A method for surface drilling and extraction of residual coalbed methane in old goaf areas of coal mines

A technology for surface drilling and old empty areas, which is applied in earthwork drilling, mining fluids, boreholes/well components, etc. It can solve problems such as unsatisfactory drainage effects, suppress spontaneous combustion of residual coal, and enhance mine safety , the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

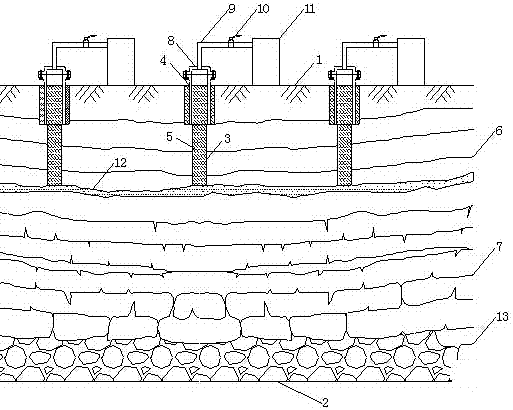

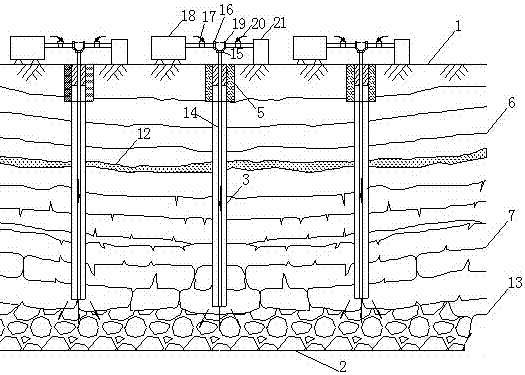

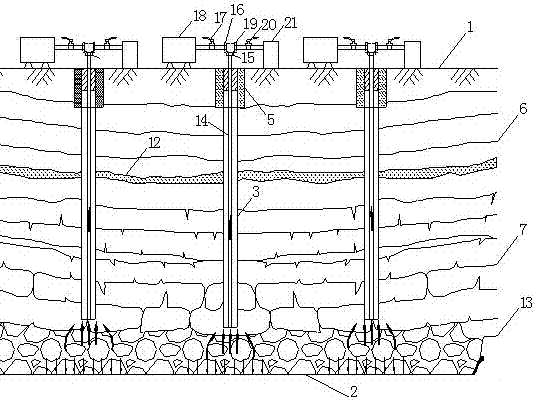

[0022] Below in conjunction with accompanying drawing, the example of the present invention will be further described:

[0023] A method of ground drilling and extraction of residual coalbed gas in the old empty area of the coal mine according to the present invention:

[0024] Drilling wells (3) with a diameter of 300-400mm and a depth of 3-5m are drilled downward from the ground (1) along the middle of the old empty area (2) at intervals of 200-300m. A casing (4) with a diameter of 250-350 mm is inserted into the bottom of the well (3), and cement mortar (5) is injected along the outer side of the casing (4) to fix the casing (4). Continue drilling (3) with a diameter of 100-200mm from inside the casing (4) to the curved subsidence zone (6) above the old empty area (2) and 5-10m away from the top of the fractured zone (7). The upper end of the casing (4) is connected to the grouting pipe (9) through the flange (8), and the other end of the grouting pipe (9) is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com