Photo-curing type hardening film with high hardness and preparation method of hardening film

A light-curing and hardening film technology, applied in optics, optical components, coatings, etc., can solve problems such as low hardness, and achieve high production efficiency, good comprehensive performance, and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] (2) Preparation of hardened coating liquid:

[0080] In the yellow light area, under the condition that the humidity is lower than 70% and the temperature is lower than 30℃, first add A, B, and C into the stirring tank, stir at 300-1000rpm for 30-60min; then at 100-500rpm While stirring, add D, E, and F in sequence. Note that the order of addition cannot be reversed. The adding speed should not be too fast, so that it does not agglomerate or splash. Finally, stir at 1000rpm for 60min. After the mixing is complete, filter it once with a filter element of 1 to 5 μm, and it can be used.

[0081] (3) Preparation of high-hardness light-curing hardened film:

[0082] Use a gravure roller to coat the above-configured hardening solution on a 188μm thick PET substrate, dry at 80°C for 1min, and irradiate UV energy at 300mj / cm 2 , The material coating is cured to obtain a hardened film with a coating thickness of less than 15μm. And test various properties after 24h as required.

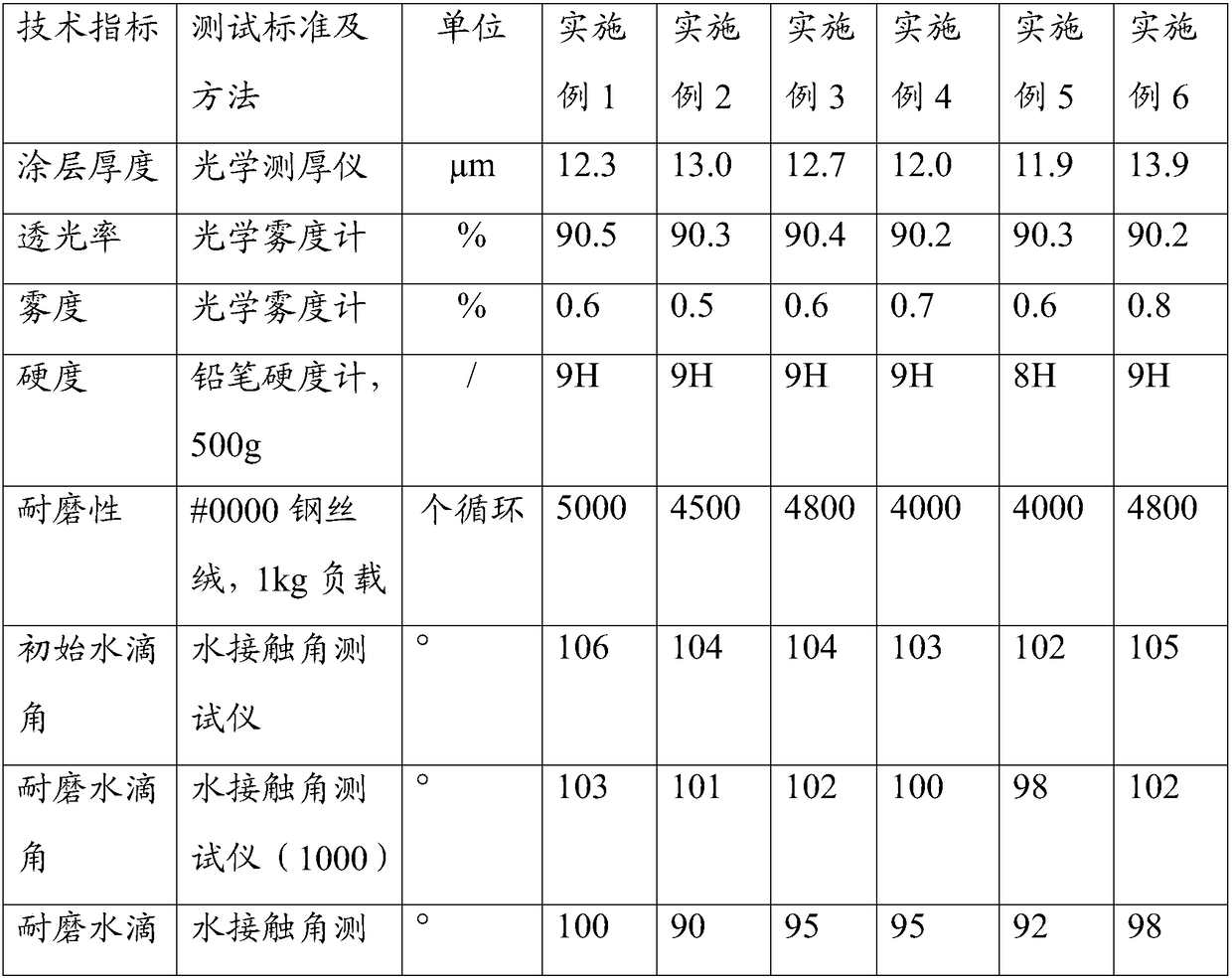

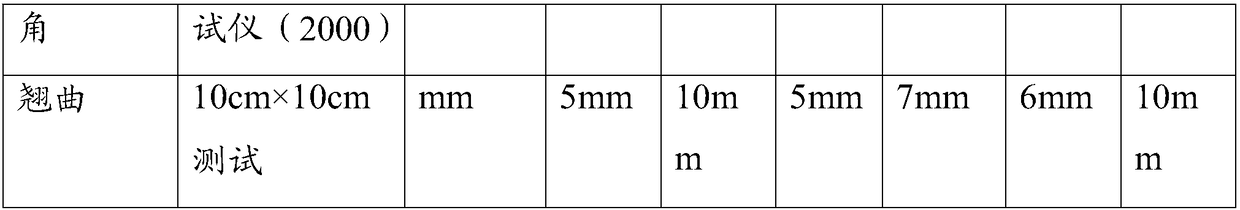

[008...

Embodiment 1

[0093] The present invention provides a high-hardness photocurable hardened film, which includes a substrate layer and a photocurable coating. The raw materials of the photocurable coating are first formulated into a photocurable coating, which is also called a hardened coating solution.

[0094] The formulation of the hardened coating solution is as follows:

[0095] A: B-530UV (Guangzhou Boxing Chemical Technology Co., Ltd., functionality 4, molecular weight 2500) 6.6kg, B: perfluorinated modified oligomer DS-710ZLC (produced by Japan Harvest Company) 2.4kg, C: photoinitiated Agent 184 (produced by Nanjing Ji'an Company) 0.6 kg, D: maleic anhydride grafted polyacrylic resin 0.15 kg, E: silica particles with a particle size of 10 nm 3 kg, F: fluorine-containing additives DAC-HP (Japan University Gold Fluorochemical Company) 0.09kg, G: Methyl isobutyl ketone (MIBK) 17.25kg.

[0096] The weight percentages of the raw materials in the hardening coating liquid are as follows:

[0097] ...

Embodiment 2

[0100] The high-hardness light-curable hardened film provided in Example 1, wherein the hardened coating liquid formula is as follows:

[0101] A: B-530UV (Guangzhou Boxing Chemical Technology Co., Ltd., functionality 4, molecular weight 2500) 6kg, B: perfluorinated modified oligomer DS-710ZLC (produced by Japan Harvest Company) 3.6kg, C: photoinitiator 184 (produced by Nanjing Ji'an Company) 0.15kg, D: silane coupling agent KH570 0.3kg, E: 10nm silica particles 3kg, F: fluorine-containing auxiliary agent DAC-HP (Japan Daikin Fluorochemical) 0.09kg, G: MIBK 16.5kg.

[0102] The weight percentages of the raw materials in the hardening coating liquid are as follows:

[0103] High-functional acrylate compound (abbreviated as A): 20.24%, perfluoromodified oligomer (abbreviated as B): 12.15%, photoinitiator (abbreviated as C): 0.51%, dispersant (abbreviated as D): 1.01%, Inorganic nanoparticles (abbreviated as E): 10.12%, fluorine-containing auxiliary agent (abbreviated as F): 0.30%, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com