Patents

Literature

55results about How to "Anti-fingerprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-dazzle and antireflection (AR) glass capable of resisting fingerprint, and processing method thereof

InactiveCN103950248AAnti-glare equippedAnti-glare lowGlass/slag layered productsOptical transmittanceFingerprint

The invention discloses anti-dazzle and antireflection (AR) glass capable of resisting fingerprint, and a processing method of the glass. An anti-dazzle film layer is sprayed onto a glass substrate of the glass processed by the method, an AR film layer is arranged on the anti-dazzle film layer by sputtering coating, and an anti-fingerprint film layer is sprayed onto the AR film layer. Therefore, the glass has the characteristics of resisting dazzle, being high in light transmittance and low in reflection, and resisting fingerprint and dirt.

Owner:SHENZHEN SANXIN JMT GLASS

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

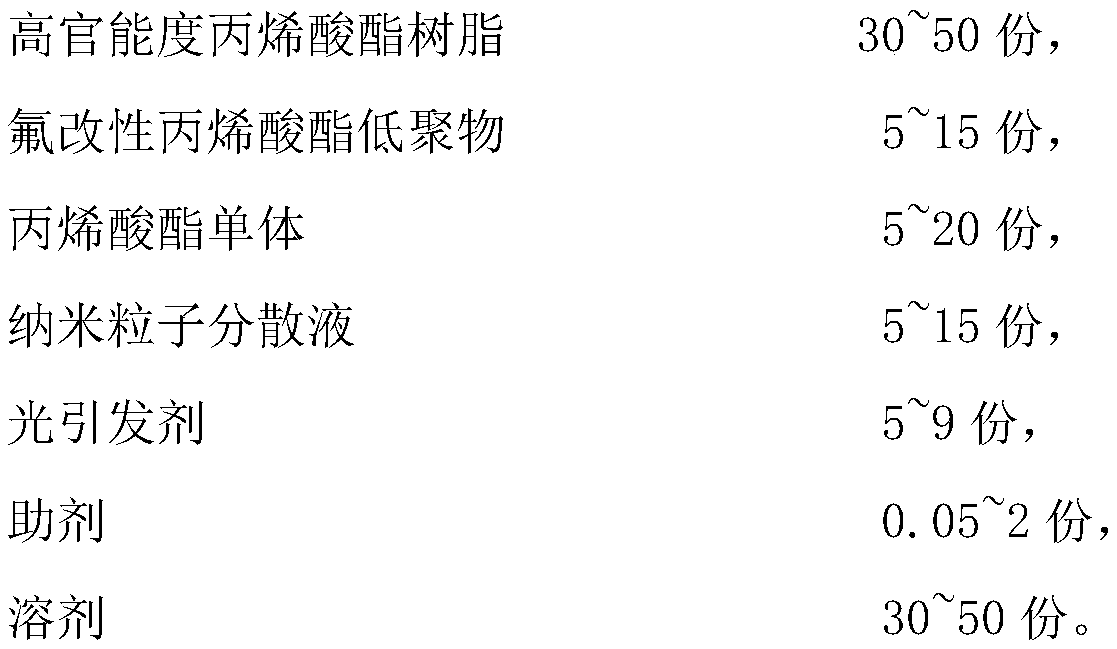

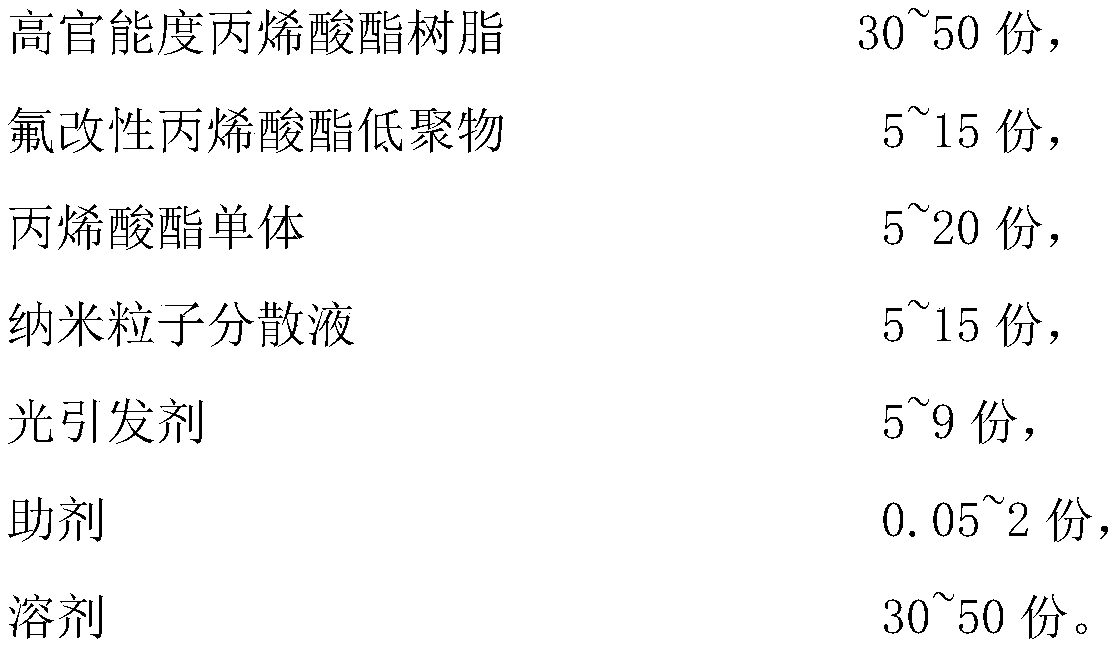

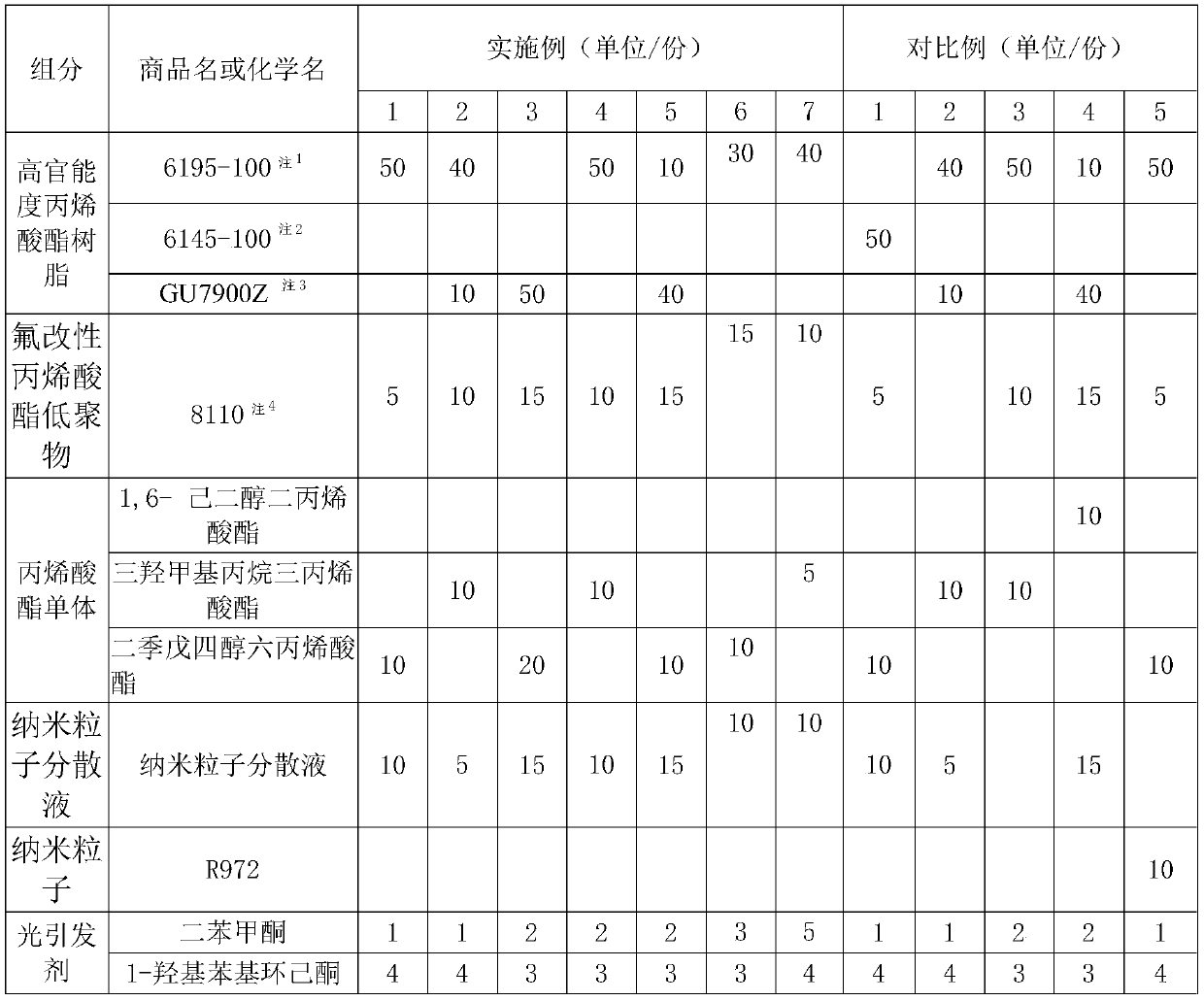

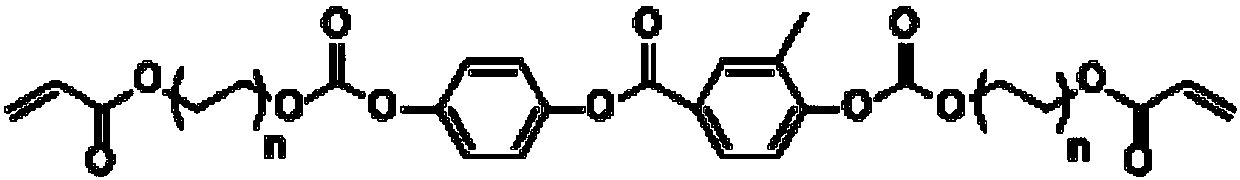

Ultraviolet curing coating composition with high wear resistance and fingerprint resistance and preparation method thereof

InactiveCN111100545AHigh steel wool wear-resistantImprove anti-fingerprintPolyurea/polyurethane coatingsPolyester coatingsPolymer scienceOligomer

The invention provides an ultraviolet curing coating composition with high wear resistance and fingerprint resistance and a preparation method thereof. The composition is prepared from the following components in parts by weight: 30-50 parts of high-functionality acrylate resin, 5-15 parts of fluorine-modified acrylate oligomer, 5-20 parts of an acrylate monomer, 5-15 parts of nanoparticle dispersion liquid, 5-9 parts of a photoinitiator, 0.05-2 parts of an auxiliary agent and 30-50 parts of a solvent. Compared with the prior art, the steel wool of the prepared ultraviolet curing coating composition is excellent in wear resistance and has fingerprint resistance and hand sweat resistance; and the coating has high hardness, is suitable for surface protection of plastic base materials, has excellent comprehensive performance, and can be applied to the related fields of mobile phone plastic rear covers, mobile phone films and the like.

Owner:SHANGHAI WEIKAI CHEM +2

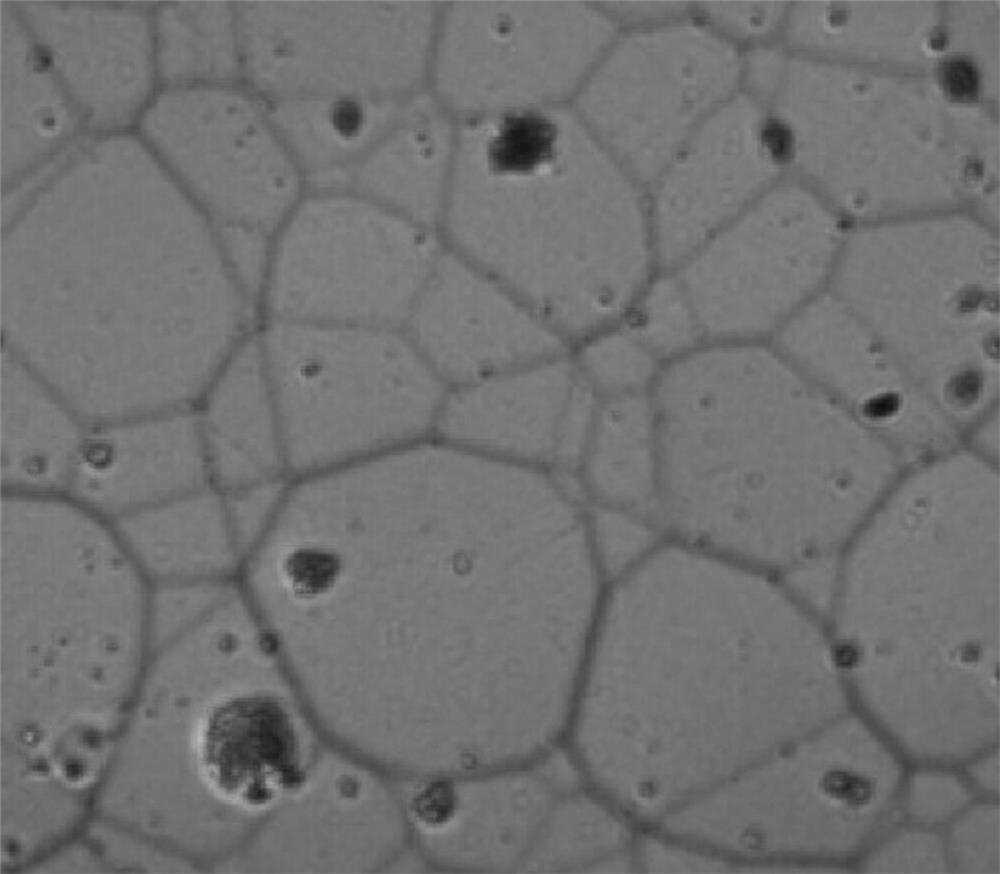

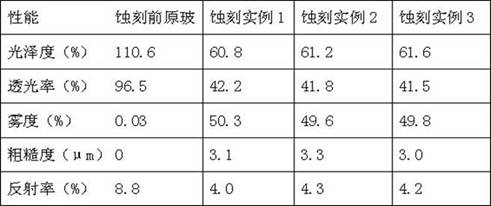

Glass etching liquid and method of etching glass therewith, cover glass and preparation method thereof

The invention provides a glass etching liquid, a method of etching glass therewith, a cover glass and a preparation method thereof. According to the embodiment in the invention, the glass etching liquid comprises: ammonium fluoride, a surfactant, an acid and water. The glass etching liquid can effectively etch glass. By the glass etching liquid, various glass products can be etched effectively according to actual requirement, so that the etched glass products have corresponding performances, and what is more, by means of the glass etching liquid to etch the cover glass, an uneven coarse surface can be formed on the cover glass, so that the cover glass achieves an anti-dazzle function. In addition, the invention also provides the etching method of etching glass with the glass etching liquid and the preparation method of the cover glass.

Owner:NANCHANG O FILM OPTICAL TECH +3

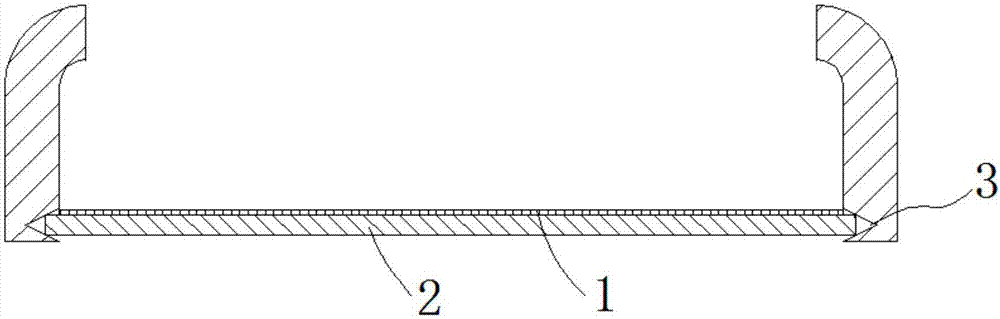

Electronic product screen protection glass film and manufacturing method thereof

InactiveCN102896839AAntifoulingAnti-fingerprintGlass/slag layered productsGlass reforming apparatusDisplay deviceEngineering

The invention discloses an electronic product screen protection glass film and a manufacturing method thereof. The glass film comprises a glass film planar part which is matched with a planar part of an electronic product screen, and a glass film curved surface part which extends out of the glass film planar part and is matched with a curved surface part of the electronic product screen. The manufacturing method comprises the following steps of: blanking, coating a glass demolding agent onto a mold, loading a blanked material onto the mold, heating the blanked material and the mold and preserving heat, pressurizing and assembling the mold, taking out for standing, reinforcing, performing vapor deposition and the like. The electronic product screen protection glass film disclosed by the invention has the functions of preventing stains, preventing fingerprints, preventing collision and the like, can be up to 7-8 H Moh's hardness on the aspect of the surface hardness, and can be widely applied to screen protection of electronic equipment such as mobile phones and electronic instrument displays; and due to the adoption of the manufacturing method of the electronic product screen protection glass film, the problem of easiness in breaking of thin glass during machining is solved, the rate of graded product is high, and the production and manufacturing costs are lowered.

Owner:蒋兰波

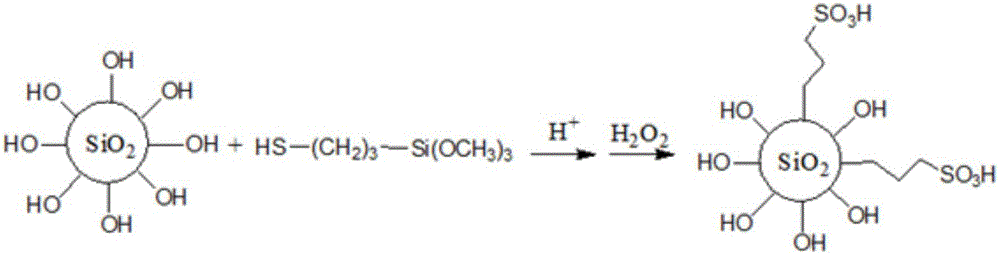

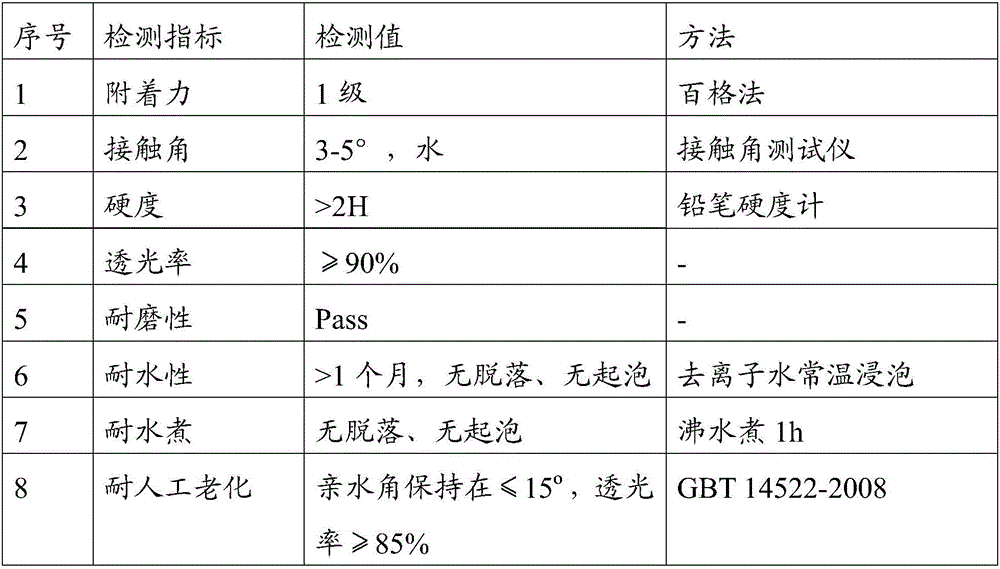

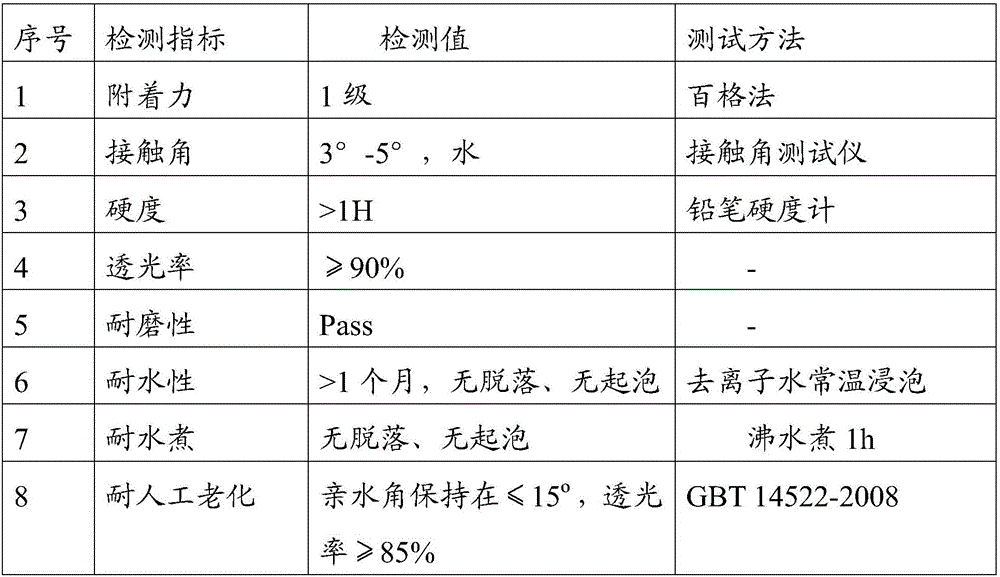

Silicon-zirconium composite super-hydrophilic abrasion-resistant coating

ActiveCN106519741AGood anti-fog performanceImprove water resistanceAntifouling/underwater paintsPaints with biocidesSolventStain

The invention relates to a silicon-zirconium composite super-hydrophilic abrasion-resistant coating. The silicon-zirconium composite super-hydrophilic abrasion-resistant coating comprises the following components in parts by weight: 5-30 parts of single-layered zirconium hydrogen phosphate, 10-50 parts of silica sol containing sulfonic acid groups, 20-30 parts of a silane coupling agent and 30-60 parts of an alcohol solvent. A preparation method of the silicon-zirconium composite super-hydrophilic abrasion-resistant coating comprises the following steps: ultrasonically dispersing the single-layered zirconium hydrogen phosphate in the alcohol solvent to obtain single-layered dispersed zirconium hydrogen phosphate, blending and compounding the single-layered dispersed zirconium hydrogen phosphate with the silica sol containing the sulfonic acid groups, then adding the silane coupling agent, simultaneously adding acid, adjusting pH value of a system to be 3-5, and carrying out cohydrolysis reaction for 1-8 hours to obtain the silicon-zirconium composite super-hydrophilic abrasion-resistant coating. The silicon-zirconium composite super-hydrophilic abrasion-resistant coating is high in hydrophilicity, fog resistance, water resistance and weather resistance, and longer in service life; a coating prepared by the coating is high in hardness, abrasion resistance, scratch resistance, fingerprint resistance and stain resistance.

Owner:GUANGDONG BINHAO TRAVELWARE

Surface bright anodic oxidation coloring method for titanium and titanium alloy

ActiveCN105316744ANo variegationNo anti-fingerprintSurface reaction electrolytic coatingMegasonic cleaningTitanium

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

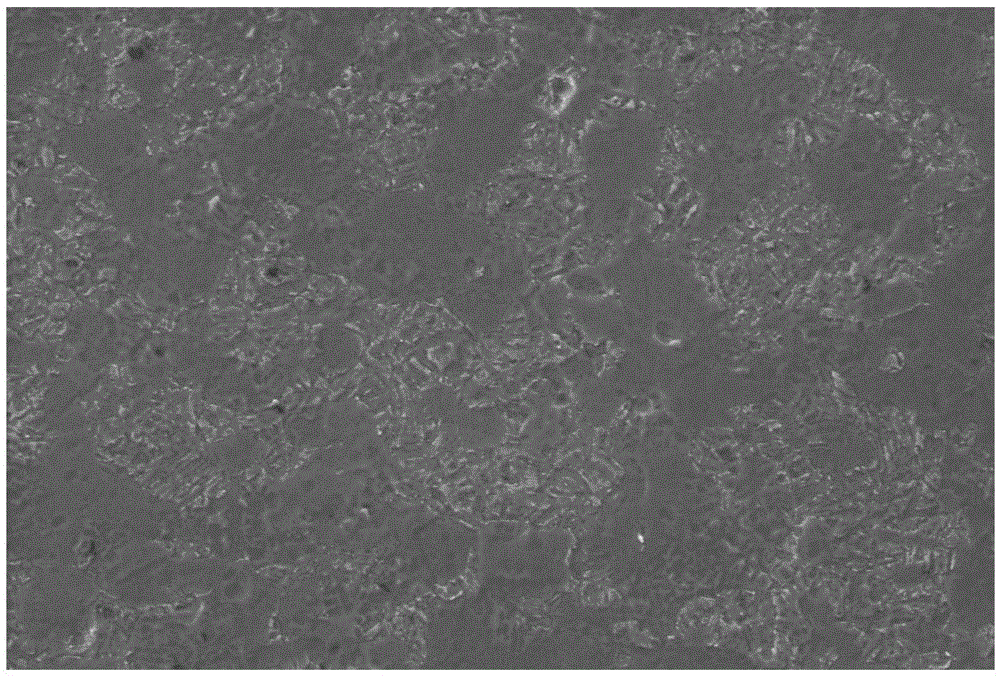

Preparation process of scratch-resistant glass with flashing sand effect

The invention belongs to the technical field of etched glass, and in particular, relates to a preparation process of scratch-resistant glass with flash sand effect. The preparation process comprises the following steps: preparing etching liquid and carrying out etching treatment on a raw glass sheet; depending on a fact that fluoride has an etching effect on glass, carrying out multi-stage chemical reaction with the surface of the glass in acid liquor with certain concentration and type; generating a nanoscale diamond-shaped microcrystalline particle adhesion layer is generated, and uniformlydistributing on the whole glass surface. Therefore, the visual effect of glittering in the light facing process is achieved; meanwhile, the excellent properties of reflection light resistance, scratchresistance, dust resistance, fingerprint resistance and the like are realized; the process is simple and practical, easy to operate and low in cost, microcrystalline diamond particles on the surfaceof the prepared scratch-resistant crystal diamond flash point effect glass are uniform in distribution and consistent in size, and the technical indexes such as roughness, glossiness, light transmittance and haze meet the specific requirements of the art decorative glass industry.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

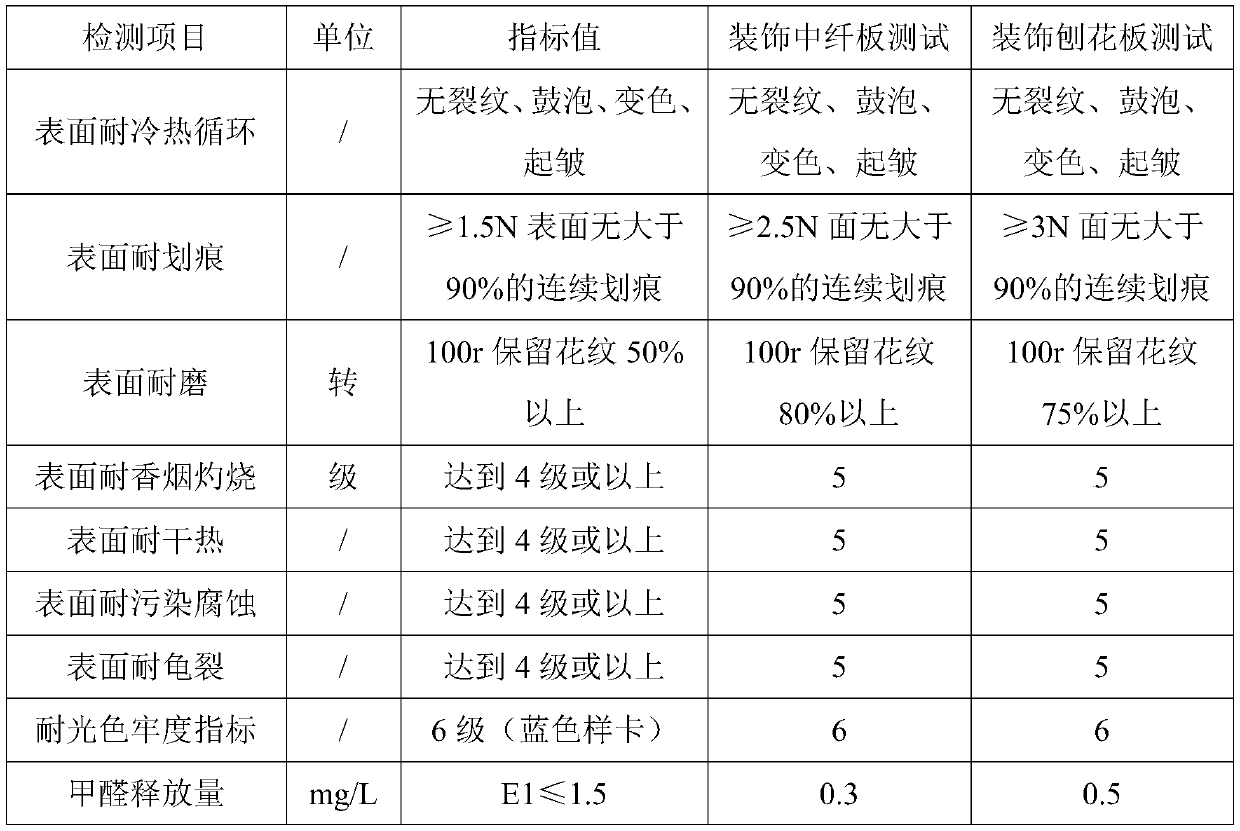

Matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper and preparing method and application thereof

ActiveCN109797598AOleophobic and hydrophobic propertiesAchieve "lotus leaf" effectCoatings with pigmentsWater-repelling agents additionMelamine formaldehyde resinMelamine resin

The invention discloses matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper and a preparing method and application thereof. The preparing method of the matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper comprises the following steps of 1, impregnating printed and decorated body paper with an adhesive, and conducting precuring to obtain asemi-finished product A; 2, coating the semi-finished product A with matt melamino-formaldehyde resin to obtain a semi-finished product B with a matt layer; 3, coating the matt layer of the semi-finished product B with oleophobic and hydrophobic melamino-formaldehyde resin, coating the other side of the semi-finished product B with melamine resin, and conducting curing and forming. The inventionfurther discloses the application of the matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper in the field of home decoration. The surface of the prepared melamine-urea-formaldehyde impregnated bond paper has the oleophobic and hydrophobic performance, the lotus-leaf effect of the melamine-urea-formaldehyde impregnated bond paper product is achieved, and the matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper has the functions of fingerprint prevention and effects of the mattness of the interior. A resin layer with mattness is arrangedbelow an oleophobic and hydrophobic layer, and matt powder cannot pollute steel plates during pressing and patching of downstream pressing plate plants.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

Blue-light-proof film and preparation method thereof

InactiveCN109553790AGood flexibilityImprove adhesionPolyurea/polyurethane coatingsUV curingOptical coating

The invention provides a blue-light-proof film which comprises a thermoplastic base material and a functional coating arranged on the thermoplastic base material; a blue-light-proof coating is arranged on one surface, opposite to the functional coating, of the thermoplastic base material, and / or, the blue-light-proof coating is arranged between the thermoplastic base material and the functional coating. Compared with the prior art, two UV-cured optical coatings are arranged on the thermoplastic base material, the two UV-cured optical coatings are the blue-light-proof coating and the functional coating respectively; by mixing the ratio of components in a reactive diluent, the blue-light-proof coating has good flexibility and re-coating adhesive force, and interlayer separation is not easyto occur; no blue light blocking agent is contained in the functional coating, the influence of the blue light blocking agent on the UV curing condition is eliminated, the functional coating can be easily endowed with other properties, by mixing the types and proportions of main body resin and the reactive diluent, the functional coating has good flexibility, and cracking and falling of the coating cannot be caused in the hot-pressing molding process.

Owner:安徽屹珹新材料科技有限公司

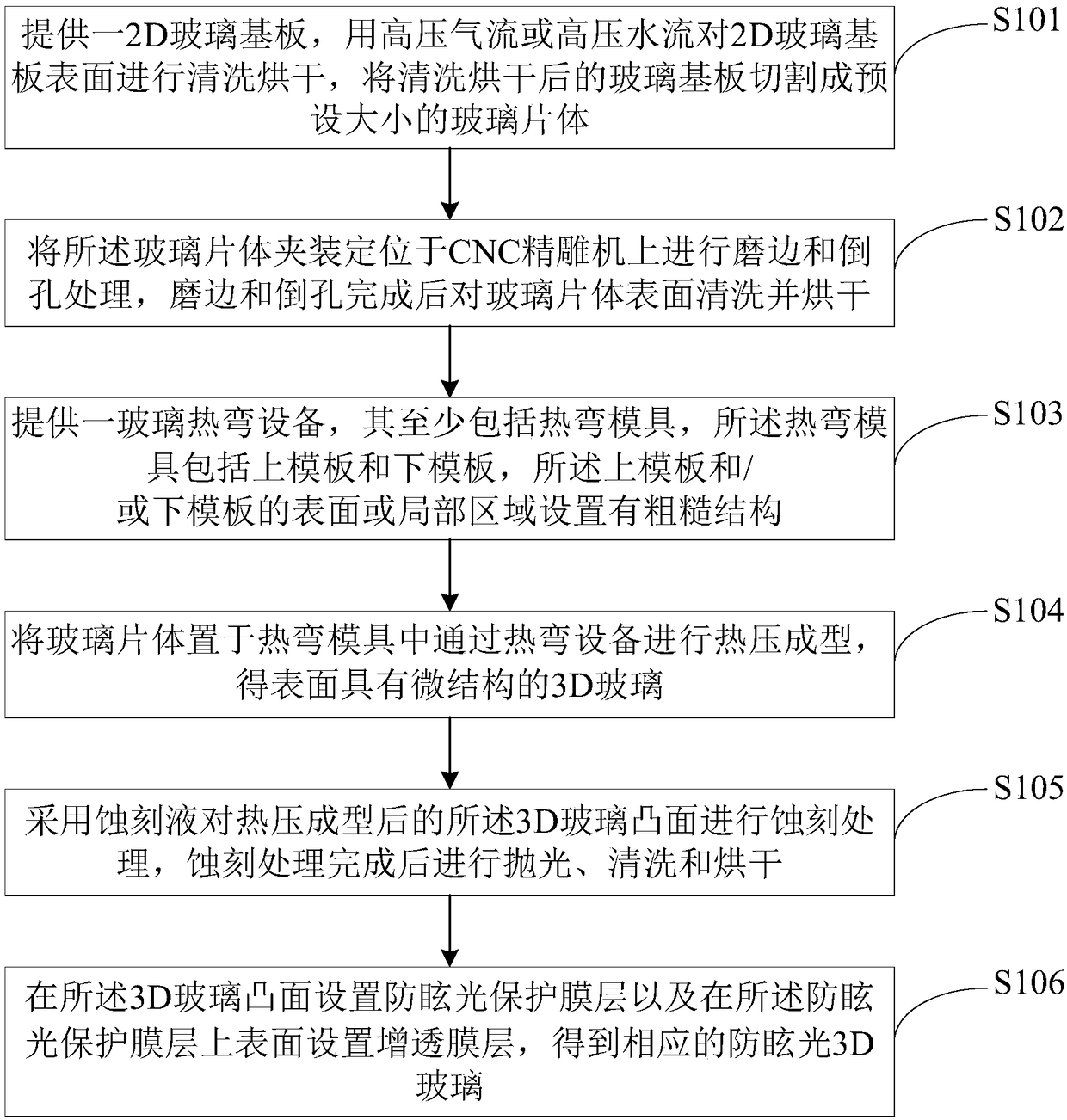

Production method of anti-glare 3D glass

The invention is applicable to the technical field of glass production and provides a production method of anti-glare 3D glass. The production method comprises the steps as follows: providing a 2D glass substrate, cleaning and drying the surface of the glass substrate, and cutting the glass substrate into glass pieces in preset size; clamping and positioning the glass pieces on an CNC carving machine for edging and chamfering treatment, and cleaning and drying the surface of the glass pieces; providing a glass hot-bending device at least comprising a hot-bending mold, wherein the hot-bending mold comprises an upper mold plate and a lower mold plate, and a rough structure is arranged on the surface or in a local area of the upper mold plate and / or the lower mold plate; placing the glass pieces in the hot-bending mold for hot-press molding by the hot-bending device to obtain 3D glass with microstructure on the surface; etching the convex surface of the hot-pressed 3D glass by an etchingsolution, and performing polishing, cleaning and drying after etching treatment; arranging an anti-glare protecting film layer on the convex surface of the 3D glass and arranging an antireflection film layer on the upper surface of the anti-glare protecting film layer to obtain the corresponding anti-glare 3D glass.

Owner:仙游县元生智汇科技有限公司

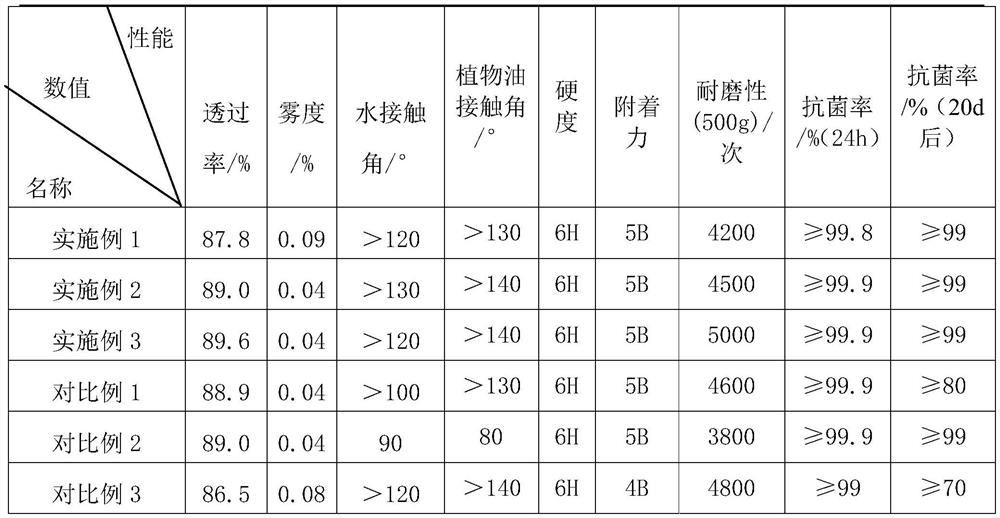

Anti-fingerprint antibacterial glass

ActiveCN113105776AStrong antibacterial abilityGood antifouling performanceAntifouling/underwater paintsPaints with biocidesDichloromethaneOrganosilicon

The invention relates to the field of antibacterial glass, in particular to an anti-fingerprint antibacterial glass. The anti-fingerprint antibacterial glass comprises an original glass sheet and an anti-fingerprint antibacterial layer which coats the upper surface of the original glass sheet, the anti-fingerprint antibacterial layer is formed by coating an antibacterial composition, and the antibacterial composition is prepared from, by mass, 2 to 10 percent of organic modified acrylic resin, 60 to 80 percent of methylbenzene, 10 to 30 percent of dichloromethane and 1 to 8 percent of fluorinated silver-loaded carbon nanohorn ethanol dispersion liquid. The fluorinated silver-loaded carbon nanohorn ethanol dispersion liquid is prepared on the basis of carboxylated single-walled carbon nanohorns and has antibacterial, antifouling and anti-fingerprint effects, and the antibacterial effect reaches 99% or above. According to the antibacterial glass, self-assembly of the antibacterial nano particles and the synergistic effect of the components are induced through solvent volatilization, so that the antibacterial glass has an excellent anti-fingerprint effect and outstanding antibacterial performance, and breeding of bacteria on the surface can be effectively inhibited.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

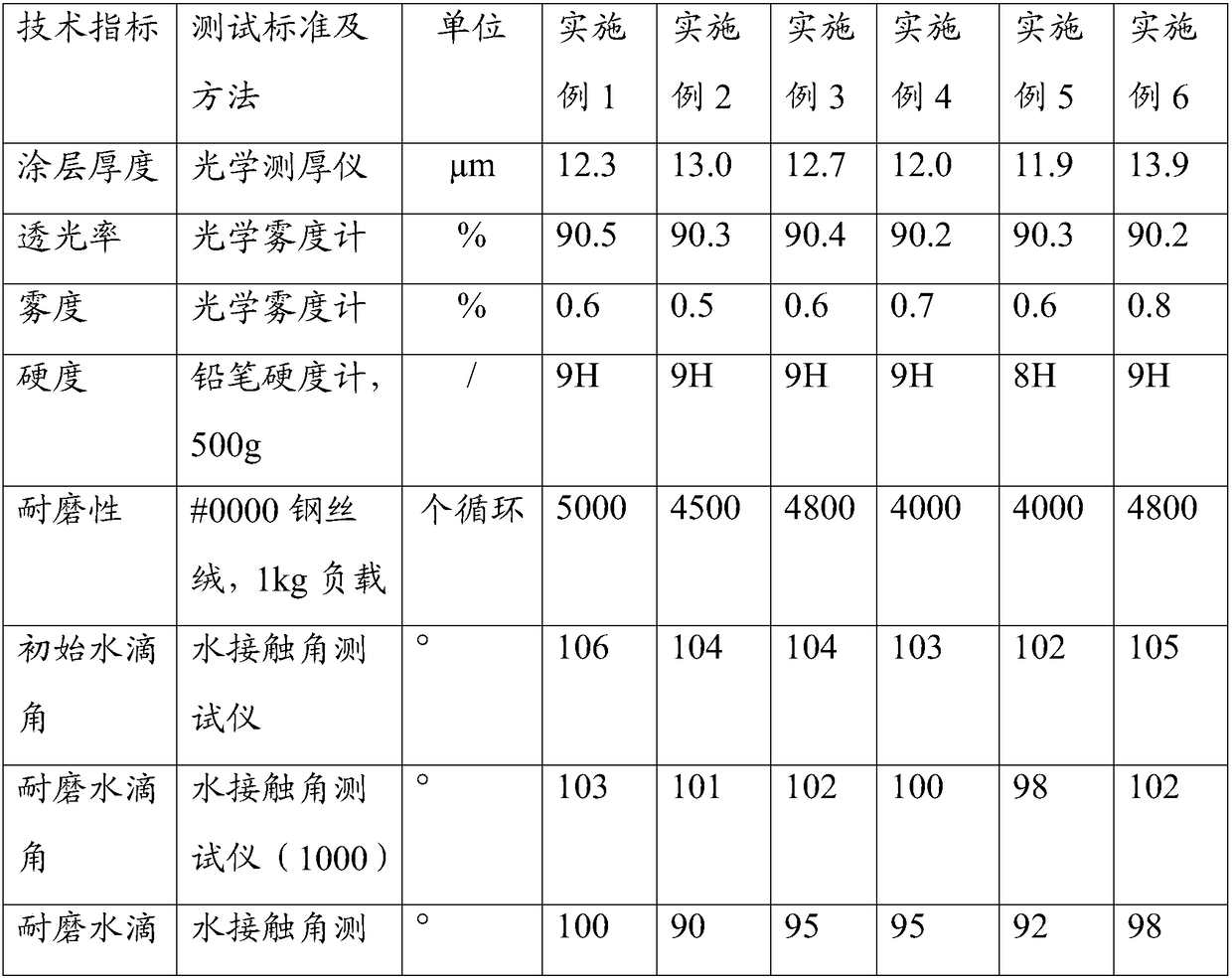

Photo-curing type hardening film with high hardness and preparation method of hardening film

InactiveCN109232942AHigh hardnessLow anti-fingerprintPolyurea/polyurethane coatingsPolyester coatingsOligomerHardness

The invention belongs to the field of optical film material application and particularly relates to a photo-curing type hardening film with high hardness and a preparation method of the hardening filmand provides the photo-curing type hardening film with high hardness and the preparation method of the hardening film to solve the technical problem of low hardness of thin coatings of hardening films. The photo-curing type hardening film with high hardness comprises a substrate layer and a photo-curing coating, wherein the photo-curing coating comprises high functional group acrylate compounds,perfluoro-modified oligomer, a photoinitiator, a dispersant, inorganic nanoparticles and a fluorine-containing aid, and raw materials of the photo-curing coating are prepared into a photo-curing coating firstly. The photo-curing type hardening film with high hardness has ultrahigh hardness, has the advantages of fingerprint prevention, super wear resistance and low warping and has very good comprehensive performance. The process of the preparation method is simple, roll-to-roll coating can be realized, and the production efficiency is high.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

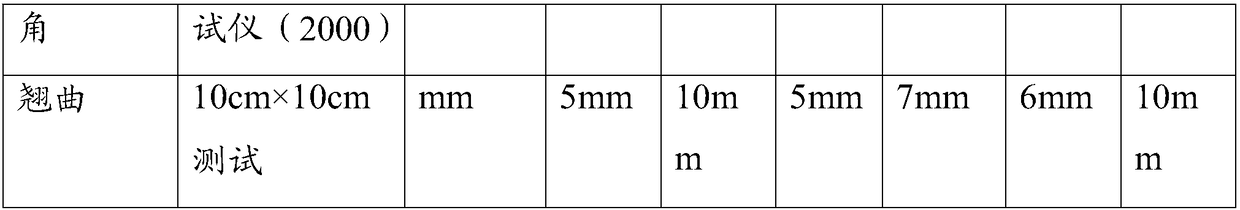

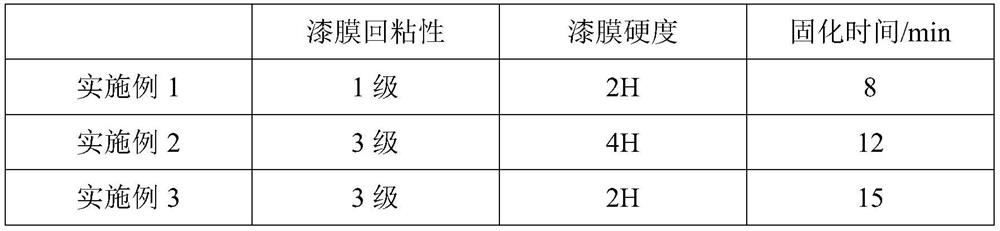

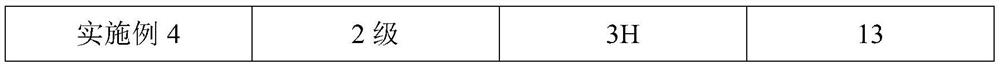

UV-ultra-matte skin-touch surface coating method applied to woodware coating and surface coating paint

PendingCN114789129AIncrease elasticityModerate crosslink densityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceExcimer lamp

The invention discloses a UV-ultra-matte skin-feeling surface coating method and a surface coating applied to woodware coating, a conventional UV roller coating process is adopted for bottom coating, a UV-ultra-matte skin-feeling surface coating process is adopted for surface coating, and specifically, special excimer equipment laser roller equipment is adopted for roller coating by adopting the UV-ultra-matte skin-feeling surface coating. The UV-ultra-matte skin-feeling coating is prepared from special raw materials through compatibility of the materials, and then the effects of extinction and skin feeling are achieved in cooperation with special excimer equipment and process. According to the UV-ultra-matte skin-touch coating, in the aspect of selection of UV resin, resin with good elasticity, moderate crosslinking density and good surface curing is selected, the resin can provide a soft framework, meanwhile, the surface curing is good, special excimer curing equipment is matched, after a paint film is cured by an excimer lamp, wrinkled textures are formed on the surface to obtain ultra-matte, the addition amount of matte powder is reduced, and the skin-touch effect is good. The hand feeling of a paint film is greatly improved, and the leveling property of a paint surface is excellent.

Owner:JIANGSU HIMONIA TECH

Surface treatment technology of automobile trims

ActiveCN105710081AHigh light transmittanceWaterproofVacuum evaporation coatingSputtering coatingEnvironmental engineeringVacuum coating

The invention discloses a surface treatment technology of automobile trims. The technology includes the following steps that (1), the trims are placed into three alkaline tanks in sequence for ultrasonic washing; (2), ultrasonic washing is conducted on the trims subjected to alkaline washing; (3), the washed trims are subjected to ultrasonic washing; (4), the trims subjected to acid pickling are sequentially washed; (5), the washed trims are sequentially placed in two drying tanks for drying; (6), the dried trims are sequentially placed into three cooling tanks for cooling; (7), the cooled trims are placed in a primer tank for varnishing; (8), the trims are placed into the two drying tanks for drying; (9), the dried trims are sequentially placed into two cooling tanks for cooling; (10), the cooled trims are placed into a hardening tank for hardening; (11), the hardened trims are sequentially placed into three hot air drying tanks for heating and drying; (12), the trims are placed into the cooling tanks to be cooled for 7 min; (13) the trims are placed in a vacuum coating machine for coating.

Owner:SUZHOU JINYAN PHOTOELECTRIC TECH CO LTD

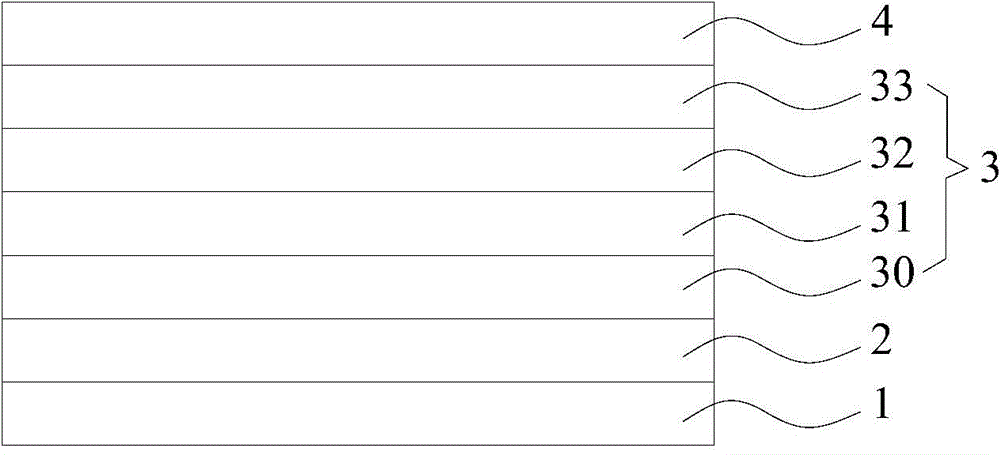

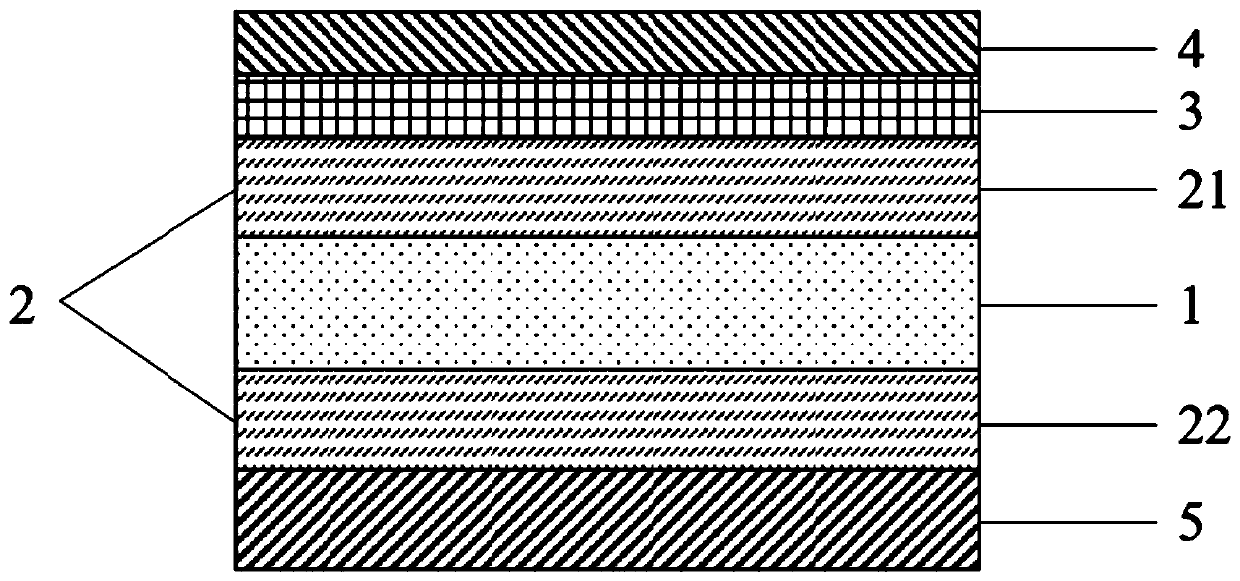

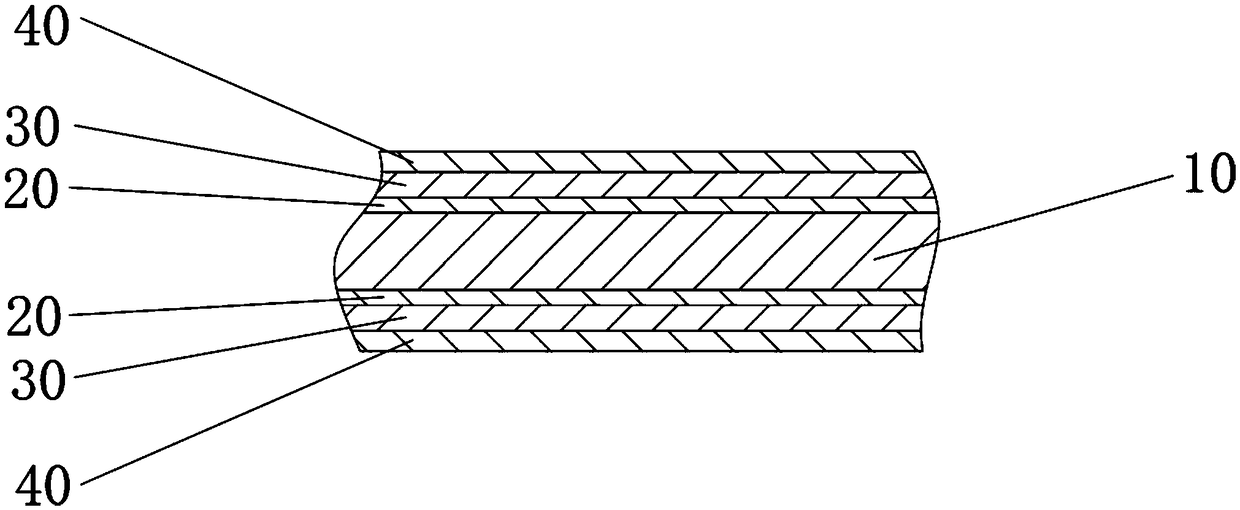

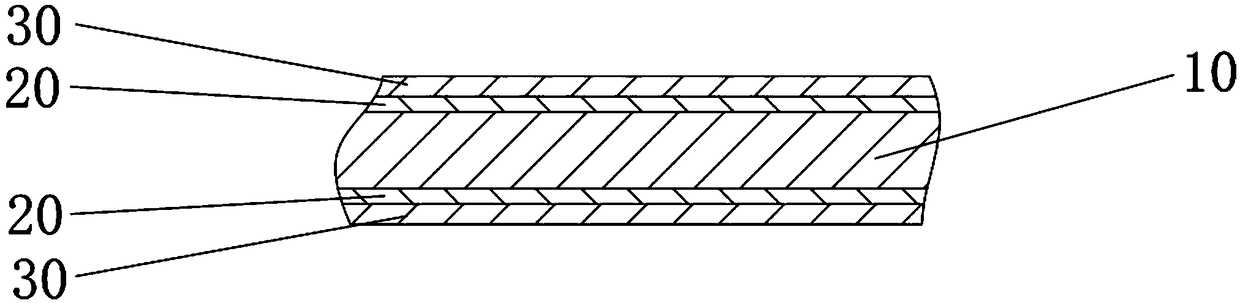

Polaroid with water-proof nano-coating and liquid crystal display

InactiveCN107247301AAnti-scratchAnti-reflectionPolarising elementsNon-linear opticsLiquid-crystal displayWater vapor

The invention provides a polaroid with a water-proof nano-coating and a liquid crystal display provided with the same. The polaroid with the water-proof nano-coating comprises the water-proof nano-coating, a first TAC film, a PVA film, a second TAC film, a PSA adhesive layer, and a release film in sequence. The water-proof nano-coating, the first TAC film, the PVA film, the second TAC film, the PSA adhesive layer, and the release film are attached to one another. The water-proof nano-coatings is used for resisting water vapor and providing structural strength, the first TAC film is used for providing protection, the PVA film is used as a polarizer layer, the second TAC film is used for providing protection, the PSA adhesive layer is used for providing cohesive property, and the release film is used for providing isolation, padding, and protection. Because the water-proof nano-coating is arranged on the outside of the polaroid, the polaroid with the water-proof nano-coating and the liquid crystal display are not only water-proof, but also have advantages of resistance to scratching, anti-reflection, fingerprint-proofness and the like.

Owner:深圳市鑫友道科技有限公司

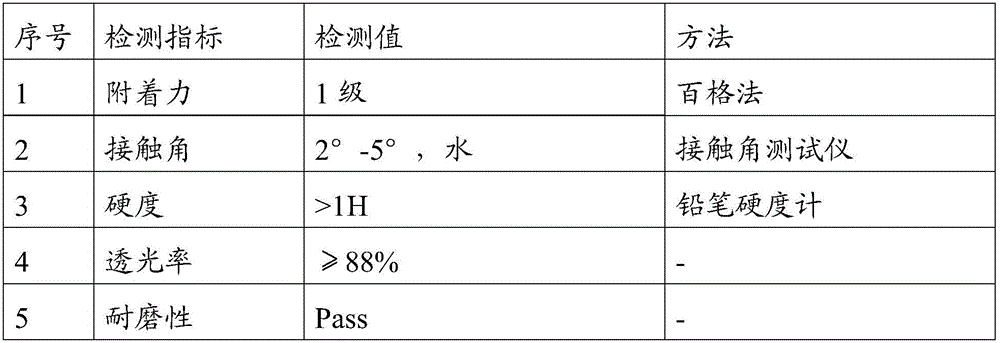

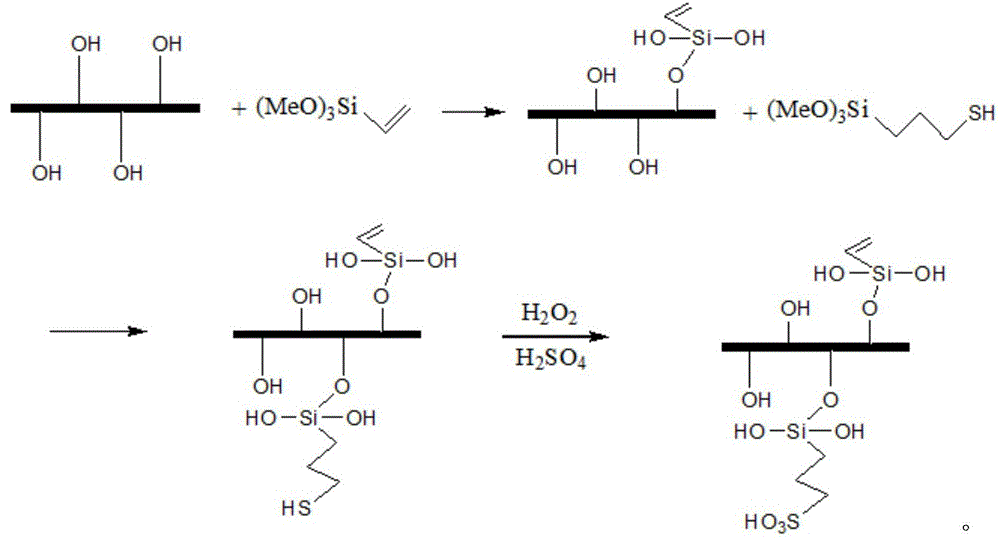

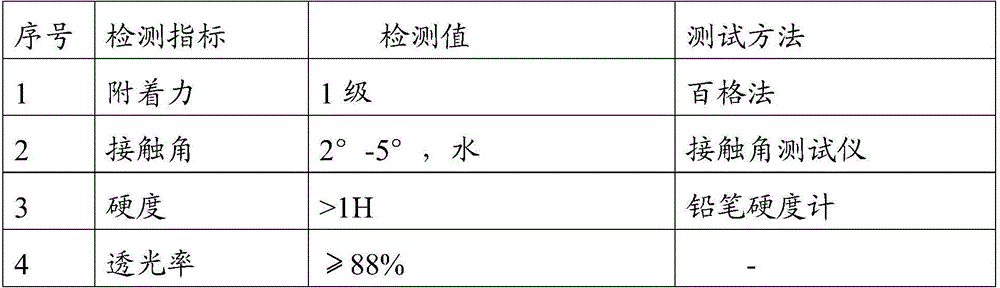

Superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating

ActiveCN106398512AImprove compatibility and hydrophilic performanceGood anti-fog performanceAntifouling/underwater paintsPaints with biocidesSolventWeather resistance

The invention relates to a superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating. The superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating comprises, by weight, 8 to 20 parts of zirconiumhydrogen phosphate containing olefinic bonds and sulfonic acid groups, 5 to 30 parts of a UV resin oligomer, 5 to 15 parts of a reactive diluent containing 1 to 6 functional groups, 0.5 to 2 parts of a levelling agent, 10 to 50 parts of a solvent, and 2 to 6 parts of a photoinitiator. A preparation method of the superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating comprises following steps: the zirconiumhydrogen phosphate containing olefinic bonds and sulfonic acid groups is subjected to ultrasonic dispersion in the solvent; the UV resin oligomer, the reactive diluent containing 1 to 6 functional groups, the leveling agent, and the photoinitiator are added; and ultrasonic dispersion is carried out for a second time after uniform stirring. The superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating possesses excellent superhydrophilic anti-fogging performance, water resistance, and weathering resistance, and long service life; and hardness, wear resistance, scratch resistance, finger print pollution resistance, and stain resistance of coating layers prepared from the superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating are excellent.

Owner:GUANGDONG BINHAO TRAVELWARE

Fingerprint-proof veneer adhesive film paper, and preparation method and application thereof

ActiveCN109695180AHydrophobic and oleophobicAchieve "lotus leaf" effectPaper coatingCoatingsAdhesiveMelamine formaldehyde resin

The invention discloses fingerprint-proof veneer adhesive film paper, and a preparation method and an application thereof. The fingerprint-proof veneer adhesive film paper includes a base material; adhesive intermediate layers are arranged on both sides of the base material, a melamine formaldehyde resin surface coating layer is arranged on the adhesive intermediate layer at one side, and a melamine resin back coating layer is arranged on the adhesive intermediate layer at the other side; the melamine formaldehyde resin surface coating layer is made of melamine formaldehyde resin with a mattefunction. At the same time, the invention also discloses the preparation method of the fingerprint-proof veneer adhesive film paper, and an application of the fingerprint-proof veneer adhesive film paper in preparation of decorative panels. The melamine formaldehyde resin used for coating is specially treated to make the melamine formaldehyde resin film have hydrophobic and oleophobic properties,so a lotus leaf effect of the veneer adhesive film paper product is realized, and the fingerprint-proof effect is realized; moreover, the modified melamine formaldehyde resin also contains matte powder which can provide the interior matte effect.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

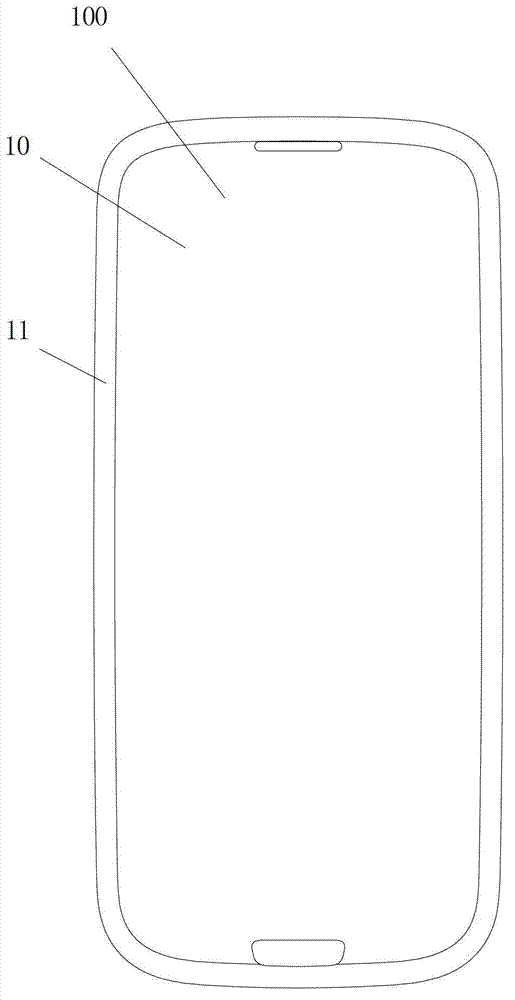

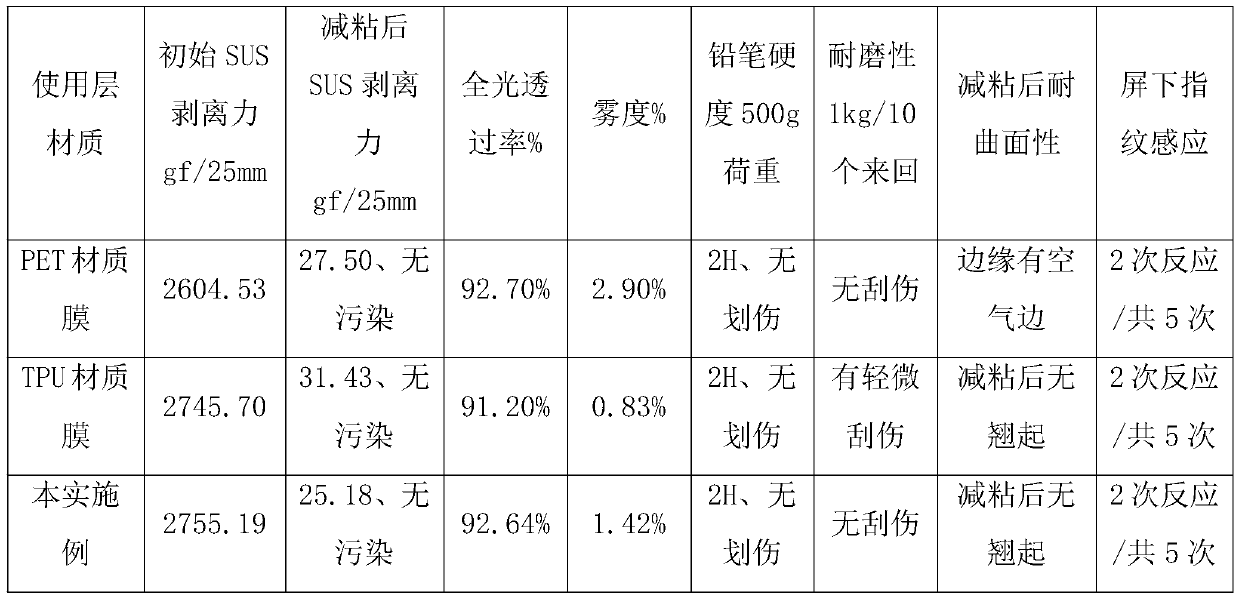

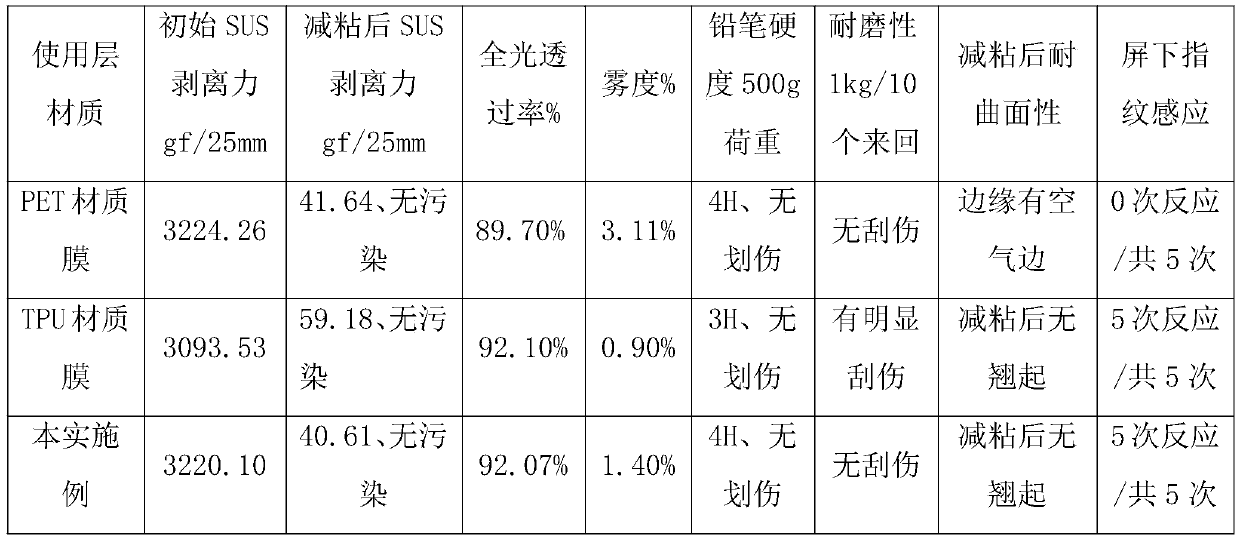

Protective film applied to curved screen mobile phone

PendingCN111087937AThere is no phase differenceSolve unrecognizedFilm/foil adhesivesComposite filmAdhesive

The protective film applied to the curved-screen mobile phone at least comprises a protective film layer, a functional coating, a composite film layer and a pressure-sensitive adhesive layer, whereinthe protective film layer is the outermost layer of the protective film; the functional coating layer is formed on the inner side of the protective film layer; the composite film layer is positioned on the inner side of the functional coating and is used for providing fitness suitable for the curved screen of the mobile phone; and the pressure-sensitive adhesive layer is positioned on the inner side of the composite film and is used for providing adhesiveness. The protective film disclosed by the invention not only has good fitting performance on a curved screen, but also is beneficial to fingerprint identification under the screen, and the use performance of the mobile phone protective film is greatly improved.

Owner:江苏晶华新材料科技有限公司

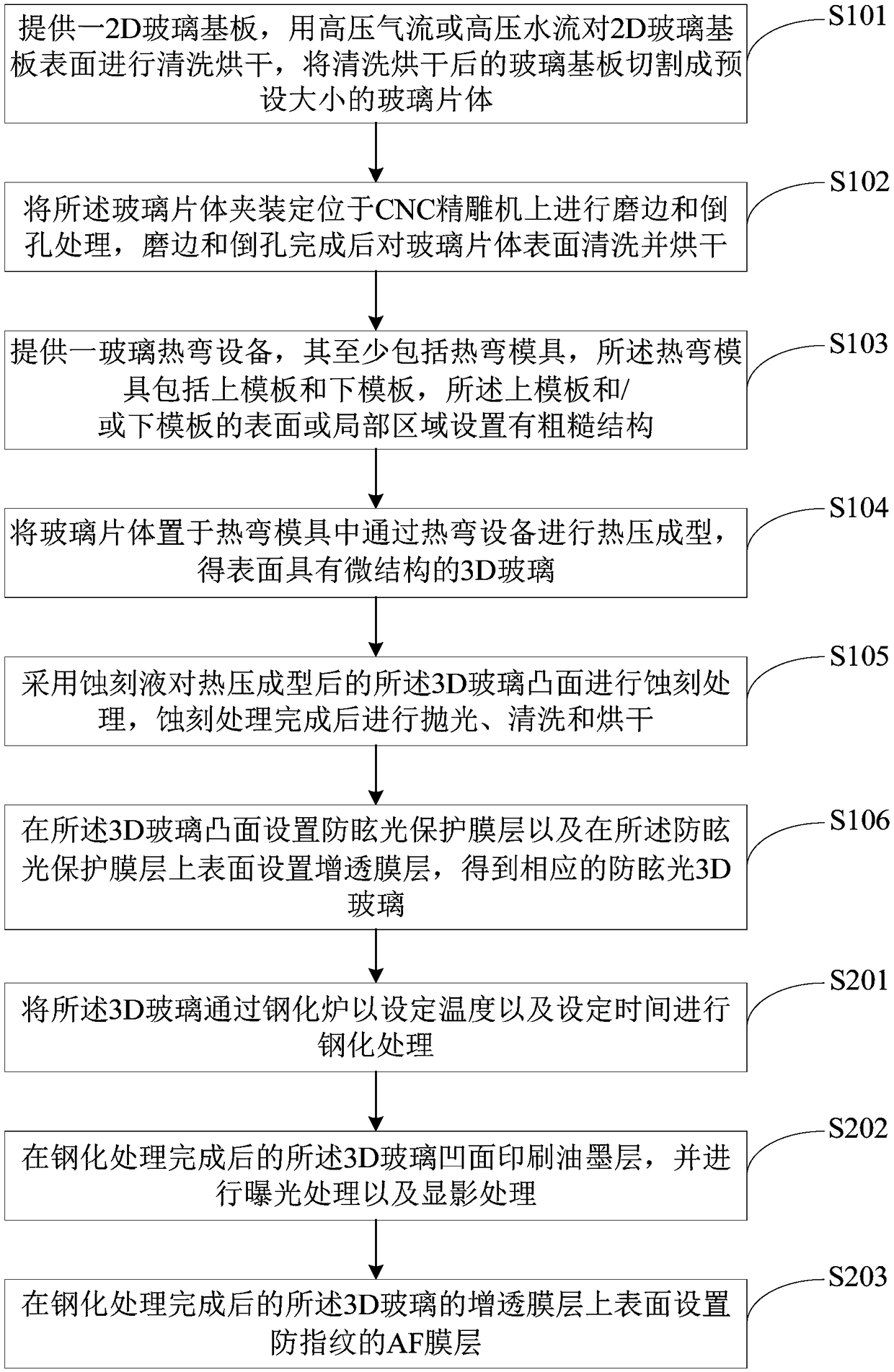

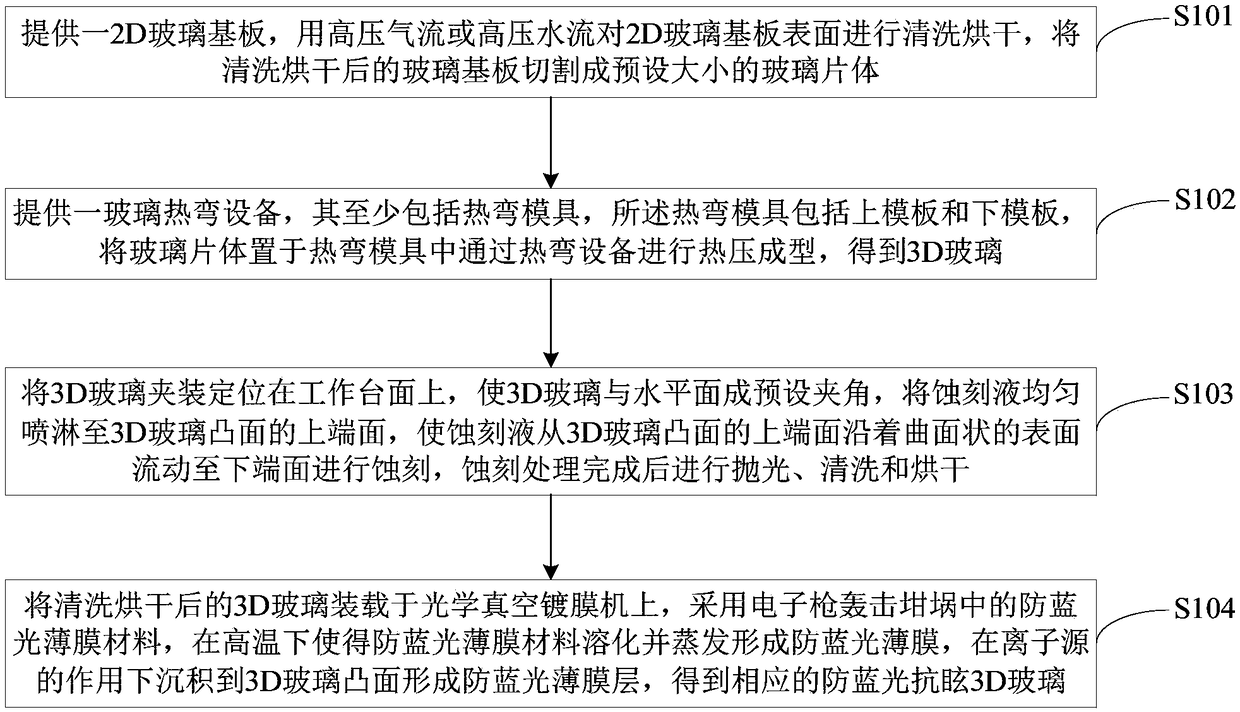

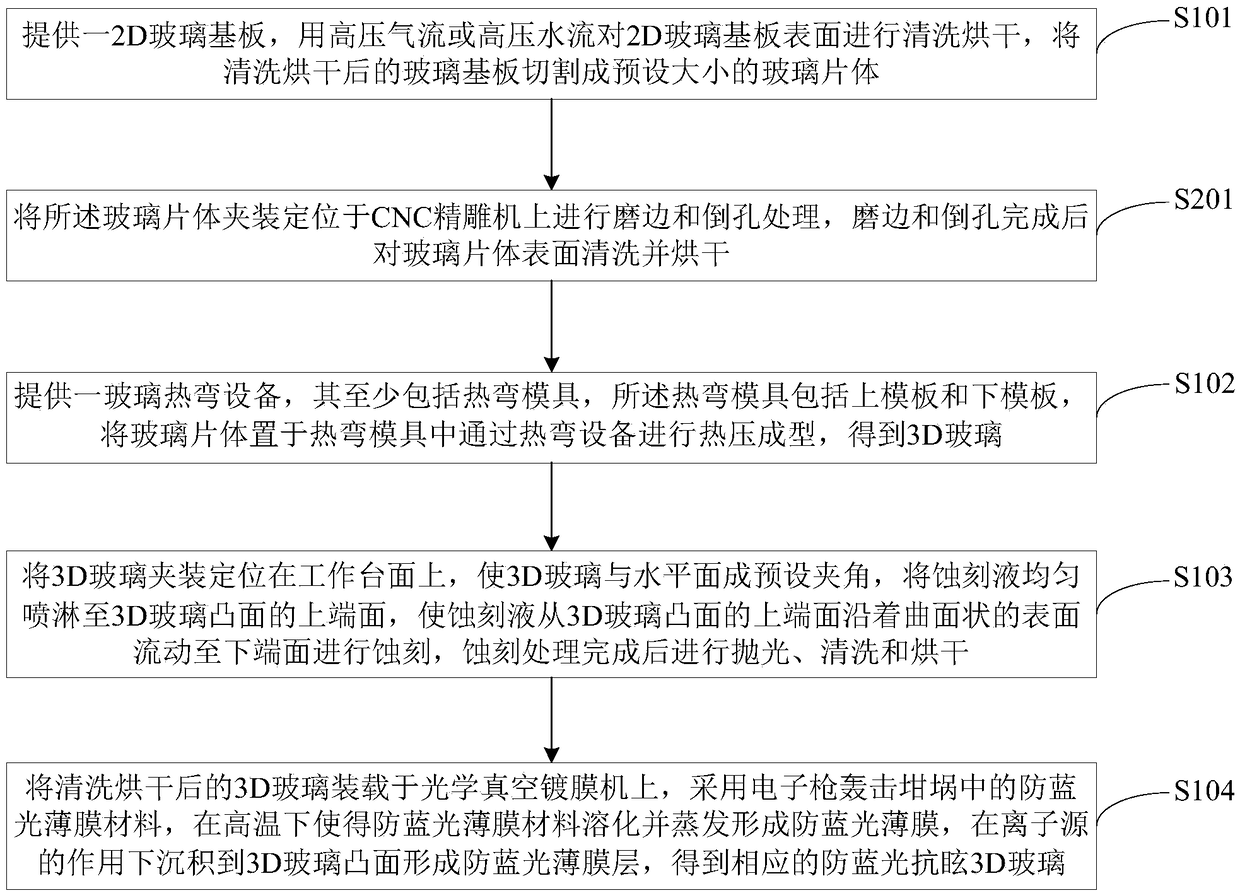

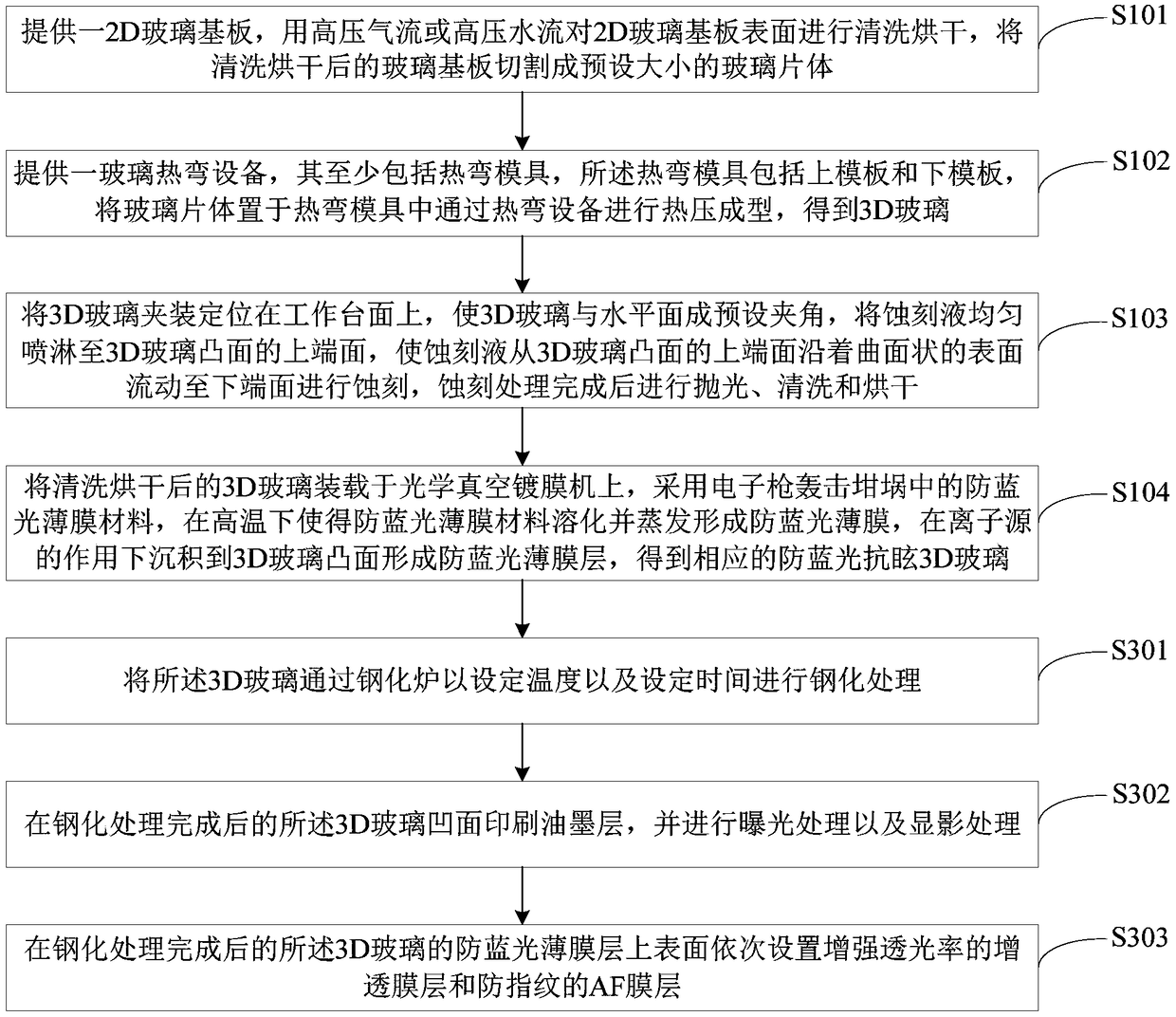

Manufacturing method of anti-blue light and anti-dizziness 3D (three-dimensional) glass

InactiveCN109455942AScratch resistantWear-resistantGlass reforming apparatusCoatingsGlass manufacturingGlass sheet

The invention is suitable for the technical field of glass manufacturing, and provides a manufacturing method of an anti-blue light and anti-dizziness 3D (three-dimensional) glass. The manufacturing method comprises the following steps of providing a 2D (two-dimensional) glass substrate, cleaning the surface of the 2D glass substrate, drying, and cutting into glass sheets with preset sizes; providing glass hot bending equipment, putting the glass sheets into a hot bending die, and performing hot pressing and forming by the hot bending equipment, so as to obtain 3D glass, wherein the hot bending equipment at least comprises the hot bending die, and the hot bending die comprises an upper die plate and a lower die plate; clamping and positioning the 3D glass on the surface of a worktable, uniformly spraying an etching liquid to the upper end surface of the convex surface of the 3D glass, enabling the etching liquid to flow from the upper end surface of the convex surface of the 3D glass to the lower end surface along with the curved surface to etch, polishing, cleaning and drying; loading the 3D glass onto an optical vacuum film plating machine, enabling an electronic gun to bombard an anti-blue light thin film material, melting and evaporating the anti-blue light thin film material at high temperature, depositing to the convex surface of the 3D glass under the function of an ionsource, and forming an anti-blue light thin film layer, so as to obtain the anti-blue light and anti-dizziness 3D glass.

Owner:仙游县元生智汇科技有限公司

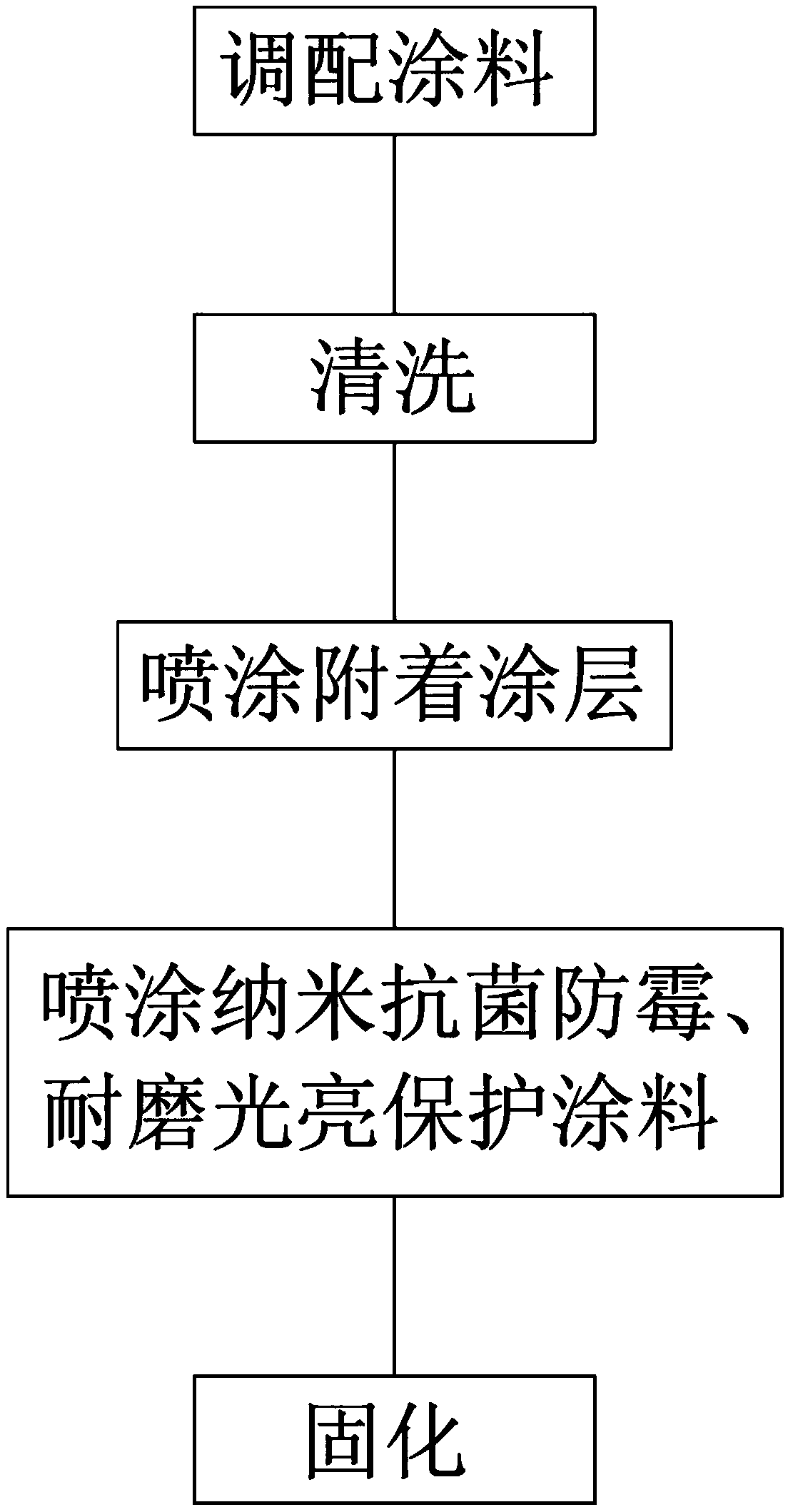

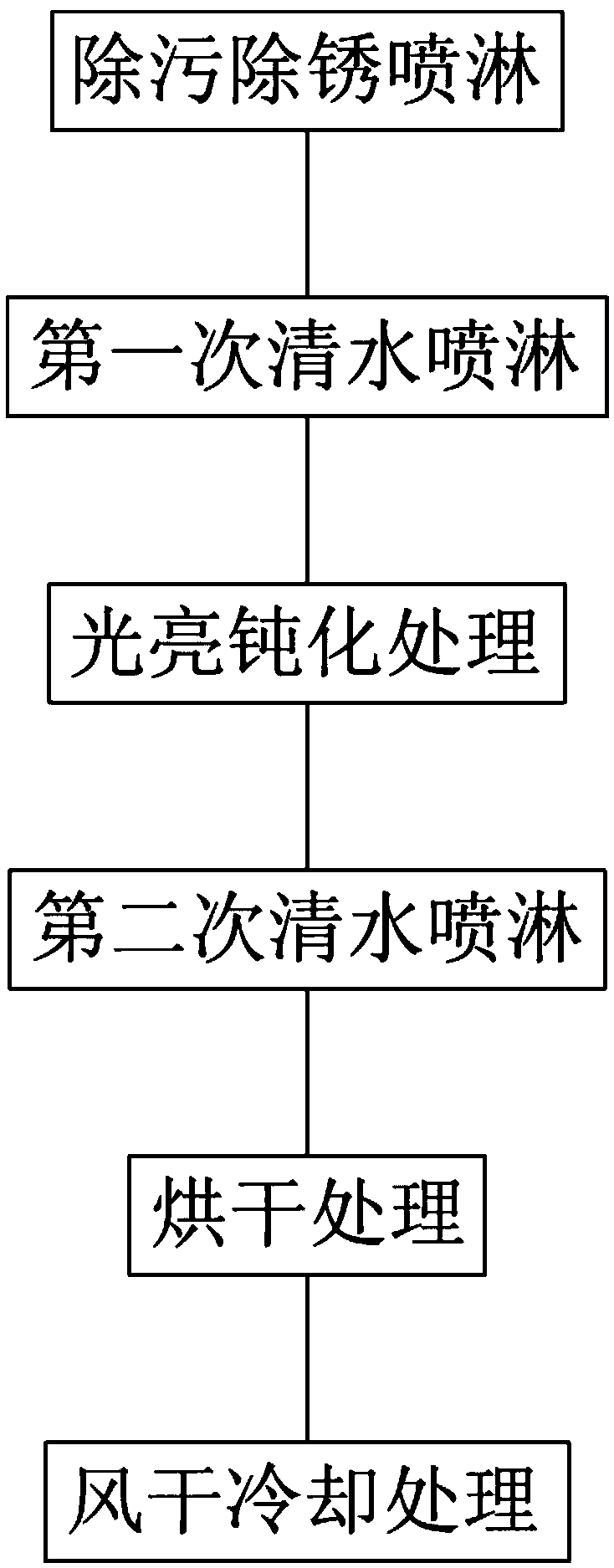

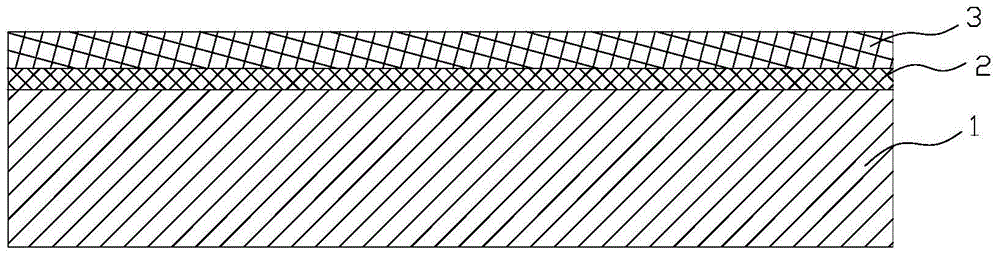

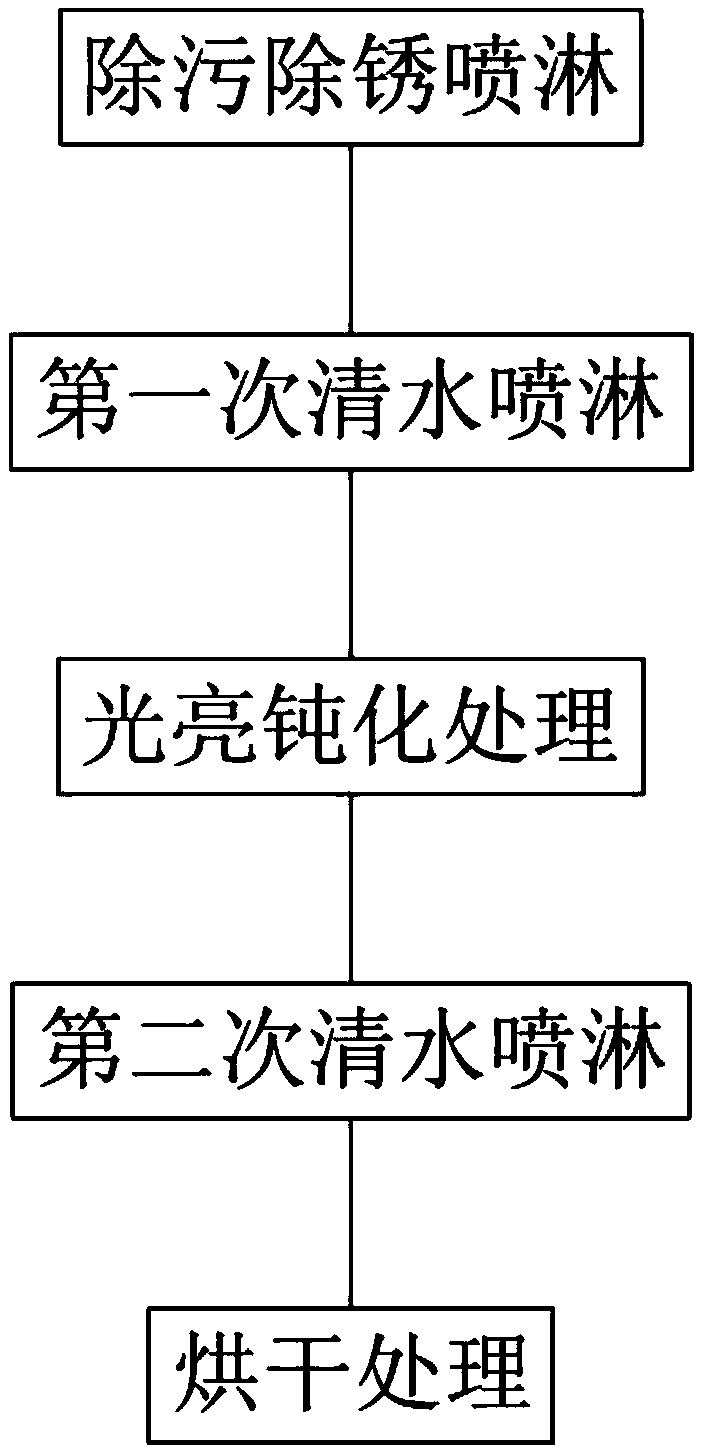

Production process of nanometer antibacterial mildewproof metal drainage floor drain

InactiveCN108797765ABacteriostaticHas anti-mildew performanceAntifouling/underwater paintsSewerage structuresSand blastingWear resistant

The invention provides a production process of a nanometer antibacterial mildewproof metal drainage floor drain. The production process sequentially comprises the following steps of paint preparation,surface treatment, cleaning, adhesion coating spray coating, nanometer bottom color spray coating, nanometer antibacterial mildewproof wear-resistant bright protection paint spray coating, and curing, wherein in the paint preparation step, the antibacterial mildewproof nanometer antibacterial mildewproof wear-resistant bright protection paint is prepared; in the surface treatment step, the wholesurface of the metal drainage floor drain is subjected to sand blasting treatment; in the cleaning step, after the sand blasting is completed, the whole surface is subjected to automatic dirt elimination and dustproof spraying treatment; in the adhesion coating spray coating step, an adhesion coating is sprayed and coated onto the whole surface; in the nanometer bottom color spray coating step, the whole surface is subjected to nanometer bottom color spray coating; in the nanometer antibacterial mildewproof wear-resistant bright protection paint spray coating step, the nanometer antibacterialmildewproof wear-resistant bright protection paint is sprayed and coated onto the whole surface; in the curing step, the curing is performed for 30 to 40 minutes in an environment with the constant temperature being 200 DEG C; and then a finished product is obtained after the automatic air cooling in a flow line.

Owner:福建戎堃科技有限公司

Electronic product screen protection film patch and preparation method thereof

InactiveCN107118475AOvercome the difficult problem of moldingImprove pass ratePolyvinyl alcoholPolyvinyl chloride

The invention discloses an electronic product screen protection film patch, which is prepared from the following raw materials in parts by weight: 20 to 40 parts of polyvinyl chloride, 12 to 25 parts of polyvinyl alcohol, 5 to 15 parts of radiation protection slurry, 3 to 10 parts of polyether polyol, 2 to 10 parts of oleic acid ester, 3 to 7 parts of polyethyleneglycol diacrylate, 3 to 6 parts of styrene-butadiene rubber, 2 to 6 parts of fluorinated ethylene propylene, 2 to 9 parts of silane coupling agents, 1.5 to 3.5 parts of solidification liquid and 1 to 4 parts of dispersoids. The invention provides the electronic product screen protection film patch and a preparation method. The problem of great forming difficulty of the protection film patch in the prior art is solved. In addition, the qualification rate of an electronic product is improved; the production and manufacturing cost is greatly reduced. The electronic product screen protection film patch prepared by the preparation method has the advantages of scratching mark resistance and anti-fingerprint effects.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Flame retardant antifogging wet tissue and processing method thereof

InactiveCN107313245AImprove hydrophobicityLong-lasting self-cleaningStain/soil resistant fibresBiochemical fibre treatmentPolystyreneOrganic glass

The invention relates to a flame-retardant antifogging wet tissue and a processing method thereof. The wet tissue is prepared from 1 part of non-woven fabric and 3 to 4 parts of flame-retardant self-cleaning antifogging liquid according to weight ratio, wherein the flame-retardant self-cleaning antifogging liquid is prepared from the following components in percentage by weight: 20 to 30% of hydrophobic resin emulsion, 0.5 to 5% of nano-meter flame retardant, 0.1 to 5% of nano-antibacterial agent, 0.1 to 3% of dispersant, 5 to 15% of antifreezing agent, 0.05 to 1.5% of defoaming agent, 0.5 to 1.5% of chelating agent, 0.5 to 3% of aromatic microcapsule emulsion and 55 to 75% of deionized water. Compared with the prior art, the flame-retardant antifogging wet tissue provided by the invention has the advantages that the nano-meter flame retardant in the formula can form a flame-retardant layer on the surface of organic glass or polymer films of acrylic, polycarbonate, polyester, polystyrene and the like, so that the flame resistance of a material is remarkably improved; an aromatic deodorization function is given to the wet tissue by the added aromatic microcapsule emulsion, and the maintenance of long-term release of the aromatic odor is facilitated.

Owner:东莞市荣腾纳米科技有限公司

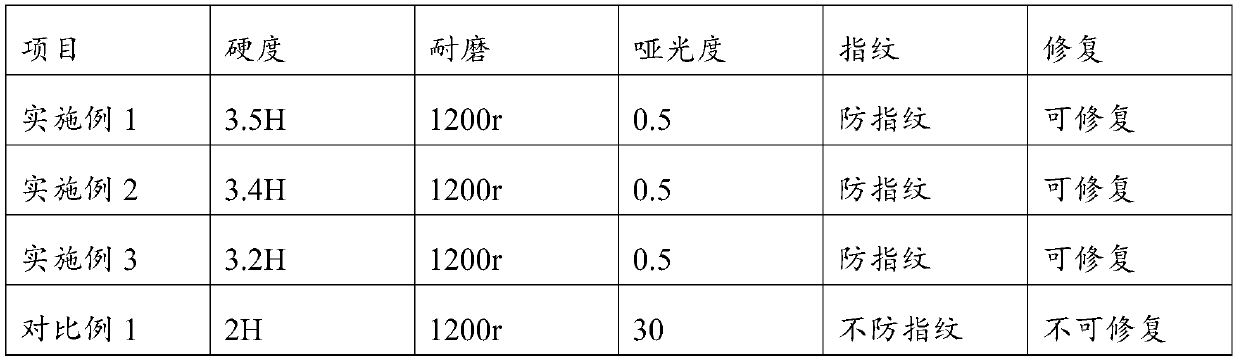

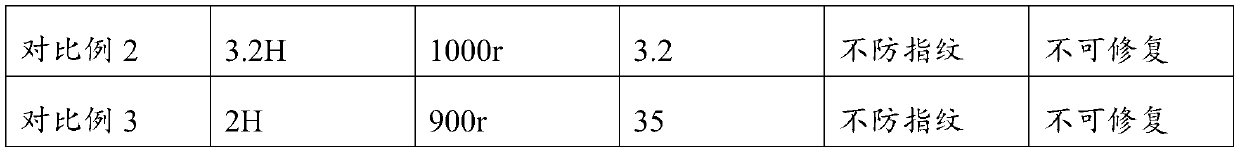

Coating process of matte veneer

InactiveCN111408526AAnti-pollutionEasy to cleanPretreated surfacesSpecial surfacesDust controlNitrogen gas

The invention belongs to the technical field of decorative plates for decoration and finishing, and discloses a coating process of a matte veneer. The coating process comprises the following steps: (1) cleaning a base material, coating putty paint in a roller mode, and carrying out UV drying and curing; (2) frosting the dried and cured base material, carrying out dust removal, coating UV sanding primer, and carrying out UV drying and curing; (3) keeping coating the UV sanding primer, carrying out UV drying and curing, and carrying out frosting after curing to obtain a semi-finished product plate; and (4) removing dust of the semi-finished product plate, coating UV matte finish paint in a roller mode, enabling the semi-finished product plate to enter a super-matte machine for matte treatment, and carrying out UV drying and curing to obtain the matte veneer, wherein the condition parameters of the super-matte machine are as follows: the nitrogen inlet pressure is 4-7 bar, the nitrogen purity is greater than or equal to 99%, and the temperature is 20-50 DEG C. According to the coating process, the super-matte machine is adopted for production, so that the matte degree of the matte veneer is 0.5-5, and the matte veneer has the advantages of being anti-pollution, convenient to clean, fingerprint-proof, scratch-resistant, repairable and odorless.

Owner:FOSHAN SHUNDE PURETE MECHANICAL CO LTD

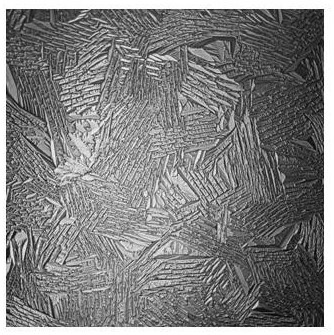

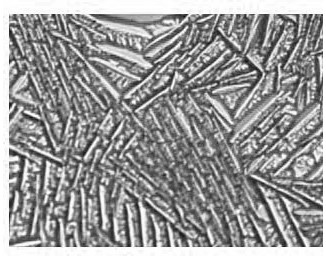

Glass etching liquid simulating rock bedding staggered stacking effect and glass manufacturing process

The invention discloses a glass etching solution simulating a rock bedding staggered stacking effect, which comprises the following raw materials: NH4HF2, NH4F, ALF3, HNO3, H3PO4, H2SO4, (NH4) 2SiF6, BaSO4, KCl, V2O5, sodium alkyl benzene sulfonate, sorbitol and H2O, and the process for preparing glass by adopting the glass etching solution comprises the following steps: 1, weighing the raw materials; 2, putting the weighed raw materials into a stirring container, fully stirring until the liquid medicine is in a uniform supersaturated solution state, and standing and curing to obtain an etching liquid medicine; 3, coating the back surface of the cleaned glass sheet with a film for protection, and putting the glass sheet into an etching liquid for etching treatment; and 4, taking the etched raw glass sheet out of the liquid medicine, cleaning the raw glass sheet with pure water, and air-drying the raw glass sheet. The etched glass surface features in the microstructure show the uniform structural features that the line arrangement lines are clear and clear, the line arrangement lines are non-directionally arranged, a plurality of groups of inclined layers in different directions are mutually staggered and overlapped, and local disordered arrangement and overall uniform distribution are realized.

Owner:许昌恒昊光学科技有限公司

Rapidly-cured UV water-based solid color finish paint and preparation method thereof

ActiveCN114763451AHigh strengthImprove adhesionPolyurea/polyurethane coatingsUrethane acrylateAcrylate ester

The invention discloses a rapidly cured UV water-based solid color finish paint, which is prepared from the following raw materials in parts by weight: 40 to 80 parts of polyurethane acrylate emulsion, 10 to 20 parts of acrylic emulsion, 1 to 5 parts of coalescing agent, 5 to 10 parts of water, 1 to 5 parts of wetting dispersant, 1 to 2 parts of defoaming agent, 1 to 2 parts of flatting agent, 1 to 10 parts of matting powder, 1 to 2 parts of thickening agent, 3 to 5 parts of photoinitiator, 0.1 to 1 part of mildew preventive and 5 to 10 parts of white paste. According to the invention, the strength of a finish paint film is improved, the bottom layer of the paint is thoroughly cured, the adhesive force of the paint is improved, the coalescing agents with different volatilization rates enable water in the paint to be rapidly volatilized, miliaria bubbles are avoided, the film-forming surface performance is good, and meanwhile, the paint is a novel environment-friendly paint, is high in curing speed, and has the advantages of fingerprint prevention, non-sticking, stain resistance, scratch resistance and the like. Self-repairing is realized; and the production efficiency is high.

Owner:上海君子兰新材料股份有限公司

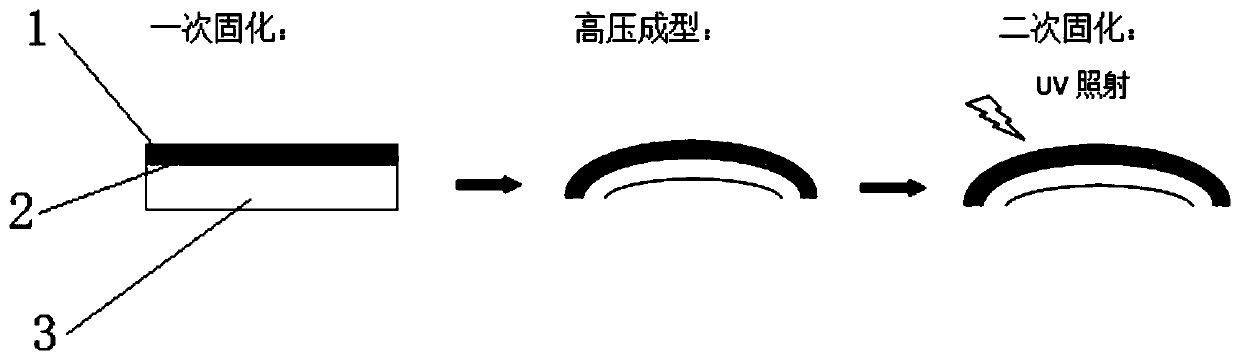

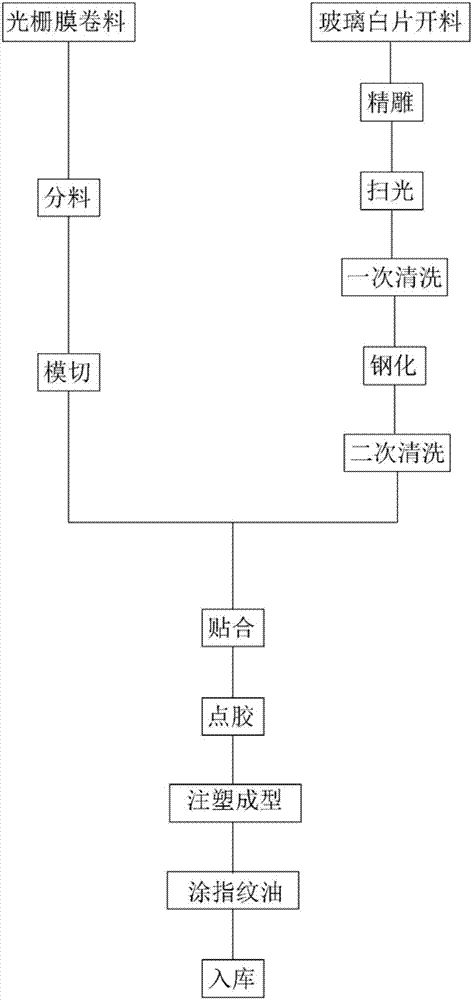

Secondary curing moulding hardening coating sheet and preparation method

InactiveCN109985789AStrong adhesionNot easy to peel offPretreated surfacesEpoxy resin coatingsUltraviolet lightsPlastic film

The invention discloses a secondary curing moulding hardening coating sheet and a preparation method. The preparation method comprises the following steps of (1), selecting an optical plastic film sheet according to coating specifications; (2), coating one surface of the selected sheet with base coat with high adhesion for the first time, then baking until the coating is dry to obtain a base coatsheet, and cooling the base coat sheet for use; (3), coating the coating of the base coat sheet prepared in step (2) with surface coating allowing secondary curing for the second time, then baking until the surface of the coating is dry to obtain a primarily cured sheet; and (4), according to the shape requirements of the product moulding, carrying out hot pressing or vacuum moulding on the primarily cured sheet, baking at a certain temperature for a certain time, and then curing and hardening by an ultraviolet light to obtain a secondarily cured finished product. The method takes the moldability and high hardenability of hardening coating plates into account and ensures that the coating has excellent stretchability during molding without appearing cracks.

Owner:SICHUAN LONGHUA FILM CO LTD

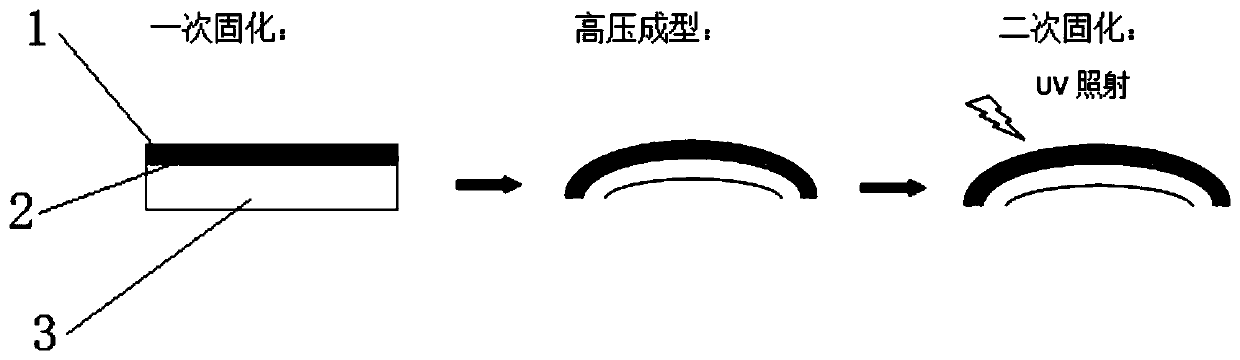

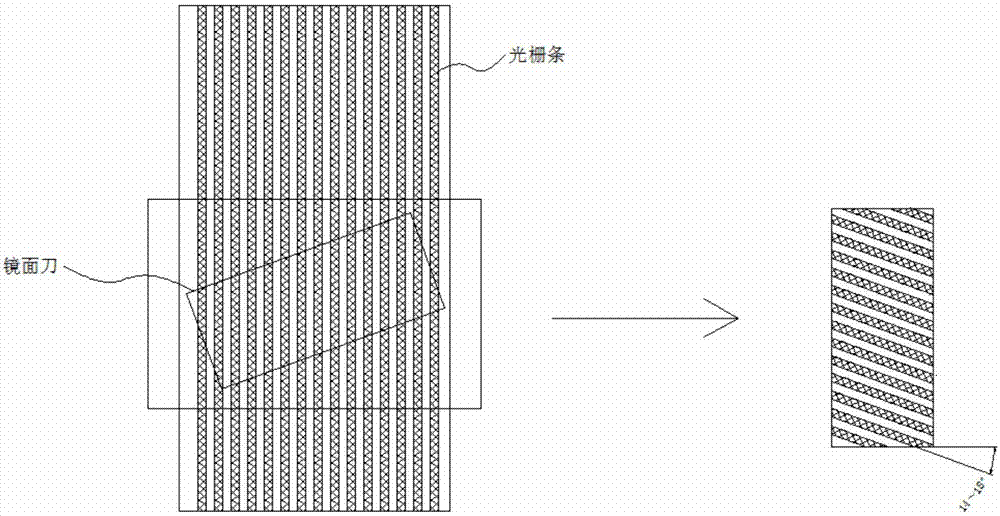

Naked eye 3D mobile phone shell manufacturing method

InactiveCN107953507AImprove the display effectImprove textureClimate change adaptationCleaning using liquidsWeather resistanceGrating

The invention relates to a naked eye 3D mobile phone shell manufacturing method. The naked eye 3D mobile phone shell manufacturing method comprises the steps of (1) coiling, (2) separation, (3) die cutting, (4) cutting, (6) polishing, (7) primary cleaning, (8) tempering, (9) secondary cleaning and (10) bonding-glue dispensing-injection molding-fingerprint oil coating-packing and warehousing; the process flow design is reasonable; the production speed is high; a grating bar is inclined by 14-18 degrees through a mirror surface cutter aslant arranged, so that the grating film display effect is excellent, the visual range is widened, and the product quality is improved; a glass white piece is machined by the method to achieve the advantages of smooth surface, transparency, cleanness, lightness, thinness, fingerprint prevention, dazzle prevention, hardness, scratch resistance, weather resistance, novel design, good texture and the like; and through combination with a grating film, an excellent 3D display effect is achieved.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

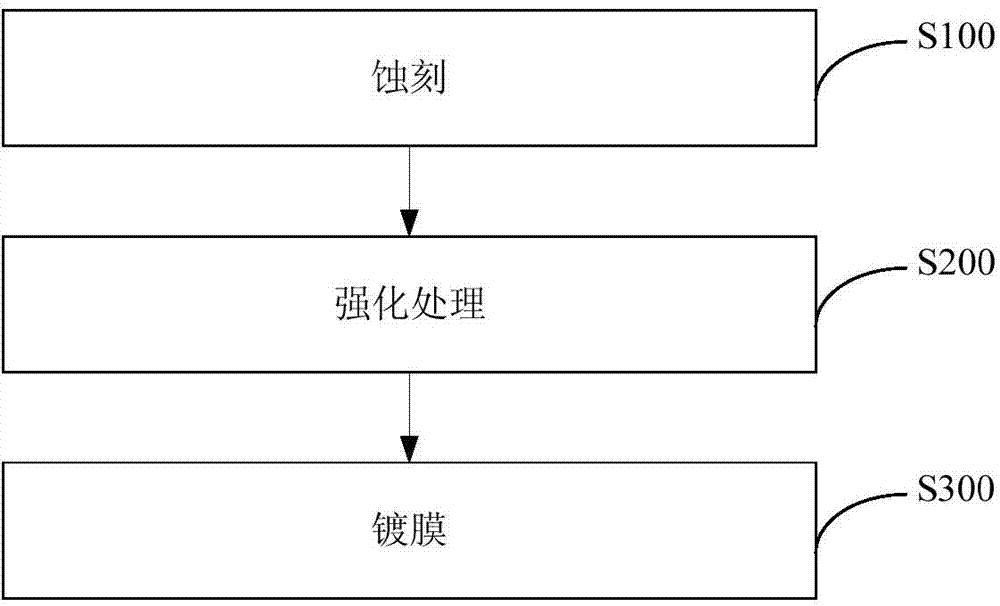

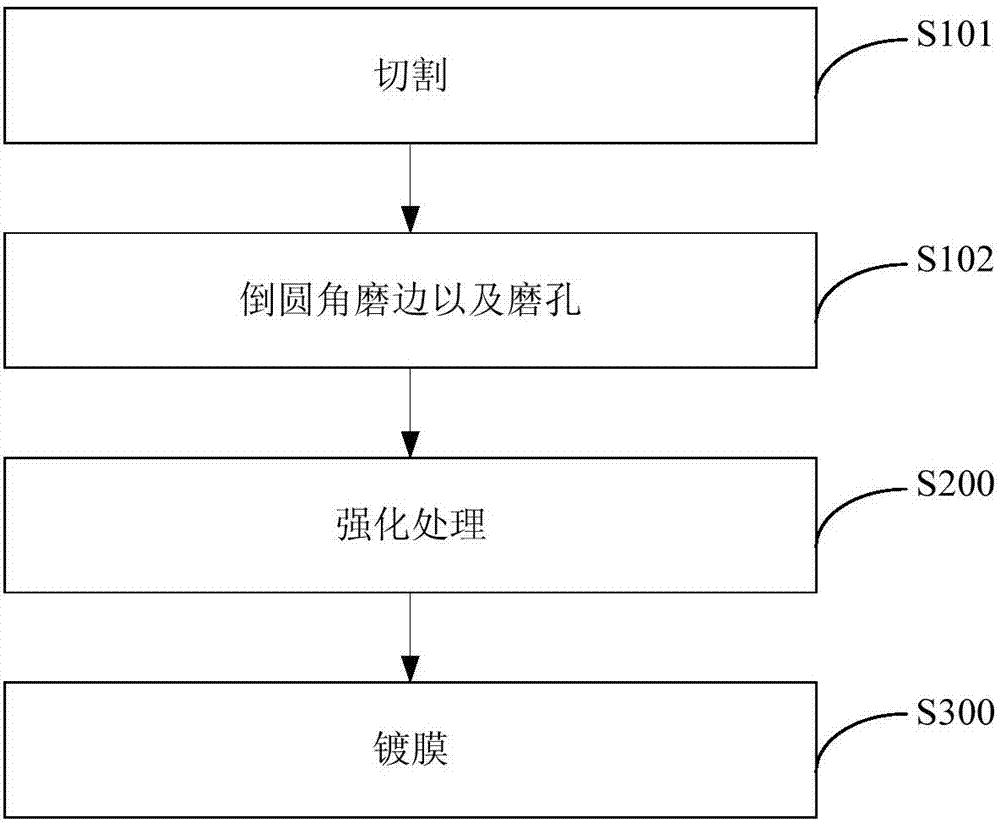

Coated glass and processing method thereof

PendingCN105060732AGuaranteed firmnessAnti-fingerprintVacuum evaporation coatingSputtering coatingPower flowHardness

The invention discloses coated glass. The coated glass comprises a glass substrate, wherein one surface of the glass substrate is sequentially plated with an SIO2 layer and an AL2O3 layer. The invention further discloses a processing method of the coated glass. The processing method comprises following steps: 1), target materials are arranged; 2), the temperature of a cavity is set to be 150 DEG C, the voltage is set to be 420 V, and the current is 15 A; 3), the coating processing is performed on the glass substrate at a production speed of 0.8 m / min and a production takt of two minutes per glass substrate. The coated glass has the advantages of low cost, high hardness, anti-falling performance, anti-fingerprint performance and oil stain resistance.

Owner:广州市颐恩汇商贸发展有限公司

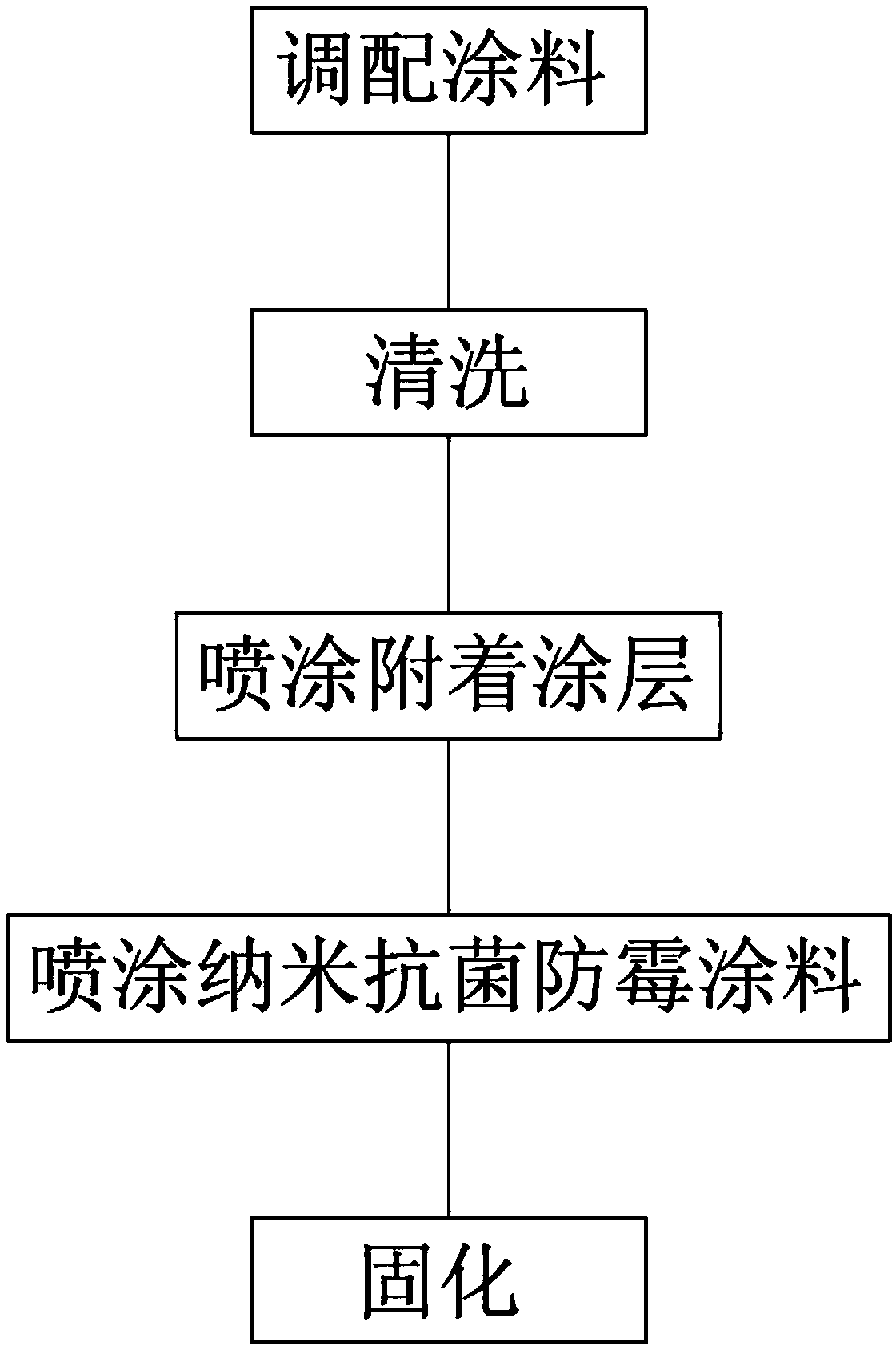

Production technology for nano antibacterial and mouldproof metal coin

InactiveCN108745810AExtend FavoritesReduce manufacturing costAntifouling/underwater paintsPretreated surfacesMetalCoating

The invention provides a production technology for a nano antibacterial and mouldproof metal coin. The production technology is used for conducting antibacterial and mouldproof treatment on the wholesurface of a metal coin body. The production technology sequentially comprises the following steps including coating blending, cleaning, adhesion coating spraying, nano antibacterial and mouldproof coating spraying and curing. During coating blending, a mouldproof and antibacterial nano antibacterial and mouldproof coating is blended. During cleaning, the whole surface of the metal coin is subjected to automatic dirt removal spraying treatment. During adhesion coating spraying, adhesion coating spraying is conducted on the whole surface of the cleaned metal coin, and an adhesion layer is formed. During nano antibacterial and mouldproof coating spraying, after at least 3 min since spraying of the adhesion coating is finished, the whole surface of the metal coin is subjected to nano antibacterial and mouldproof coating spraying, and a nano antibacterial and mouldproof layer is formed. During curing, the metal coin to which the nano antibacterial and mouldproof coating is sprayed is conveyed into a high-temperature curing area, and drying is conducted for 30-50 min in the environment at the temperature ranging from 150 DEG C to 300 DEG C.

Owner:福建戎堃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com