Solvent-free ultraviolet curing quaternary ammonium salt resin and preparation method thereof

A technology of ultraviolet light and quaternary ammonium salt, which is applied in the field of solvent-free ultraviolet light curing quaternary ammonium salt type resin and its preparation, can solve the problem of less research on quaternary ammonium salt, achieve good anti-fog performance and improve the efficiency of light curing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

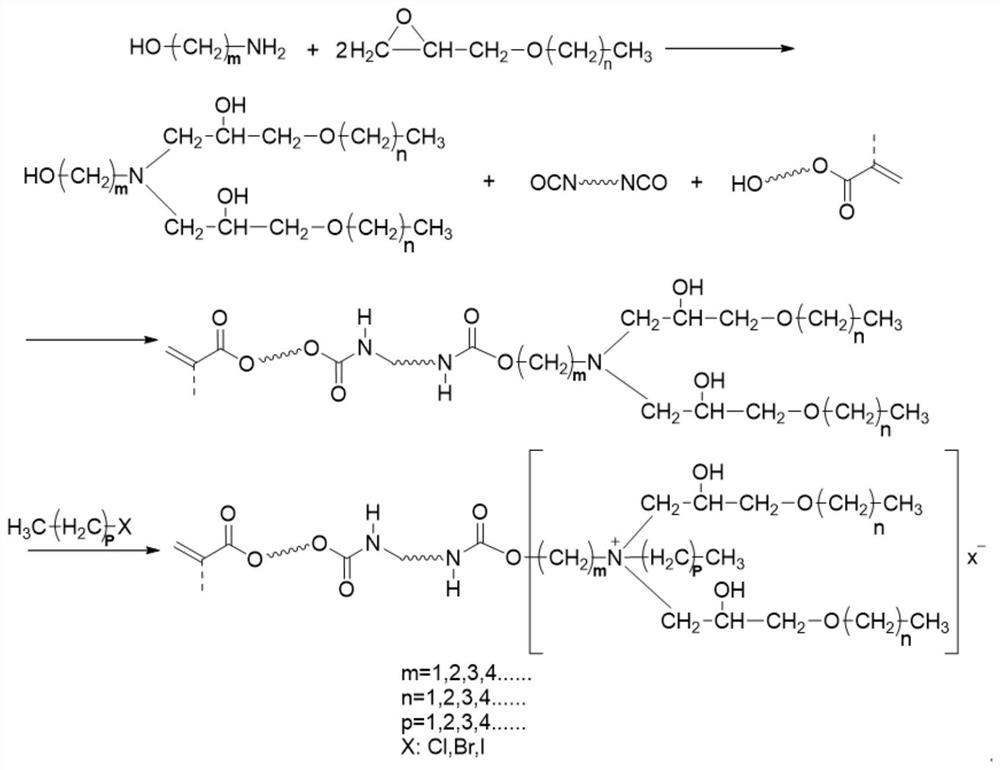

Method used

Image

Examples

Embodiment 1

[0030] (1) At room temperature, add 1.0 mol of ethanolamine into the dry reaction flask, and raise the temperature to 58°C;

[0031] (2) Add 2.0 mol of dodecyl glycidyl ether into the reaction flask in batches, and raise the temperature to 70°C, stir and react for 2 hours, and then lower the reaction solution to room temperature;

[0032] (3) At room temperature, add 1.0mol pentaerythritol triacrylate and 0.2wt% 2,6-p-di-tert-butyl-p-cresol into the reaction flask, then add 1.0mol isophorone diisocyanate and appropriate amount of dilauric acid di The mixed solution of butyltin was added dropwise into the reaction flask, and the temperature was raised to 60°C, and the reaction was stirred until the measured -NCO value was 0.18%;

[0033] (4) Cool down to 40° C., then add 1.0 mol ethyl bromide dropwise into the reaction bottle, keep the temperature and continue the reaction for 1 hour, and finally obtain a solvent-free UV-curable quaternary ammonium salt resin.

Embodiment 2

[0035] (1) At room temperature, add 1.0 mol of ethanolamine into the dry reaction flask, and raise the temperature to 60°C;

[0036] (2) Add 2.0 mol of myristyl glycidyl ether into the reaction flask in batches, and raise the temperature to 70°C, stir and react for 2 hours, and then lower the reaction solution to room temperature;

[0037] (3) At room temperature, add 1.0mol pentaerythritol triacrylate and 0.2wt% 2,6-p-di-tert-butyl-p-cresol into the reaction flask, then add 1.0mol hexamethylene diisocyanate and an appropriate amount of dilauric acid di The mixed solution of butyltin was added dropwise into the reaction flask, and the temperature was raised to 65°C, and the reaction was stirred until the measured -NCO value was 0.20%;

[0038] (4) Cool down to 42° C., then add 1.0 mol ethyl bromide dropwise into the reaction bottle, keep the temperature and continue the reaction for 1 hour, and finally obtain a solvent-free UV-curable quaternary ammonium salt resin.

Embodiment 3

[0040] (1) At room temperature, add 0.5mol ethanolamine into the dry reaction flask, and heat up to 60°C;

[0041] (2) Add 1.0 mol of dodecyl-tetradecyl glycidyl ether into the reaction bottle in batches, and raise the temperature to 70°C, stir and react for 2 hours, and then lower the reaction solution to room temperature;

[0042] (3) At room temperature, add 0.5mol pentaerythritol triacrylate and 0.2wt% 2,6-p-di-tert-butyl-p-cresol into the reaction flask, then add 1.0mol hexamethylene diisocyanate and an appropriate amount of dilauric acid di The mixed solution of butyltin was added dropwise into the reaction flask, and the temperature was raised to 65°C, and the reaction was stirred until the measured -NCO value was 0.15%;

[0043] (4) Lower the temperature to 40° C., then drop 0.5 mol ethyl bromide into the reaction bottle, keep the temperature and continue the reaction for 1 hour, and finally obtain a solvent-free UV-curable quaternary ammonium salt resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com