Radiation-curable benzophenone-terminated polyurethane resin and application thereof

A technology of polyurethane resin and benzophenone, applied in the field of new polymer materials, can solve the problems of high odor, excessive coating curing and high VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0056] The synthesis of embodiment 1 benzophenone-terminated polyurethane oligomer / polymer

[0057] To a 3-liter round bottom flask, add 62.5 g of diphenylmethane 4,4'-diisocyanate (MDI) and 0.4 g of dibutyltin dilaurate, 11.5 g of 4-(2-hydroxyepoxy) diisocyanate Benzophenone, mixture with 0.01 g p-methoxyphenol. After heating to 80° C. under moderate stirring, a mixed solution of 600 g of toluene and 878 g of hydrogenated polybutadiene-type bifunctional polyol (L-2203, Kraton Polymer) was slowly added. After the addition was complete, it was further heated to 100° C. and kept stirring at this temperature for 3 hours until the level of isocyanate (NCO) was below 0.1%. The molecular weight and polydispersity of the benzophenone-terminated polyurethane polymers of this example were determined by conventional gel permeation chromatography (GPC) methods. It has a number average molecular weight of 34000 and a polydispersity of 2.95.

[0058] The sample of this example is coated...

Embodiment 2

[0059] The synthesis of embodiment 2 acrylic acid terminated polyurethane oligomers / polymers

[0060] To a 3-liter round-bottom flask, add 62.5 g of diphenylmethane 4,4'-diisocyanate (MDI) and 0.8 g of dibutyltin dilaurate, 5.8 g of 2-hydroxyethyl acrylate, and 0.1 g p-Methoxyphenol mixture. After heating to 80° C. under moderate stirring, a mixed solution of 600 g of toluene and 878 g of hydrogenated polybutadiene-type bifunctional polyol (L-2203, Kraton Polymer) was slowly added. After the addition was complete, it was further heated to 90° C. and kept stirring at this temperature for 3 hours until the level of isocyanate (NCO) was below 0.1%. Lower the temperature to 80 °C, then weigh 5 g of TPO (photoinitiator) into a 3 L round bottom flask, and continue stirring at this temperature for 1 hour. The molecular weight and polydispersity of the acrylic-terminated polyurethane polymers of this example were determined by conventional gel permeation chromatography (GPC) methods...

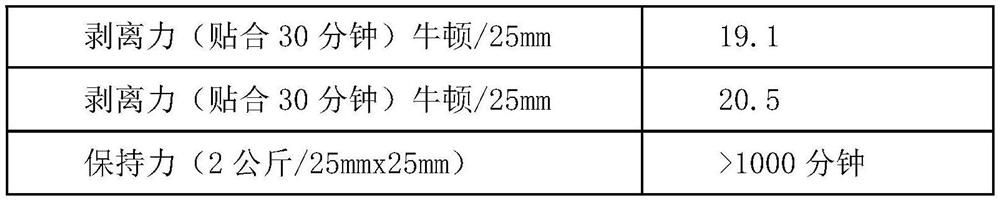

Embodiment 3

[0062] Example 3 Preparation of solvent-based pressure-sensitive adhesive based on benzophenone-terminated polyurethane polymer

[0063] To a 3-liter round bottom flask, add 62.5 g of diphenylmethane 4,4'-diisocyanate (MDI) and 0.4 g of dibutyltin dilaurate, 11.5 g of 4-(2-hydroxyepoxy)benzidine Ketone, mixture with 0.01 g p-methoxyphenol. After heating to 80° C. under moderate stirring, a mixed solution of 600 g of toluene and 878 g of hydrogenated polybutadiene-type bifunctional polyol (L-2203, Kraton Polymer) was slowly added. After the addition was complete, it was further heated to 100° C. and kept stirring at this temperature for 3 hours until the level of isocyanate (NCO) was below 0.1%. Lower the temperature to 80°C, then weigh (solid tackifier resin), (liquid tackifying resin), 40g HDODA (1,6-hexanediol diacrylate), and 1gTPO (photoinitiator) into a 3L round bottom flask, and continue stirring at this temperature for 1 hour.

[0064] The sample of this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com