Naphthalimide aryl sulfide type photoinitiator suitable for uv-led light curing, preparation method and application

A naphthalimide aryl sulfide and UV-LED technology, which is applied in the field of photosensitive polymers, can solve the problems of poor initiation performance of photoinitiators, and achieve the effects of prolonged ultraviolet absorption wavelength and high photocuring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Photoinitiator NAS1 has the following structural formula:

[0035]

[0036] Its preparation method comprises the following steps:

[0037] (a) 4-bromo-1,8-naphthalic anhydride (7.20g, 0.026mol), p-toluidine (27.86g, 0.26mol) and 100mL acetic acid were added to a 250mL single-necked flask, under nitrogen protection, Raise the temperature to 120°C and stir at constant temperature for 24 hours; after the reaction, the reaction solution was cooled to room temperature, the reaction solution was poured into 1000 mL of ice water, filtered, the filter cake was washed with deionized water for 3 times, and the crude product was obtained after vacuum drying. The crude product was recrystallized with acetic acid to obtain an intermediate product named MPNB;

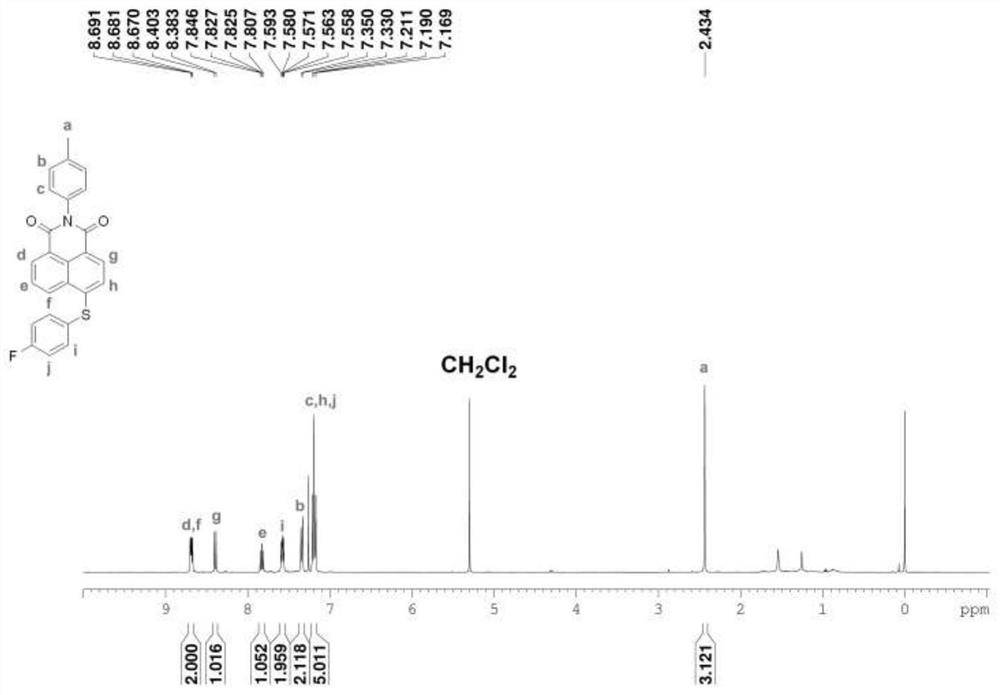

[0038] (b) The intermediate product MPNB (732mg, 2mmol), iodobenzene (408mg, 2mmol), potassium thioacetate (228mg, 2mmol), bis(dibenzylideneacetone) palladium (115mg, 0.2mmol), 1,1 '-Bis(diphenylphosphino)ferrocene (155mg...

Embodiment 2

[0042] Photoinitiator NAS2 has the following structural formula:

[0043]

[0044] Its preparation method comprises the following steps:

[0045]The intermediate product MPNB (732mg, 2mmol) synthesized in Example 1, p-iodoacetophenone (492mg, 2mmol), potassium thioacetate (228mg, 2mmol), bis(dibenzylideneacetone) palladium (115mg, 0.2 mmol), 1,1'-bis(diphenylphosphino)ferrocene (155mg, 0.28mmol), anhydrous tripotassium phosphate (1.02g, 4.8mmol), 4mL toluene and 2mL acetone were added to a 25mL three-necked flask, Under the protection of nitrogen, the temperature was raised to 70° C., stirred at a constant temperature for 3 hours, and then the temperature was raised to 110° C., and stirred at a constant temperature for 12 hours. After the reaction was completed, the reaction solution was cooled to room temperature, the reaction solution was poured into 10 mL of saturated ammonium chloride aqueous solution, extracted 3 times with dichloromethane, the organic layers were com...

Embodiment 3

[0049] Photoinitiator NAS3 has the following structural formula:

[0050]

[0051] Its preparation method comprises the following steps:

[0052] The intermediate product MPNB (732mg, 2mmol) synthesized in Example 1, p-nitroiodobenzene (498mg, 2mmol), potassium thioacetate (228mg, 2mmol), bis(dibenzylideneacetone) palladium (115mg, 0.2 mmol), 1,1'-bis(diphenylphosphino)ferrocene (155mg, 0.28mmol), anhydrous tripotassium phosphate (1.02g, 4.8mmol), 4mL toluene and 2mL acetone were added to a 25mL three-necked flask, Under the protection of nitrogen, the temperature was raised to 70° C., stirred at a constant temperature for 3 hours, and then the temperature was raised to 110° C., and stirred at a constant temperature for 12 hours. After the reaction was completed, the reaction solution was cooled to room temperature, the reaction solution was poured into 10 mL of saturated ammonium chloride aqueous solution, extracted 3 times with dichloromethane, the organic layers were co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com