Production technology for nano antibacterial and mouldproof metal coin

An antibacterial and antifungal, production process technology, applied to paints containing biocides, antifouling/underwater coatings, devices for coating liquids on surfaces, etc., can solve mildew and rust, yellow spots on metal coins, There are no problems such as antibacterial and antibacterial functions, and the effects of high quality and efficiency, extended storage, and low production costs are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the nano antibacterial and antifungal coating: under normal environment and the stirring condition that the stirring speed is 350-400 rpm, mix the acrylic resin, polyester resin and organic solvent in the reaction tank evenly, and then Add nano-inorganic nano-antibacterial agent and anti-mildew additive into the reaction tank to make the ingredients mix and disperse evenly, and finally add the curing agent into the reaction tank and mix evenly to form the nano-anti-bacterial and anti-mold coating.

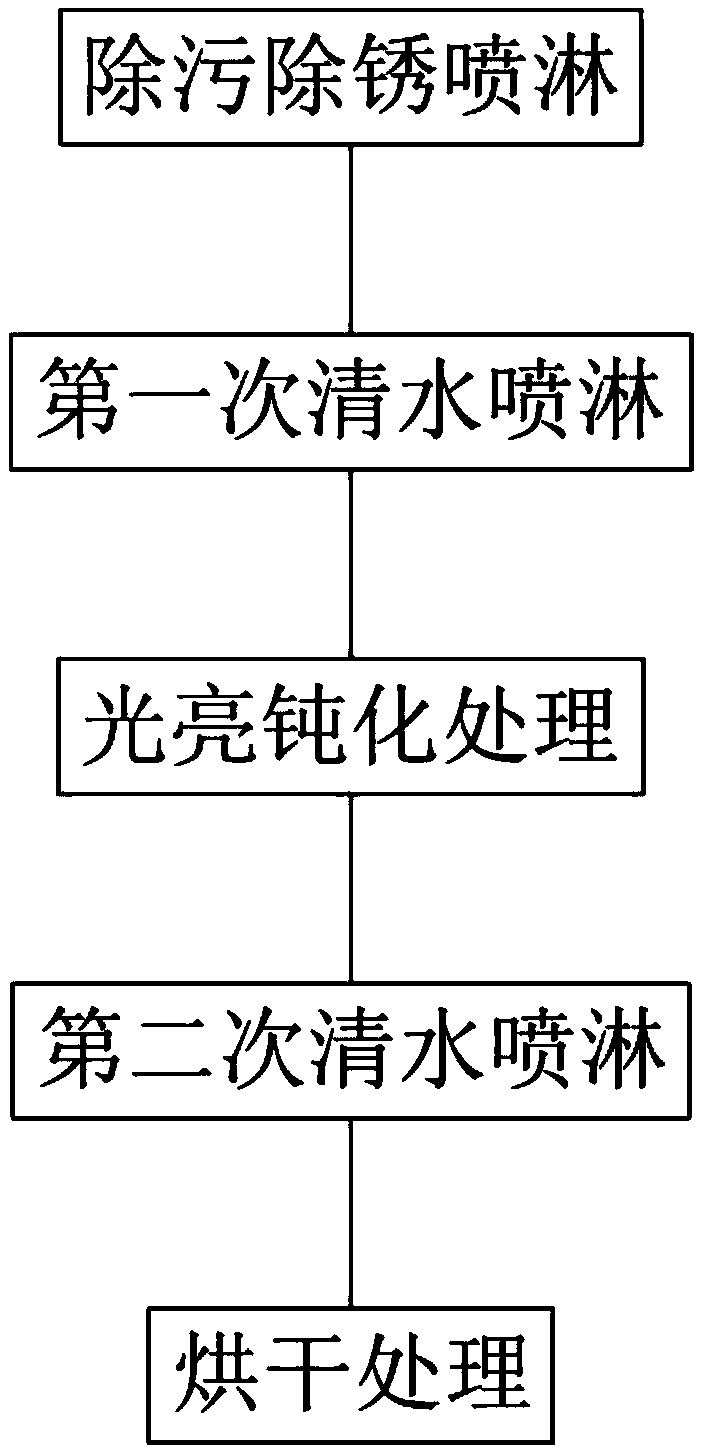

[0047] Described cleaning comprises the following specific steps:

[0048] a. Decontamination and derusting spray;

[0049] b. The first water spray;

[0050] c. Bright passivation treatment;

[0051] d, the second water spray;

[0052] e. Drying treatment: Automatically dry at a constant temperature for 15-20 minutes under water vapor at a temperature of 130 degrees Celsius, and the error range of the temperature of 130 degrees Celsius is controll...

Embodiment 1

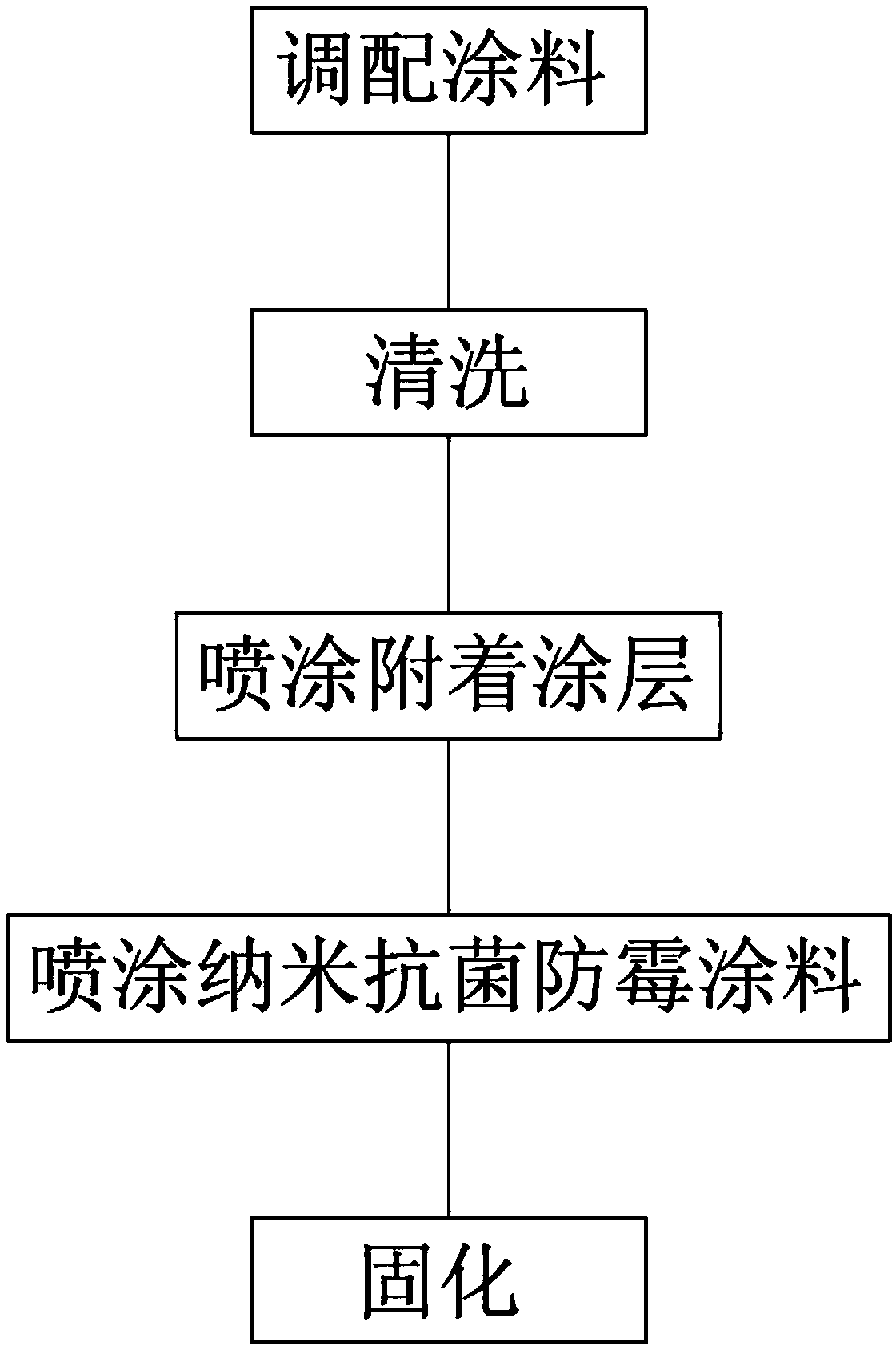

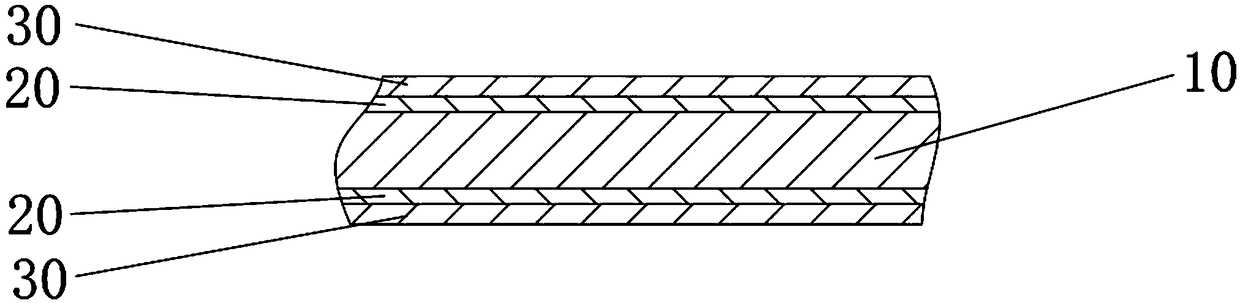

[0054] A production process of nano antibacterial and mildew-proof metal coins, which is used to carry out antibacterial and anti-mildew treatment on the entire surface of the metal coin body 10. Curing; wherein, the cleaning, spraying of the attached coating, spraying of the nano antibacterial and mildew-proof coating, and curing are all completed through the assembly line, and the spraying of the attached coating is sprayed with a dust-free automatic spraying work cabinet. Specifically include the following steps:

[0055] Coating preparation: deploy anti-mildew, antibacterial nano-antibacterial and anti-mold coatings, wherein the nano anti-bacterial and anti-mold coatings components: 82 parts by weight of acrylic resin, 65 parts by weight of polyester resin, 32 parts by weight of organic solvent, 1.8 parts by weight The inorganic nano antibacterial agent of weight part, the antimold additive of 2.2 weight parts and the curing agent of 40 weight parts, and nano antibacterial...

Embodiment 2

[0061] A production process of nano antibacterial and mildew-proof metal coins, which is used to carry out antibacterial and anti-mildew treatment on the entire surface of the metal coin body 10. Curing; wherein, the cleaning, spraying of the attached coating, spraying of the nano antibacterial and mildew-proof coating, and curing are all completed through the assembly line, and the spraying of the attached coating is sprayed with a dust-free automatic spraying work cabinet. Specifically include the following steps:

[0062] Deployment paint: deployment anti-mildew, antibacterial nano-antibacterial anti-mold coating, wherein nano anti-bacterial anti-mold coating components: 95 parts by weight of acrylic resin, 80 parts by weight of polyester resin, 40 parts by weight of organic solvent, 2 The inorganic nano antimicrobial agent of weight part, the antimold additive of 3 weight parts and the curing agent of 55 weight parts, and nano antibacterial antifungal coating adopts follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com