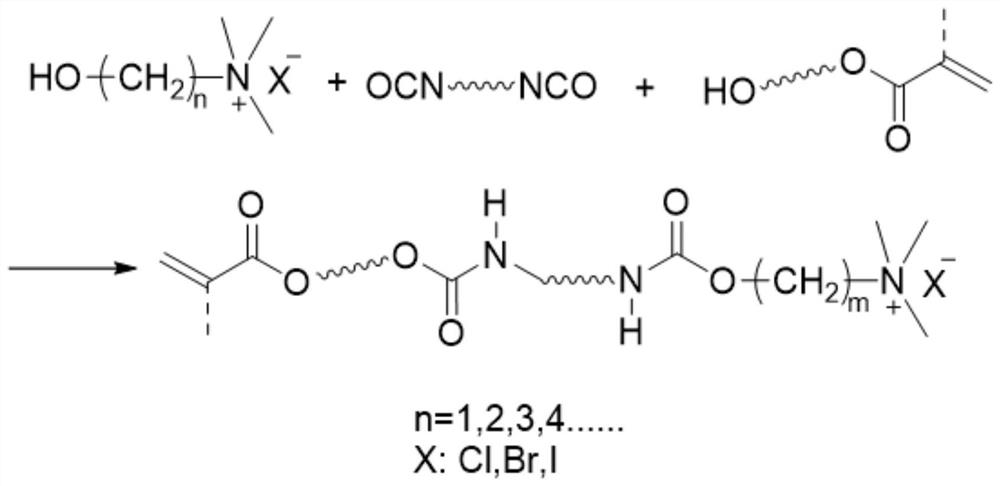

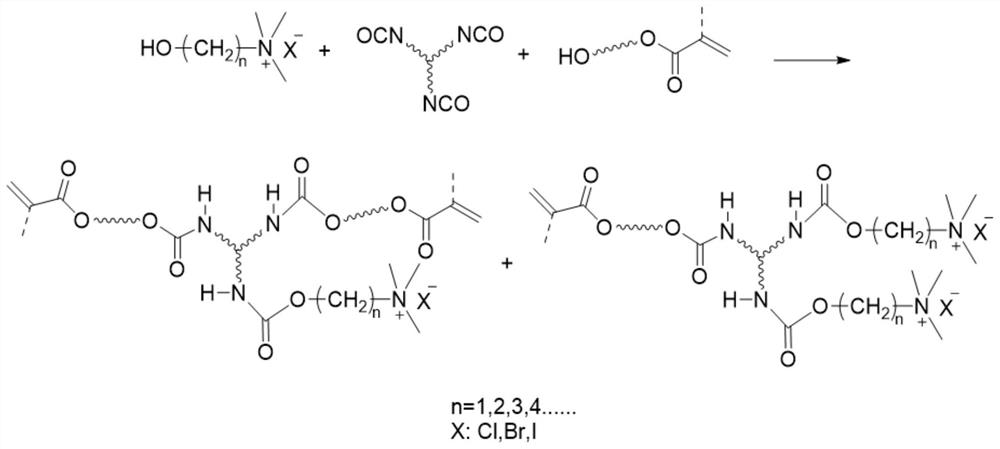

Anti-fogging polyurethane acrylate resin and preparation method thereof

A technology of urethane acrylate and hydroxyl-terminated acrylate, which is applied in the field of anti-fogging urethane acrylate resin and its preparation, can solve problems such as practical application obstacles, time-consuming and labor-intensive, and achieve good anti-fogging performance and simple operation process. , Improve the effect of light curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 1.0mol of isophorone diisocyanate (IPDI), 0.2wt% 2,6-p-di-tert-butyl-p-cresol, 1.0mol of hydroxyethyl acrylate (HEA) and an appropriate amount of N,N-dimethyl Add methyl formamide in the dry reaction bottle, stir and react at room temperature for 30 minutes;

[0026] (2) At room temperature, add 1.0 mol of choline chloride into the reaction flask, heat up to 60°C, and stir for 30 minutes;

[0027] (3) Add an appropriate amount of dibutyltin dilaurate into the reaction flask, heat up to 80° C., stir and react until the measured -NCO value is 0.19%, to obtain quaternary ammonium chloride urethane acrylate resin.

Embodiment 2

[0029] (1) Add more than 1.0mol hexamethylene diisocyanate (HDI), 0.2wt% 2,6-p-di-tert-butyl-p-cresol, 1.0mol hydroxyethyl acrylate (HEA) and appropriate amount of N,N-dimethyl Add methyl formamide in the dry reaction bottle, stir and react at room temperature for 30 minutes;

[0030] (2) At room temperature, add 1.0 mol of choline chloride into the reaction flask, heat up to 60°C, and stir for 30 minutes;

[0031] (3) Then add an appropriate amount of dibutyltin dilaurate into the reaction flask, and raise the temperature to 80° C., stir the reaction until the measured -NCO value is 0.15%, and obtain the quaternary ammonium chloride urethane acrylate resin.

Embodiment 3

[0033] (1) Add 0.6mol hexamethylene diisocyanate (HDI), 0.2wt% 2,6-p-di-tert-butyl-p-cresol, 0.6mol polycaprolactone acrylate (CA) and appropriate amount of N,N- Dimethylacetamide was added into a dry reaction flask, and stirred and reacted at room temperature for 30 minutes;

[0034] (2) At room temperature, add 0.6mol choline chloride into the reaction flask, and heat up to 60°C, and stir for 30 minutes;

[0035] (3) Add an appropriate amount of dibutyltin dilaurate into the reaction flask, heat up to 80° C., stir and react until the measured -NCO value is 0.18%, to obtain quaternary ammonium chloride urethane acrylate resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com