Nanometer calcium silicate hydrate super-hydrophilicity thin film as well as preparation method and applications of thin film

A hydrated calcium silicate and super-hydrophilic technology, which is applied in the field of organic-inorganic super-hydrophilic composite membranes, super-hydrophilic films and their preparation, can solve the problems of unfavorable industrial application, complicated preparation process, and high cost of raw materials , to achieve the effects of lower raw material prices, simple preparation process, and good anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

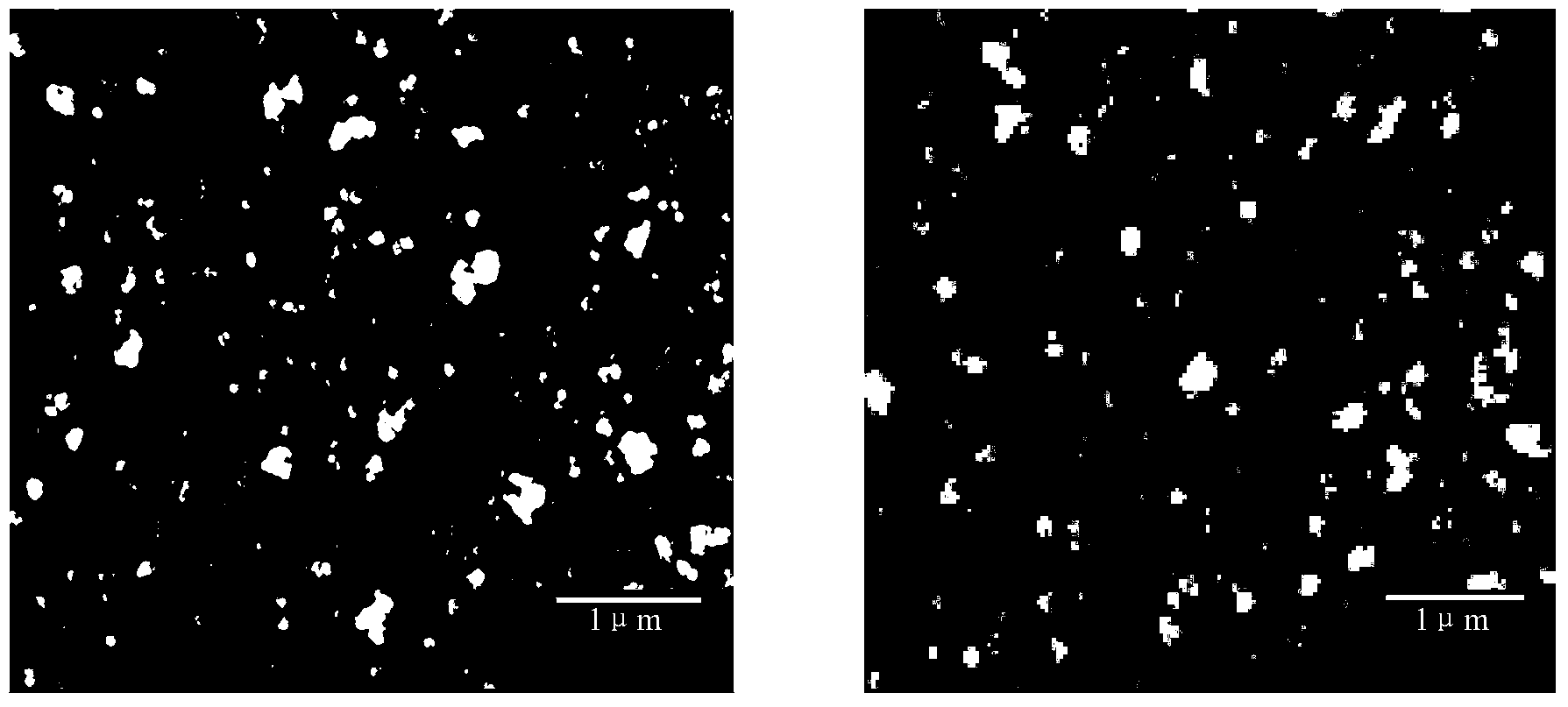

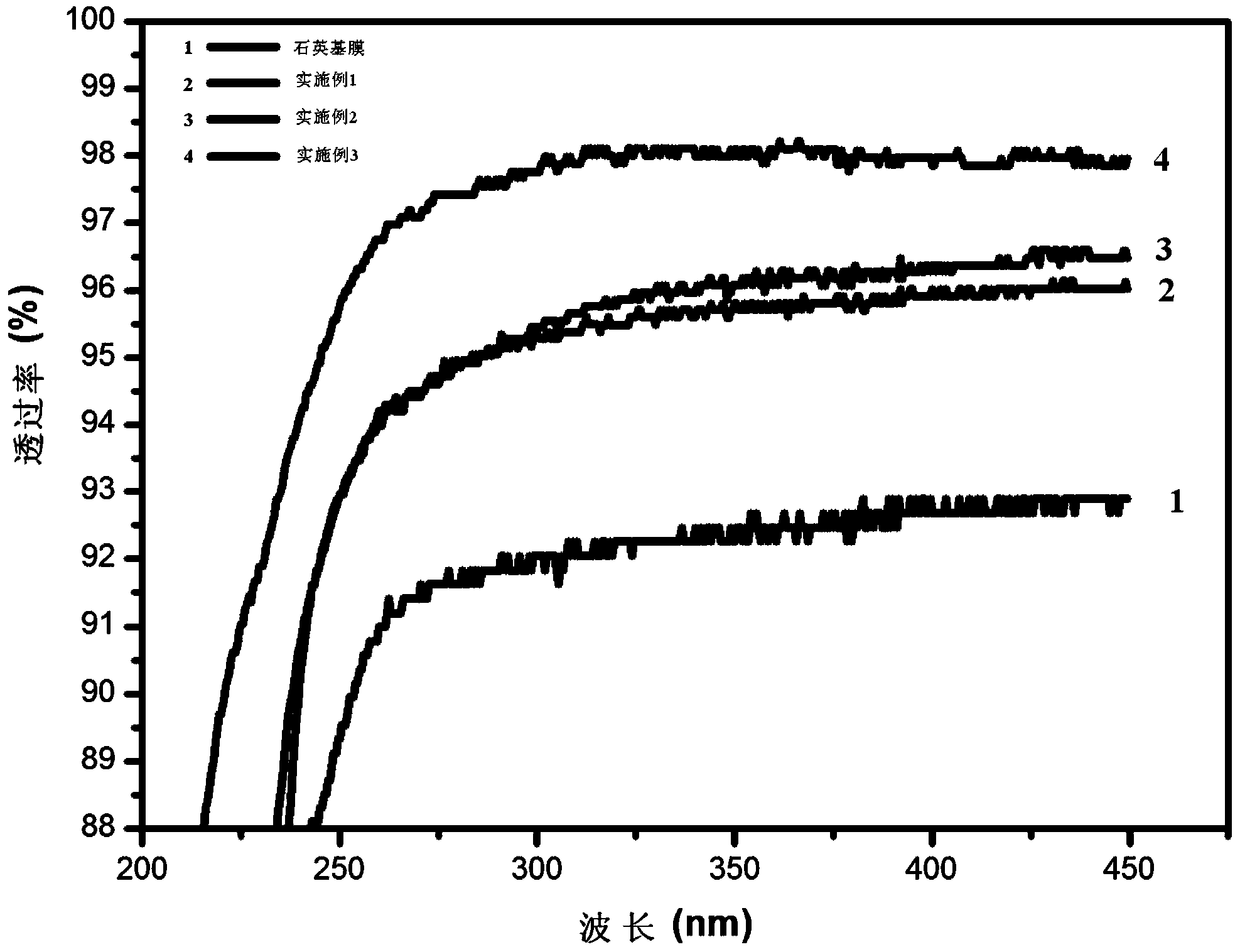

[0024] Using a quartz substrate as the base film, the organic matter on the surface was first removed with ethanol / chloroform, and then 98wt%H with a volume ratio of 7:3 at 70°C 2 SO 4 , with 30wt%H 2 o 2 Soak in the mixed aqueous solution for 60 minutes, clean with deionized water; then soak in the mixed solution of concentrated ammonia / hydrogen peroxide / water with a volume ratio of 1:1:5 for 20 minutes, and wash with deionized water until neutral; Immerse the base film in a 1.0g / L polyethyleneimine (PEI) solution containing 0.01mol / mL calcium acetate, take it out after 30min, rinse it with deionized water, and then immerse it in a 1.0g / L solution containing 0.01mol / mL sodium silicate. g / L polystyrene sodium sulfonate (PSS) solution, after 30min, take it out, wash thoroughly with deionized water, repeat the above operation and immerse in 1.0g / L polyethyleneimine (PEI) containing 0.01mol / mL calcium acetate ) solution and immersed in 1.0g / L polystyrene sodium sulfonate (PSS)...

Embodiment 2

[0026] Using a quartz substrate as the base film, the organic matter on the surface was first removed with ethanol / chloroform, and then 98wt%H with a volume ratio of 7:3 at 100°C 2 SO 4 , with 30wt%H 2 o 2 Soak in the mixed aqueous solution for 15 minutes, clean with deionized water; then soak in the mixed solution of concentrated ammonia / hydrogen peroxide / water with a volume ratio of 1:1:5 for 20 minutes, and wash with deionized water until neutral; The final basement film was immersed in 8.0g / L polyethyleneimine (PEI) solution containing 0.1mol / mL calcium acetate. 8.0g / L polystyrene sodium sulfonate (PSS) solution, after 10min, take it out, wash thoroughly with deionized water, repeat the above operation and immerse in 8.0g / L polyethyleneimine containing 0.1mol / mL calcium acetate ( PEI) solution and immersed in 8.0g / L polystyrene sodium sulfonate (PSS) solution containing 0.1mol / mL sodium silicate once to obtain polyelectrolyte nano calcium silicate hydrate superhydrophil...

Embodiment 3

[0028] Using a quartz substrate as the base film, the organic matter on the surface was first removed with ethanol / chloroform, and then 98wt%H with a volume ratio of 7:3 at 80°C 2 SO 4 , with 30wt%H 2 o 2 Soak in the mixed aqueous solution for 30 minutes, clean with deionized water; then soak in the mixed solution of concentrated ammonia / hydrogen peroxide / water with a volume ratio of 1:1:5 for 20 minutes, and wash with deionized water until neutral; Immerse the base film in 4.0g / L polyethyleneimine (PEI) solution containing 0.5mol / mL calcium acetate, take it out after 15min, rinse it with deionized water, and then immerse it in 4.0g / L solution containing 0.5mol / mL sodium silicate g / L polystyrene sodium sulfonate (PSS) solution, after 15 minutes, take it out, wash thoroughly with deionized water, repeat the above operation and immerse in 4.0g / L polyethyleneimine (PEI) containing 0.5mol / mL calcium acetate ) solution and immersed in 4.0g / L polystyrene sodium sulfonate (PSS) so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com