UV-ultra-matte skin-touch surface coating method applied to woodware coating and surface coating paint

An ultra-dumb skin-feeling, UV-technology, used in polyurea/polyurethane coatings, devices for coating liquids on surfaces, coatings, etc., which can solve problems such as soft visual effects, poor topcoat transparency, and large powder volume. , to achieve the effect of improving hand feel, reducing surface tension and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

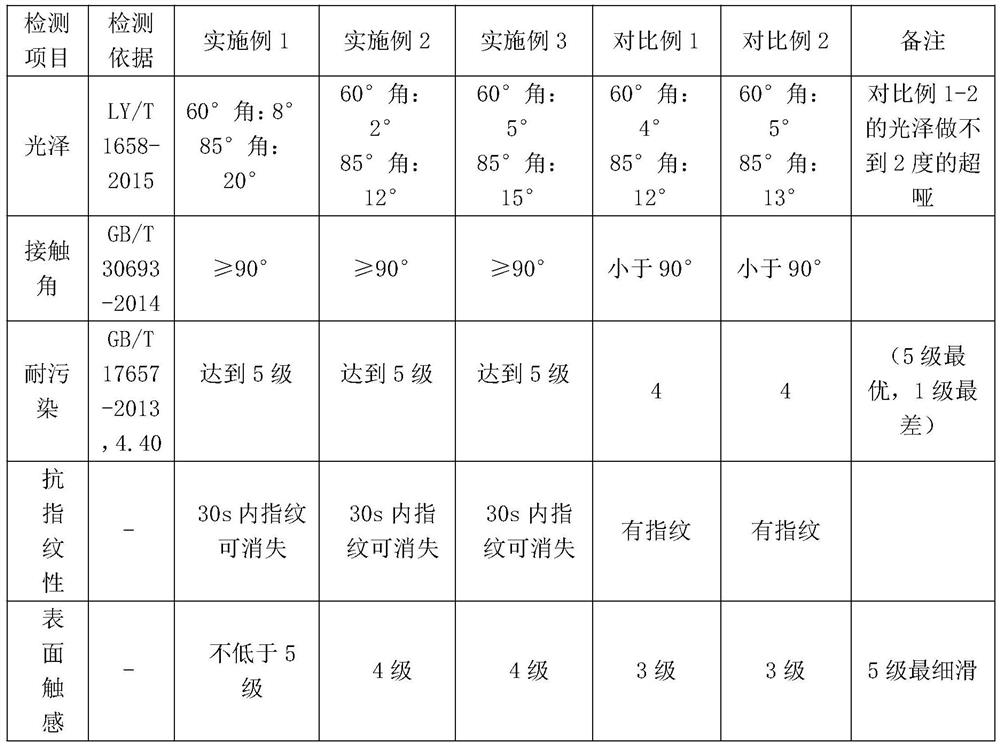

Examples

Embodiment 1

[0027] A UV-super-matte skin-feeling surface coating method applied to wood coating, the base coating is a conventional UV roller coating process, and the top coating is a UV-super-matte skin-feeling surface coating process, specifically using a special excimer equipment laser roller The equipment adopts UV-ultra-matte skin-feeling surface coating for roller coating, and the coating weight is 25g / m 2 .

[0028] The specific steps of the surface coating process are:

[0029] S1: Laser roller coating to obtain a sufficiently thick paint film and flatness;

[0030] S2: Pre-curing stage, pre-cured by energy-adjustable UV-LED lamp, curing energy is 20%; UV-ultra-matte skin effect coating that can obtain matte effect;

[0031] S3: Cured with an excimer lamp with a wavelength of 172 nm. During the curing process of the excimer lamp, nitrogen is used to isolate the oxygen on the surface of the coated substrate, providing a wrinkled surface, obtaining an ultra-matte gloss, and formin...

Embodiment 2

[0037] A UV-super-matte skin-feeling surface coating method applied to wood coating, the base coating is a conventional UV roller coating process, and the top coating is a UV-super-matte skin-feeling surface coating process, specifically using a special excimer equipment laser roller The equipment adopts UV-ultra-matte skin-feeling surface coating for roller coating, and the coating weight is 40g / m 2 . The topcoating process is the same as that of Example 1, except that the ratio of UV-ultramatte skin-feeling topcoat is different. details as follows:

[0038] Wherein, the UV-ultra-dumb skin-feeling surface coating comprises the following ingredients by weight: 100% UV resin 60%, defoamer 0.5%, dispersant 1.0%, skin-feeling powder 5%, hand feel 2% of agent, 4% of initiator, 1.5% of anti-settling agent, and the balance is monomer.

[0039] The 100% UV-resin is 3-off UV urethane acrylic resin, the specific manufacturer is CYTEC; the monomer is acrylate, the manufacturer is CYT...

Embodiment 3

[0042] A UV-super-matte skin-feeling surface coating method applied to wood coating, the base coating is a conventional UV roller coating process, and the top coating is a UV-super-matte skin-feeling surface coating process, specifically using a special excimer equipment laser roller The equipment adopts UV-ultra-matte skin-feeling surface coating for roller coating, and the coating weight is 25g / m 2 .

[0043] The surface coating process is as follows:

[0044] S1: Laser roller coating to obtain a sufficiently thick paint film and flatness;

[0045]S2: Pre-curing stage, pre-cured by energy-adjustable UV-LED lamp, curing energy is 35%; UV-ultra-matte skin effect coating that can obtain micro-frosting effect;

[0046] S3: Cured with an excimer lamp with a wavelength of 172nm. During the curing process of the excimer lamp, nitrogen is used to isolate the oxygen on the surface of the coated substrate, providing a wrinkled surface, obtaining an ultra-dumb gloss, and forming diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com