Production process of nanometer antibacterial mildewproof metal drainage floor drain

An antibacterial and antifungal production process technology, applied in drainage structures, antifouling/underwater coatings, water supply devices, etc. The effect of black, reducing production cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

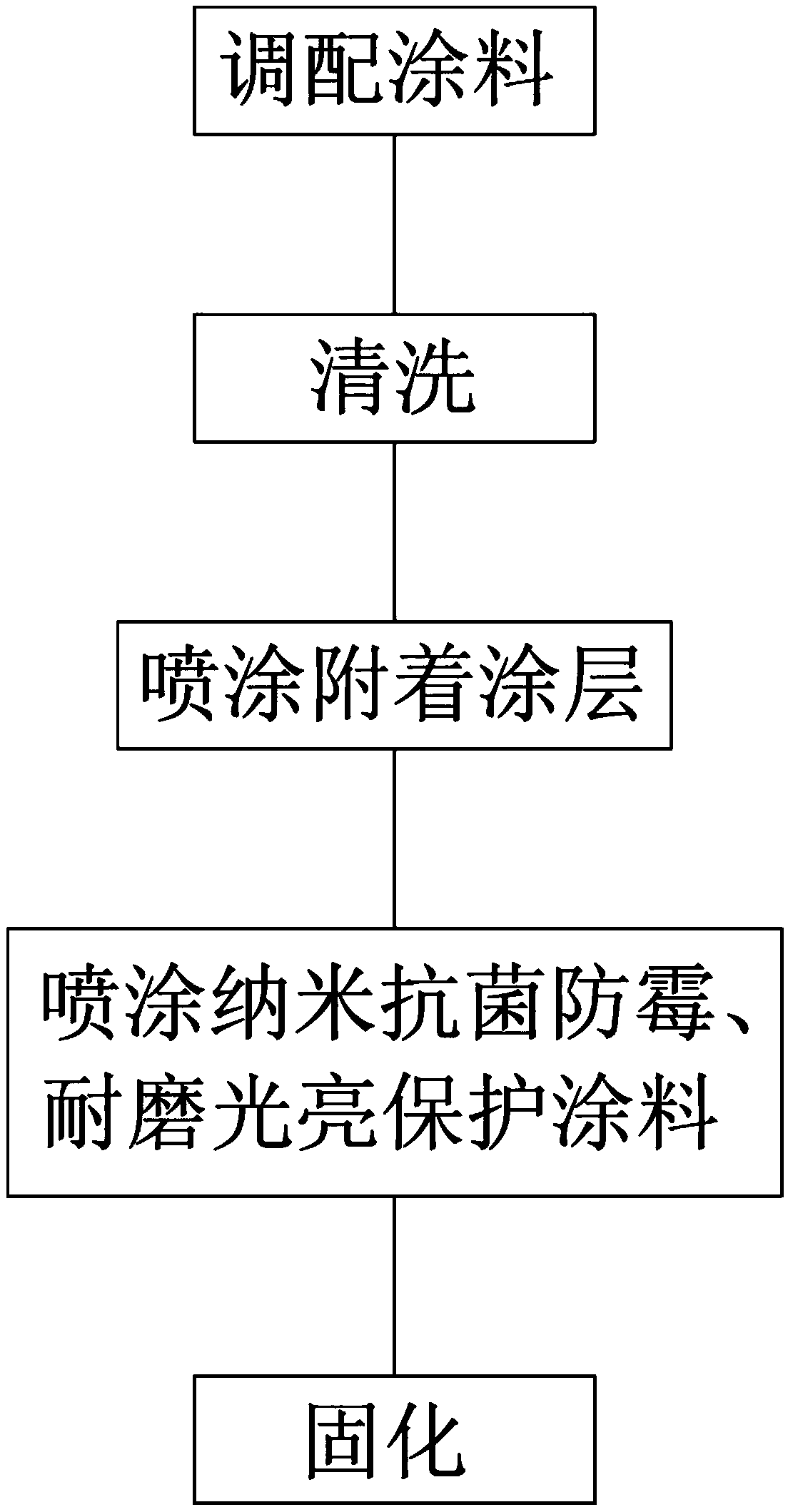

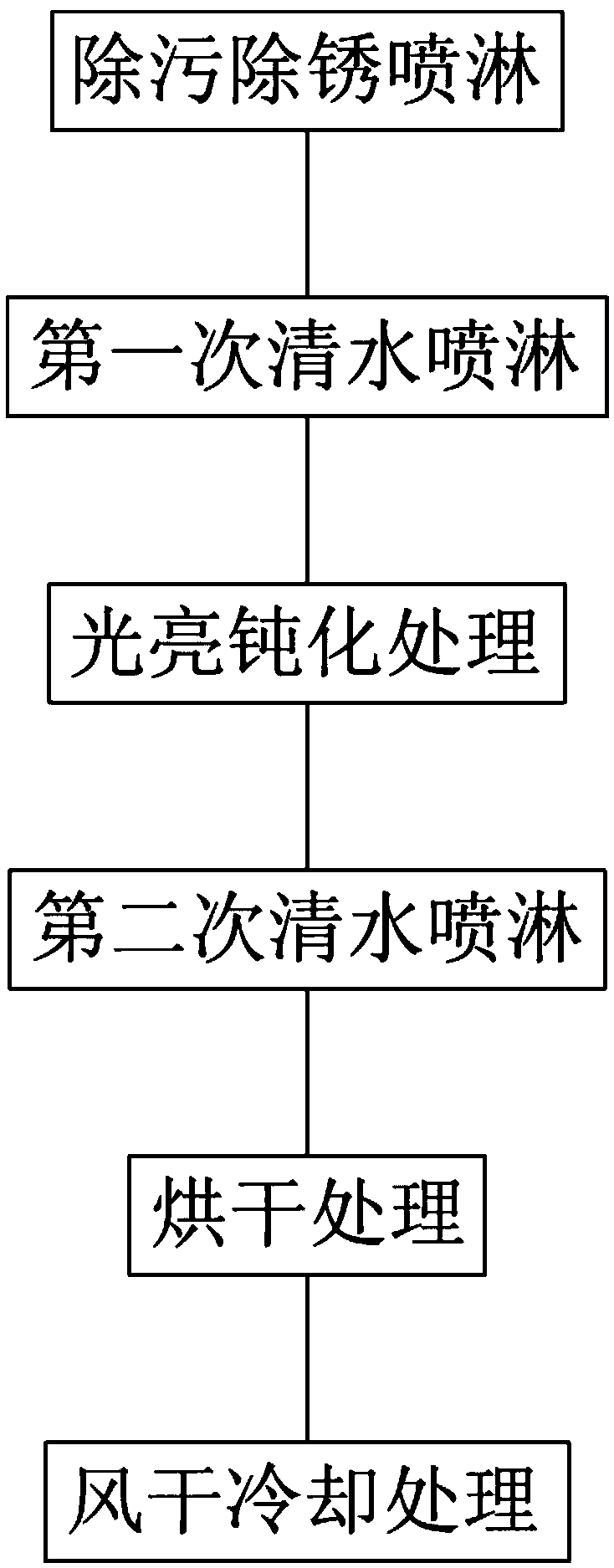

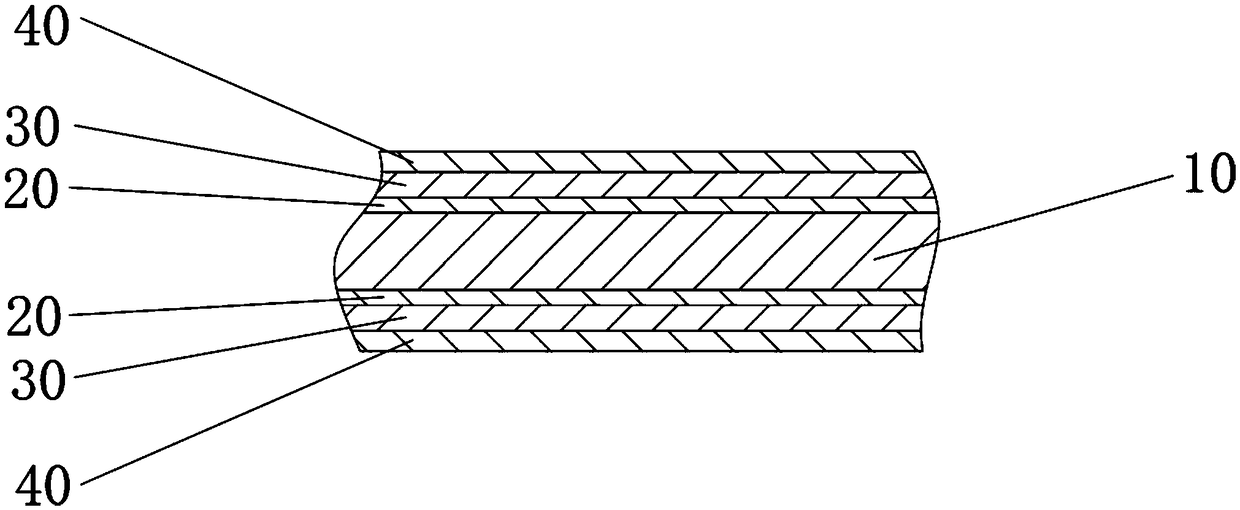

[0063] A production process for nano antibacterial and antifungal metal drainage floor drain, which is used for antibacterial and antifungal treatment on the entire surface of the metal drainage floor drain body 10. Base color, spraying nano antibacterial and mildew-proof, wear-resistant bright protective coating, curing; wherein, the surface treatment, cleaning, spraying adhesion coating, spraying nano-base color, spraying nano anti-bacterial and mildew-proof, wear-resistant bright protective coating, curing It is completed through the assembly line, and the spraying adhesion coating is sprayed with a dust-free automatic spraying work cabinet. Specifically include the following steps:

[0064] Deployment paint: deployment anti-mildew, antibacterial nano anti-bacterial, anti-mildew, wear-resistant bright protective coating, wherein nano anti-bacterial, anti-mildew, wear-resistant bright protective coating components: 82 parts by weight of acrylic resin, 65 parts by weight of p...

Embodiment 2

[0072] A production process for nano antibacterial and antifungal metal drainage floor drain, which is used for antibacterial and antifungal treatment on the entire surface of the metal drainage floor drain body 10. Base color, spraying nano antibacterial and mildew-proof, wear-resistant bright protective coating, curing; wherein, the surface treatment, cleaning, spraying adhesion coating, spraying nano-base color, spraying nano anti-bacterial and mildew-proof, wear-resistant bright protective coating, curing It is completed through the assembly line, and the spraying adhesion coating is sprayed with a dust-free automatic spraying work cabinet. Specifically include the following steps:

[0073] Deployment paint: deploy anti-mildew, anti-bacterial nano anti-bacterial, anti-mildew, wear-resistant bright protective coating, wherein the nano anti-bacterial anti-mildew, wear-resistant bright protective coating components: 95 parts by weight of acrylic resin, 80 parts by weight of p...

Embodiment 3

[0081] A production process for nano antibacterial and antifungal metal drainage floor drain, which is used for antibacterial and antifungal treatment on the entire surface of the metal drainage floor drain body 10. Base color, spraying nano antibacterial and mildew-proof, wear-resistant bright protective coating, curing; wherein, the surface treatment, cleaning, spraying adhesion coating, spraying nano-base color, spraying nano anti-bacterial and mildew-proof, wear-resistant bright protective coating, curing It is completed through the assembly line, and the spraying adhesion coating is sprayed with a dust-free automatic spraying work cabinet. Specifically include the following steps:

[0082] Deployment paint: deploy anti-mildew, anti-bacterial nano anti-bacterial, anti-mildew, wear-resistant bright protective coating, wherein the nano anti-bacterial anti-mildew, wear-resistant bright protective coating components: 108 parts by weight of acrylic resin, 95 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com