A grouting reinforcement method for coal mine fault fracture zone based on tracer technology

A tracer technology and grouting reinforcement technology, applied in mining equipment, earthwork drilling, mining equipment, etc., can solve the problems of heavy workload, lack of pertinence, water waste, etc., and achieve simple construction, high excavation efficiency, and energy saving The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

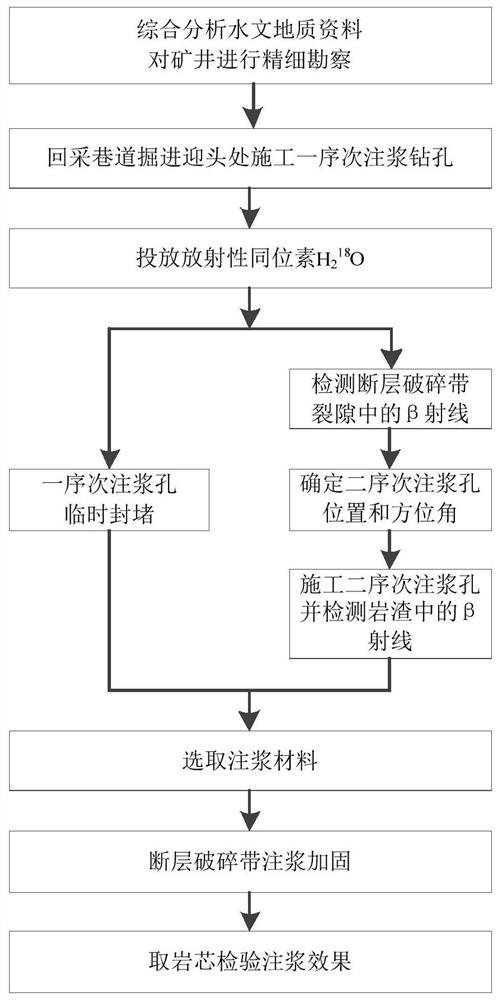

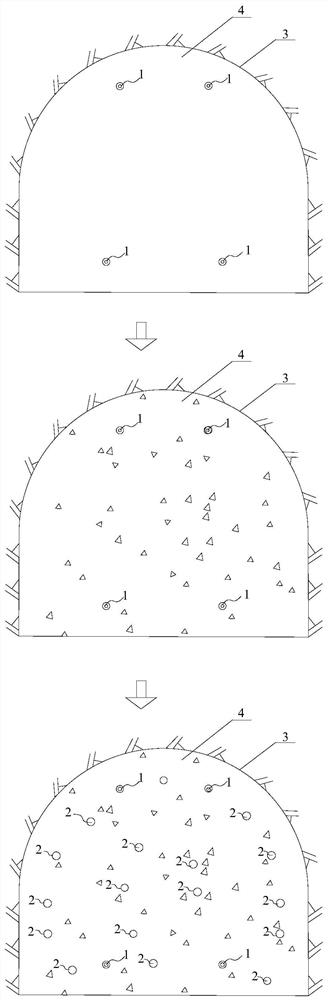

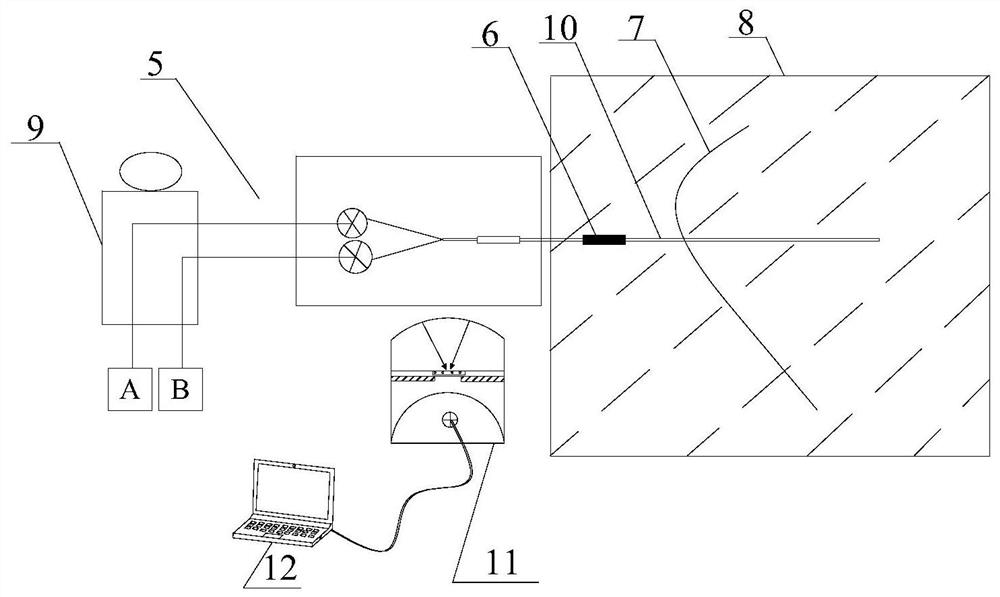

[0032] A method of grouting reinforcement for coal mine fault fracture zones based on tracer technology, such as figure 1 As shown, the specific steps include:

[0033] Step A. When the recovery roadway is 8-12m away from the fault, stop the excavation and drill a sequential grouting hole 1 on the side of the fault in the excavation work, and inject isotope tracers through the sequential grouting hole 1 . When the mining roadway 4 is excavated to 10m away from the fault, the excavation is suspended, and the first-order grouting drilling 1 is arranged in the shape of a square, and the isotope tracer is selected as H 2 18 O. isotope tracer in H 2 After being evenly stirred in the O, it is pumped into the first-order grouting borehole 1, and the first-order grouting borehole 1 is arranged along the edge of the excavation working face section.

[0034] The distance from the excavation working face of mining roadway 4 to the fault is judged according to the hydrogeological data...

Embodiment 2

[0043] In order to further explain the method of grouting reinforcement for fault fracture zones in coal mines based on tracer technology, take the 1201 working face section of a mine as an example. To avoid fault activation and water inrush when the roadway passes through the fault, increase the safety factor, carry out grouting reinforcement for the fault in front of the transport level roadway in this section, and adopt the method of grouting reinforcement for the fractured zone of the coal mine fault based on tracer technology. The specific steps include:

[0044] Step 1. Collect mine hydrogeological data, wherein the mine hydrogeological data include the location, thickness and distribution of aquifers, impact layers and aquitards, as well as the occurrence and stability of faults. When the transportation level roadway in the mining roadway-1201 section is 8-12m away from the fault, stop the excavation, and set up 4 one-sequence grouting holes on the side of the fault in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com