UV ink for glass base material printing and preparation method thereof

A glass substrate and ink technology, used in the field of ink, can solve the problems of ink layer adhesion, boiling resistance, aging resistance, difficult to meet the requirements, UV ink has not been launched, the surface is too smooth and hard, etc., to achieve non-irritating Odor, excellent water resistance, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

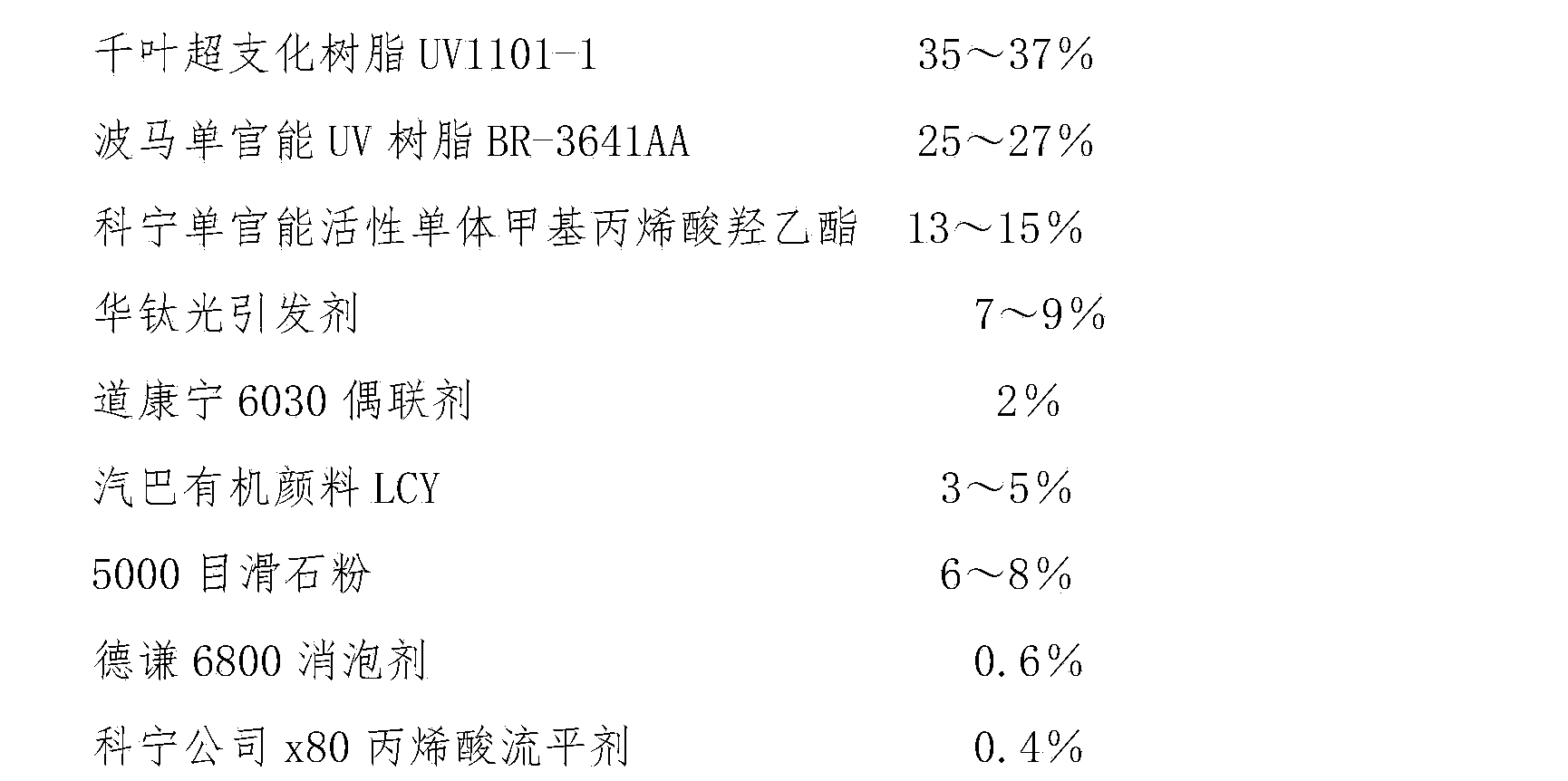

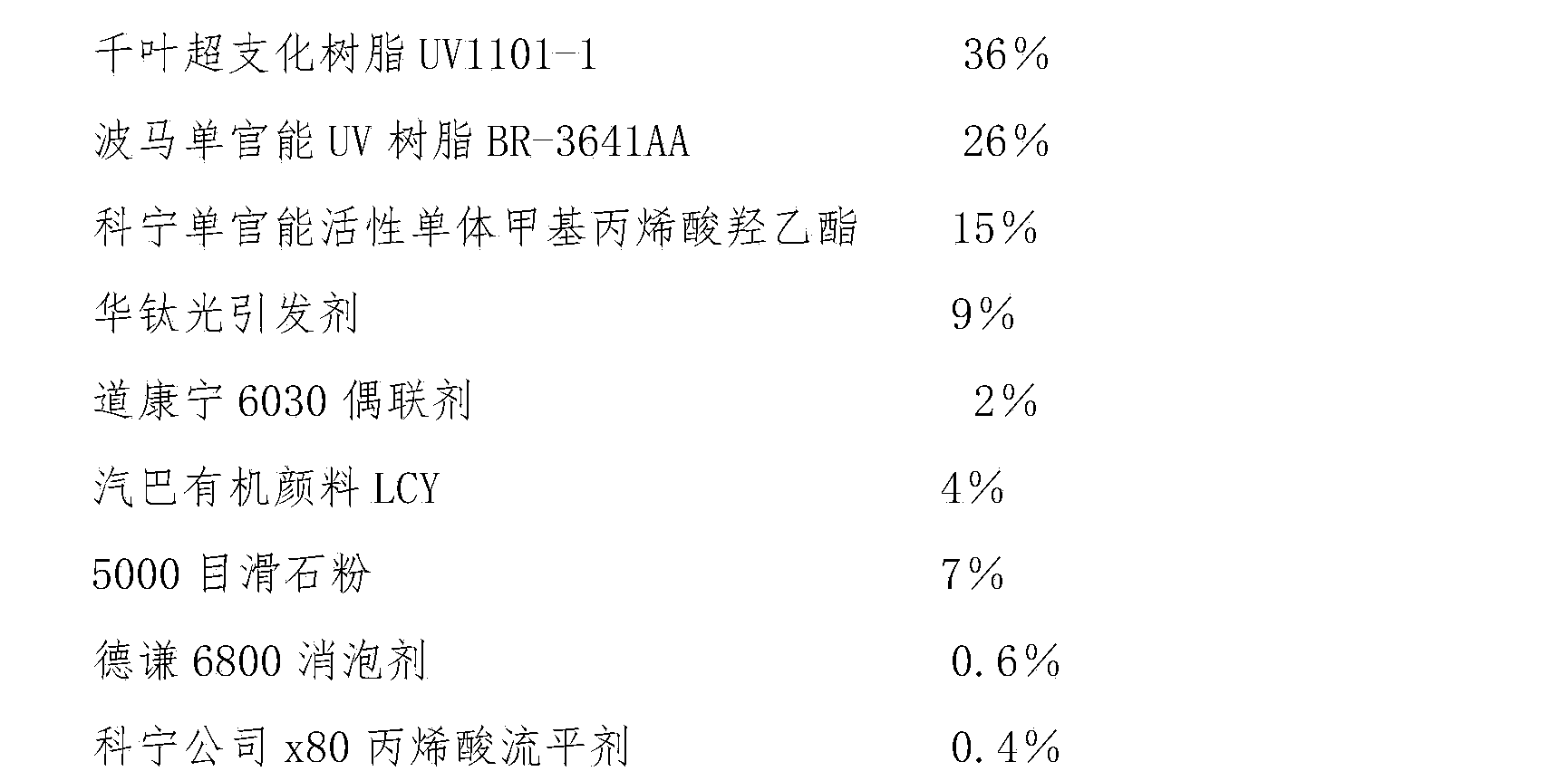

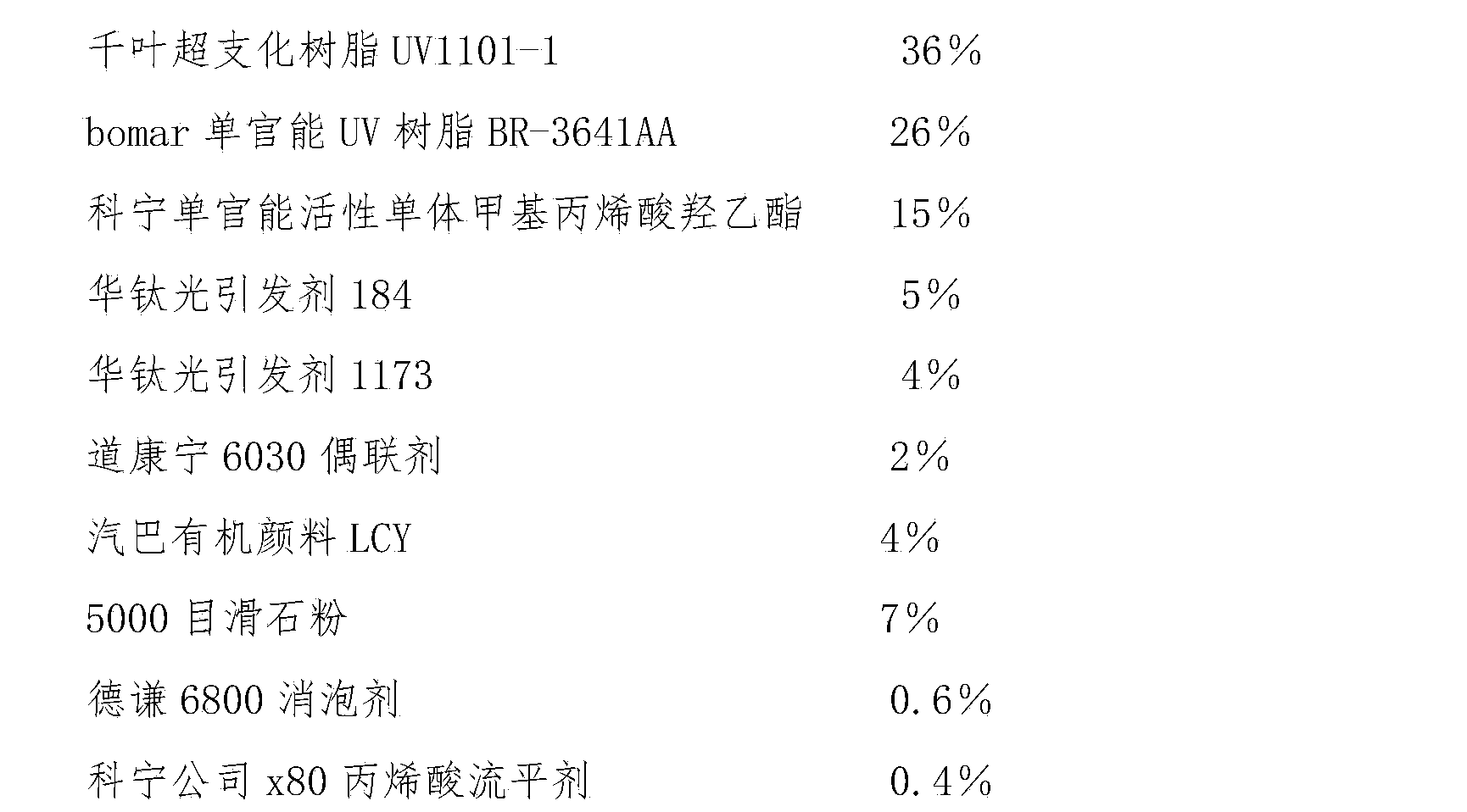

[0028] The raw material ratio is as follows:

[0029]

[0030] The preparation method is as follows:

[0031] First disperse Chiba hyperbranched resin UV1101-1, monofunctional UV resin BR-3641AA, Corning monofunctional reactive monomer hydroxyethyl methacrylate, Dow Corning 6030 coupling agent, and Huati photoinitiator through a high-speed mixer until all Dissolve and prepare semi-finished product A; on the basis of semi-finished product A, add Ciba organic pigment LCY, 5000 mesh talcum powder, Corning x80 acrylic leveling agent, Deqian 6800 defoamer, fully stir until preliminary dispersion, and make semi-finished product B;

[0032] Fully grind the semi-finished product B on a three-roll machine until the ink reaches the specified fineness; the product is packed into cans.

[0033] The performance testing results are shown in Table 1.

[0034] Table 1

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com