Patents

Literature

31results about How to "Improve Surface Curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

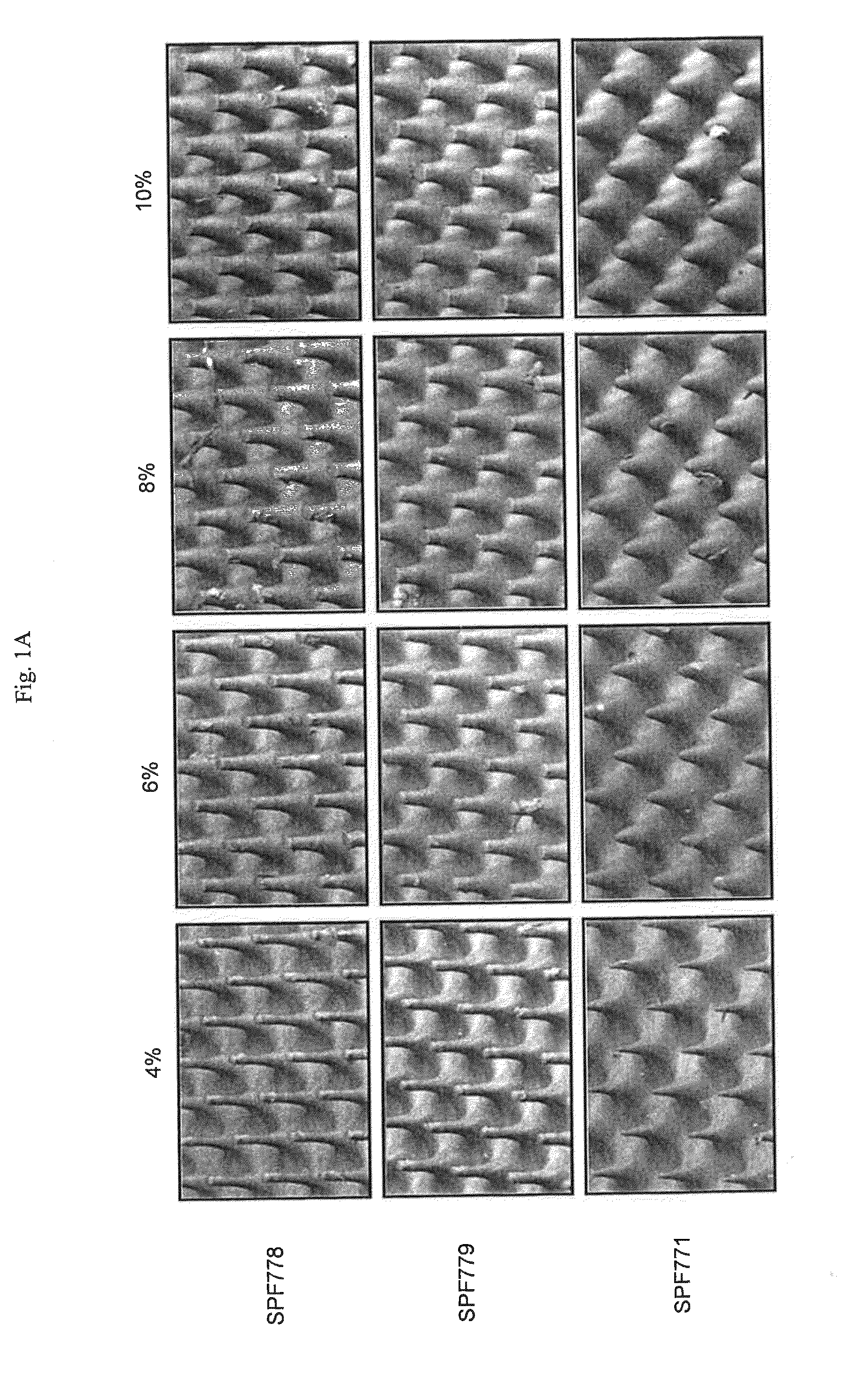

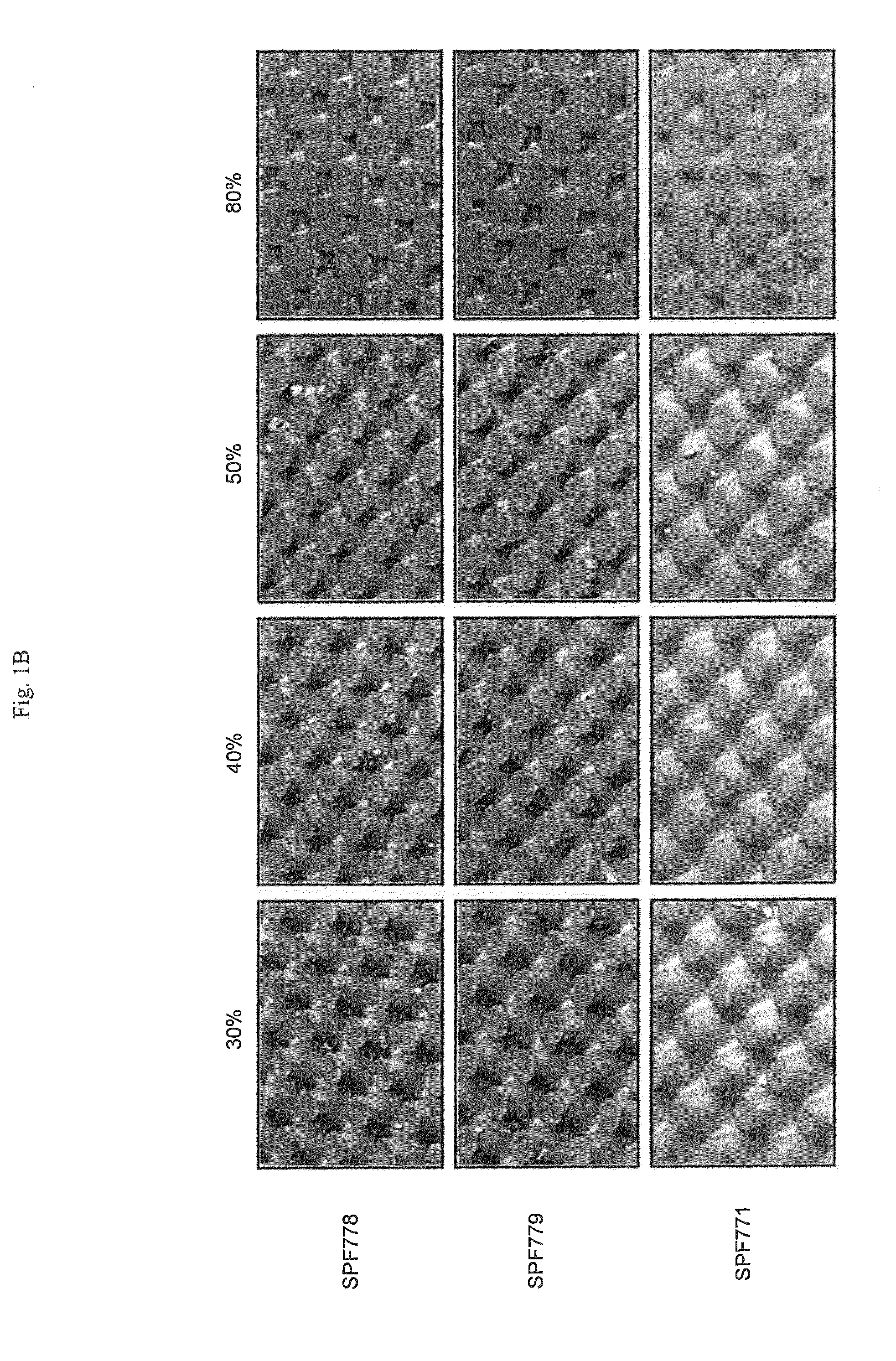

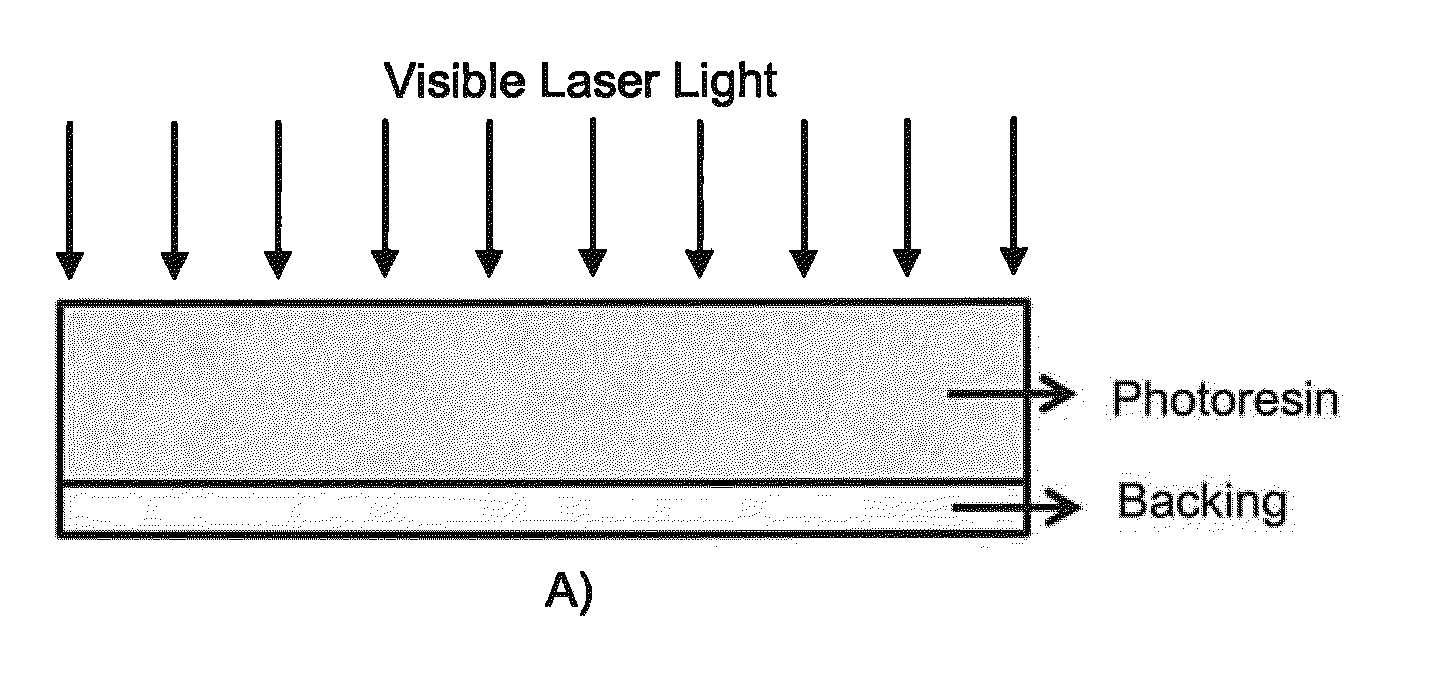

Method of improving surface cure in digital flexographic printing plates

ActiveUS8808968B2Improve Surface CuringSimple working processPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer sciencePhosphite ester

Owner:MACDERMID PRINTING SOLUTIONS

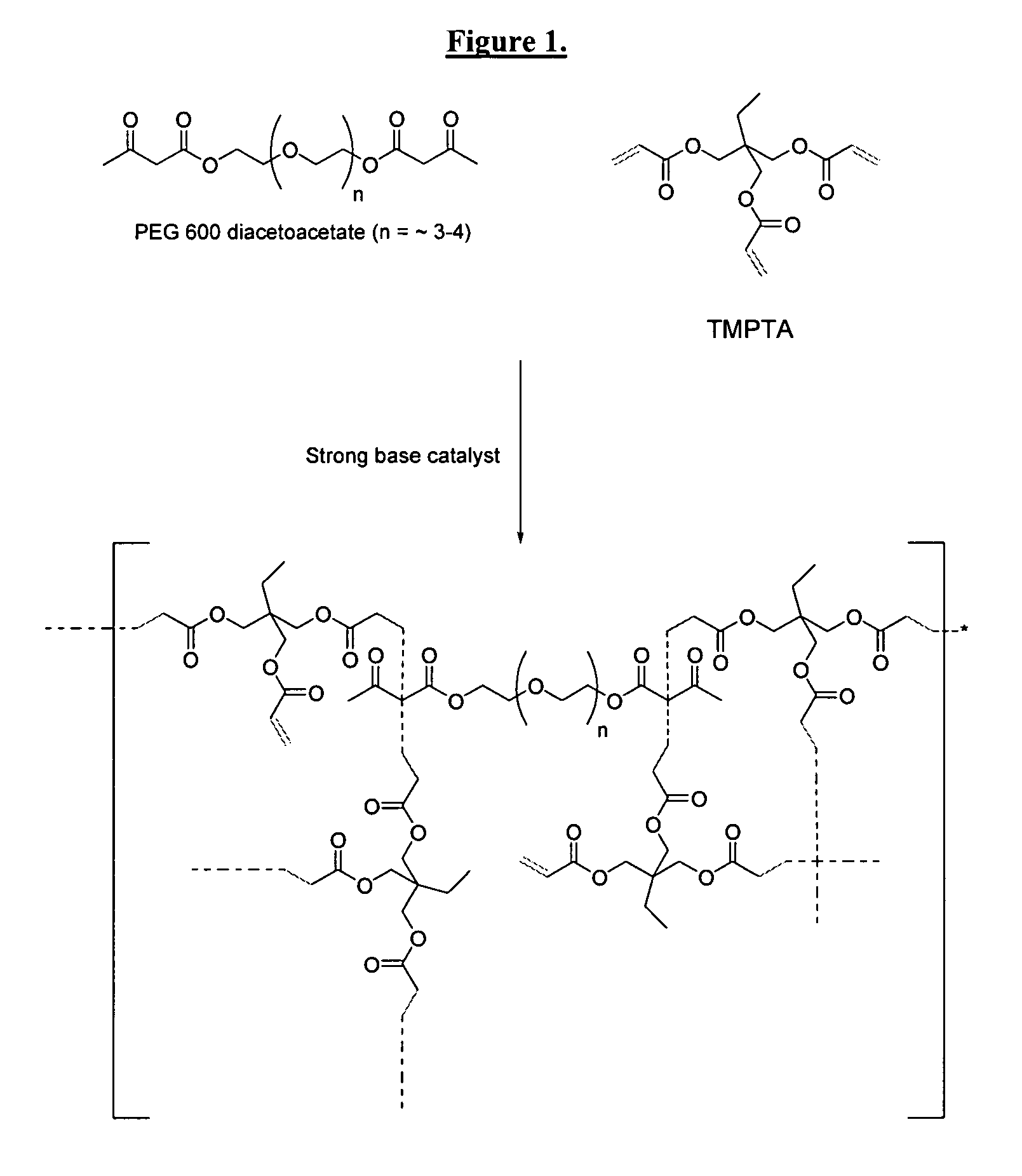

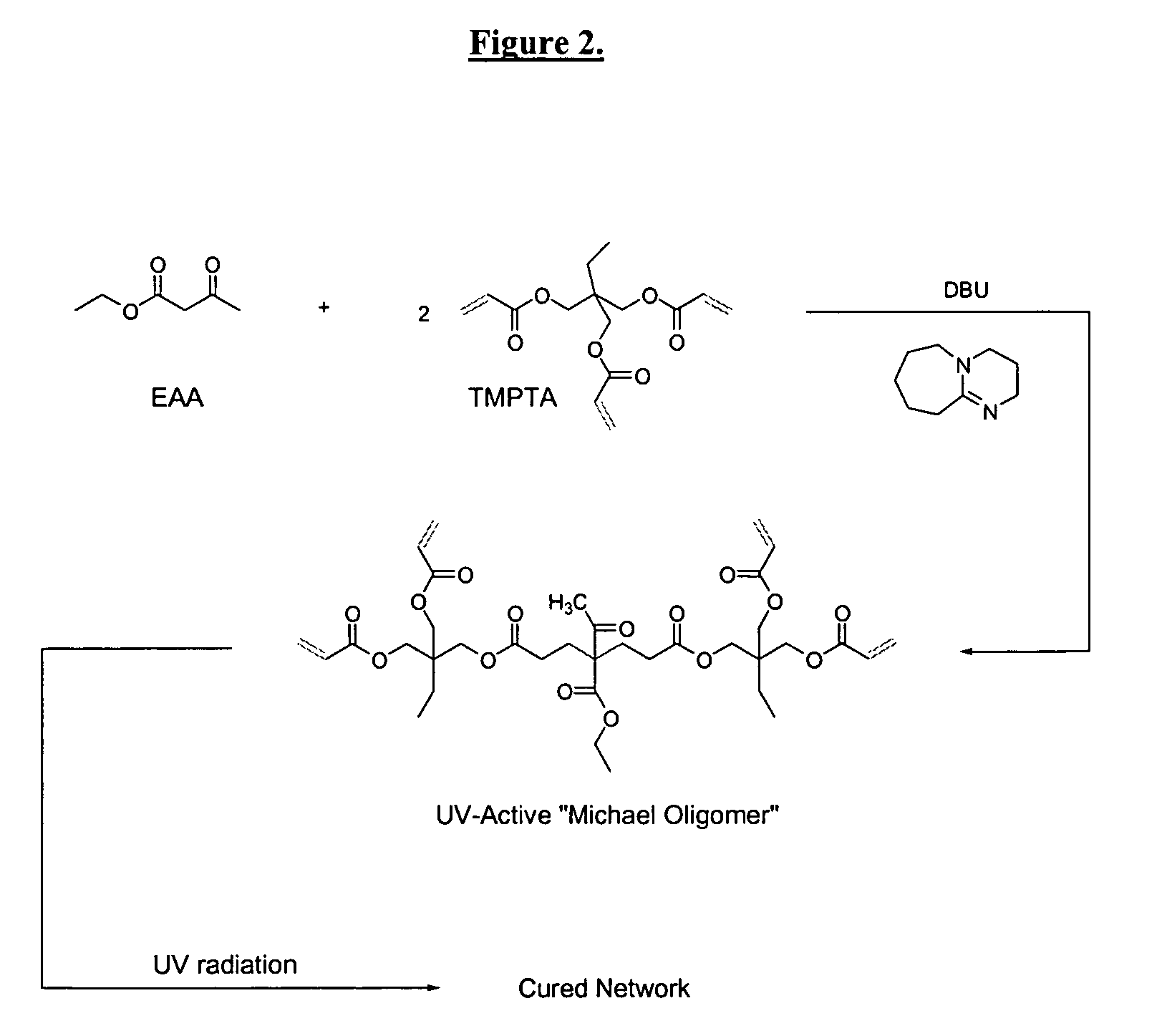

Dual cure reaction products of self-photoinitiating multifunction acrylates with cycloaliphatic epoxy compounds

ActiveUS20040115437A1Improve Surface CuringImprove adhesionHybrid capacitor electrolytesSolid electrolytic capacitorsDual cureDiketone

Owner:INEOS COMPOSITES IP LLC

Dual cure reaction products of self-photoinitiating multifunctional acrylates with thiols and synthetic methods

ActiveUS7169825B2Improve Surface CuringImprove adhesionMixing methodsGlass/slag layered productsDual cureThiol

Owner:ARKEMA FRANCE SA

Dental coating kit

InactiveUS20060078510A1Improve Surface CuringIncrease opaque propertyCosmetic preparationsImpression capsBleaching toothPolymer chemistry

The invention provides a dental coating kit with high adhesiveness to teeth that contains a primer composition including an acidic group-containing polymeric monomer (a), water (b) and a water-soluble solvent (c) and a surface smoothing composition including a polyfunctional polymeric monomer (f), a volatile solvent (g) and a photopolymerization initiator (h); and a dental coating kit with high adhesiveness to teeth and minimally suffering from chipping and peeling off that contains a primer composition including an acidic group-containing polymeric monomer (a), water (b) and a water-soluble solvent (c), a coating composition including a polymeric monomer (d) and a photopolymerization initiator (e), and a surface smoothing composition including a polyfunctional polymeric monomer (f), a volatile solvent (g) and a photopolymerization initiator (h). Either dental coating kit is particularly useful as a kit for preventing stain and color return of a bleached tooth.

Owner:KURARAY NORITAKE DENTAL

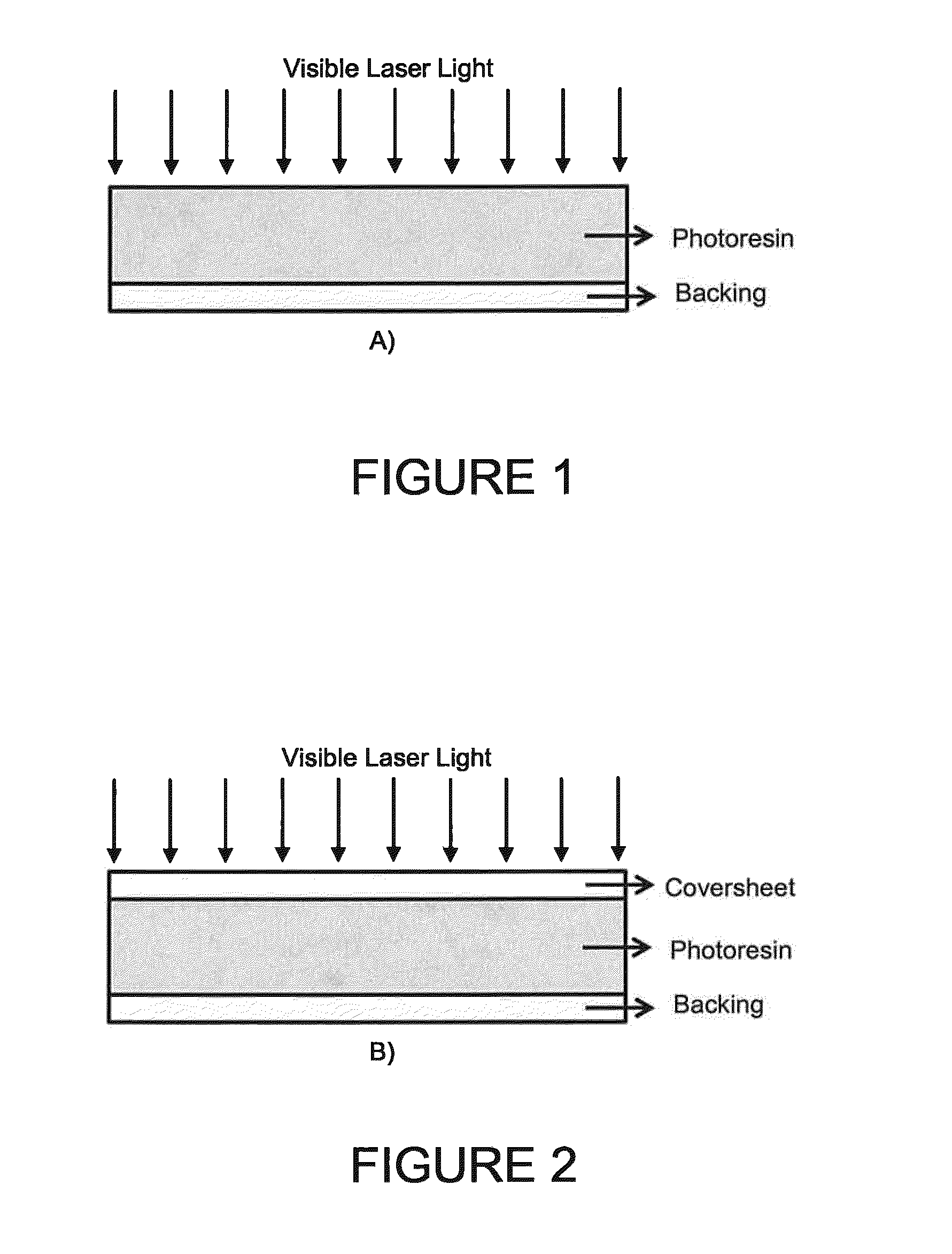

Method of Improving Surface Cure in Digital Flexographic Printing Plates

ActiveUS20140057205A1Improve Surface CuringSimple working processPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundMedicine

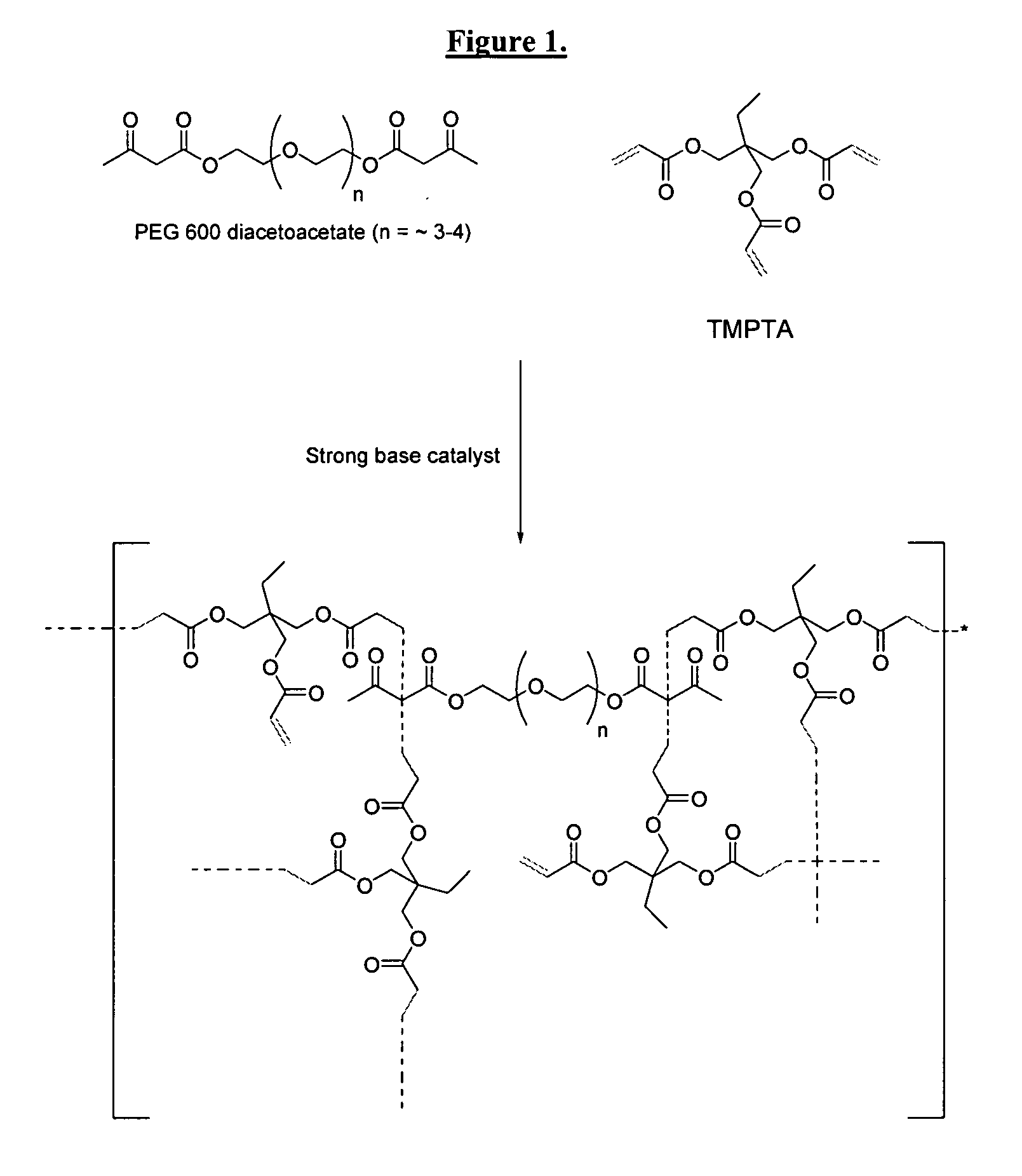

A photocurable relief image printing element is described. The photocurable relief image printing element comprises (a) a support layer; (b) one or more photocurable layers disposed on the support layer, wherein the one or more photocurable layers comprise: (i) a binder; (ii) one or more monomers; (iii) a photoinitiator; and (iv) an additive selected from the group consisting of phosphites, phosphines, thioether amine compounds, and combinations of one or more of the foregoing; (c) a laser ablatable masking layer disposed on the one or more photocurable layers, the laser ablatable masking layer comprising a radiation opaque material; and (d) optionally, a removable coversheet. The photocurable relief image printing element provides improved surface cure in digital relief image printing elements.

Owner:MACDERMID PRINTING SOLUTIONS

Dual cure reaction products of self-photoinitiating multifunction acrylates with cycloaliphatic epoxy compounds

ActiveUS7041749B2Improve Surface CuringImprove adhesionHybrid capacitor electrolytesSolid electrolytic capacitorsDual cureALLYL SUCROSE

Owner:INEOS COMPOSITES IP LLC

Tetraalkylammonium carboxylate salts as trimerization catalysts for spray foam applications

InactiveCN101323659AAcupressure dry time is goodAcupressure dry time is shortPolyisocyanurateCarboxylic acid

The invention relates to tetraalkylammonium carboxylate salts as trimerization catalysts for spray foam applications. The present invention provides a method to produce a polyisocyanurate / polyurethane spray foam using a trimerization catalyst composition having tetraalkylammonium salt of a sterically hindered carboxylic acid or an alpha, belta-unsaturated carboxylic acid.

Owner:AIR PROD & CHEM INC

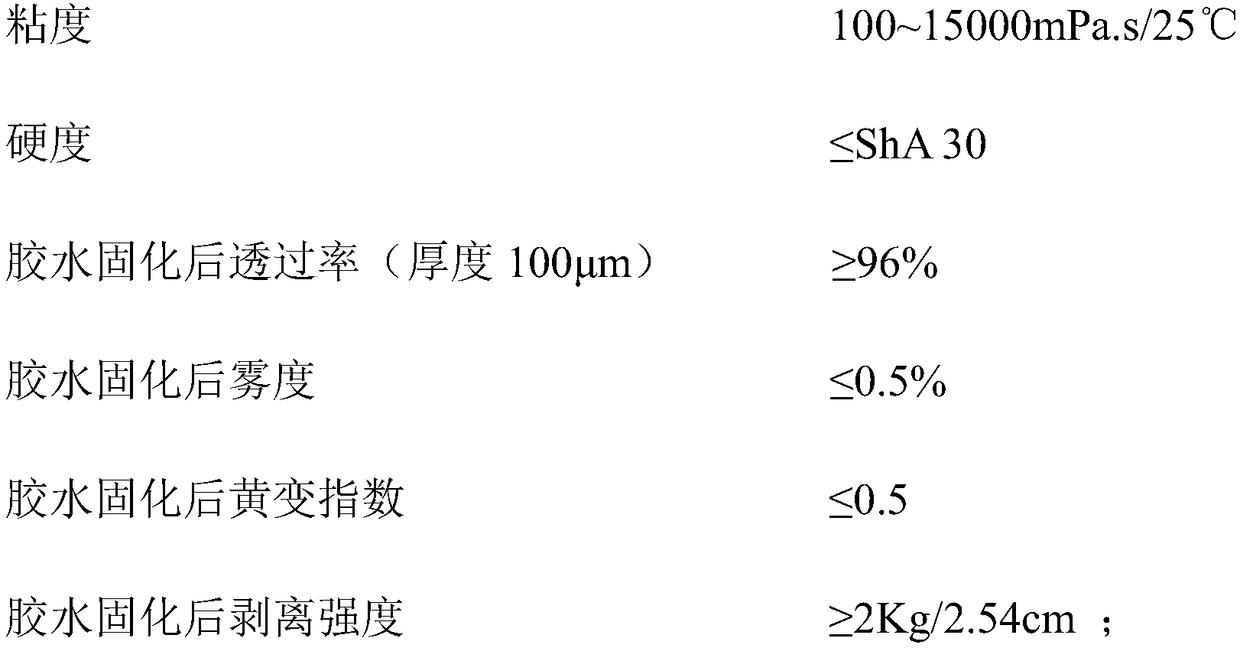

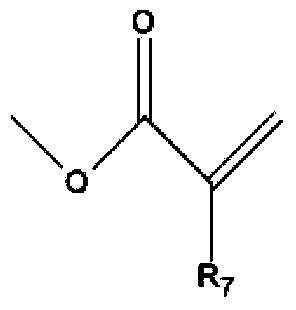

UV semi-curing OCA (optical clear adhesive) and use thereof

InactiveCN108977160AGood optical performanceSmall yellowing indexPolyureas/polyurethane adhesivesAdhesiveAntioxidant

The invention relates to a UV-curing adhesive composition. Based on 100 parts by weight of the adhesive composition, the composition mainly comprises a component A, namely 30-70 parts of one or more of polyurethane (methyl) acrylate polymers, a component B, namely 15-50 parts of one or more of monofunctional acrylate monomers which at least include a soft monomer with the glass transition temperature lower than 20 DEG C, a component C, namely 2-20 parts of one or more of hydroxy-containing functional (methyl) acrylate monomers, a component D, namely 0.02-1.0 part of a foaming agent, a component E, namely 0.3-5 parts of two or more of pyrolytic photoinitiators, and a component F, namely 0.10-3.0 parts of an antioxidant. One or more of difunctional or trifunctional acrylate monomers can be added into the composition as a crosslinking agent, plasticizer or silane coupling agent according to needs so as to improve the release force and cohesive force of glue, and the composition can be used in preparation of a UV semi-curing (secondary curing) optical film.

Owner:江苏科琪高分子材料研究院有限公司

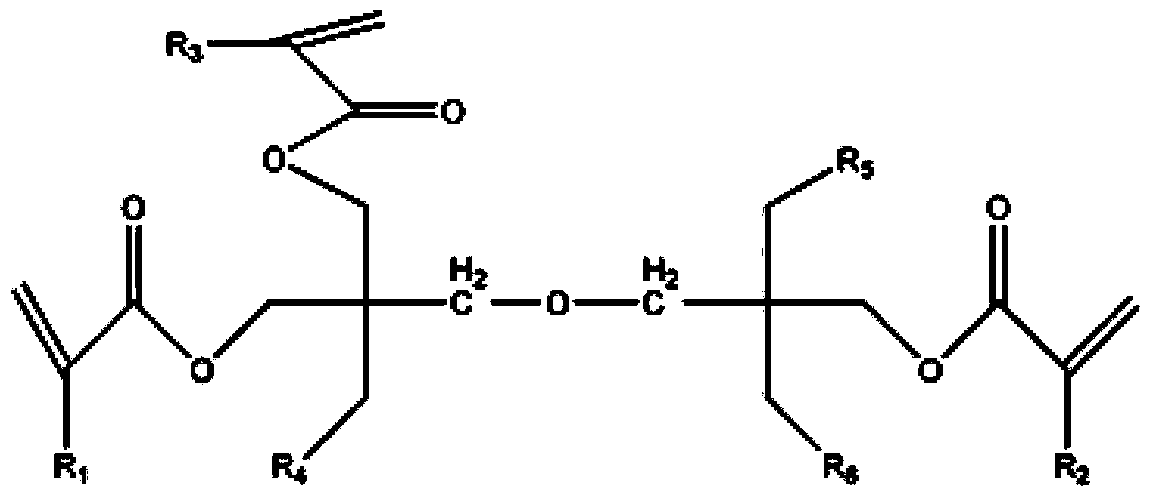

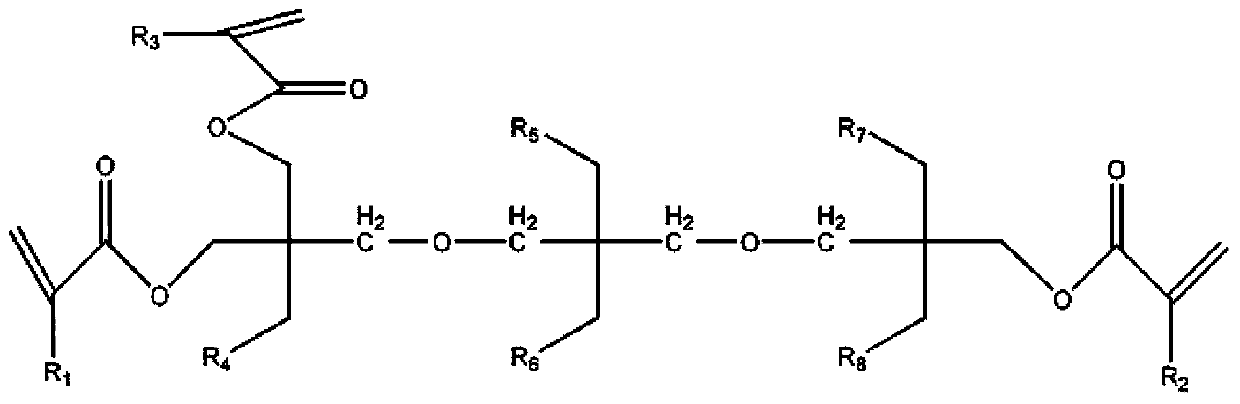

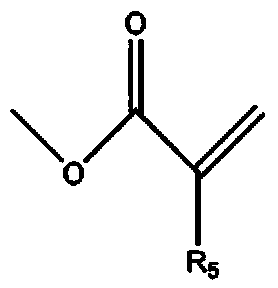

Low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate and preparation method thereof

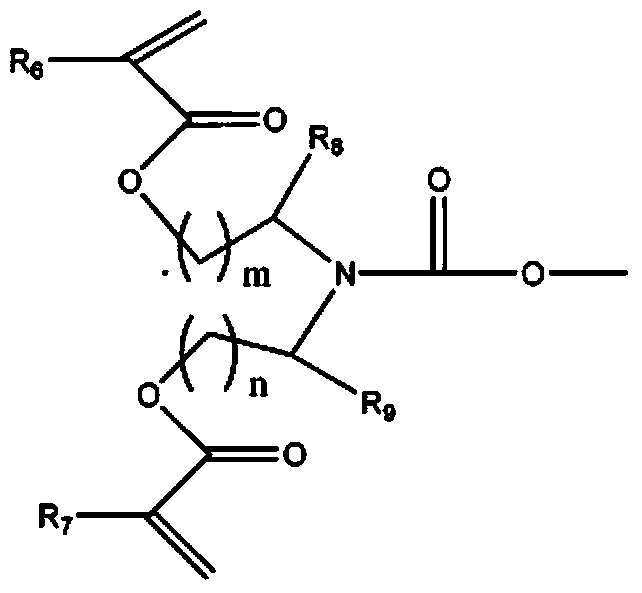

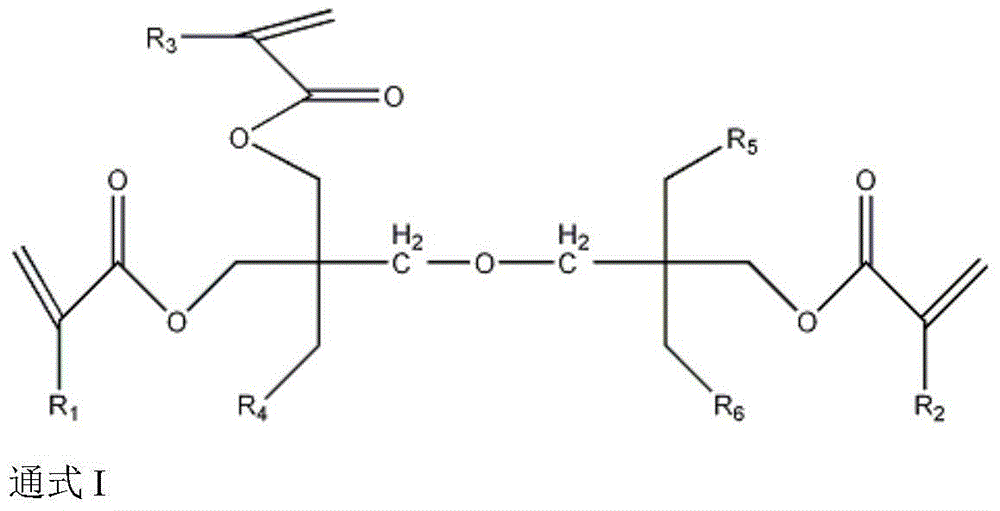

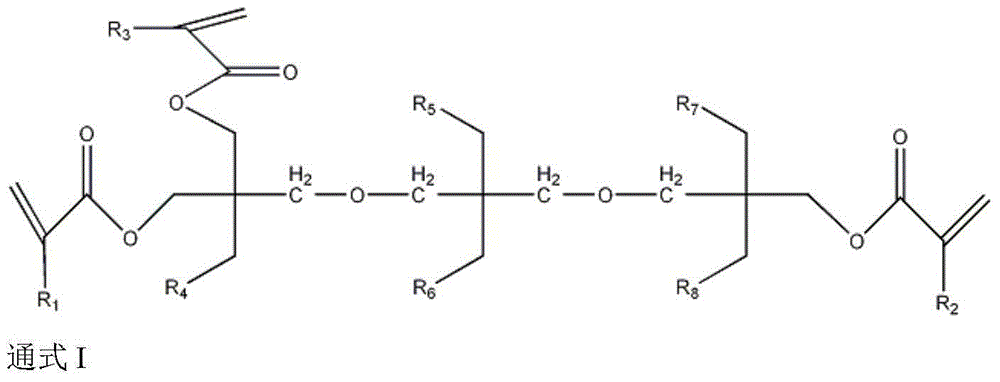

ActiveCN103408464ALow viscosityLow viscosity high reactivityCarbamic acid derivatives preparationOrganic compound preparationPentaerythritolContraction rate

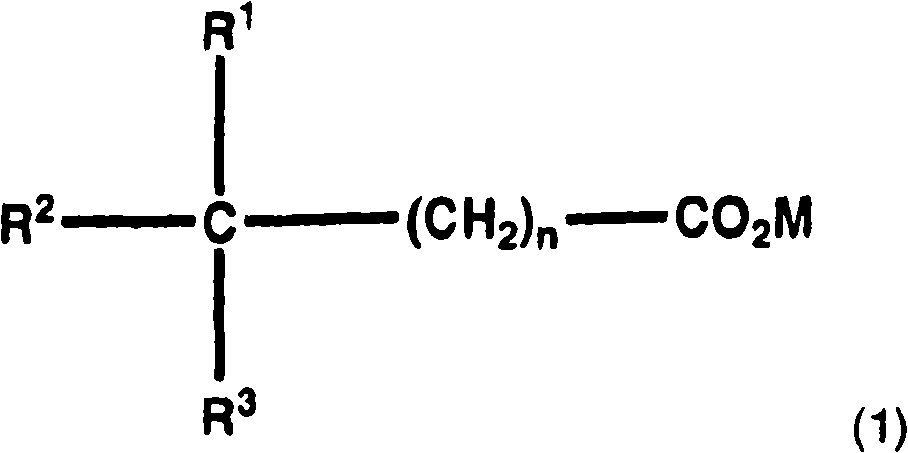

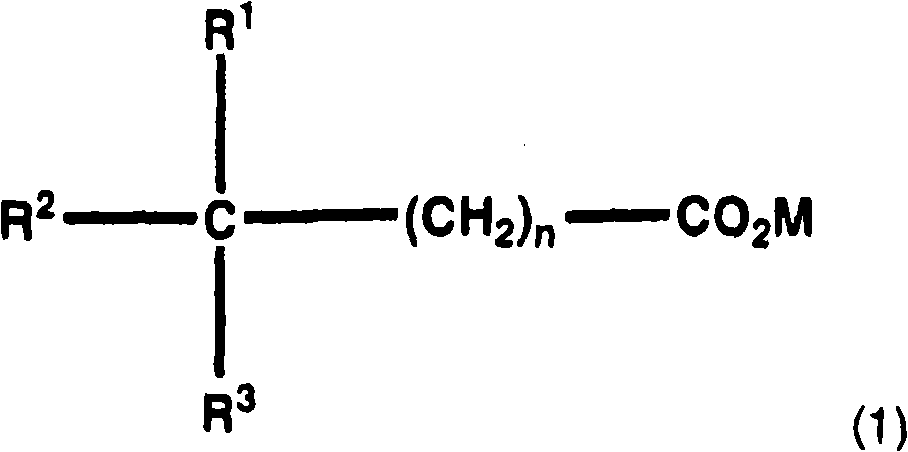

The invention discloses low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate and a preparation method thereof. The low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate has a structural formula as shown in the specification. The degree of functionality of the low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate is 6-9, the viscosity is 300-2000mPa.s, and the molecular weight is 750-2500, so that the low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate has very high reactivity, lower viscosity, high molecular weight, low migration, high curing efficiency, low volume contraction rate, good adhesive force and adjustable flexibility, and a prepared coating is good in impact resistance and strong in adhesive force; and the preparation method disclosed by the invention is simple and easy to control, and an obtained product is high in purity and good in performance.

Owner:JIANGSU RUIYANG CHEM

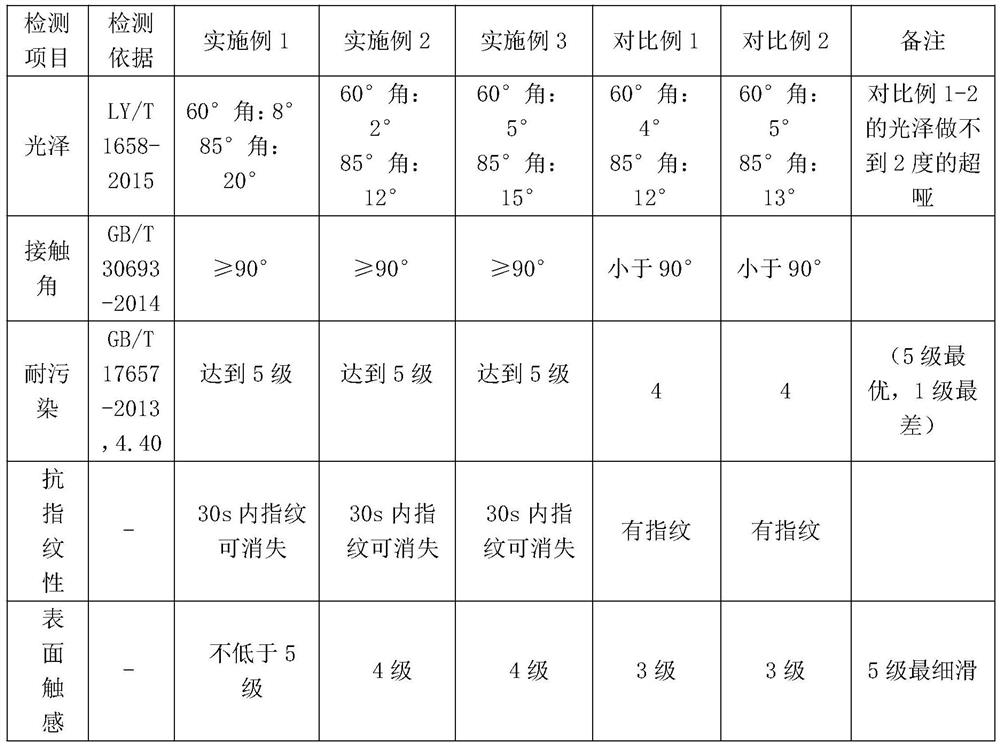

UV-ultra-matte skin-touch surface coating method applied to woodware coating and surface coating paint

PendingCN114789129AIncrease elasticityModerate crosslink densityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceExcimer lamp

The invention discloses a UV-ultra-matte skin-feeling surface coating method and a surface coating applied to woodware coating, a conventional UV roller coating process is adopted for bottom coating, a UV-ultra-matte skin-feeling surface coating process is adopted for surface coating, and specifically, special excimer equipment laser roller equipment is adopted for roller coating by adopting the UV-ultra-matte skin-feeling surface coating. The UV-ultra-matte skin-feeling coating is prepared from special raw materials through compatibility of the materials, and then the effects of extinction and skin feeling are achieved in cooperation with special excimer equipment and process. According to the UV-ultra-matte skin-touch coating, in the aspect of selection of UV resin, resin with good elasticity, moderate crosslinking density and good surface curing is selected, the resin can provide a soft framework, meanwhile, the surface curing is good, special excimer curing equipment is matched, after a paint film is cured by an excimer lamp, wrinkled textures are formed on the surface to obtain ultra-matte, the addition amount of matte powder is reduced, and the skin-touch effect is good. The hand feeling of a paint film is greatly improved, and the leveling property of a paint surface is excellent.

Owner:JIANGSU HIMONIA TECH

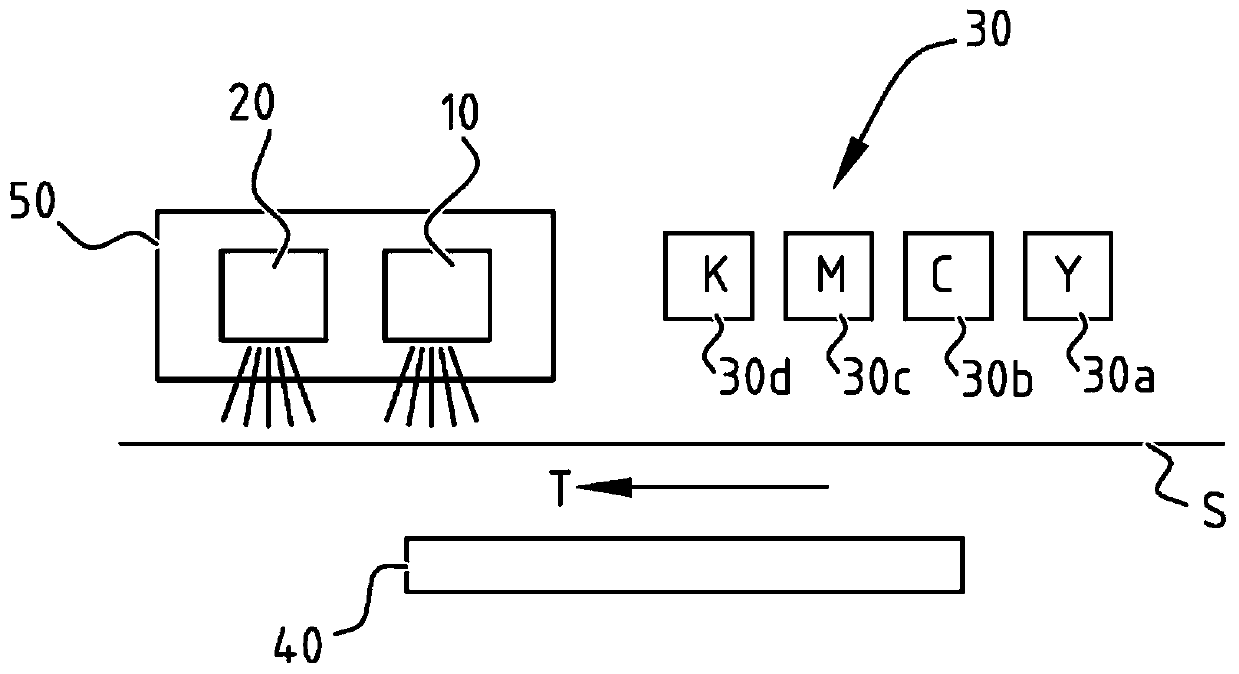

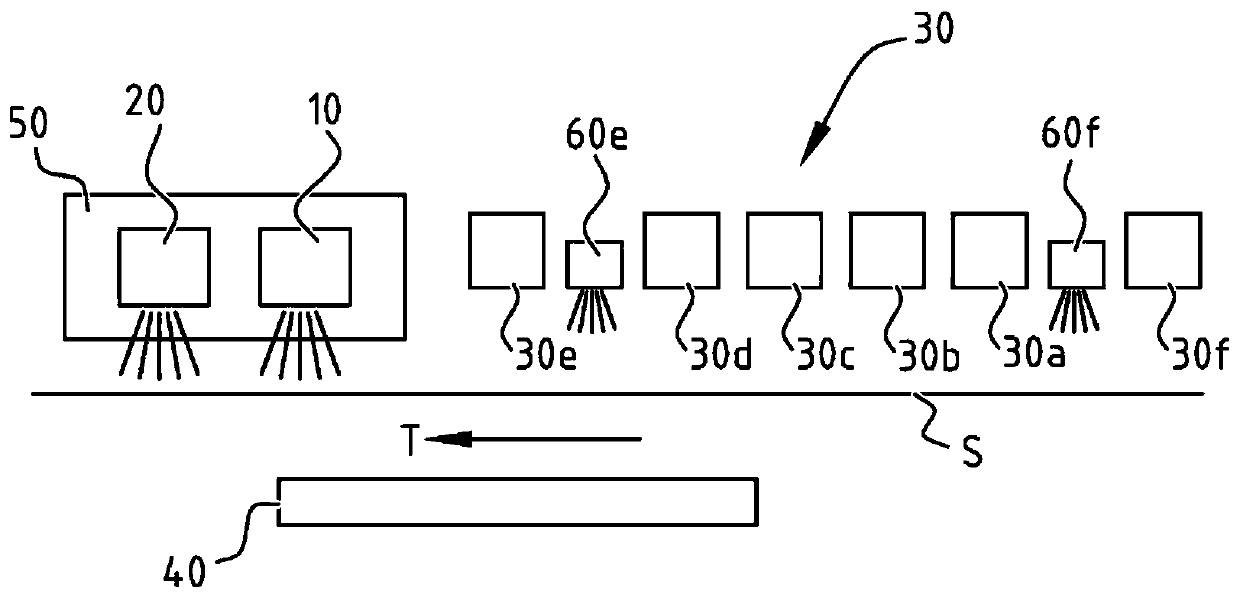

Printing method

ActiveUS8975307B2Improve adhesionImprove Surface CuringImpression capsDuplicating/marking methodsEngineeringXenon

The present invention provides a method comprising: applying a UV-curable ink to a substrate; partially curing the ink by exposing the ink to UV radiation from an LED source; and exposing the partially cured ink to UV radiation from a flash lamp. The flash lamp is a xenon or krypton flash lamp. An apparatus for performing the method and an ink adapted for use in the method are also provided.

Owner:SERICOL GROUP

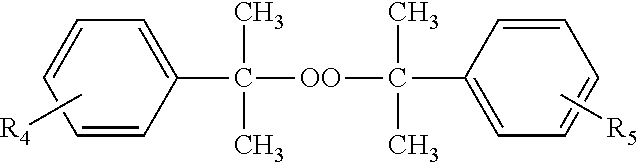

Compositions and methods for crosslinking polymers in the presence of atmospheric oxygen

ActiveUS20170260343A1Reduce surface tackImprove Surface CuringOther chemical processesQuinoneElastomer

Embodiments of organic peroxide formulations provide significant improvements in surface tackiness (often including tack-free surfaces) when curing elastomers in the presence of oxygen. The peroxide formulations may include, for example, one or more compounds selected from sulfur-containing compounds, organophosphite compounds, HALS (Hindered Amine Light Stabilizer) compounds, aliphatic allyl urethane compounds, and blends comprising nitroxides (e.g., 4-hydroxy-TEMPO) and quinones (e.g., mono-tert-butylhydroquinone).

Owner:ARKEMA INC

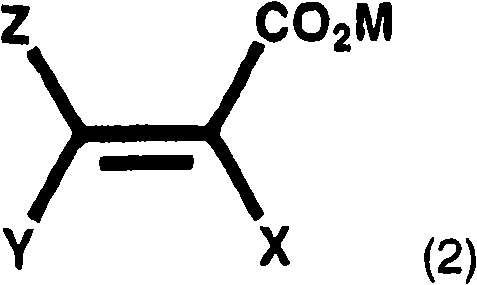

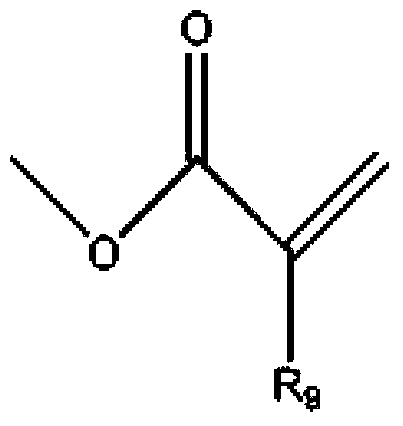

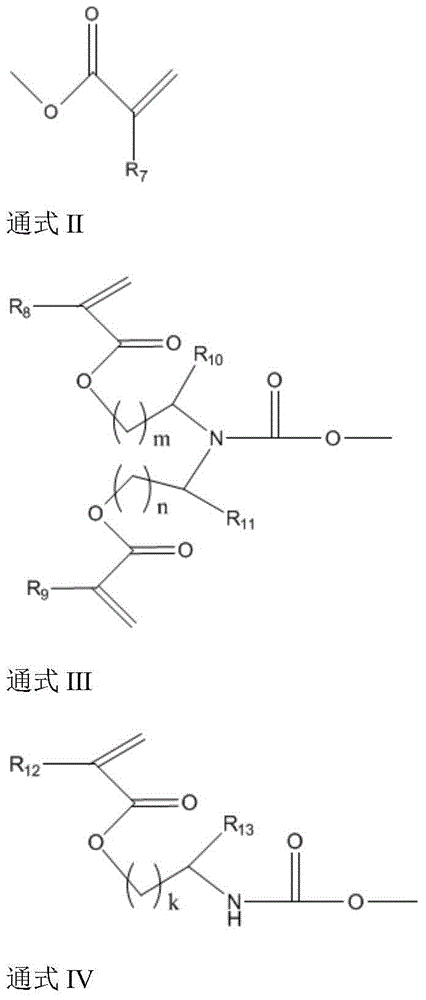

Modified tripentaerythritol acrylic ester with low viscosity, high reactivity and shrunk volume as well as preparation method thereof

ActiveCN103435516ALow viscositySmall molecular weightCarbamic acid derivatives preparationOrganic compound preparationPentaerythritolLow volume

The invention discloses a modified tripentaerythritol acrylic ester with low viscosity, high reactivity and shrunk volume as well as a preparation method thereof. The structural formula of the modified tripentaerythritol acrylic ester with low viscosity, high reactivity and shrunk volume is shown in specification. The modified tripentaerythritol acrylic ester has degree of functionality of 8-12, viscosity of 800-4000 m Pa.s and molecular weight of 1000-4000, and the modified tripentaerythritol acrylic ester also has very high reactivity, low viscosity, low migration of high molecular weight, high solidification efficiency, low volume shrinkage, excellent adhesive force, adjustable softness and adjustable flexibility. A prepared coating is good in impact resistance and strong in adhesive force. The preparation method is simple and easy to control, and the obtained product is high in purity and good in properties.

Owner:JIANGSU RUIYANG CHEM

Method of improving light stability of flexographic printing plates featuring flat top dots

ActiveUS10599035B2Improve Surface CuringProduced in advancePlate printingPhotomechanical exposure apparatusPhoto stabilityPhosphine

A photocurable relief image printing blank comprising: (a) a support layer; (b) one or more photocurable layers disposed on the support layer, wherein the one or more photocurable layers comprise: i) a binder; ii) one or more monomers; iii) an alpha-aminoketone photoinitiator; and optionally, iv) an additive selected from the group consisting of phosphites, phosphines, thioether amine compounds, and combinations of one or more of the foregoing; (c) a laser ablatable masking layer disposed on the one or more photocurable layers, the laser ablatable masking layer comprising a radiation opaque material; and (d) optionally, a removable coversheet. Upon exposure and development, the resulting relief image printing element does not degrade if left under ambient lights for an extended period of time.

Owner:MACDERMID PRINTING SOLUTIONS

Method of improving light stability of flexographic printing plates featuring flat top dots

ActiveUS10108087B2Improve Surface CuringProduced in advancePhotomechanical exposure apparatusMicrolithography exposure apparatusPhotoinitiatorPhosphine

A photocurable relief image printing blank comprising: (a) a support layer; (b) one or more photocurable layers disposed on the support layer, wherein the one or more photocurable layers comprise: i) a binder; ii) one or more monomers; iii) a photoinitiator; iv) an additive selected from the group consisting of phosphites, phosphines, thioether amine compounds, and combinations of one or more of the foregoing; and v) an additional component comprising amine moieties; (c) a laser ablatable masking layer disposed on the one or more photocurable layers, the laser ablatable masking layer comprising a radiation opaque material; and (d) optionally, a removable coversheet. Upon exposure and development, the resulting relief image printing element does not degrade if left under ambient UV lights for an extended period of time.

Owner:MACDERMID PRINTING SOLUTIONS

Method of Improving Light Stability of Flexographic Printing Plates Featuring Flat Top Dots

ActiveUS20170259607A1Improve Surface CuringProduced in advancePrinting blanketsOther printing apparatusPhotoinitiatorPhosphine

A photocurable relief image printing blank comprising: (a) a support layer; (b) one or more photocurable layers disposed on the support layer, wherein the one or more photocurable layers comprise: i) a binder; ii) one or more monomers; iii) a photoinitiator; iv) an additive selected from the group consisting of phosphites, phosphines, thioether amine compounds, and combinations of one or more of the foregoing; and v) an additional component comprising amine moieties; (c) a laser ablatable masking layer disposed on the one or more photocurable layers, the laser ablatable masking layer comprising a radiation opaque material; and (d) optionally, a removable coversheet. Upon exposure and development, the resulting relief image printing element does not degrade if left under ambient UV lights for an extended period of time.

Owner:MACDERMID PRINTING SOLUTIONS

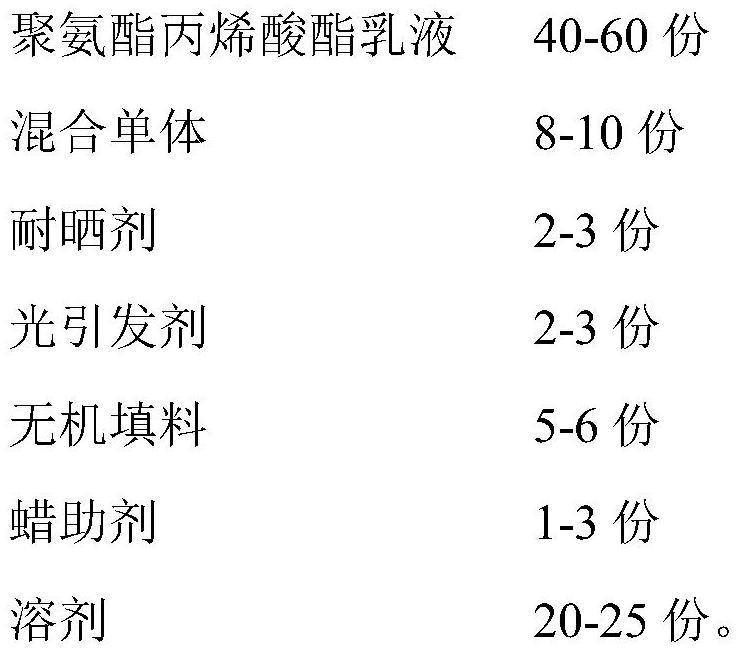

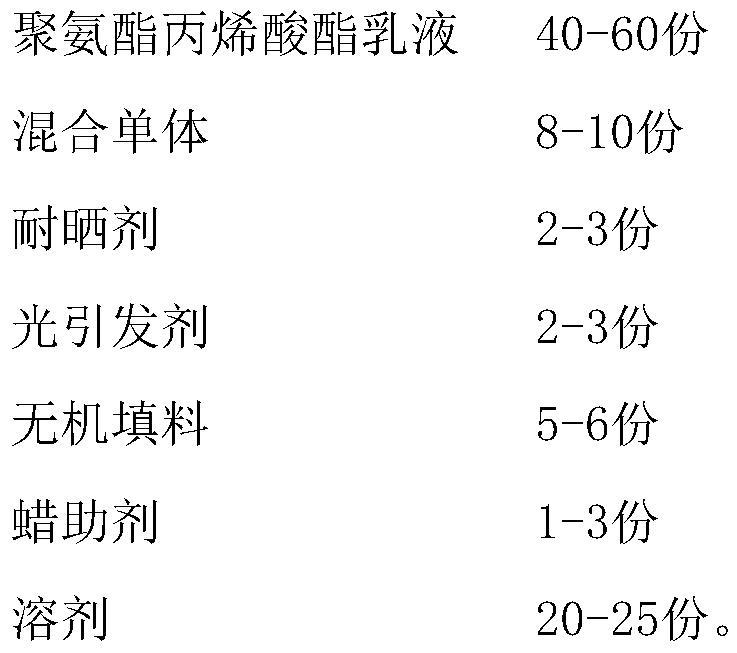

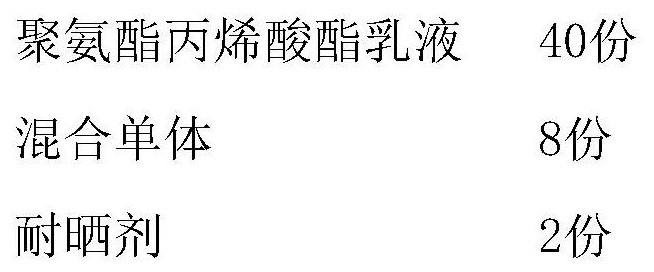

High-sun-resistance printing ink for impregnated paper and preparation method of high-sun-resistance printing ink

The invention relates to the technical field of printing ink, in particular to high-sun-resistance printing ink for impregnated paper and a preparation method of the high-sun-resistance printing ink.The high-sun-resistance printing ink for the impregnated paper is prepared from the following raw materials in parts by weight: 40-60 parts of a urethane acrylate emulsion, 8-10 parts of mixed monomer, 2-3 parts of a sun-resistant agent, 2-3 parts of photoinitiator, 5-6 parts of inorganic filler, 1-3 parts of a wax additive and 20-25 parts of a solvent. The high-sun-resistance printing ink for theimpregnated paper is good in adhesive force and can be stably attached to the surface of the impregnated paper, and an ink layer formed after painting is sun-resistant, not prone to yellowing and aging and good in stability. The adopted urethane acrylate emulsion contains an acrylic functional group and a polyurethane component, is good in adhesion, can be stably attached to the stable surface ofimpregnated paper, and is fast to cure, and meanwhile, the contained polyurethane component can enable the ink to have relatively good flexibility and peel strength after being cured.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

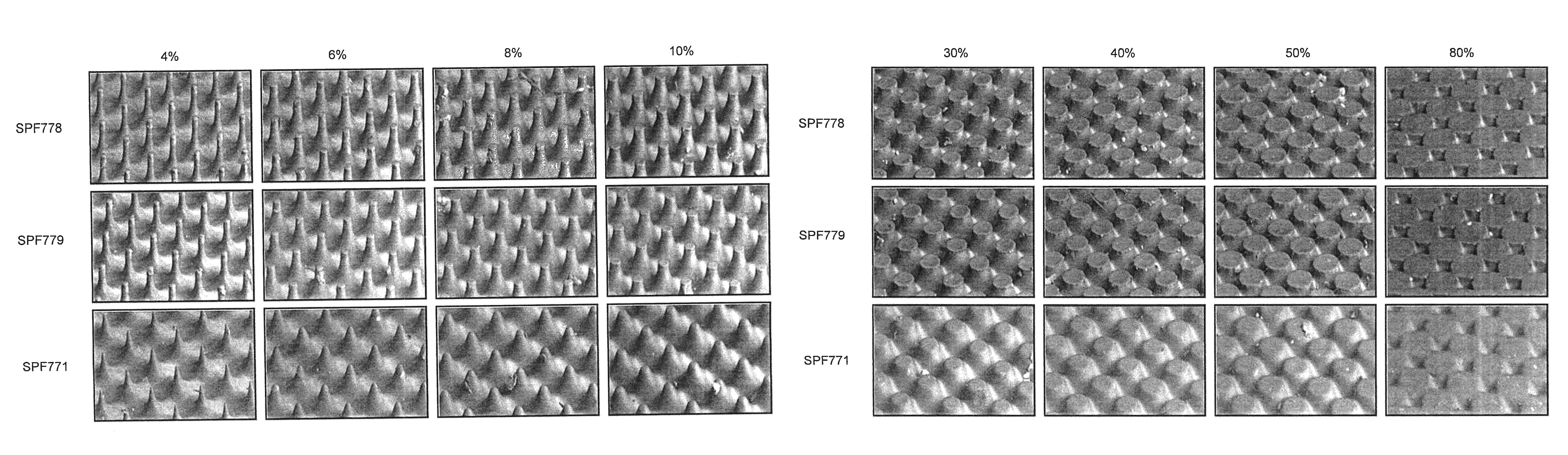

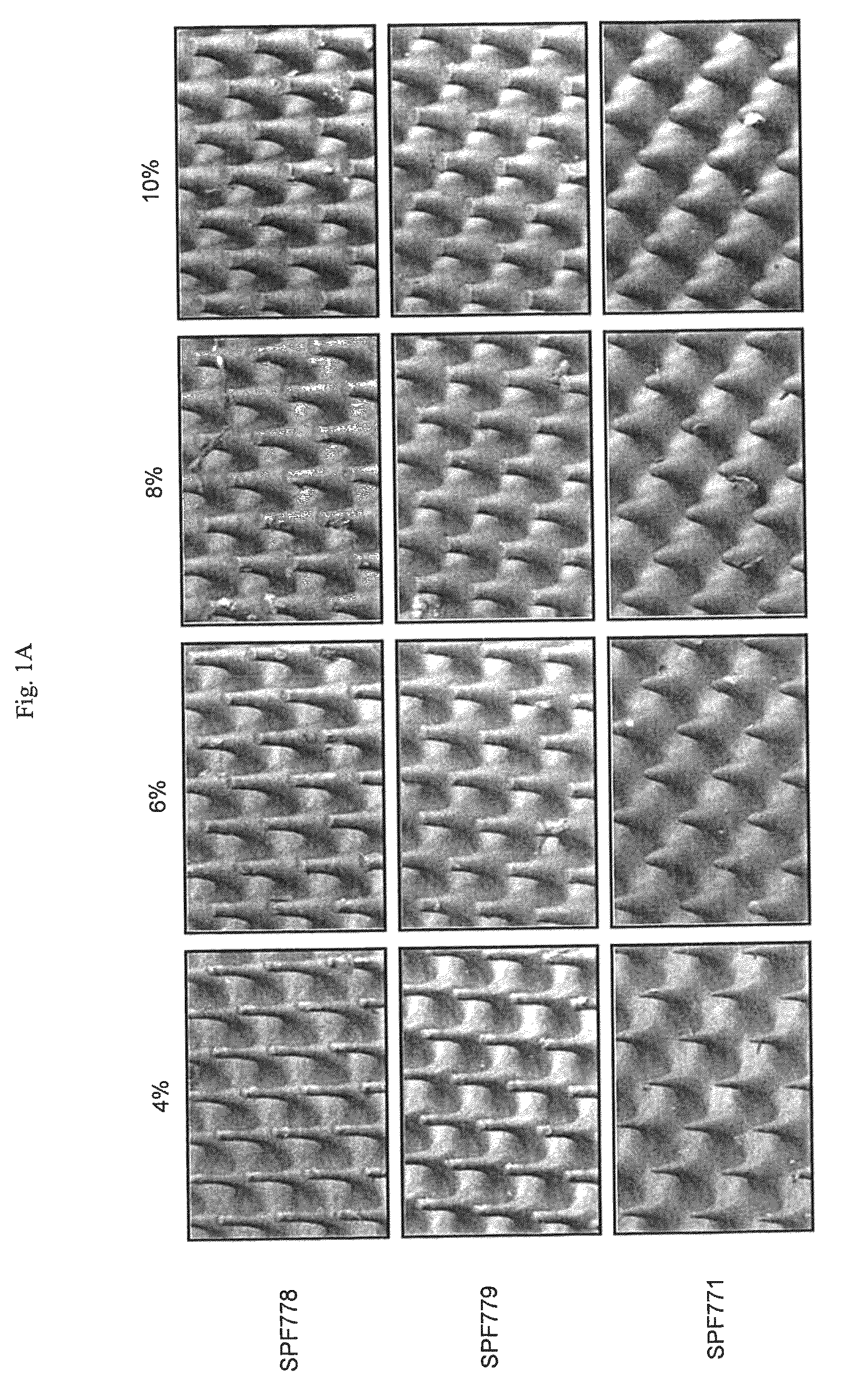

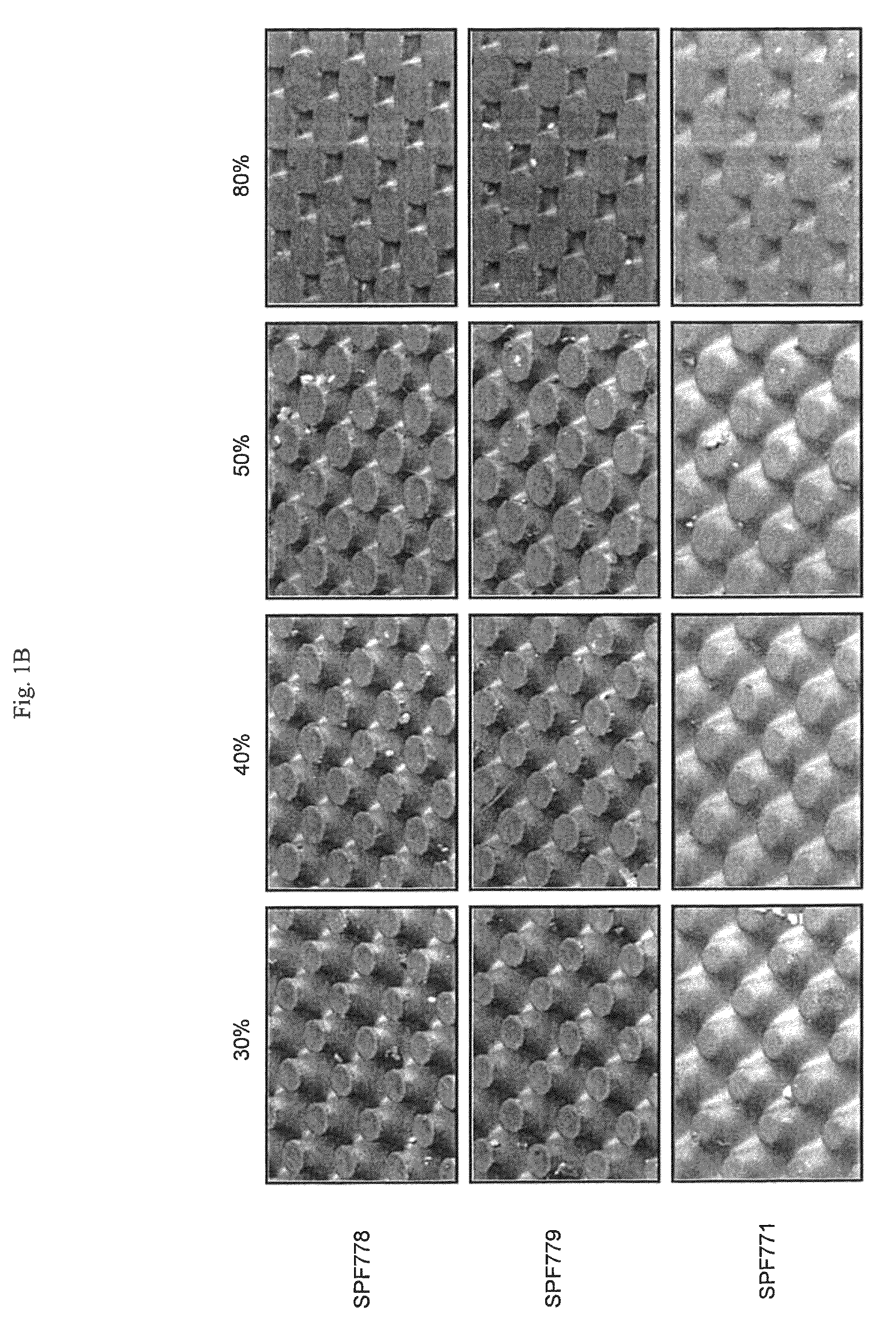

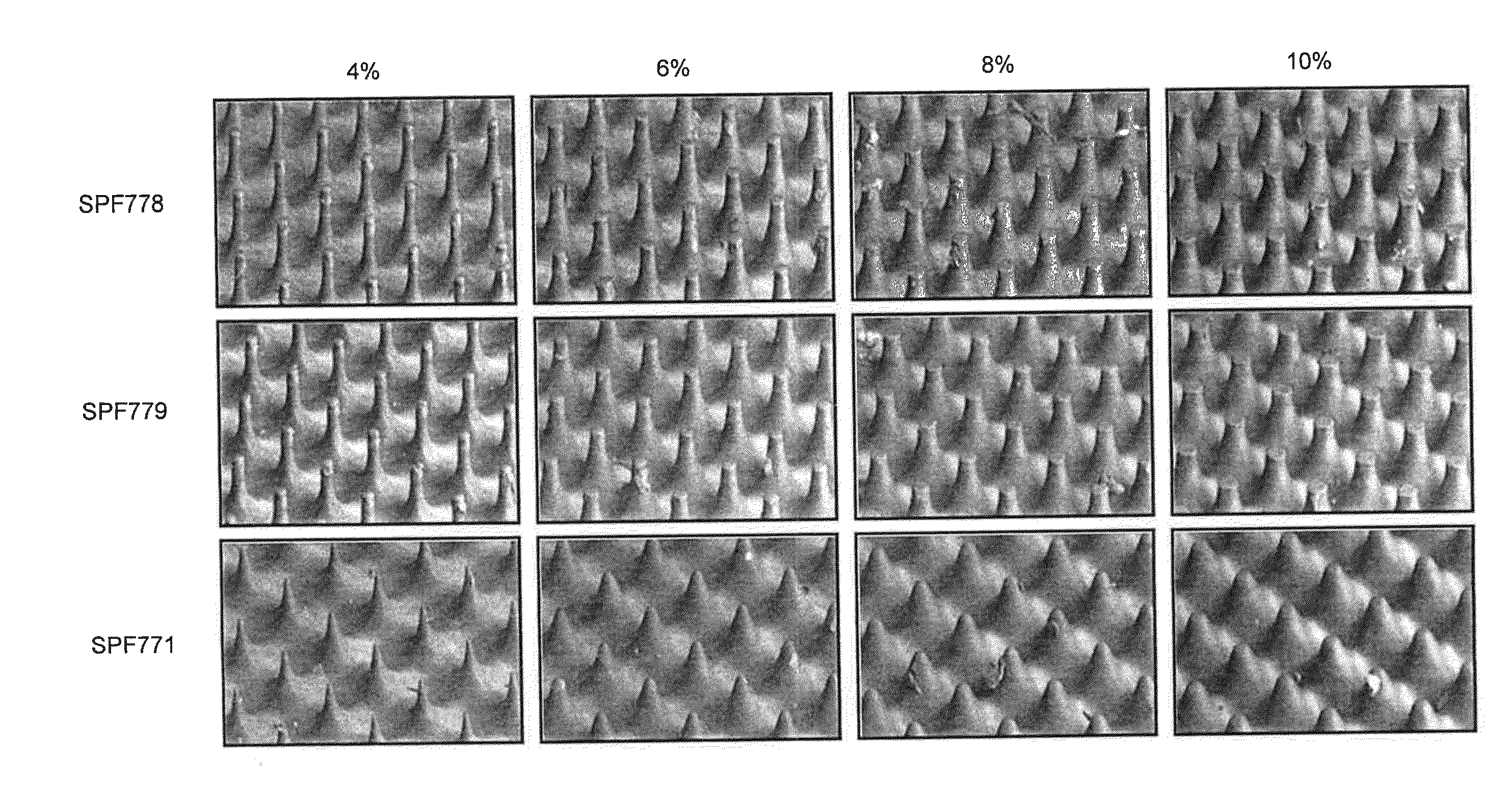

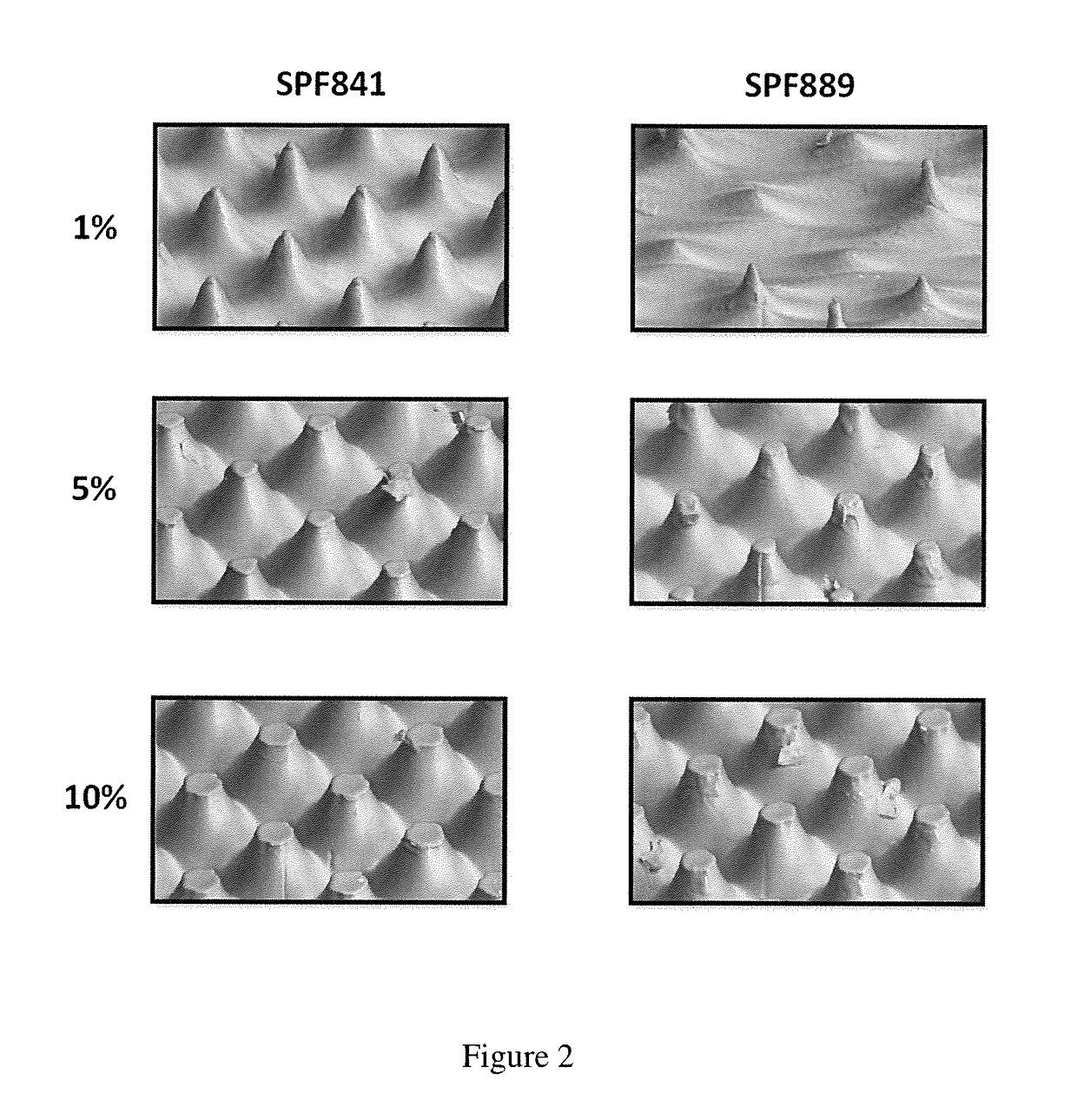

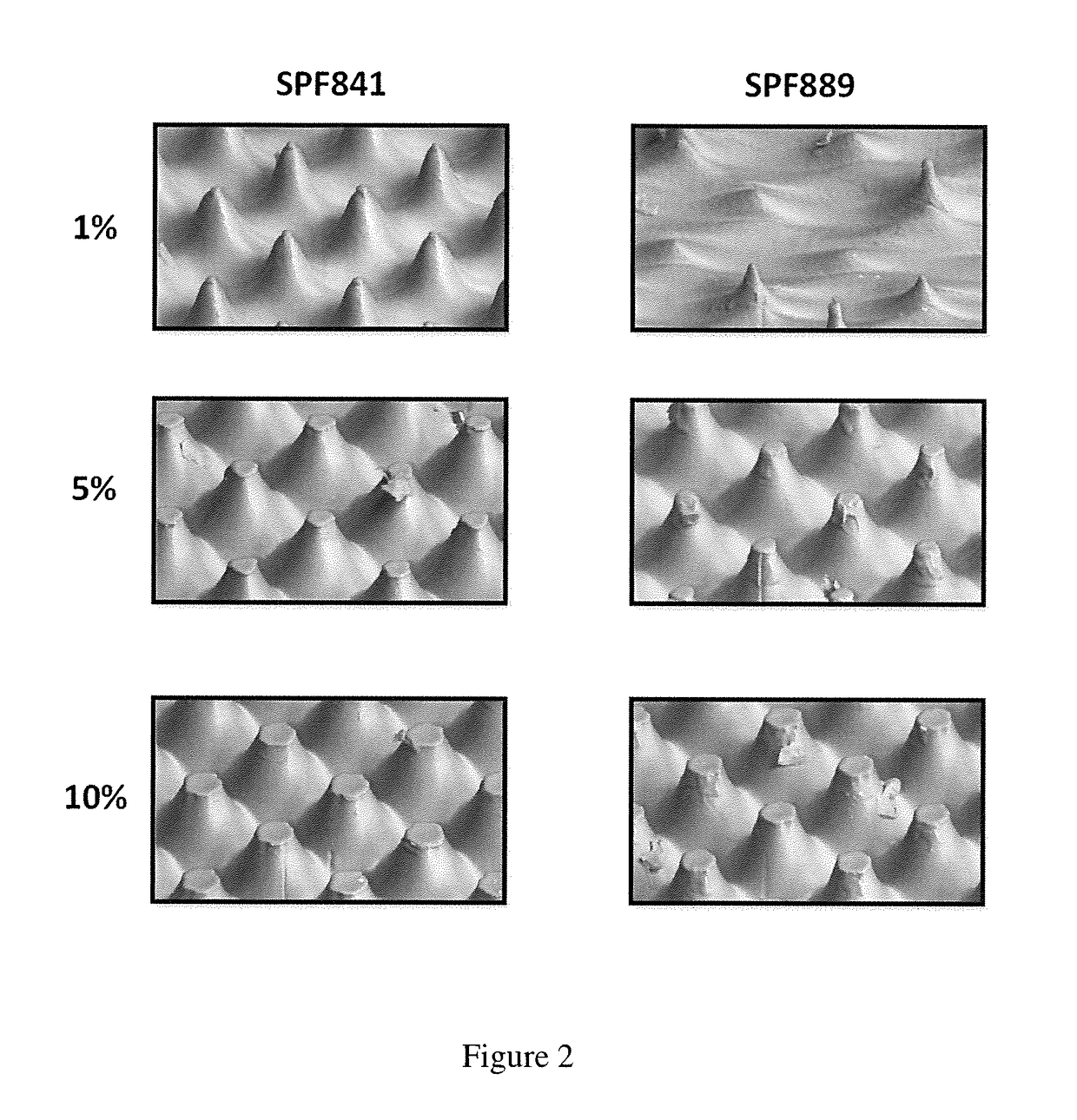

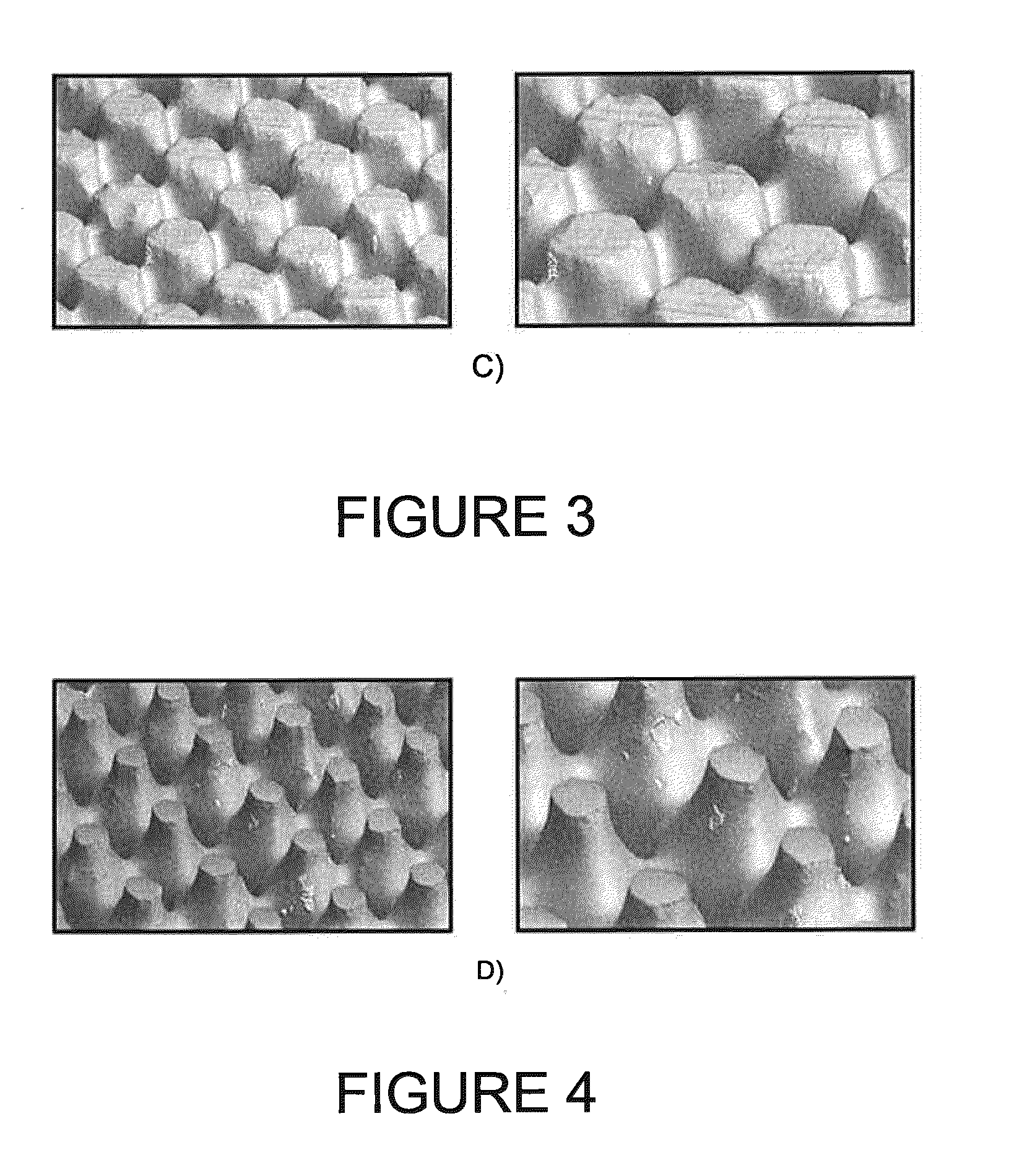

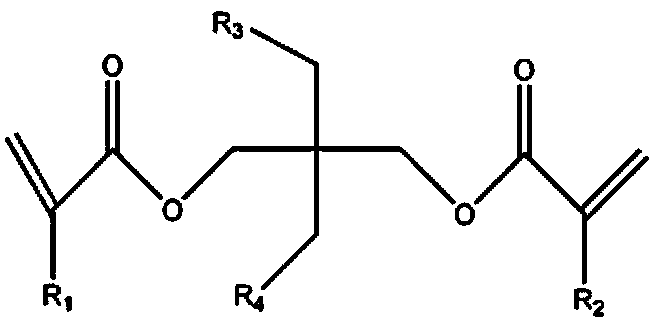

Method of improving print performance in flexographic printing plates

ActiveUS8795950B2Control roughnessImprove Surface CuringPhotosensitive materialsDuplicating/marking methodsEngineeringFlexography

Owner:MACDERMID PRINTING SOLUTIONS

Low-viscosity high-reactivity low-volume-shrinkage modified pentaerythritol acrylate and preparation method thereof

ActiveCN103435515ALow viscosityHigh viscosityCarbamic acid derivatives preparationOrganic compound preparationPentaerythritolStructural formula

The invention discloses low-viscosity high-reactivity low-volume-shrinkage modified pentaerythritol acrylate and a preparation method thereof. The low-viscosity high-reactivity low-volume-shrinkage modified pentaerythritol acrylate has a structural formula as shown in the specification. The functionality of the low-viscosity high-reactivity low-volume-shrinkage modified pentaerythritol acrylate is 4-6, the viscosity is 40-70mPa.s, and the molecular weight is 750-2500, so that the low-viscosity high-reactivity low-volume-shrinkage modified pentaerythritol acrylate is very high in reactivity, low in viscosity, high in molecular weight, low in migration, high in curing efficiency, low in volume shrinkage ratio, good in adhesive force and adjustable in flexibility, and a prepared paint is good in impact resistance and strong in adhesive force. The preparation method disclosed by the invention is simple and easy to control, and the obtained product is high in purity and good in performance.

Owner:JIANGSU RUIYANG CHEM

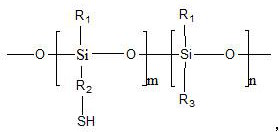

UV curable silicone release agent

The invention discloses a UV-curable silicone release agent. The release agent has good storage stability at room temperature, and it will not be moisture-cured when exposed to the air, but UV light can quickly trigger moisture curing and UV curing. It belongs to the UV / moisture dual curing system, which is different from ordinary UV / Moisture dual-cure systems are different in that moisture curing is initiated only after UV exposure. The specific composition is (meth)acryloyloxyalkylureido double-capped polydimethylsiloxane, mercapto silicone oil, organotin catalyst capable of forming a complex with mercapto silicone oil, and a photoinitiator. Compared with ordinary UV-curable silicone, the release agent of the invention is beneficial to eliminate the polymerization inhibition effect of oxygen on the surface of the silicone, improve the surface curability of the silicone, and the cured product has a good release effect.

Owner:郝建强 +1

Modified dipentaerythritol acrylate with low viscosity, high reactivity and low volume shrinkage and preparation method thereof

ActiveCN103408464BLow viscosityLow viscosity high reactivityCarbamic acid derivatives preparationOrganic compound preparationPolymer sciencePentaerythritol

The invention discloses low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate and a preparation method thereof. The low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate has a structural formula as shown in the specification. The degree of functionality of the low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate is 6-9, the viscosity is 300-2000mPa.s, and the molecular weight is 750-2500, so that the low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate has very high reactivity, lower viscosity, high molecular weight, low migration, high curing efficiency, low volume contraction rate, good adhesive force and adjustable flexibility, and a prepared coating is good in impact resistance and strong in adhesive force; and the preparation method disclosed by the invention is simple and easy to control, and an obtained product is high in purity and good in performance.

Owner:JIANGSU RUIYANG CHEM

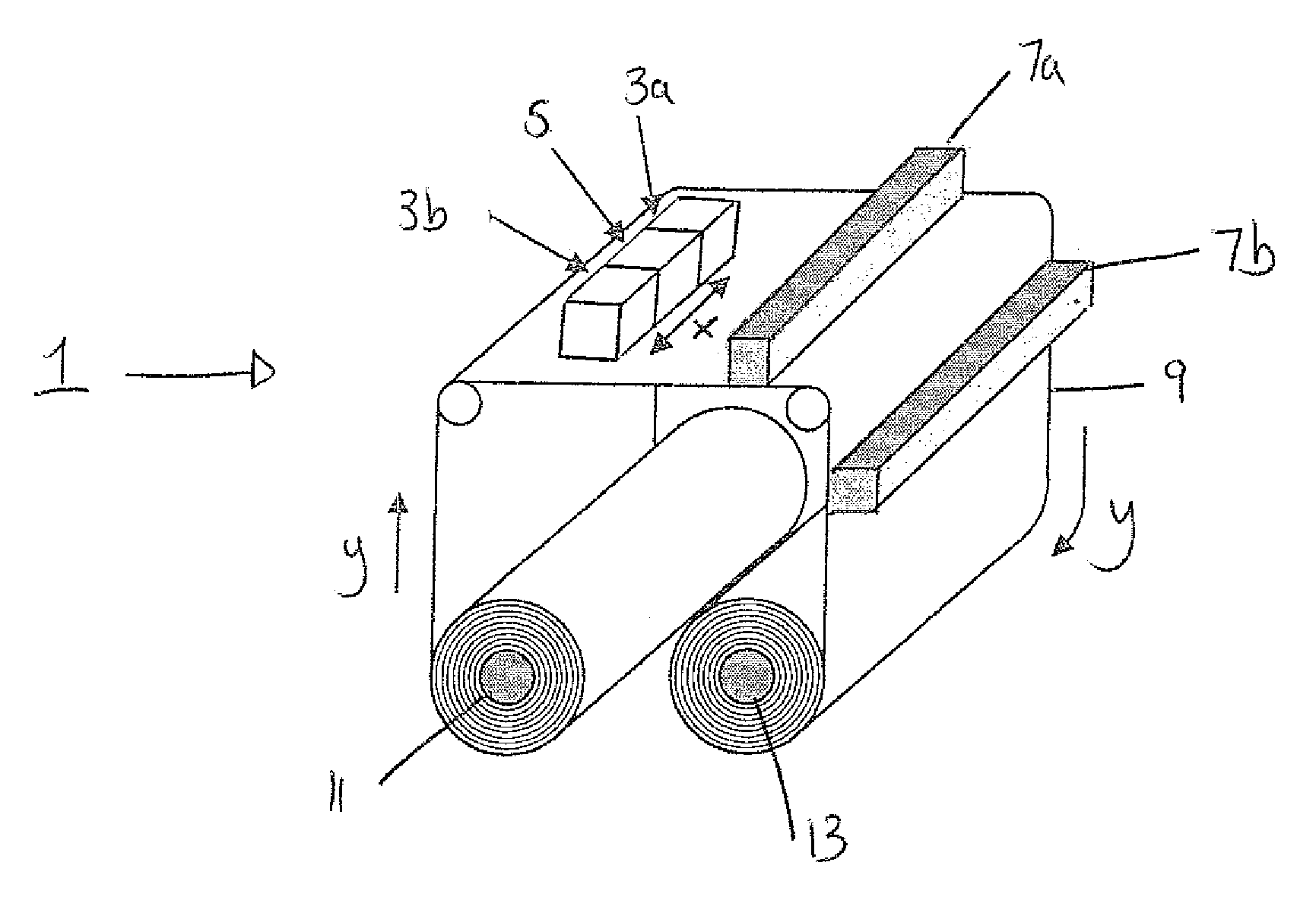

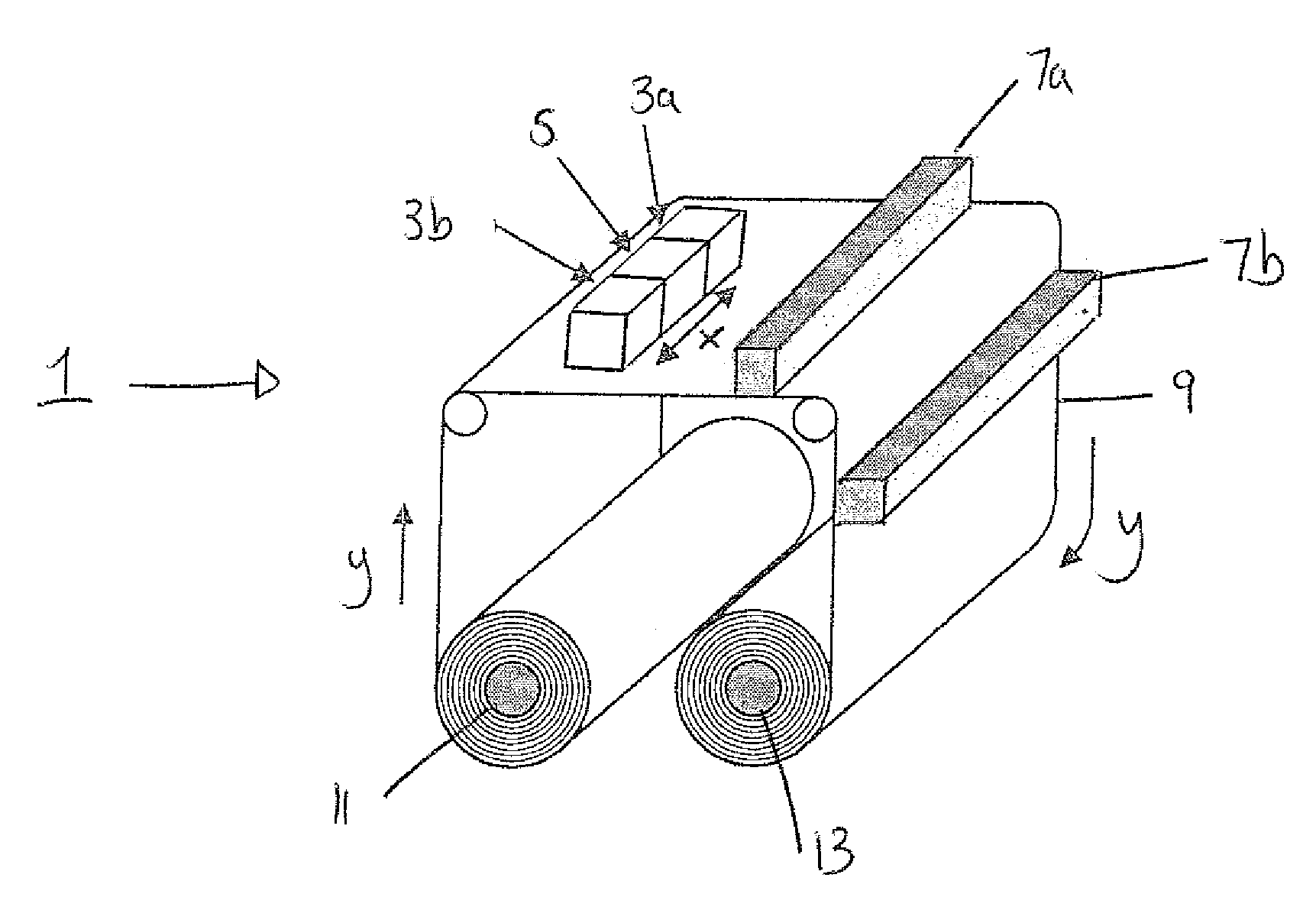

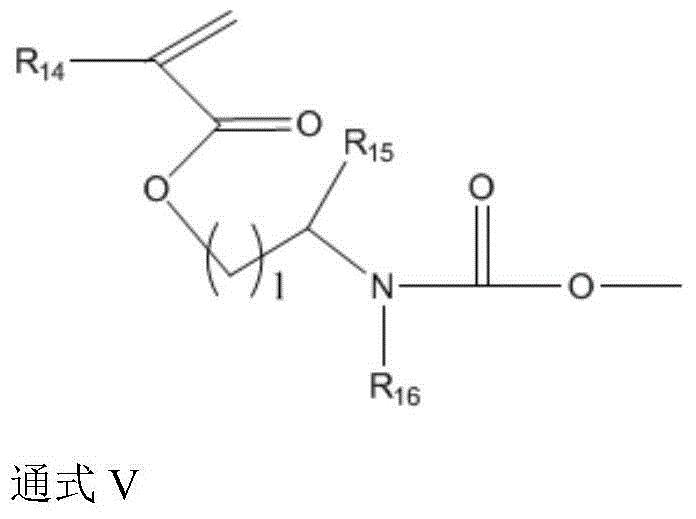

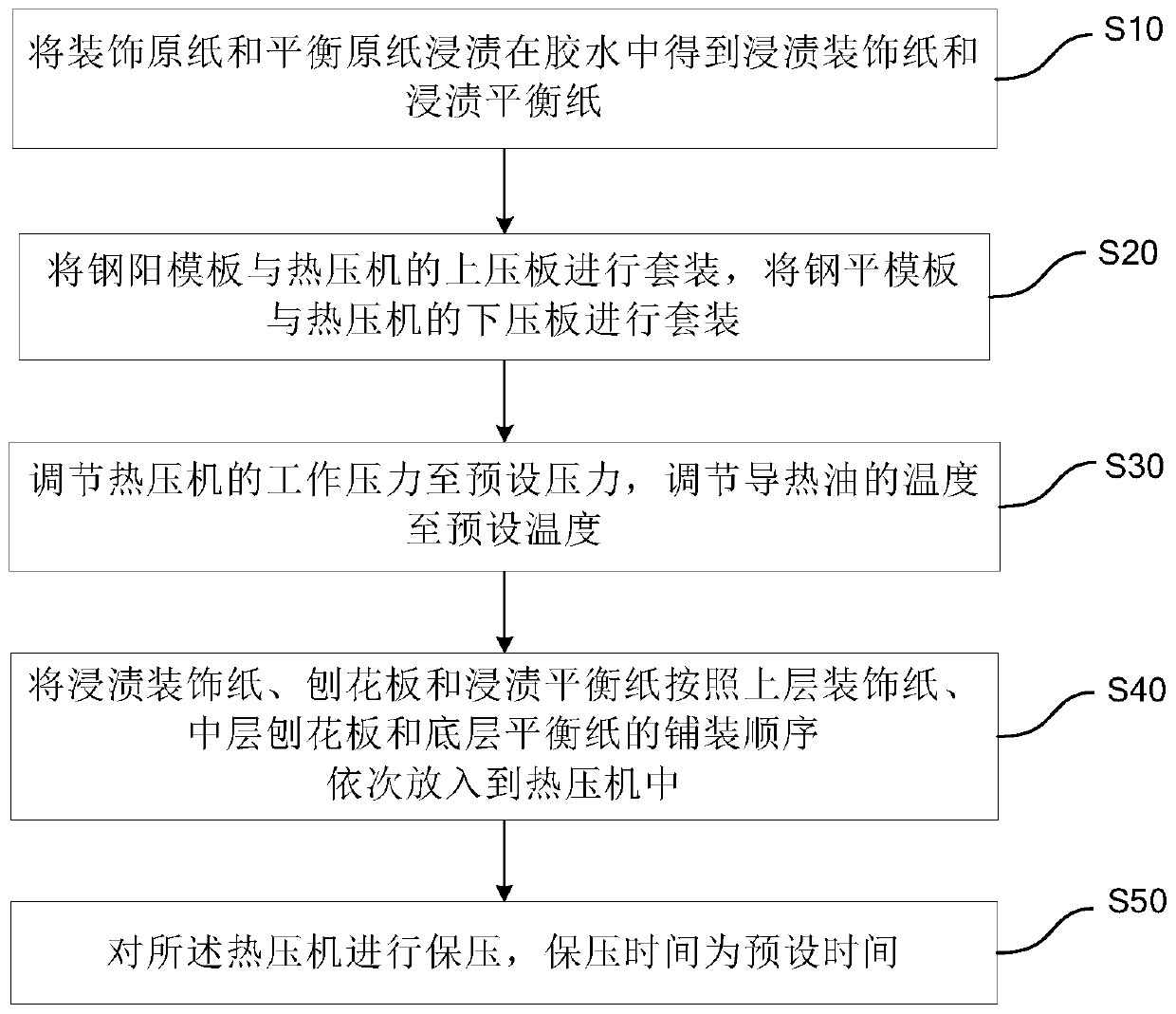

Manufacturing method of multilayer composite paint-free molded three-dimensional board, and system applied to manufacturing method

ActiveCN107020788AAvoid crackingNot easy to dry flowersLamination ancillary operationsLaminationManufacturing technologyPulp and paper industry

The invention discloses a manufacturing method of a multilayer composite paint-free molded three-dimensional board, and a system applied to the manufacturing method. The manufacturing method comprises the steps of S10, impregnating decorative base paper and balance base paper into glue to obtain impregnated decorative paper and impregnated balance paper; S20, using a steel male template to sleeve an upper press plate of a hot press, and using a steel flat template to sleeve a lower press plate of the hot press; S30, adjusting the working pressure of the hot press to a preset pressure, and adjusting the temperature of heat conduction oil to a preset temperature; S40, sequentially putting the impregnated decorative paper, a shaving board and the impregnated balance paper into the hot press in a paving sequence that the decorative paper is positioned at the upper layer, the shaving board is arranged at the middle layer, and the balance paper is positioned at the bottom layer; S50, maintaining the pressure of the hot press, wherein the pressure maintaining time is set in advance. After the manufacturing method and the system are adopted, the multilayer composite paint-free molded three-dimensional board can be obtained by taking the shaving board as a base material; a paint layer does not exist, so that the manufacturing technology is simplified, and the three-dimensional board is environment-friendly; furthermore, the produced three-dimensional board can be directly used for final consumption.

Owner:CROSPLUS HOME FURNISHINGSSHANGHAI

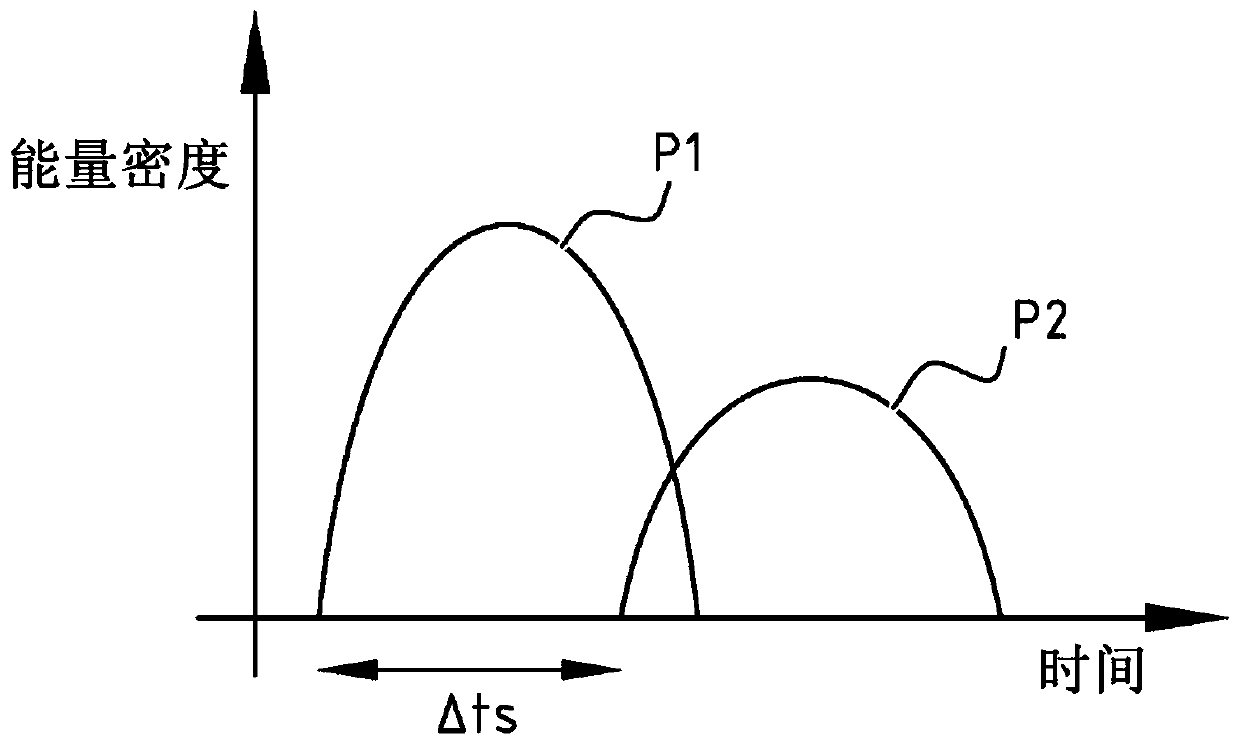

Method for curing of an ink or toner layer and printing system with curing unit

ActiveCN110997335AImprove Surface CuringImproved Surface CuringDuplicating/marking methodsPretreated surfacesLight spectrumLight sensitive

A method for curing of an actinic light sensitive ink or toner layer on a substrate comprising an irradiating step of irradiating the actinic light sensitive ink or toner layer, with a first radiationdose D1 in a first spectral range between 320 nm and 445 nm; followed by a second radiation dose D2 in a second spectral range between 200 nm and 319 nm, wherein the ratio D1 / D2 of the first radiation dose and the second radiation dose is between 0.25 and 500, more preferably between 0.25 and 200, even more preferably between 0.50 and 100.

Owner:西康制造有限公司

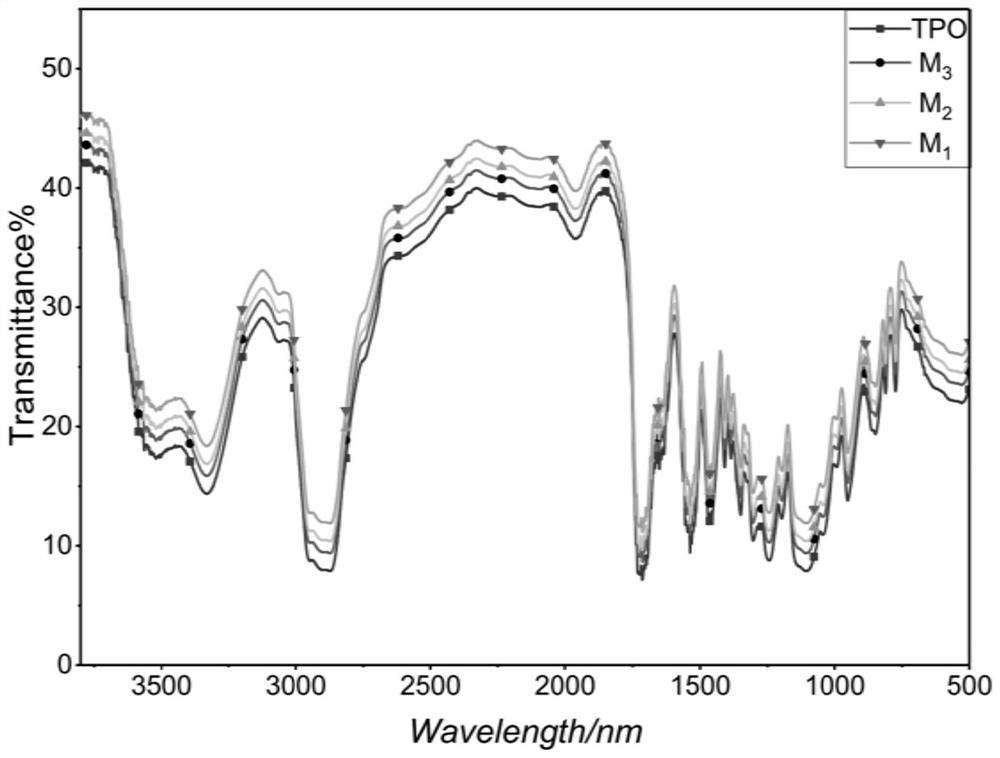

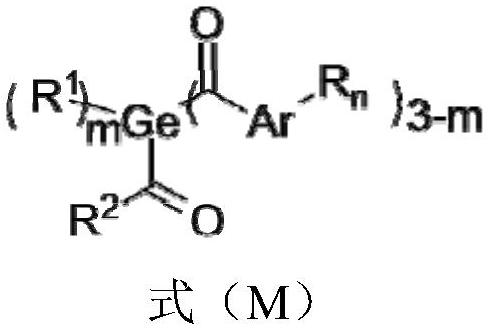

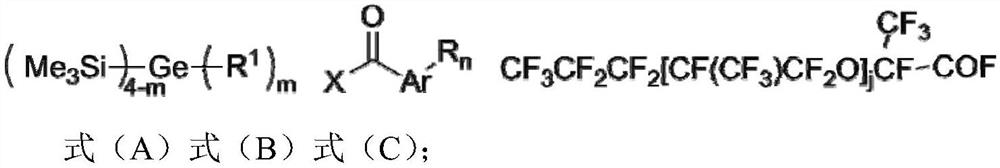

Photoinitiator as well as preparation method and application thereof

ActiveCN112062879AExcellent photoinitiated polymerization efficiencyWith anti-reflection and anti-reflection functionPolyurea/polyurethane coatingsPerfluoropolyetherUltraviolet lights

The invention discloses a photoinitiator as well as a preparation method and application thereof. The photoinitiator has a structure as shown in a formula (M) which is described in the specification.The photoinitiator provided by the invention takes a Type I cracking type photoinitiator acyl germanium group as a parent nucleus which is bonded with an environment-friendly perfluoropolyether alkylchain group with low surface tension. The photoinitiator has excellent photo-initiation polymerization efficiency, and is sensitive to ultraviolet light of a UVA section. The photoinitiator can be applied to commercial LED curing, and can be enriched on the surface of a formula coating to increase the content of the surface photoinitiator, thereby promoting the curing of the surface coating and inhibiting the oxygen inhibition of the surface. A cured film prepared from the photo-cured composition is low in surface layer refractive index and high in inner layer refractive index, and has anti-reflection and anti-reflection functions.

Owner:新丰博兴聚合材料有限公司

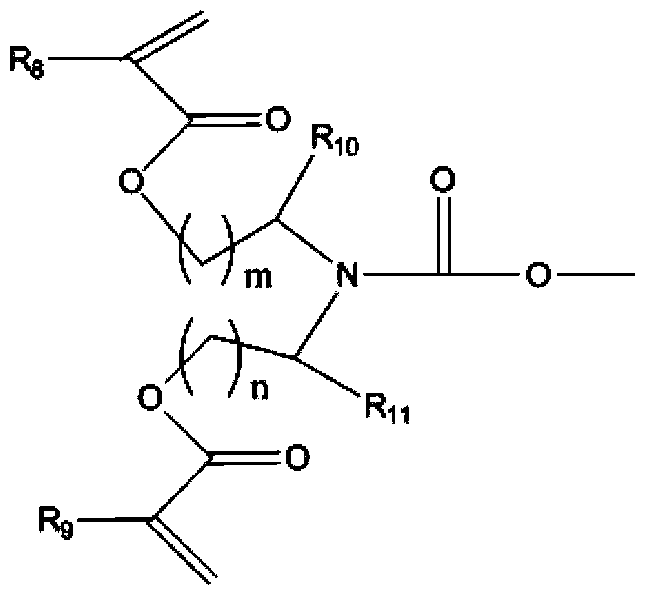

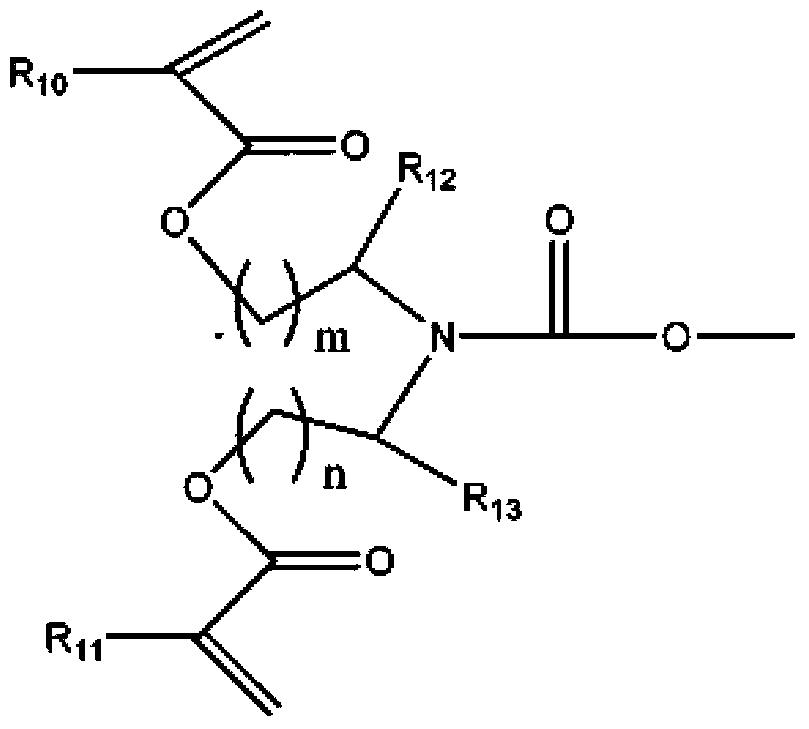

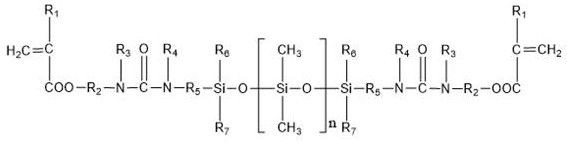

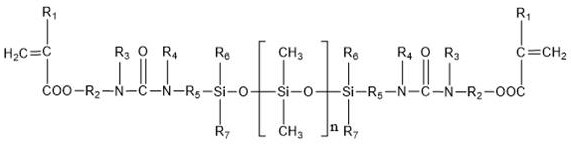

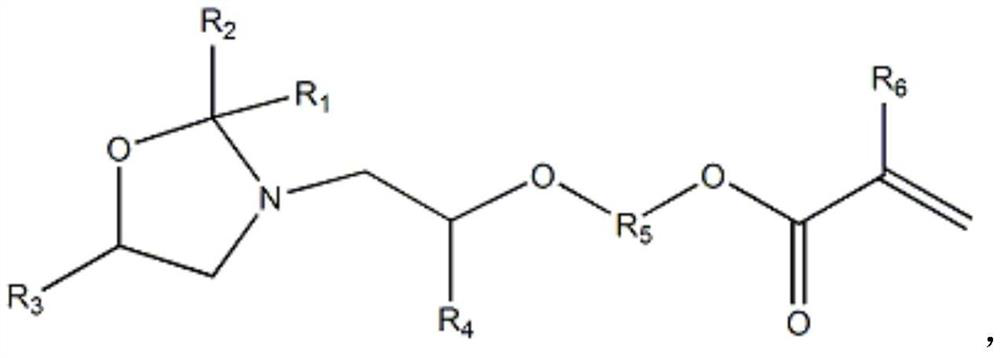

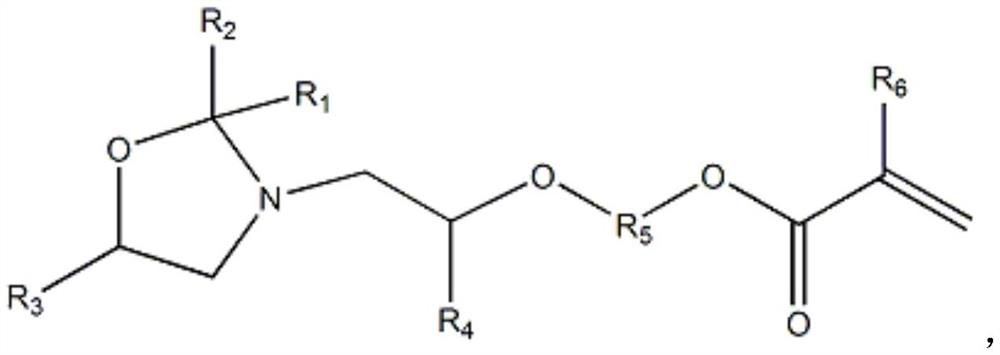

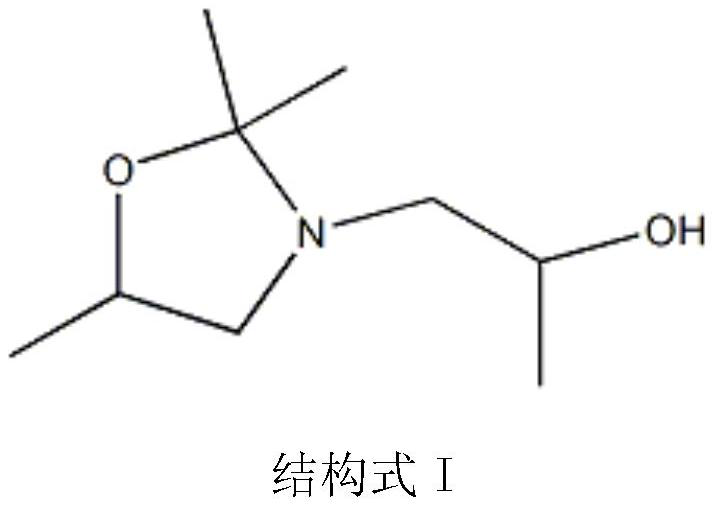

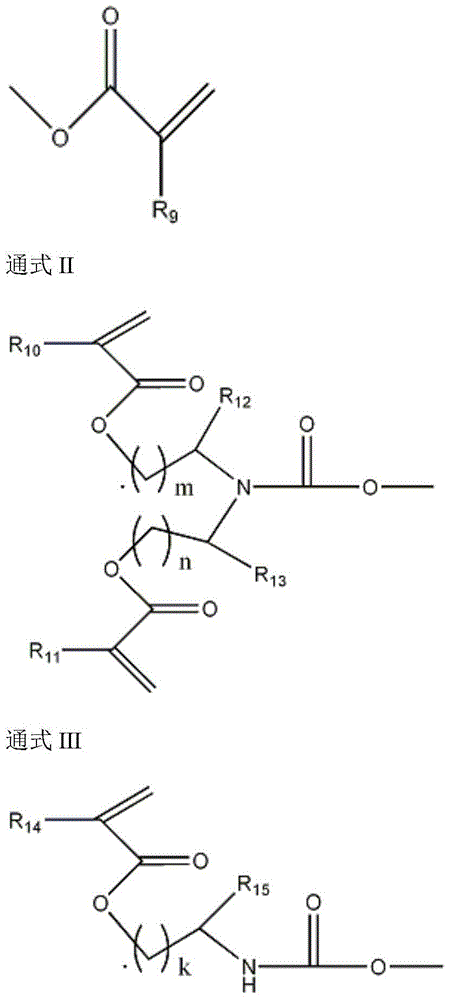

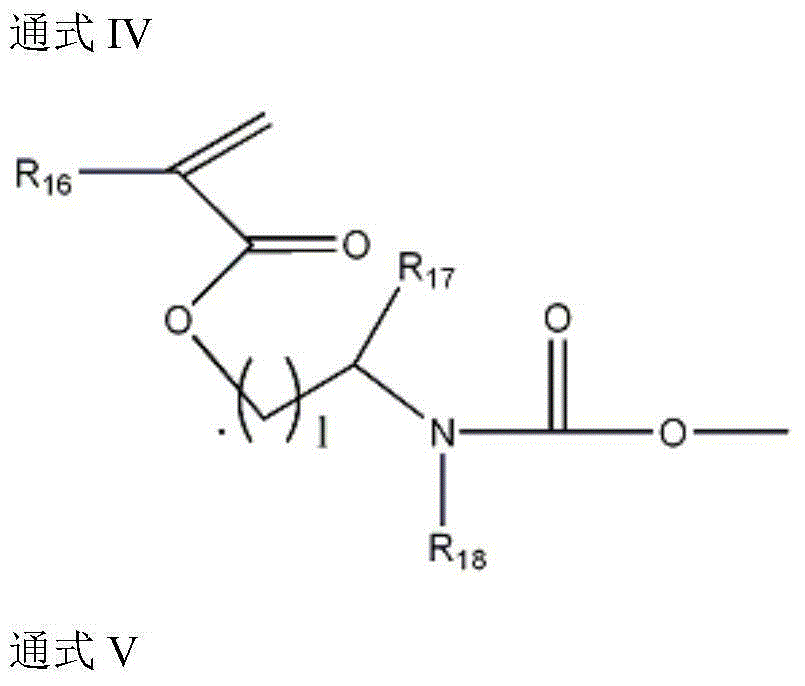

Oxazolidine-containing radiation-curable urethane(meth)acrylate and preparation method thereof

ActiveCN112851596AStrong adhesionGood adhesionOrganic chemistryEpoxy resin coatingsMethacrylatePolymer science

The invention discloses oxazolidine-containing radiation-curable urethane(meth)acrylate and a preparation method thereof. The structural formula of the oxazolidine-containing radiation-curable urethane(meth)acrylate is shown in the specification, R1 is optional C1-C4 alkyl, R2, R3 and R4 are all hydrogen or optional C1-C4 alkyl, R5 is diisocyanate residue containing C2-C6 aliphatic branched chain or aliphatic ether chain, and R6 is hydrogen or methyl. The compound adopts a modification mode of combining oxazolidine monohydric alcohol and urethane, so that the hardness and flexibility of the prepared photocuring material (coating, ink or adhesive) and the adhesive force of the photocuring material on a plastic base material are greatly improved; and the preparation method is simple and easy to control, and the obtained product is high in purity and good in performance.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

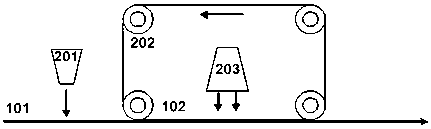

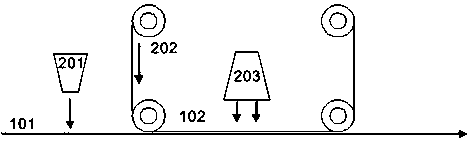

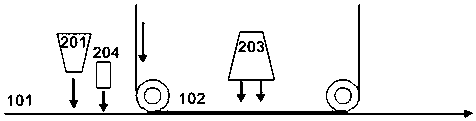

Method for improving UV ink-jet printing efficiency and quality

InactiveCN109720085AImprove printing efficiencyImprove printing qualityPrinting after-treatmentPrinting press partsUV curingEngineering

The invention discloses a method for improving UV ink-jet printing efficiency and quality. The method comprises the following steps that after a UV ink jet unit operates, a transparent thin film covers the surface of a jet printed pattern, then UV curing is performed, then the transparent thin film is stripped, and a smooth printed pattern is obtained. According to the method, after the UV ink jetunit operates, the transparent thin film covers the surface of the jet printed pattern, then UV curing is performed, then the transparent thin film is stripped, and the smooth printed pattern is obtained; and according to the provided method, the flat and smooth UV ink-jet printed pattern can be obtained, the surface is well cured, the pattern is clear, and the UV ink-jet printing efficiency andquality are improved.

Owner:LUCKY HUAGUANG GRAPHICS

Method and system for manufacturing multi-layer composite paint-free molded three-dimensional board

ActiveCN107020788BAvoid crackingAvoid deformationLamination ancillary operationsLaminationManufacturing technologyPulp and paper industry

The invention discloses a manufacturing method of a multilayer composite paint-free molded three-dimensional board, and a system applied to the manufacturing method. The manufacturing method comprises the steps of S10, impregnating decorative base paper and balance base paper into glue to obtain impregnated decorative paper and impregnated balance paper; S20, using a steel male template to sleeve an upper press plate of a hot press, and using a steel flat template to sleeve a lower press plate of the hot press; S30, adjusting the working pressure of the hot press to a preset pressure, and adjusting the temperature of heat conduction oil to a preset temperature; S40, sequentially putting the impregnated decorative paper, a shaving board and the impregnated balance paper into the hot press in a paving sequence that the decorative paper is positioned at the upper layer, the shaving board is arranged at the middle layer, and the balance paper is positioned at the bottom layer; S50, maintaining the pressure of the hot press, wherein the pressure maintaining time is set in advance. After the manufacturing method and the system are adopted, the multilayer composite paint-free molded three-dimensional board can be obtained by taking the shaving board as a base material; a paint layer does not exist, so that the manufacturing technology is simplified, and the three-dimensional board is environment-friendly; furthermore, the produced three-dimensional board can be directly used for final consumption.

Owner:CROSPLUS HOME FURNISHINGS(SHANGHAI) CO LTD

A kind of modified tripentaerythritol acrylate and preparation method thereof

ActiveCN103435516BLow viscositySmall molecular weightCarbamic acid derivatives preparationOrganic compound preparationPolymer sciencePentaerythritol

The invention discloses a modified tripentaerythritol acrylic ester with low viscosity, high reactivity and shrunk volume as well as a preparation method thereof. The structural formula of the modified tripentaerythritol acrylic ester with low viscosity, high reactivity and shrunk volume is shown in specification. The modified tripentaerythritol acrylic ester has degree of functionality of 8-12, viscosity of 800-4000 m Pa.s and molecular weight of 1000-4000, and the modified tripentaerythritol acrylic ester also has very high reactivity, low viscosity, low migration of high molecular weight, high solidification efficiency, low volume shrinkage, excellent adhesive force, adjustable softness and adjustable flexibility. A prepared coating is good in impact resistance and strong in adhesive force. The preparation method is simple and easy to control, and the obtained product is high in purity and good in properties.

Owner:JIANGSU RUIYANG CHEM

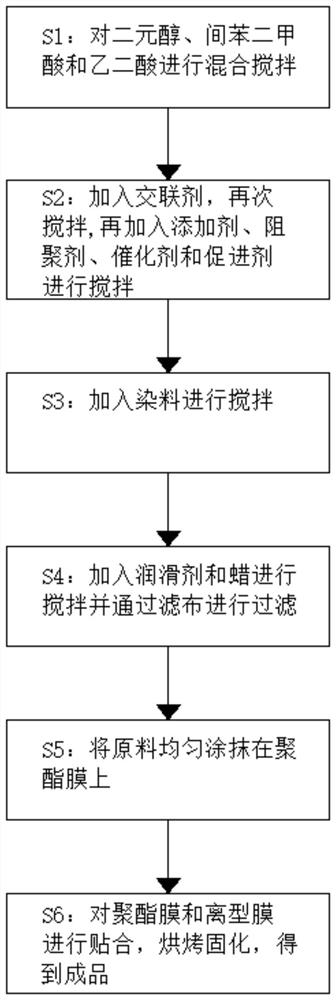

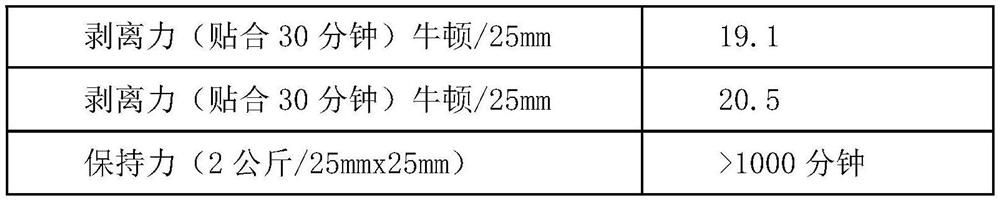

Polyester release film for optical film and preparation method of polyester release film

InactiveCN113150351AImprove performanceImprove product qualityCoatingsOXALIC ACID DIHYDRATEPolymer science

The invention discloses a polyester release film for an optical film and a preparation method of the polyester release film in the field of optical films, the polyester release film comprises a release film layer and a polyester film layer, the release film layer is arranged on one side of the polyester film layer; the release film layer is prepared from the following raw materials in parts by weight: 10-15 parts of dihydric alcohol, 10-15 parts of isophthalic acid, 10-15 parts of oxalic acid, 1-5 parts of a cross-linking agent, 1-5 parts of an additive, 1-5 parts of a polymerization inhibitor, 1-5 parts of a catalyst, 1-5 parts of an accelerant, 1-5 parts of dye, 1-5 parts of a lubricant and 1-2 parts of wax; the method comprises the following steps: S1, adding dihydric alcohol, isophthalic acid and oxalic acid into a container, mixing and stirring, and standing for later use after stirring is completed. According to the invention, unsaturated polyester resin can be dissolved, double bonds of the unsaturated polyester resin are subjected to a copolymerization reaction to obtain a body type product so as to improve the performance of cured resin, and meanwhile, a small amount of wax is added into the raw materials, so that a thin film is formed on the surface of a coating film, air is isolated so as to promote surface curing, the product quality of the polyester release film is improved, and the use of people is facilitated.

Owner:扬州万润光电科技股份有限公司

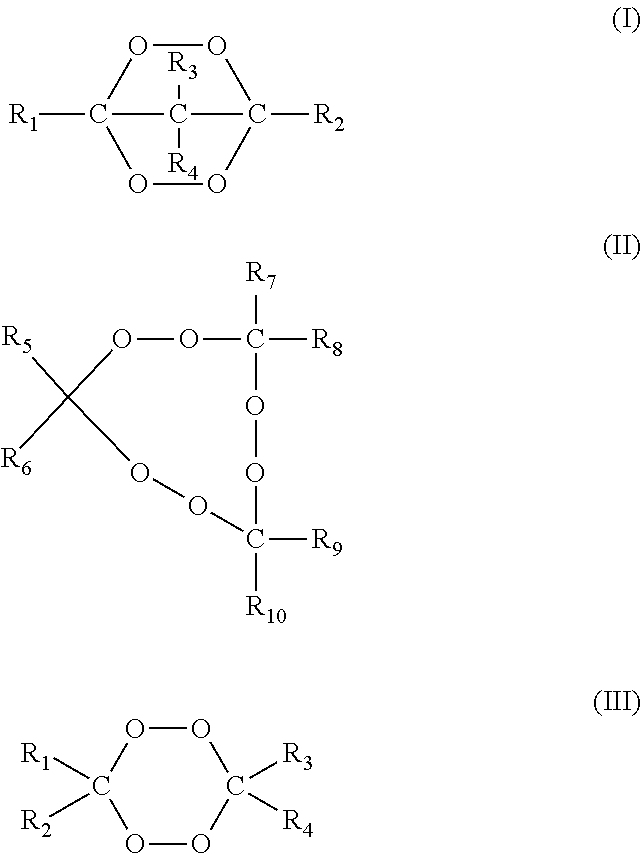

Radiation-curable benzophenone-terminated polyurethane resin and application thereof

PendingCN113072679AImprove thermal stabilityImprove stabilityMacromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer sciencePolyol

The invention discloses a radiation-curable benzophenone-terminated polyurethane resin and an application thereof, aims to provide a novel benzophenone-terminated polyurethane resin, and mainly overcomes the defects of poor thermal stability and difficult surface curing of the existing unsaturated group-terminated polyurethane resin. The radiation-curable benzophenone-terminated polyurethane resin is a reaction product of components (I), (II) and (III): at least one polyisocyanate (I); at least one polyol compound (II) containing at least two polyol compounds capable of reacting with isocyanate groups; and (III) at least one compound containing a benzophenone capable of reacting with an isocyanate group. The invention belongs to the technical field of novel polymer materials.

Owner:SHENZHEN LIHE BOHUI PHOTOSENSITIVE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com