Protective film applied to curved screen mobile phone

A protective film and curved screen technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of unrecognizable fingerprint mobile phones under the screen, large phase difference of PET materials, etc., and achieve the effect of improving recognition sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

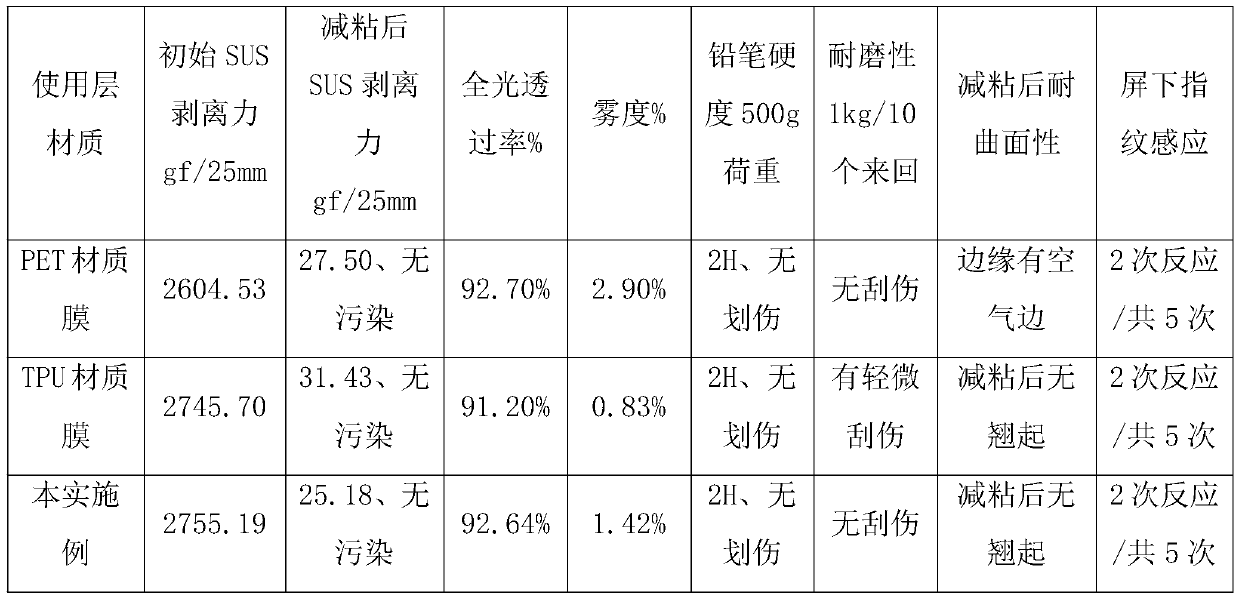

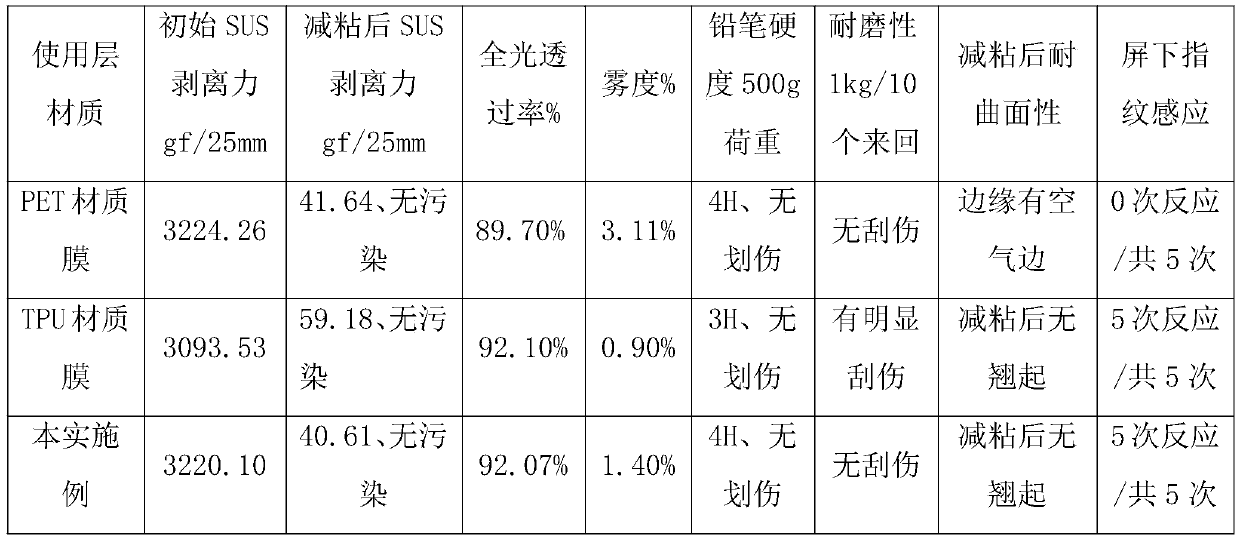

Embodiment 101

[0048]The protective film of this embodiment includes an acrylic pressure-sensitive adhesive PET protective film layer with a thickness of 50 μm as the outermost layer, an acrylic resin functional coating with a thickness of 30 μm arranged on the inner side of the PET protective film layer, and an acrylic resin functional coating with a thickness of 30 μm arranged on the functional coating. A PET / TPU composite film with a thickness of 12μm on the inner side of the layer (the light transmittance>90%, haze<1.5%, 5μm PET+5μm TPU and bonded with 2μm polyurethane structural adhesive) and set on the inside of the PET / TPU composite film An acrylic pressure-sensitive adhesive layer with a thickness of 10 μm is used to provide adhesion. The protective film is attached to the mobile phone screen through the pressure-sensitive adhesive layer. Through the cooperation between the PET protective film layer of appropriate thickness and the PET / TPU composite film It overcomes the problems of p...

Embodiment 102

[0052] The protective film of this embodiment includes an acrylic pressure-sensitive adhesive PET protective film layer (SUS peeling force 3-6gf / 25mm) with a thickness of 60 μm as the outermost layer, and an acrylic pressure-sensitive adhesive film layer with a thickness of 1 μm disposed inside the PET protective film layer. Acrylic resin functional coating, a PET / TPU composite film layer with a thickness of 100 μm (50 μm PET + 50 μm TPU) arranged on the inner side of the functional coating, the composite film can be bonded by polyurethane structural adhesive, light transmittance > 90%, haze <1.5%) and an acrylic pressure-sensitive adhesive layer with a thickness of 25 μm arranged inside the TPU composite film layer to provide adhesion, the protective film is attached to the mobile phone screen through the pressure-sensitive adhesive layer, through the PET protective film layer, The combination of rigidity and flexibility between the TPU composite film layers overcomes the prob...

Embodiment 103

[0056] The protective film of this embodiment includes an acrylic pressure-sensitive adhesive PET protective film layer with a thickness of 100 μm as the outermost layer, an acrylic resin functional coating with a thickness of 10 μm arranged on the inner side of the PET protective film layer, and an acrylic resin functional coating layer arranged on the functional coating layer. A PET / TPU composite film with a thickness of 10 μm on the inner side of the layer (the light transmittance >90%, haze <1.5%, 4 μm PET+5 μm TPU and laminated with 1 μm polyurethane structural adhesive) and set on the inside of the PET / TPU composite film An acrylic pressure-sensitive adhesive layer with a thickness of 50 μm is used to provide adhesion. The protective film is attached to the screen of the mobile phone through the pressure-sensitive adhesive layer. Through the cooperation between the PET protective film layer of appropriate thickness and the PET / TPU composite film It overcomes the problems ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com