Naked eye 3D mobile phone shell manufacturing method

A manufacturing method and technology for a mobile phone case, which are applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of limited use range, cumbersome installation, inconvenient portability, etc., and achieve good display effect and expand Viewing range, fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

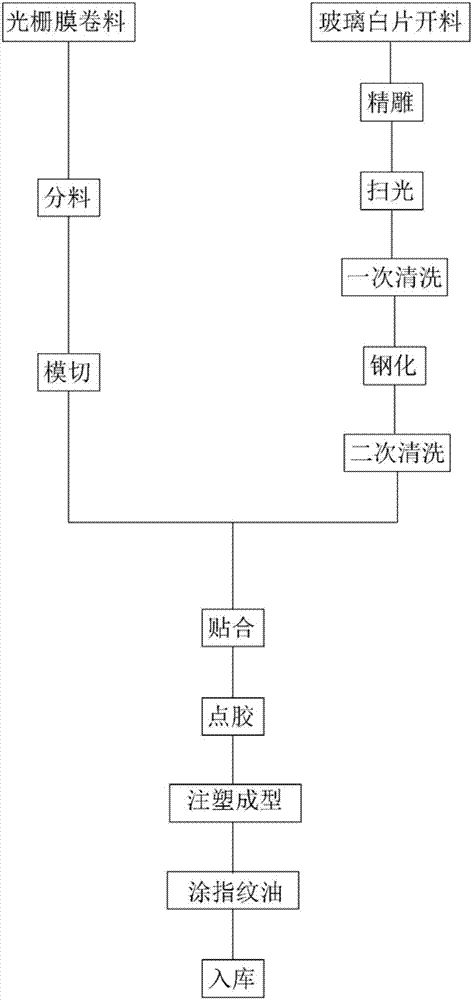

[0029] Embodiment 1: A method for manufacturing a naked-eye 3D mobile phone case, comprising the following steps:

[0030] ① Coil material, the grating film is placed on the coiler, and the coiler winds the grating film onto a large roll;

[0031] ② Dividing, the distributing machine cuts and divides the lenticular film on the large reel, and rewinds the lenticular film to the small reel;

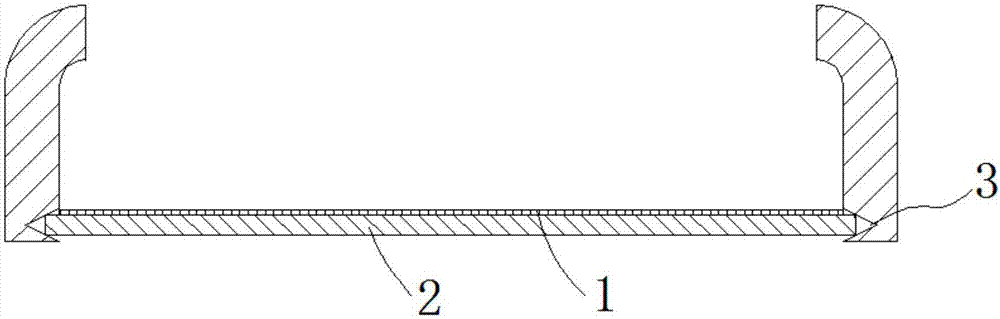

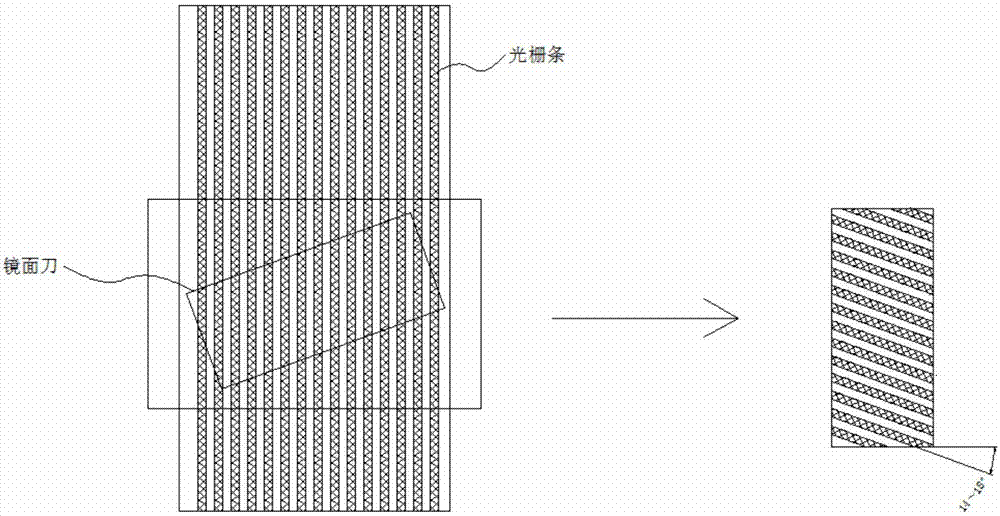

[0032] ③Die-cutting, the small reel is placed on the die-cutting machine to unwind. The forming mold of the die-cutting machine is square, and the four sides of the forming mold are equipped with mirror knives placed obliquely. The angle between the mirror knife and the moving direction of the grating film is 14-18 °, the forming mold clamping mirror knife cuts the grating film into a square grating film 1, and the grating strips on the grating film 1 are inclined at 14-18°;

[0033] ④Material cutting, place the glass white sheet 2 material on the working table of the three-axis cutting ma...

Embodiment approach 2

[0044] Embodiment 2: A method for manufacturing a naked-eye 3D mobile phone case, comprising the following steps:

[0045] ① Coil material, the grating film is placed on the coiler, and the coiler winds the grating film onto a large roll;

[0046] ② Dividing, the distributing machine cuts and divides the lenticular film on the large reel, and rewinds the lenticular film to the small reel;

[0047] ③Die-cutting, the small reel is placed on the die-cutting machine to unwind. The forming mold of the die-cutting machine is square, and the four sides of the forming mold are equipped with mirror knives placed obliquely. The angle between the mirror knife and the moving direction of the grating film is 14-18 °, the forming mold clamping mirror knife cuts the grating film into a square grating film 1, and the grating strips on the grating film 1 are inclined at 14-18°;

[0048] ④Material cutting, place the glass white sheet 2 material on the working table of the three-axis cutting ma...

Embodiment approach 3

[0059] Embodiment 3: A method for manufacturing a naked-eye 3D mobile phone case, comprising the following steps:

[0060] ① Coil material, the grating film is placed on the coiler, and the coiler winds the grating film onto a large roll;

[0061] ② Dividing, the distributing machine cuts and divides the lenticular film on the large reel, and rewinds the lenticular film to the small reel;

[0062] ③Die-cutting, the small reel is placed on the die-cutting machine to unwind. The forming mold of the die-cutting machine is square, and the four sides of the forming mold are equipped with mirror knives placed obliquely. The angle between the mirror knife and the moving direction of the grating film is 14-18 °, the forming mold clamping mirror knife cuts the grating film into a square grating film 1, and the grating strips on the grating film 1 are inclined at 14-18°;

[0063] ④Material cutting, place the glass white sheet 2 material on the working table of the three-axis cutting ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com