Advance grouting reinforcement method for narrow coal pillars in gob-side roadway

A technology of advanced grouting and narrow coal pillars, which is applied in tunnels, earthwork drilling, tunnel linings, etc., can solve problems such as loss of bearing capacity, coal pillar deformation and fracture, and impact on mining, so as to improve bearing capacity and stability, repeat The operation time is short and the reinforcement effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

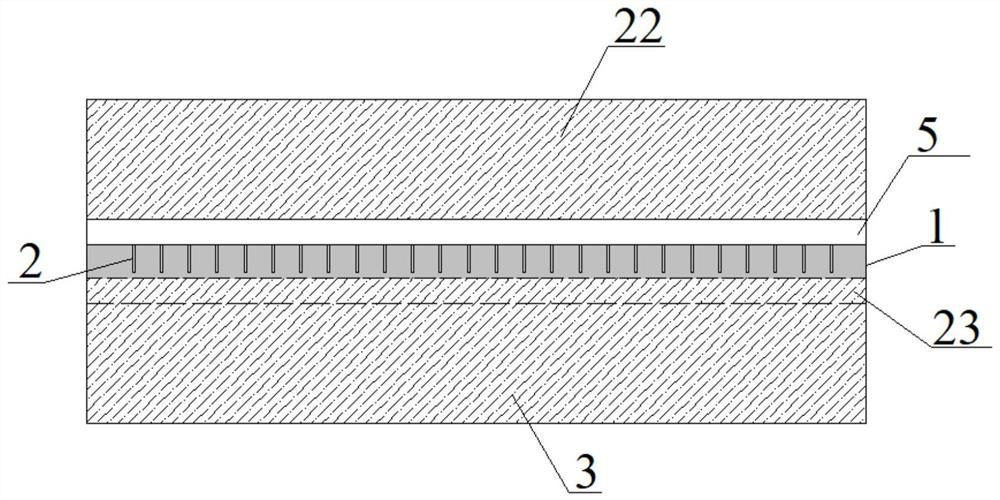

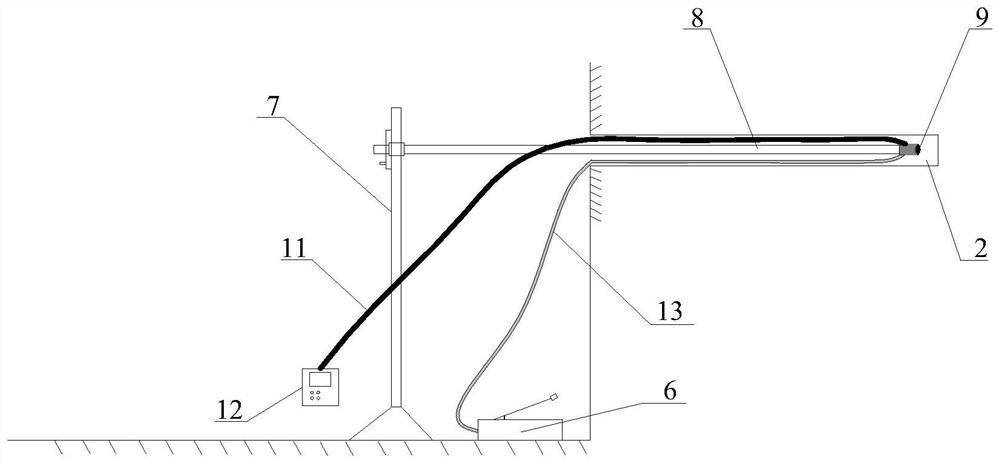

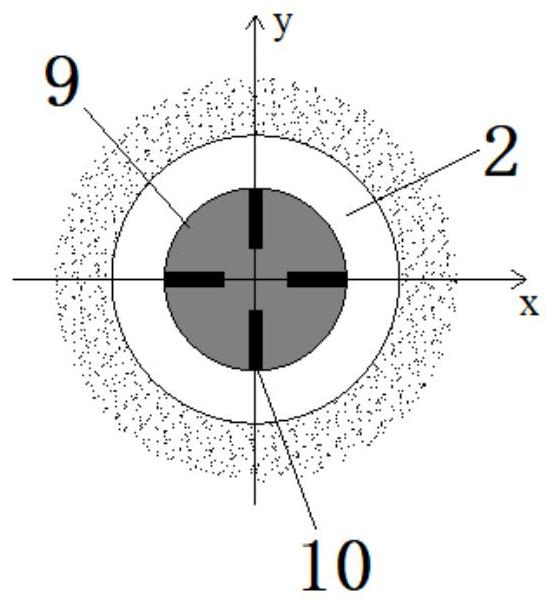

[0032] Such as Figure 1 to Figure 10 As shown, a narrow coal pillar advance grouting reinforcement method in gob-side roadway includes a borehole penetrometer and an electric pulse device 4, and the borehole penetrometer includes a conveying rod 8, a lifter 7, a probe 9, a probe 10. Hand pump 6 and data acquisition instrument 12. The delivery rod 8 is a telescopic rod, and one end of the delivery rod 8 is connected to the lifter 7, and its outer diameter is smaller than the inner diameter of the borehole 2 to be detected; the lifter 7 is installed in the roadway 5 in the upper section. The elevator 7 is a liftable structure, and the pitch angle can be adjusted, so that not only the depth of the conveying rod 8 entering the drilling 2 can be adjusted, but also the angle of the conveying rod 8 can be adjusted to adapt to different Angle drilling 2; the probe 9 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com