Large-aperture single-hole non-pressure grouting method for karst water inrush

A large-aperture, water-inrush technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of large karst channels, high water pressure, and poor water glass pouring effect, and achieve the effect of efficient grouting and water stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

[0024] The karst water inrush large-aperture single-hole pressureless grouting method includes the following steps:

[0025] Step 1. Construction of the grouting hole and the air outlet hole. With the grouting hole as the center of the circle, the air outlet holes are arranged in a cross shape or a plum blossom shape in the circumferential direction. PVC pipes are inserted in the air outlet holes, and a metal jacket can be set at the grouting hole;

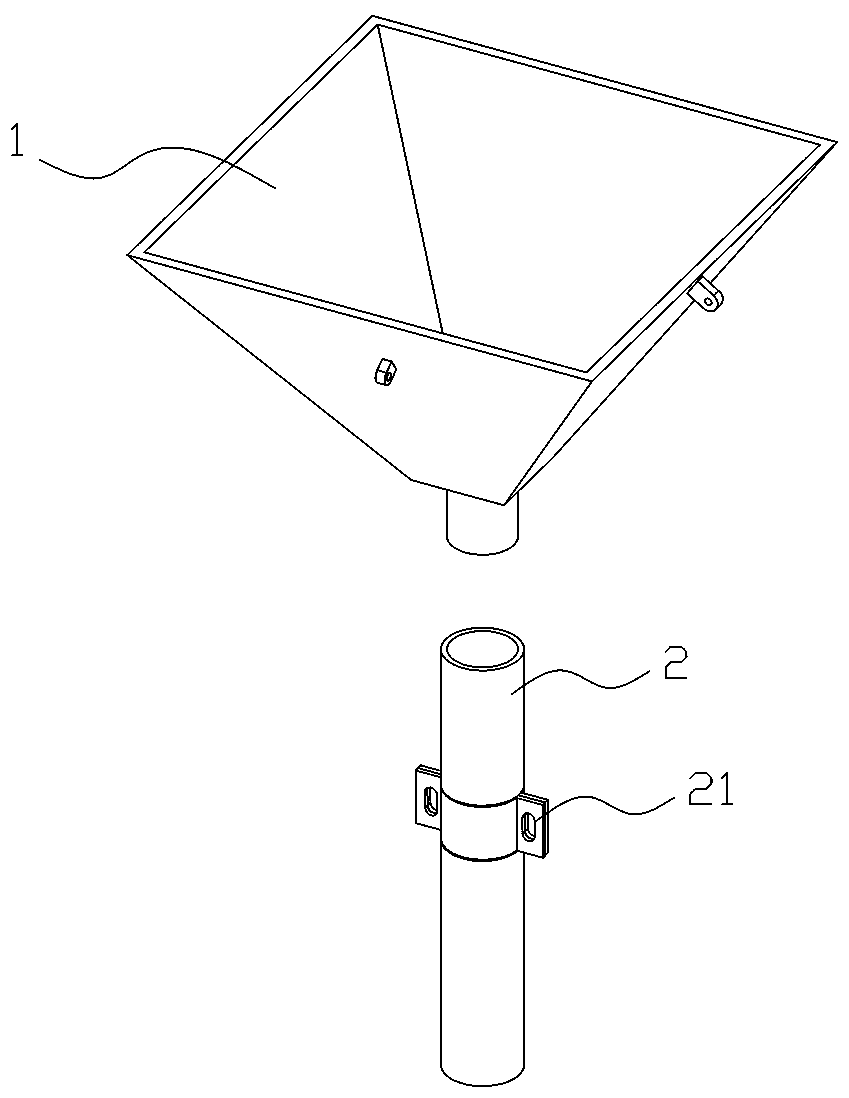

[0026] Step 2. Lift the casing 2 with a truck crane and put it into the grouting hole, hoist the grouting bucket 1 and insert it into the upper end of the casing, connect the lifting gear of the crane to the lifting lug 21 on the casing, and inject it through the grouting pump truck. The grouting material is injected into the grouting pipe from the upper end of the grouting hopper, and at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com