Superhydrophilic anti-fogging nano zirconiumhydrogen phosphate hybrid coating

A technology of zirconium hydrogen phosphate and hydrogen phosphate, which is applied in the field of super-hydrophilic and anti-fog nano-zirconium hydrogen phosphate hybrid coatings, can solve the problem of wear resistance, scratch resistance, anti-fingerprint printing, poor stain resistance, and super-hydrophilic coating. The problems of short service life and low coating hardness can achieve the effect of good water resistance and weather resistance, improved compatibility and hydrophilic properties, and high stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

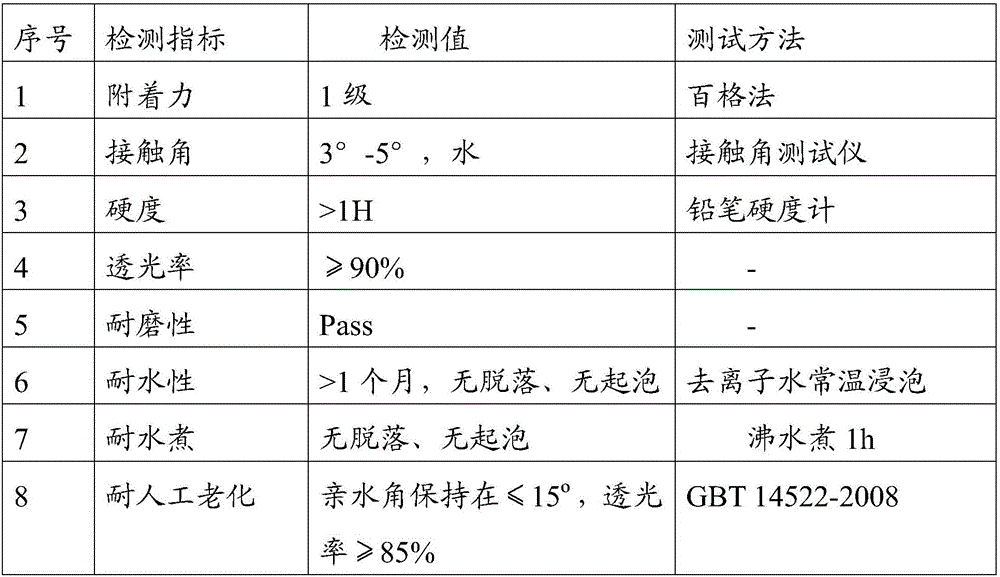

Embodiment 1

[0035]The superhydrophilic anti-fog nano zirconium hydrogen phosphate hybrid coating of the present invention comprises the following components by weight: 10 grams of zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups, low chroma UV resin oligomer 10 grams, 15 grams of reactive diluent containing 1-6 functional groups, 0.5 grams of leveling agent, 50 grams of solvent, 2-6 grams of photoinitiator, among which, the low chroma UV resin oligomer is low chroma polyurethane UV Oligomer, chroma Fe-Co≤2; reactive diluent is hydroxyethyl acrylate mixed with hexanediol diacrylate in a mass ratio of 2:1, leveling agent is silicon-containing leveling agent, solvent is iso propanol, and the photoinitiator is UV photoinitiator 184.

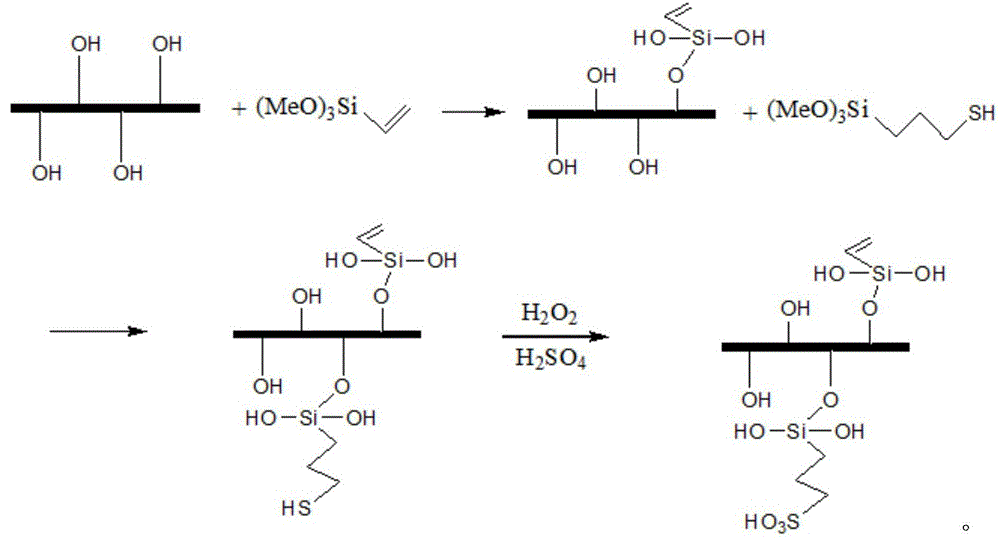

[0036] Zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups is prepared by the following method: 10 grams of α-zirconium hydrogen phosphate is ultrasonically stripped with 100 ml of 0.1 mol / liter propyl...

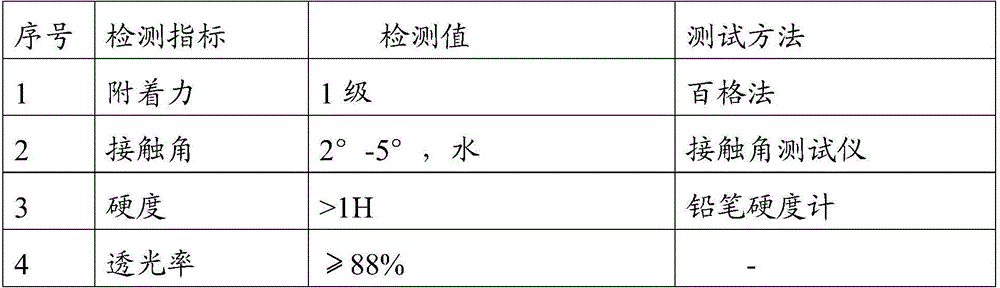

Embodiment 2

[0042] The superhydrophilic anti-fog nano-zirconium hydrogen phosphate hybrid coating of the present invention comprises the following components by weight:

[0043] 15 grams of zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups, 5 grams of low-color UV resin oligomers, 10 grams of reactive diluents containing 1-6 functional groups, 1.2 grams of leveling agents, 20 grams of solvents, Initiator 2 grams, wherein, low chroma UV resin oligomer is low chroma polyurethane acrylate, chroma Fe-Co≤2; Reactive diluent is (meth) hydroxypropyl acrylate, leveling agent is Contains silicon leveling agent, the solvent is ethanol, and the photoinitiator is UV photoinitiator 184.

[0044] Zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups is prepared by the following method: 15 grams of gamma-zirconium hydrogen phosphate is ultrasonically stripped with 120 ml of 0.1 mol / liter propylamine solution, and 140 ml of 0.1 mol / liter hydrochlo...

Embodiment 3

[0051] The superhydrophilic anti-fog nano-zirconium hydrogen phosphate hybrid coating of the present invention comprises the following components by weight:

[0052] 20 grams of zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups, 30 grams of low-color UV resin oligomers, 5 grams of reactive diluents containing 1-6 functional groups, 2 grams of leveling agents, 40 grams of solvents, 5 grams of initiator, wherein the low-chroma UV resin oligomer is mixed with low-chroma polyether acrylate and low-chroma phosphoric acid acrylate at a mass ratio of 1:1, and the chroma Fe-Co≤2; reactive diluent It is difunctional hexanediol diacrylate, the leveling agent is silicon-containing leveling agent, the solvent is isopropanol, and the photoinitiator is UV photoinitiator 184.

[0053] Zirconium hydrogen phosphate containing ethylenic bonds and sulfonic acid groups is prepared as follows: 10 grams of α-zirconium hydrogen phosphate and γ-zirconium hydrogen phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com