A fast photocuring nozzle for 3D printing equipment

A 3D printing and light-curing technology, which is applied in coating devices and additive processing, can solve the problems of low light-curing efficiency, difficulty in supporting rapid prototyping, and large volume, and achieve high light-curing efficiency, rapid solidification, and structural small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

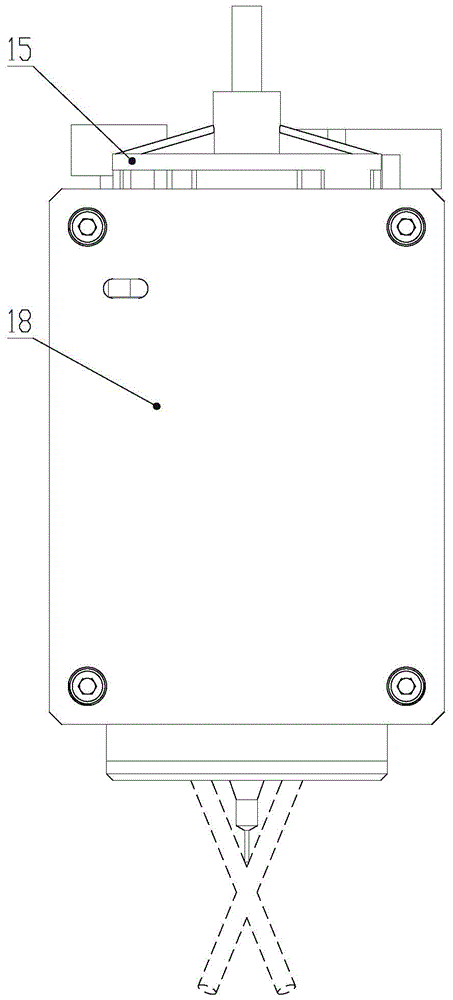

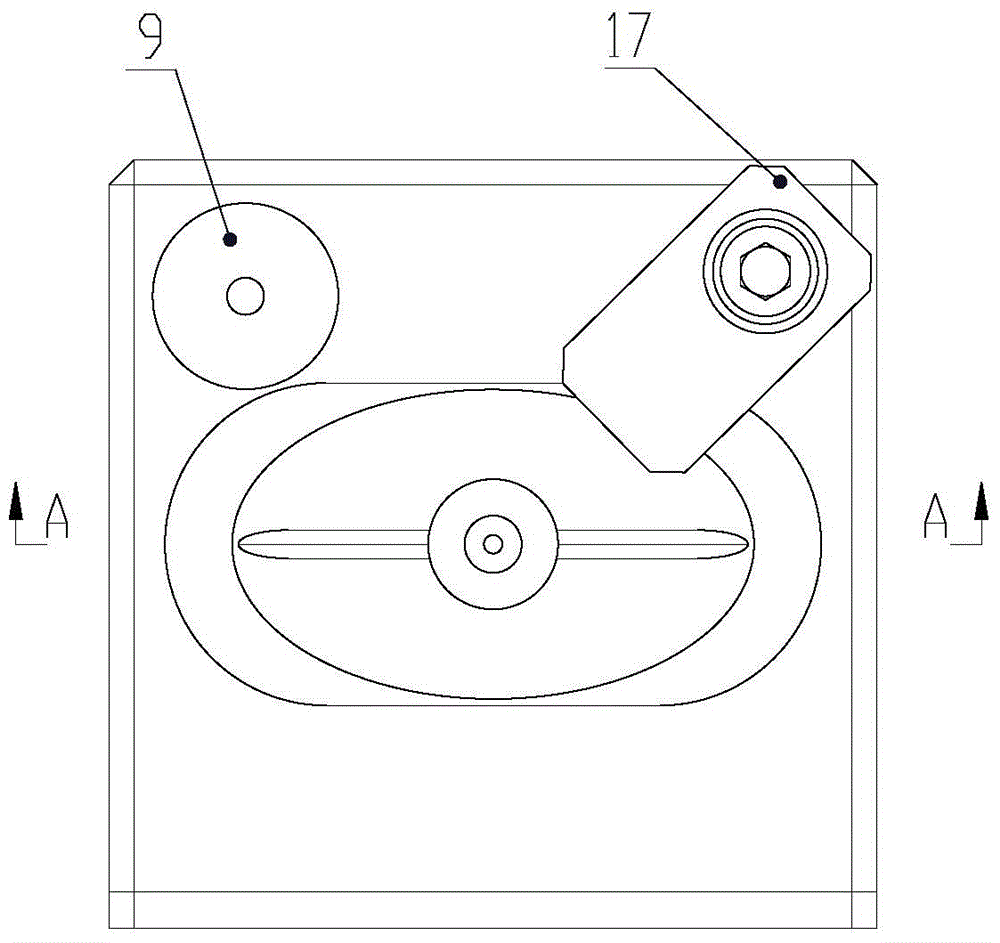

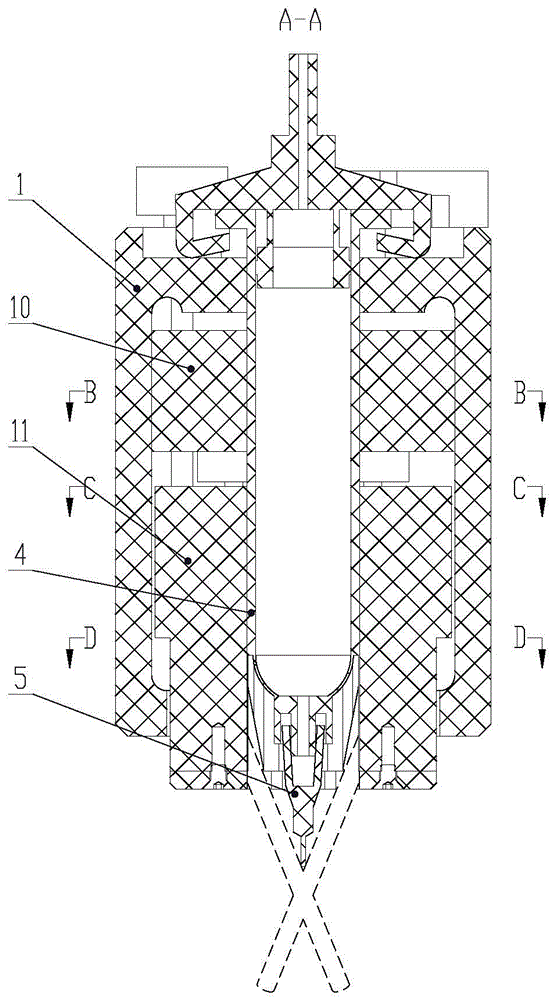

[0027] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

[0028] See Figure 1-10 The intention of this embodiment is to irradiate real-time curing light at the tip of the nozzle under the condition that the nozzle is small in size and high in light curing efficiency. Since the dispensing needle 5 at the tip of the nozzle has different specifications, the length of the dispensing needle 5 of different specifications is different, so the position of the material extrusion will change with the change of the length of the dispensing needle 5, which means four The focal point of the laser beam emitted by the laser point light source 16 after being reflected by the laser reflection lens can change with the change of the length of the dispensing needle 5. In order to achieve the above-mentioned purpose, this embodiment designs three structures of the light curing nozzle housing 1, the barrel part, the point light source part,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com