Preparation method and application of ultraviolet-curable acrylic copolymer

A technology of copolymer and acrylic acid, which is applied in the field of pressure-sensitive adhesives, can solve the problems of high cost, high cost, and restrictions on commercial production, and achieve the effect of accelerated reaction rate and high photocuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

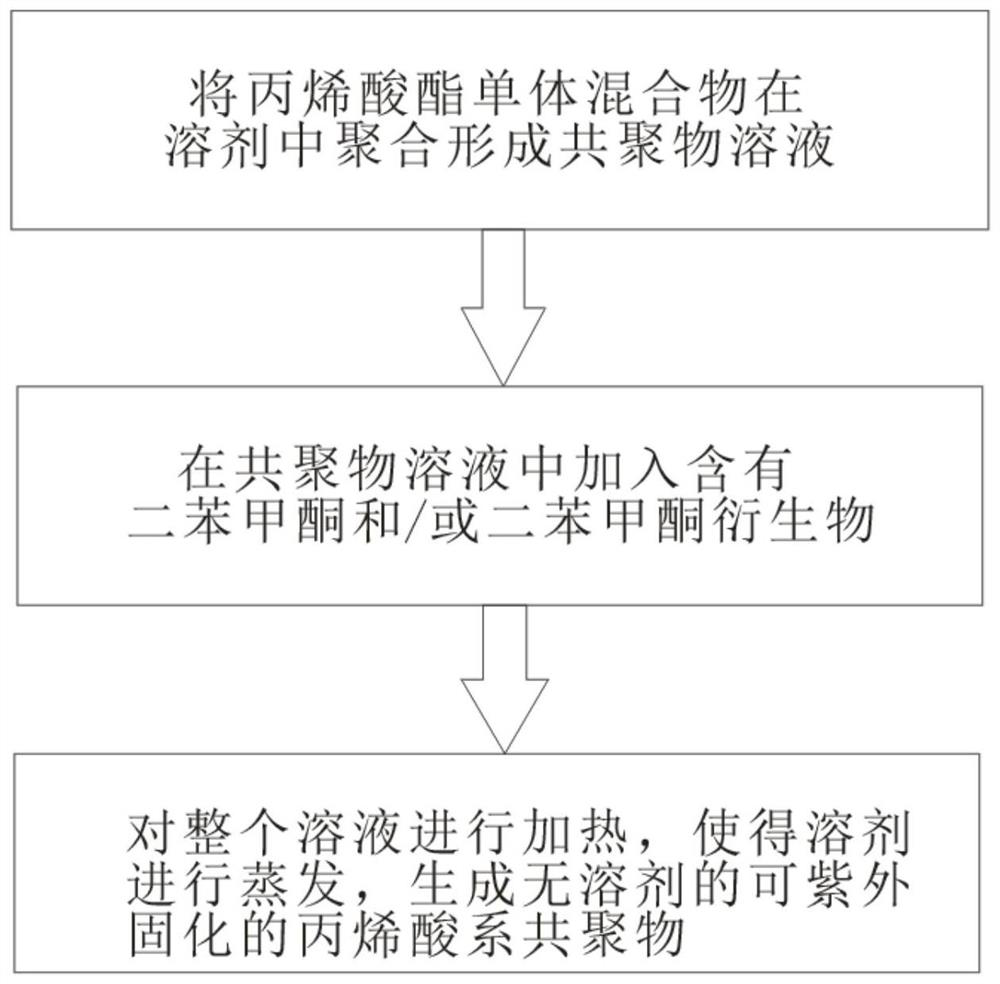

[0024] see figure 1 , the application discloses a preparation method of an ultraviolet-curable acrylic copolymer, comprising the following steps: S1: polymerizing the acrylate monomer mixture in a solvent to form a copolymer solution; S2: adding two Benzophenone and / or benzophenone derivatives; S3: the entire solution is heated to evaporate the solvent to generate a solvent-free UV-curable acrylic copolymer.

[0025] The monomer mixture comprises: 70-95 parts by weight of the molecular formula CH 2 Acrylic or methacrylate monomers of -CH(R1)(C00R2), where R1 is H or CH 3 , R2 is an alkyl group containing 1-20 carbons. The monomer mixture can also be 0.1 to 30 parts by weight of (meth)acrylic acid or vinyl functional monomers, and the functional groups contained in the functional monomers include carboxyl, hydroxyl, anhydride, amine, amide one or more of epoxy, isocyanate or isocyanate groups.

[0026] The reactive group contained in the benzophenone derivative includes one...

Embodiment 1

[0032] Weigh the ingredients according to the table below

[0033] components Weight / grams) (2-Ethylhexyl) Acrylate 100 Methyl acrylate 10 acrylic acid 70 vinyl acetate 30 2-Hydroxyethyl Acrylate 10 n-butyl acrylate 780 AIBN initiator 4

[0034] 500 grams of the monomer mixture and 500 grams of ethyl acetate solvent were transferred to a 3 liter jacketed reactor. The reactor contents were heated to reflux temperature (approximately 80° C.) under nitrogen purge and stirring. After maintaining reflux for about 15 minutes, the remaining monomer mixture and 300 g of ethyl acetate solvent were added to the reactor via the dropping funnel, and the dropping time was 3 hours. After the dropwise addition was completed, the reaction was continued at reflux temperature for 4 hours to ensure that all residual AIBN was reacted. At this point, 3 grams of 4-aminobenzophenone was added to the reactor and slowly heated to about 160°...

Embodiment 2

[0036] According to the weighing of each material in Example 1, 500 g of monomer mixture and 500 g of ethyl acetate solvent were transferred to a 3-liter jacketed reactor. The reactor contents were heated to reflux temperature (approximately 80° C.) under nitrogen purge and stirring. After maintaining reflux for about 15 minutes, the remaining monomer mixture and 300 g of ethyl acetate solvent were added to the reactor via the dropping funnel, and the dropping time was 3 hours. After the dropwise addition was completed, the reaction was continued at reflux temperature for 4 hours to ensure that all residual AIBN was reacted. And slowly heated to about 160 ° C, most of the solvent and other organic volatiles are devolatilized. Then the reactor was evacuated at this temperature, and the remaining organic volatiles were continuously devolatilized until the residual organic volatiles content in the copolymer sample was less than 0.5%. The melt viscosity of the copolymer sample at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com