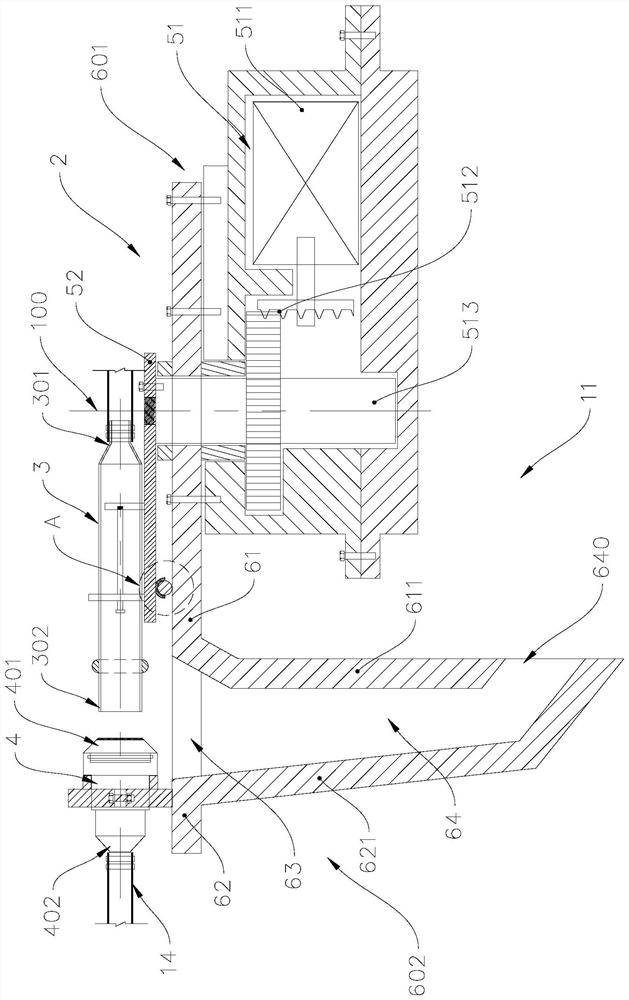

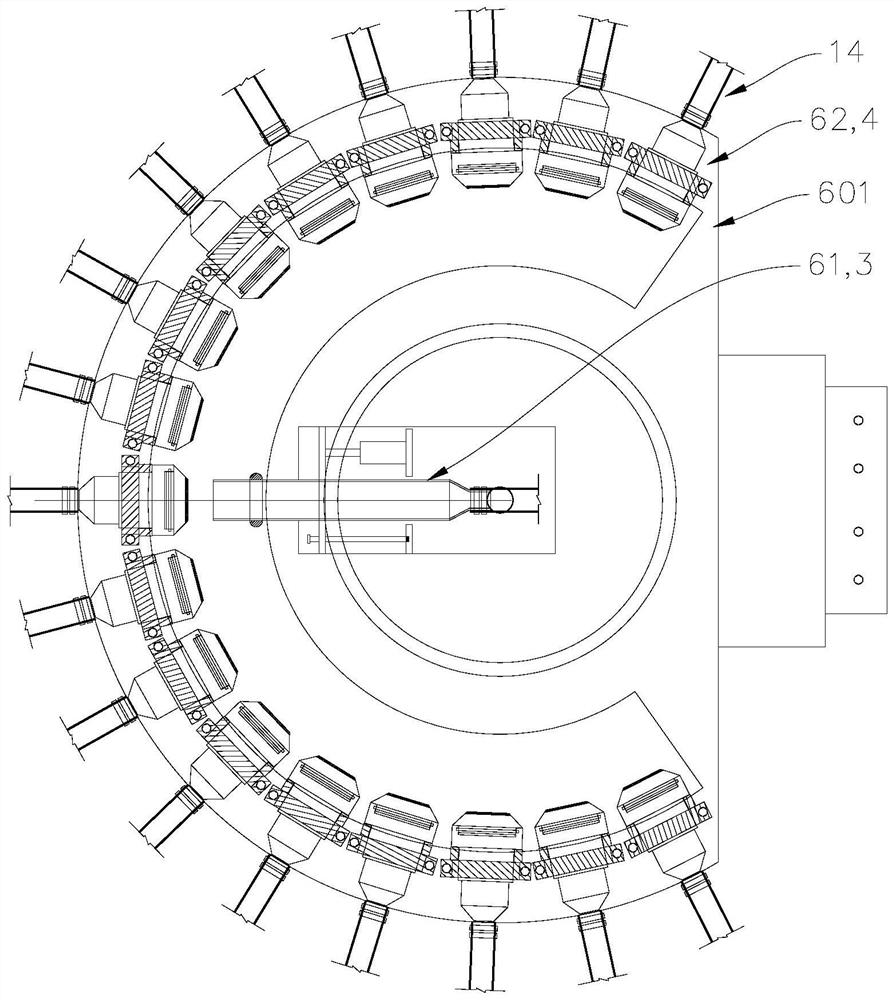

[0036] see figure 1, The tunnel grouting system is used for radial grouting of multiple hollow bolts that have been laid. The tunnel grouting system includes a slurry mixing drum 11, a grouting machine 12, the tunnel multi-channel quick grouting joint device 2 of the present invention, and a plurality of hollow bolts (not shown in the figure) that need to be grouted. shown), the tunnel multi-channel quick grouting joint device 2 includes a second grouting hose 13, a push pipe 3, a joint 4 and a first grouting hose 14, and the outlet of the slurry mixing drum 11 is connected to the outlet of the grouting machine 12. The grouting port 121 communicates with the grouting machine 12 , and the grouting machine 12 communicates with the first extension end of the second grouting hose 13 , and the second extension end of the second grouting hose 13 communicates with the input end of the push pipe 3 31 is connected, the output end 32 of the push pipe 3 is selectively connected with one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com