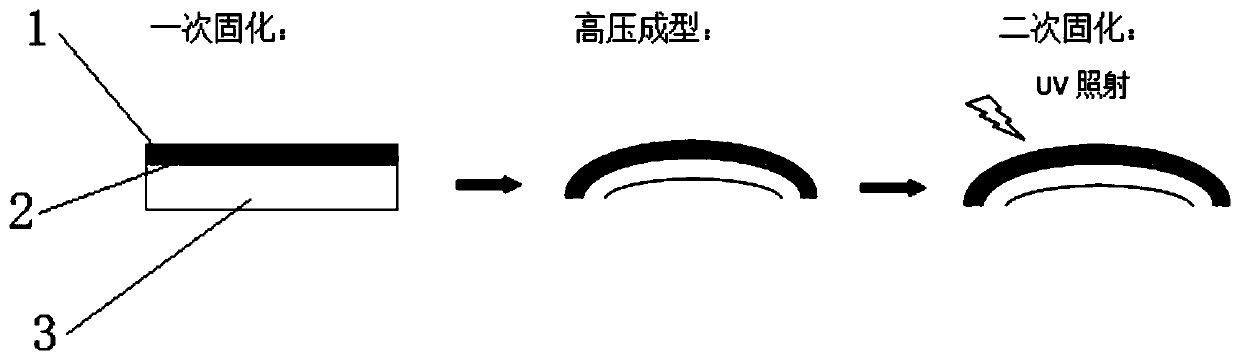

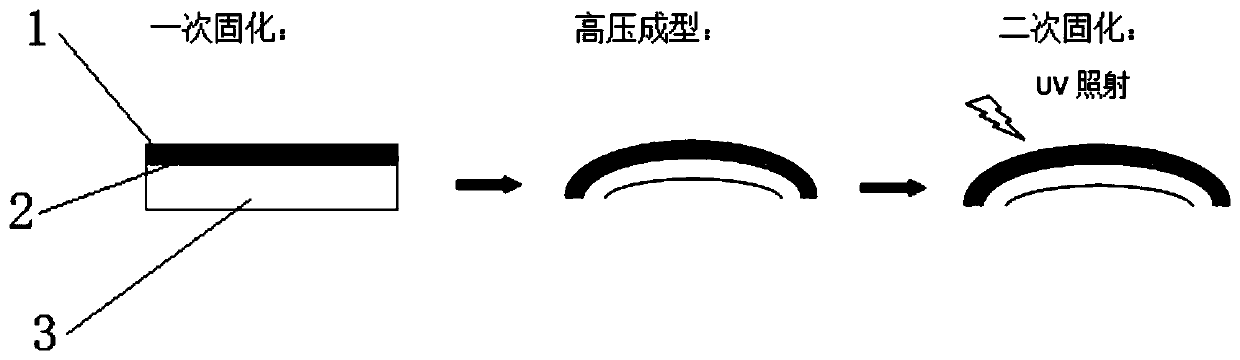

Secondary curing moulding hardening coating sheet and preparation method

A secondary curing and hardening coating technology, applied in coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc. Excellent stretchability, excellent adhesion, not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A PC / PMMA two-layer co-extruded composite material sheet with a thickness of 0.64 mm and a size of 1270 mm×1690 mm was selected as the base material of this embodiment.

[0025] Undercoating, the solution of 22 parts by weight of main agent A, the solution of 2.2 parts by weight of curing agent B, the solution of 0.020 parts by weight of catalyst C, and the organic solvent of 75 parts by weight are fully stirred and mixed uniformly to prepare the primer coating.

[0026] Wherein, the solution of main agent A includes 30% acrylate, 46.7% ethyl acetate and 23.3% methyl ethyl ketone by mass fraction, and the solution of curing agent B includes 40% isocyanate curing agent and 60% by mass fraction. % ethyl acetate, catalyst C is 25% dibutyltin dilaurate and 75% ethyl acetate, and the organic solvent is methyl isobutyl ketone.

[0027] Apply the primer coating uniformly on the PMMA surface of the substrate in a flat coating, and then bake at a temperature of 110°C for 6 minut...

Embodiment 2

[0039] (1) A PC sheet with a thickness of 0.80 mm and a size of 1270 mm×1690 mm is selected as the base material of this embodiment.

[0040] (2) Undercoating, the main agent A of 35 parts by weight, the curing agent B of 3.5 parts by weight, the catalyst C of 0.035 parts by weight, and the organic solvent of 61 parts by weight are fully stirred and mixed uniformly to prepare the primer coating.

[0041] Main agent A is 30% acrylate, 46.7% ethyl acetate and 23.3% methyl ethyl ketone, curing agent B is 40% isocyanate curing agent and 60% ethyl acetate, catalyst C is 25% Dimethyl tin neodecanoate and 75% ethyl acetate, the organic solvent is methyl isobutyl ketone.

[0042] Apply the primer coating evenly on the PMMA surface of the substrate in a flat coating, and then bake it at a temperature of 120°C for 5 minutes. After the baking is completed, the primer sheet is obtained and cooled at room temperature stand-by.

[0043](3) Topcoat, fully stir and mix 75 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com