A grouting reinforcement technology for underground coal seam floor based on three steps and three speeds

A technology of grouting reinforcement and coal seam floor, which is applied in shaft equipment, wellbore lining, underground chambers, etc., can solve the problem of no grout in drilling holes, so as to ensure safe production, enhance grouting effect, and solve difficult drilling problems The effect of pulp problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

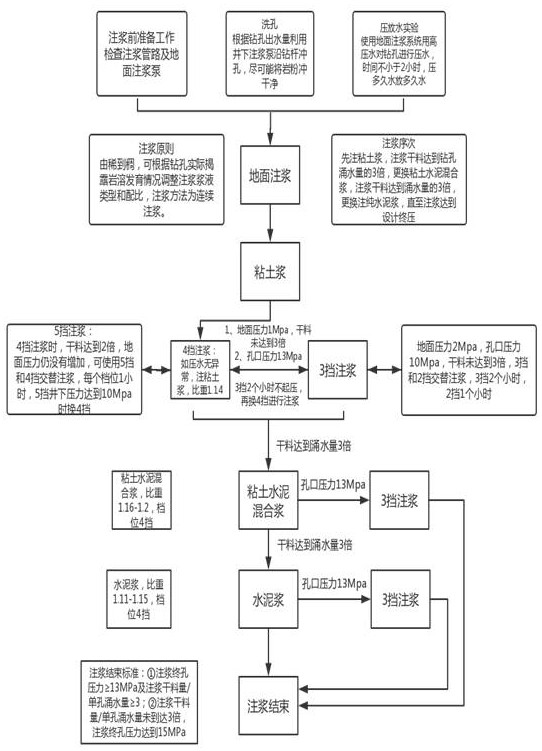

[0018] In order to improve the grouting efficiency and overcome the problem that some boreholes do not eat grout during the grouting process, a "three-step and three-speed" high-efficiency grouting method was proposed through experimental research.

[0019] 1. "Three steps and three speeds" high-efficiency grouting technology

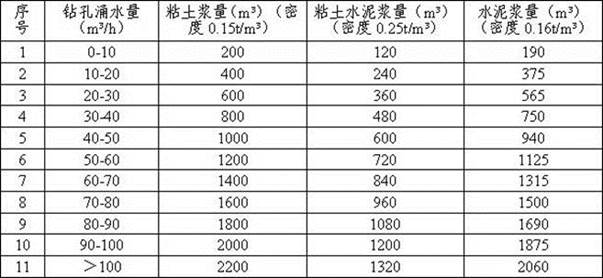

[0020] "Three steps" means that the selection of grouting materials is carried out in three steps. First, clay slurry is selected and injected, followed by clay-cement mixed slurry, and finally the order of grouting is gradually selected. At the top, the clay slurry filling layer, the clay cement mixed slurry reconstruction layer, and the cement slurry reinforcement slurry layer are formed successively to form a three-layer water-resisting layer. The main basis for changing the type of grout is that the amount of dry grouting material for each type of grout reaches three times the water yield of the borehole.

[0021] "Three speeds" means that the flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com