Patents

Literature

330results about How to "Improve bending accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

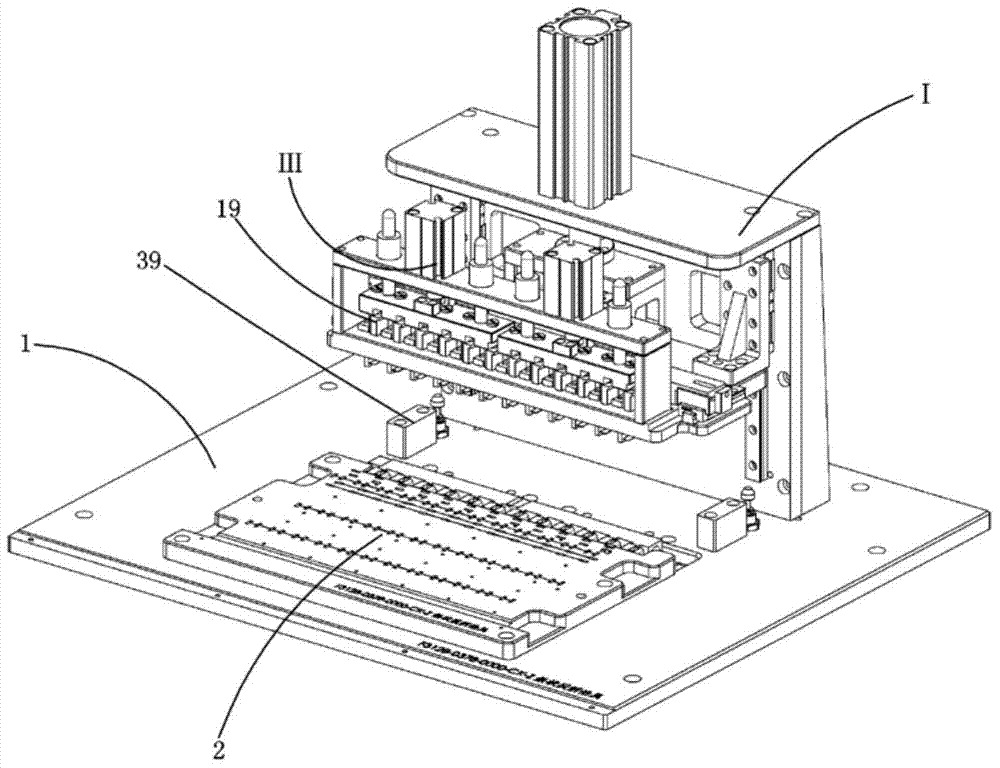

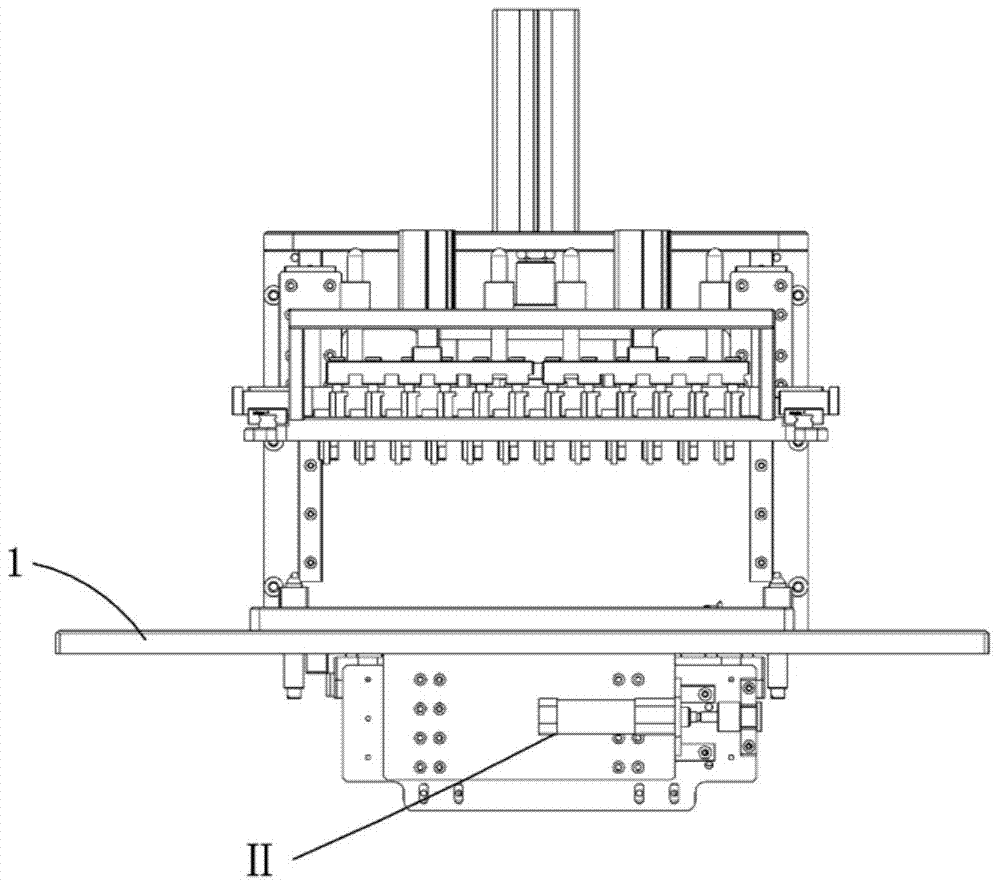

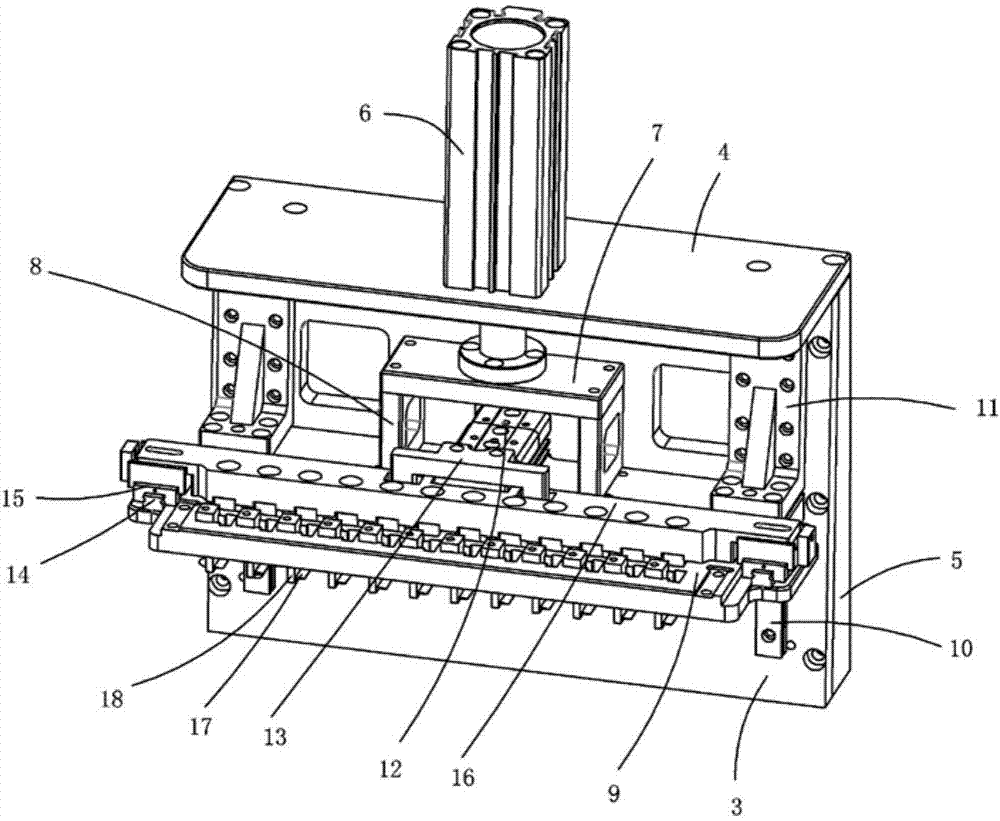

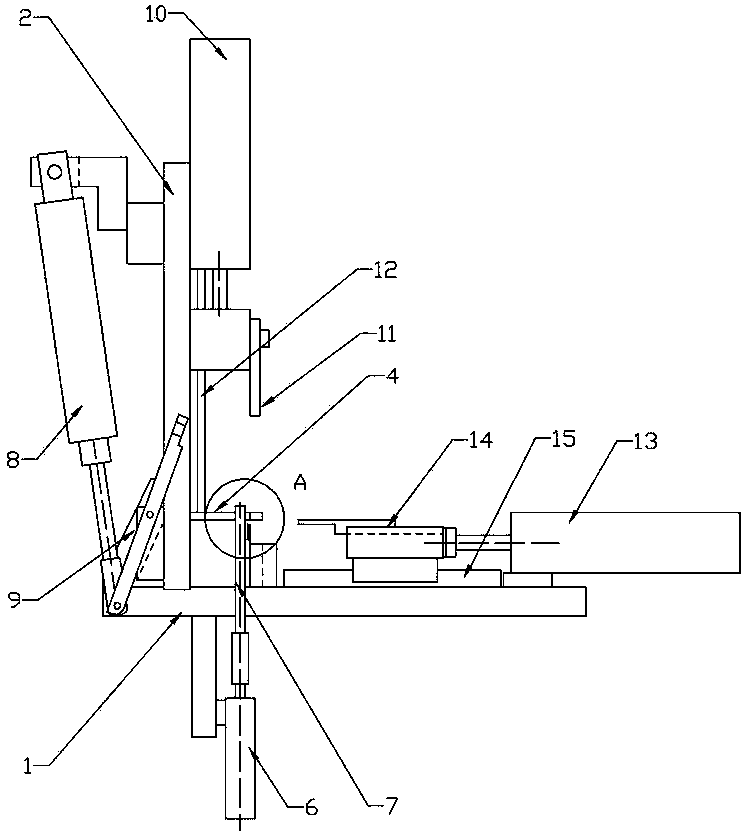

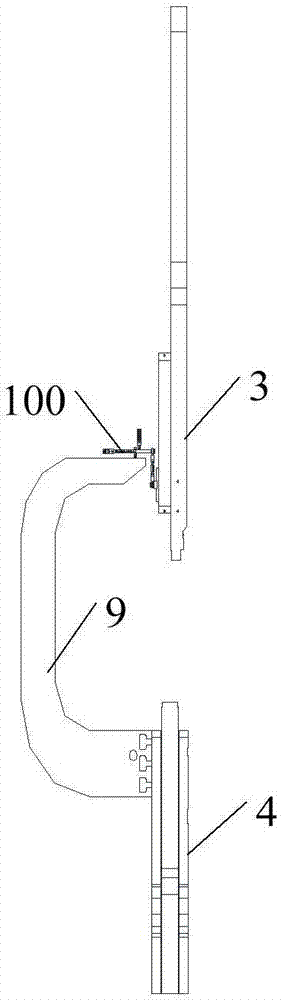

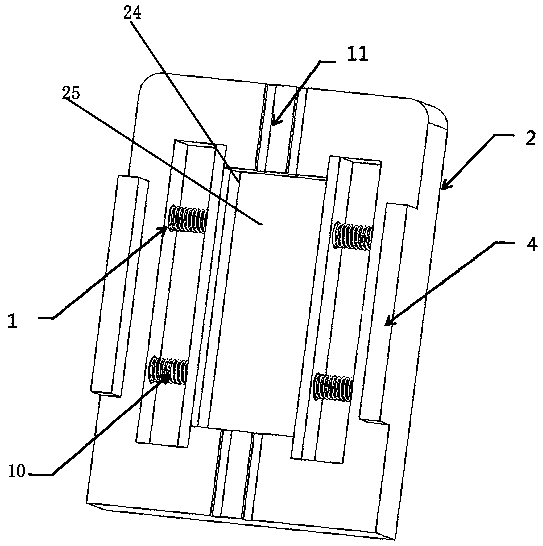

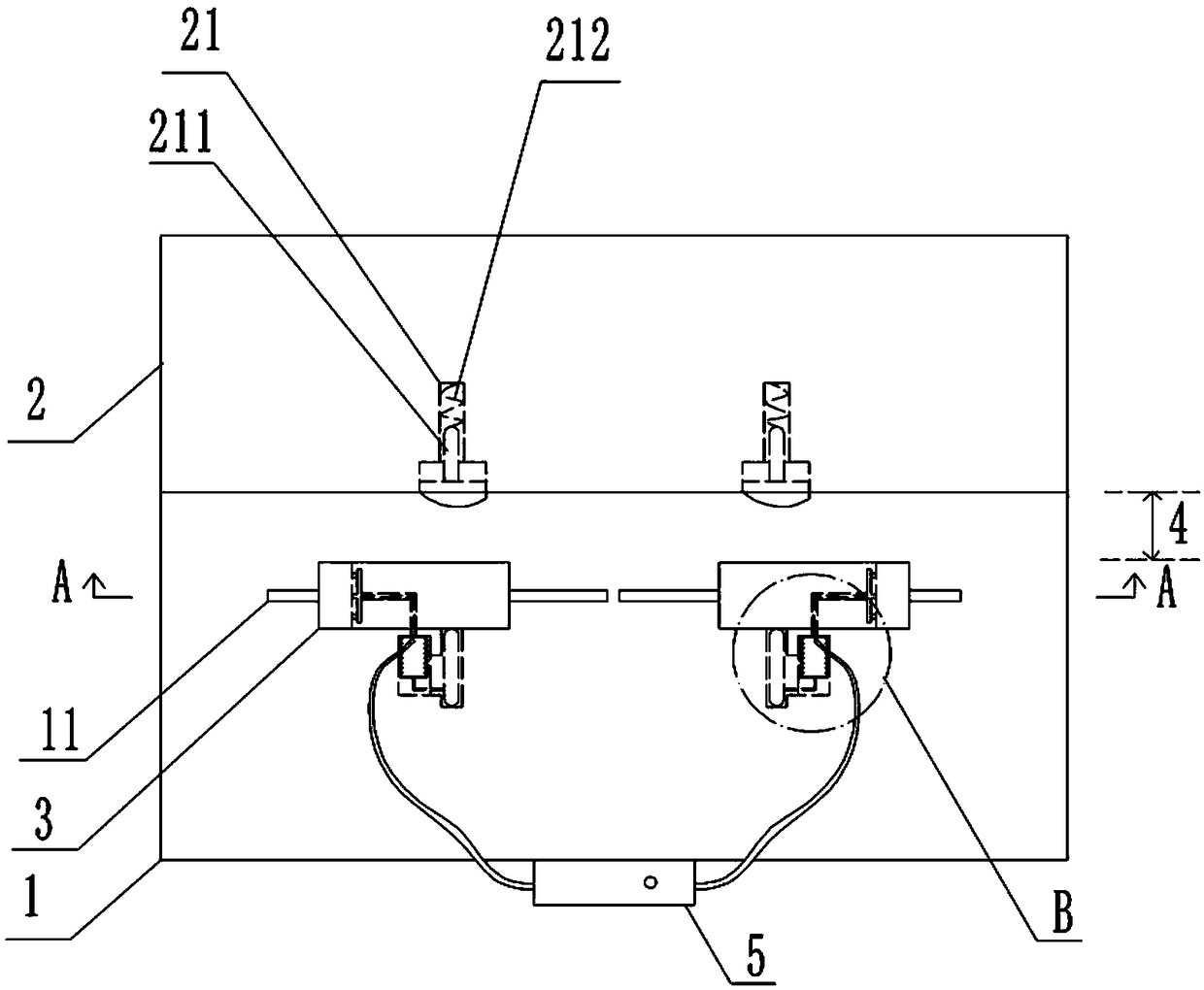

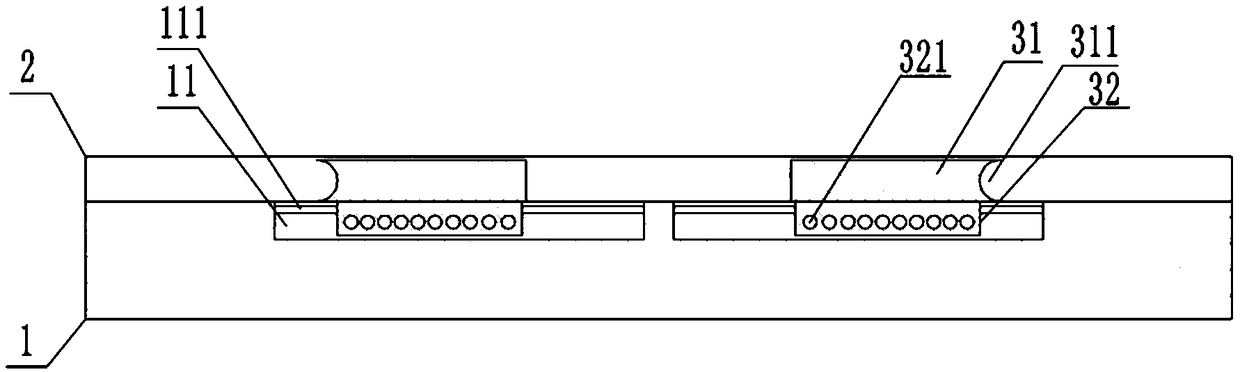

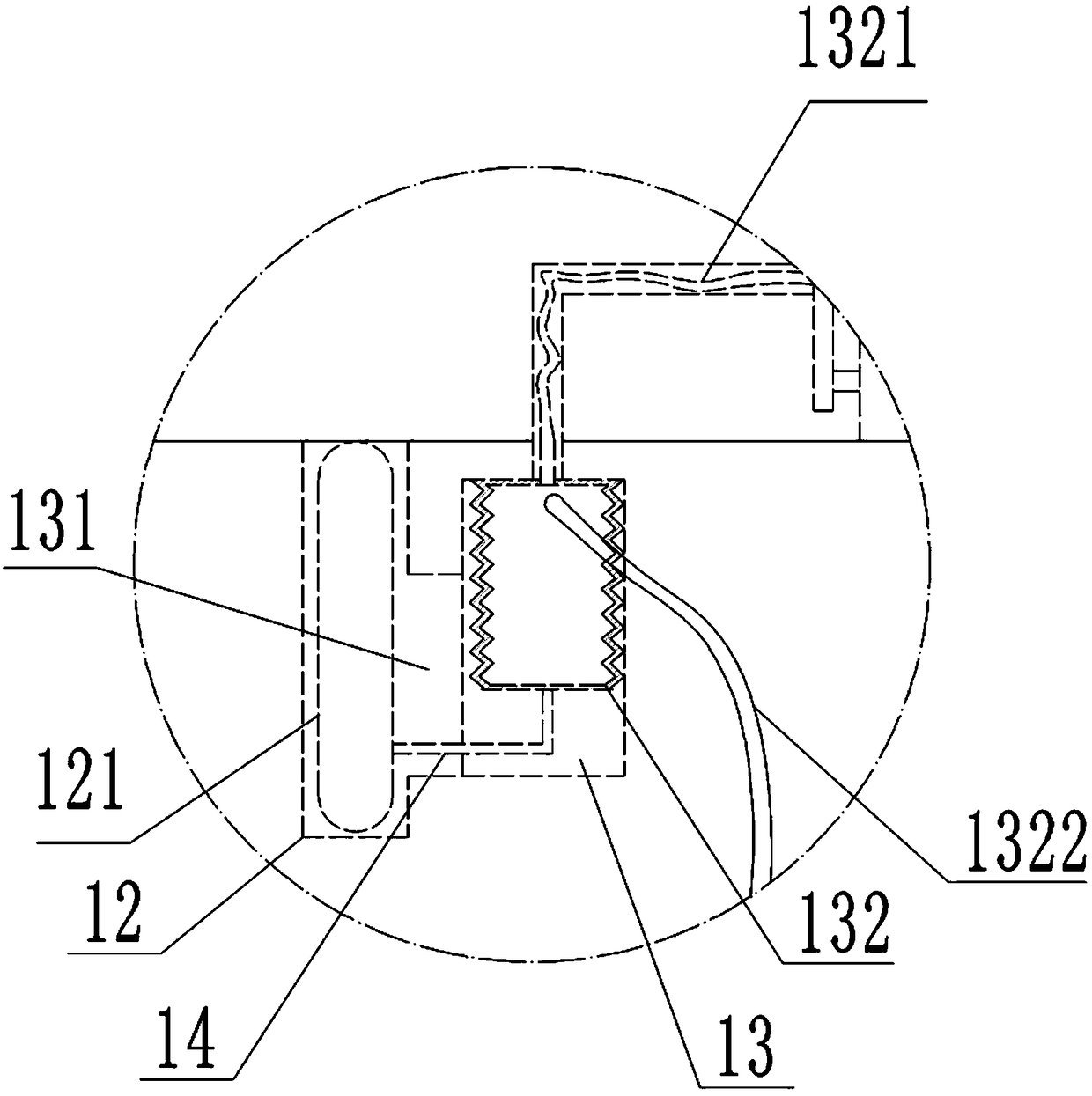

Flexible flat cable bending mechanism

ActiveCN104242019AEasy to moveWith anti-bounce functionLine/current collector detailsEngineeringVertical cylinder

The invention relates to the field of bending equipment, in particular to a flexible flat cable bending mechanism. The flexible flat cable bending mechanism comprises a panel, a carrier plate, an upper mold device and a lower mold device, wherein the carrier plate is arranged on the panel; a product is positioned on the carrier plate; the upper mold device is arranged on the upper portion of the panel; the lower mold device is arranged on the lower portion of the panel; the upper mold device is driven by a vertical cylinder and a transverse cylinder so that a pre-pressing block and a bending stopping block can reach standard operation positions, and preparations are made for bending of flexible flat cables; the upper mold device is also provided with a bending stopping block micro-adjusting mechanism; bending positions can be slightly adjusted by the bending stopping block micro-adjusting mechanism so that the bending precision of the flexible flat cables is high; a horizontal pushing block which is driven by a horizontal cylinder of the lower mold device drives a connecting plate to move along a horizontal sliding track in the left-right direction, and a bending mold is driven to move in the left-right direction; and under the driving effect of a lifting cylinder, a fixing seat can be pushed to move along a lifting sliding track in the up-down direction, and the bending mold is driven to move in the up-down direction. By the flexible flat cable bending mechanism, the flexible flat cables of a plurality of groups of connecting plates can be bent. The bending mechanism is stable and reliable and is high in bending precision, so that the production efficiency and the yield are improved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

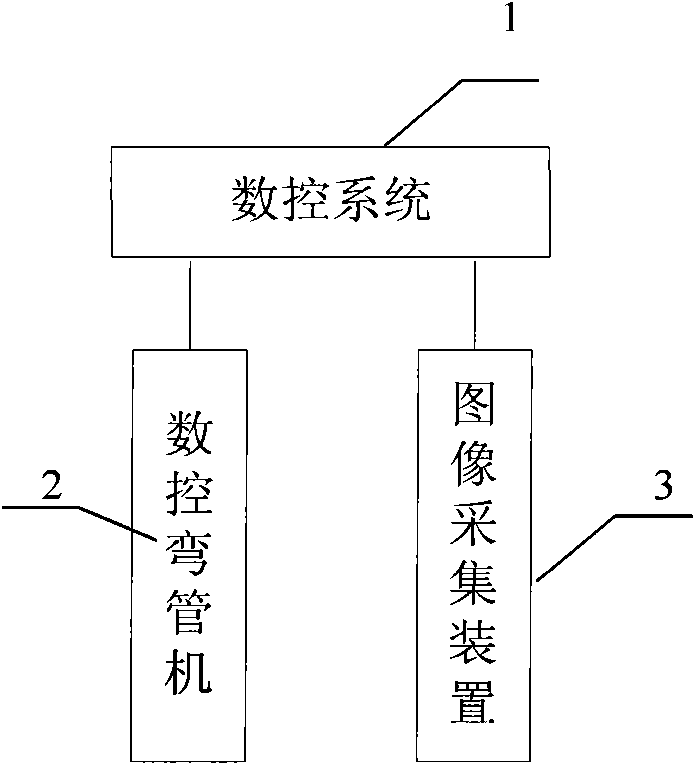

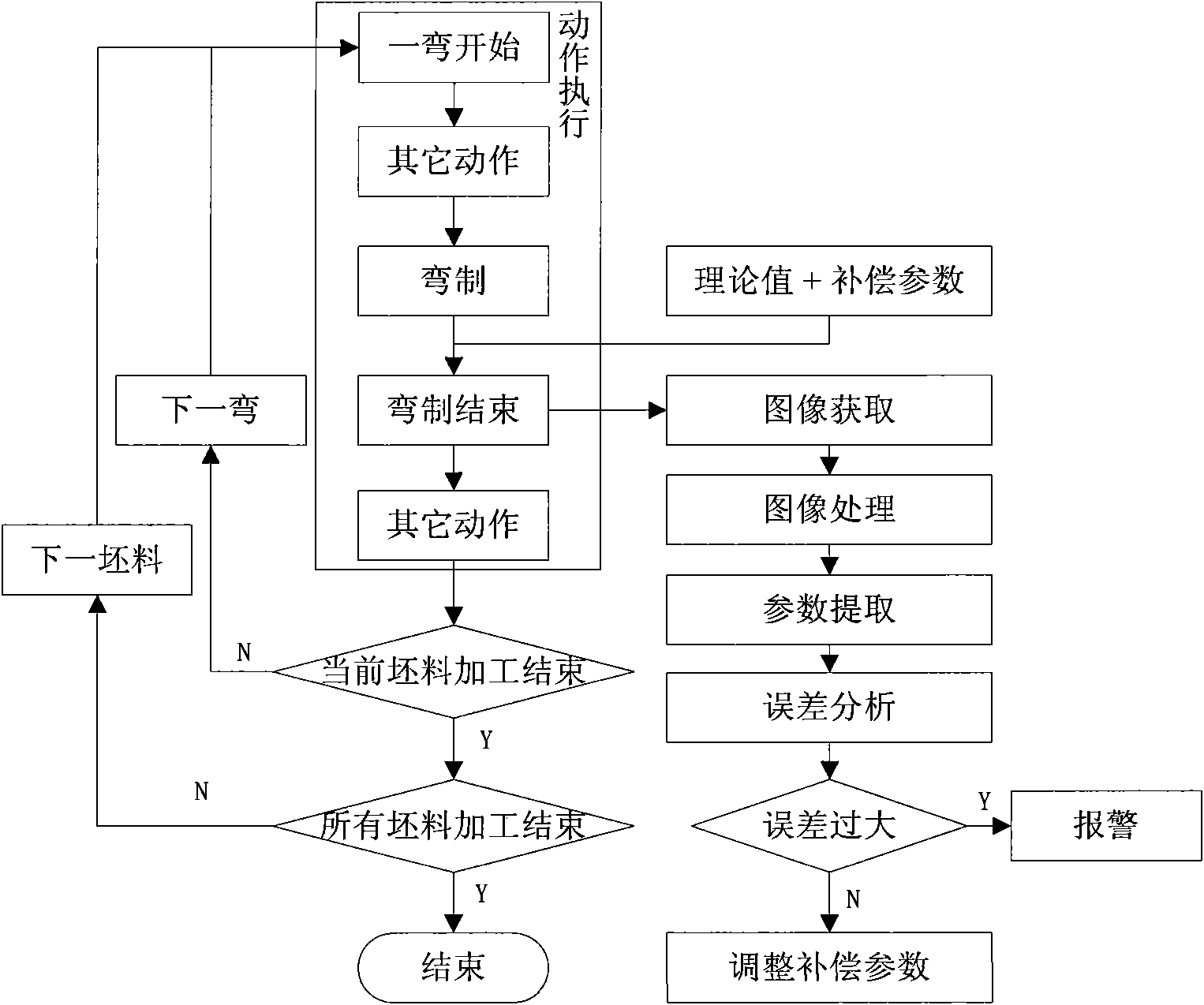

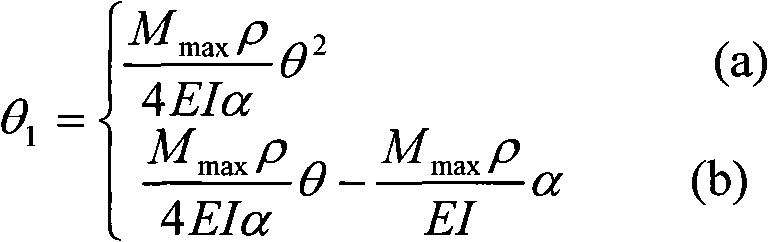

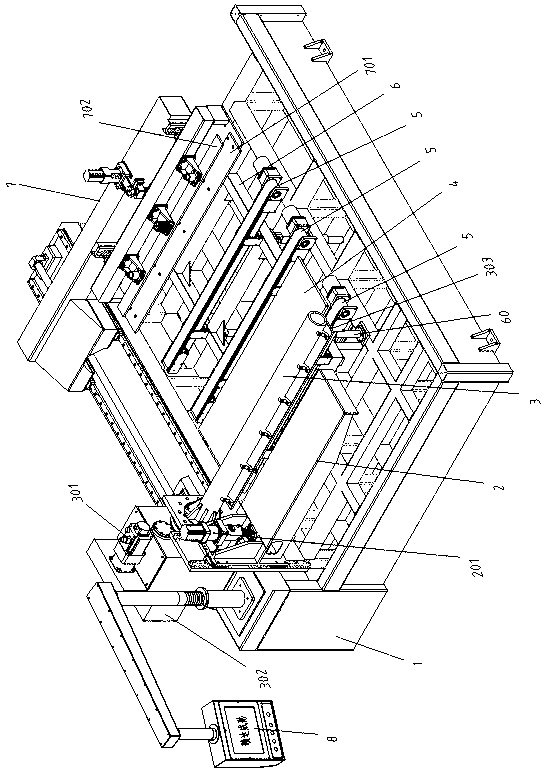

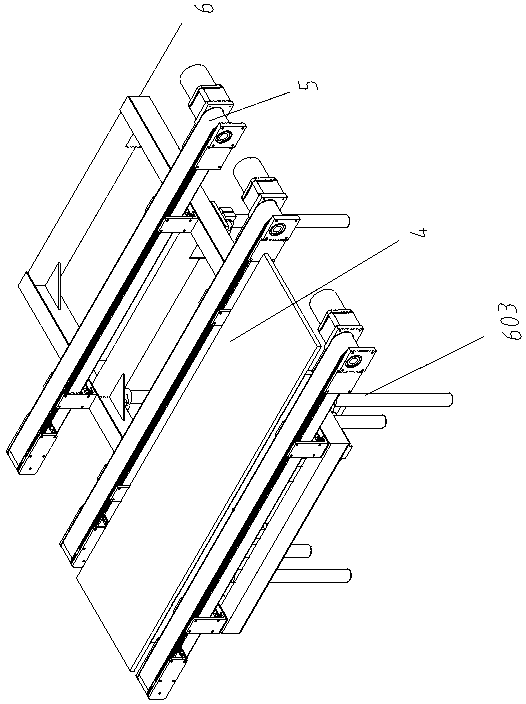

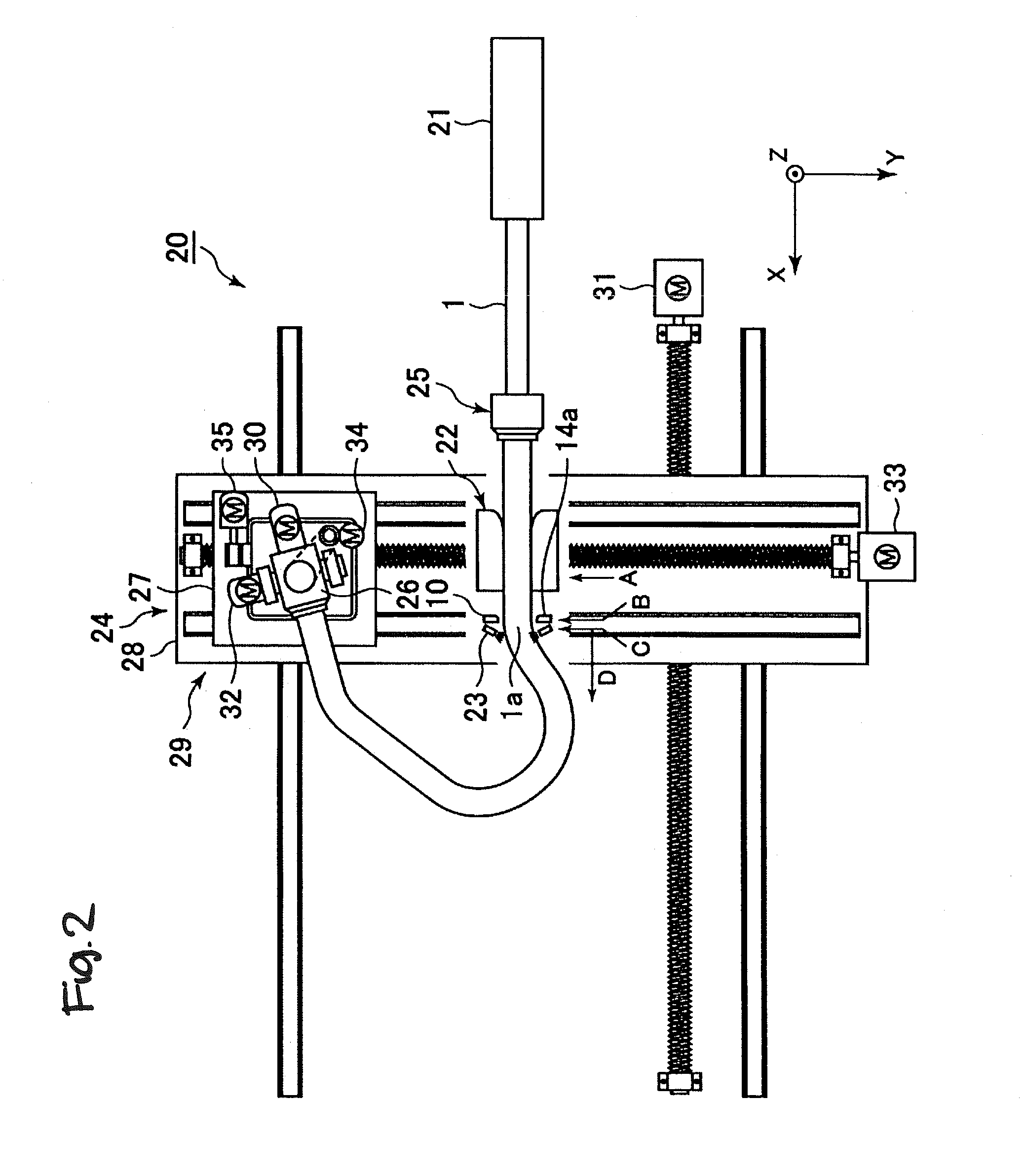

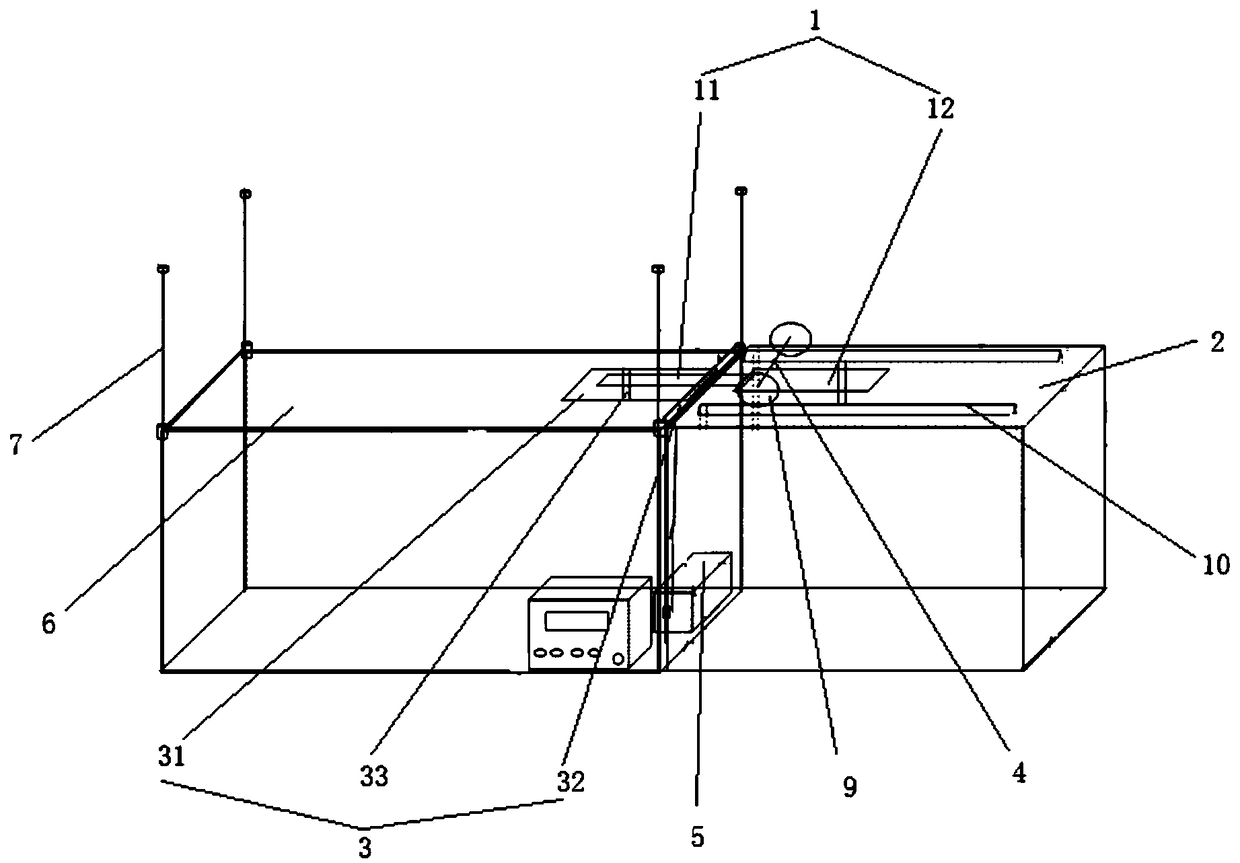

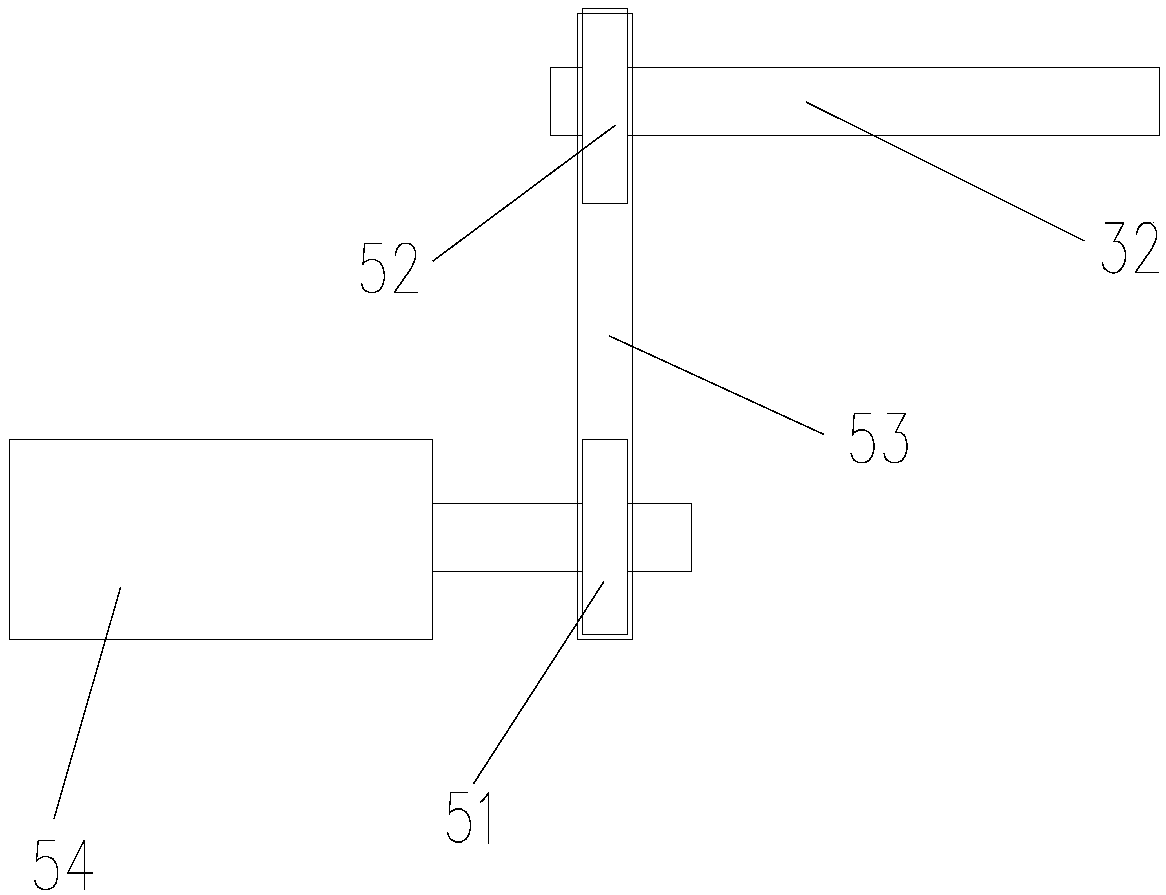

On-line detection and compensation system applied to bend processing

InactiveCN101898211AImprove bending accuracyRealize the alarmProgramme controlComputer controlComputer moduleEngineering

The invention relates to an on-line detection and compensation system applied to bend processing. The on-line detection and compensation system comprises a numerical control pipe bender, an image acquisition device and a numerical control system, wherein the numerical control pipe bender is used for pipe bend processing; the image acquisition device is used for acquiring an image; the numerical control system is used for realizing on-line detection and compensation; the bend station of the numerical control pipe bender is positioned in the visual range of the image acquisition device; the numerical control system comprises an action execution module, an image acquisition module, an on-line detection module and a real-time compensation module; the action execution module is used for controlling the work of the numerical control pipe bender; the image acquisition module is used for acquiring the springback condition of the bent pipe shot by the image acquisition device; the on-line detection module is used for computing the current value after springback according to the acquired image; and the real-time compensation module is used for performing dynamic feedback control on a compensation parameter of the next bent pipe according to a springback error between the current value and the designed value. The on-line detection and compensation system has the advantages of high reliability and effective improvement on bending accuracy.

Owner:杭州捷塔科技有限公司

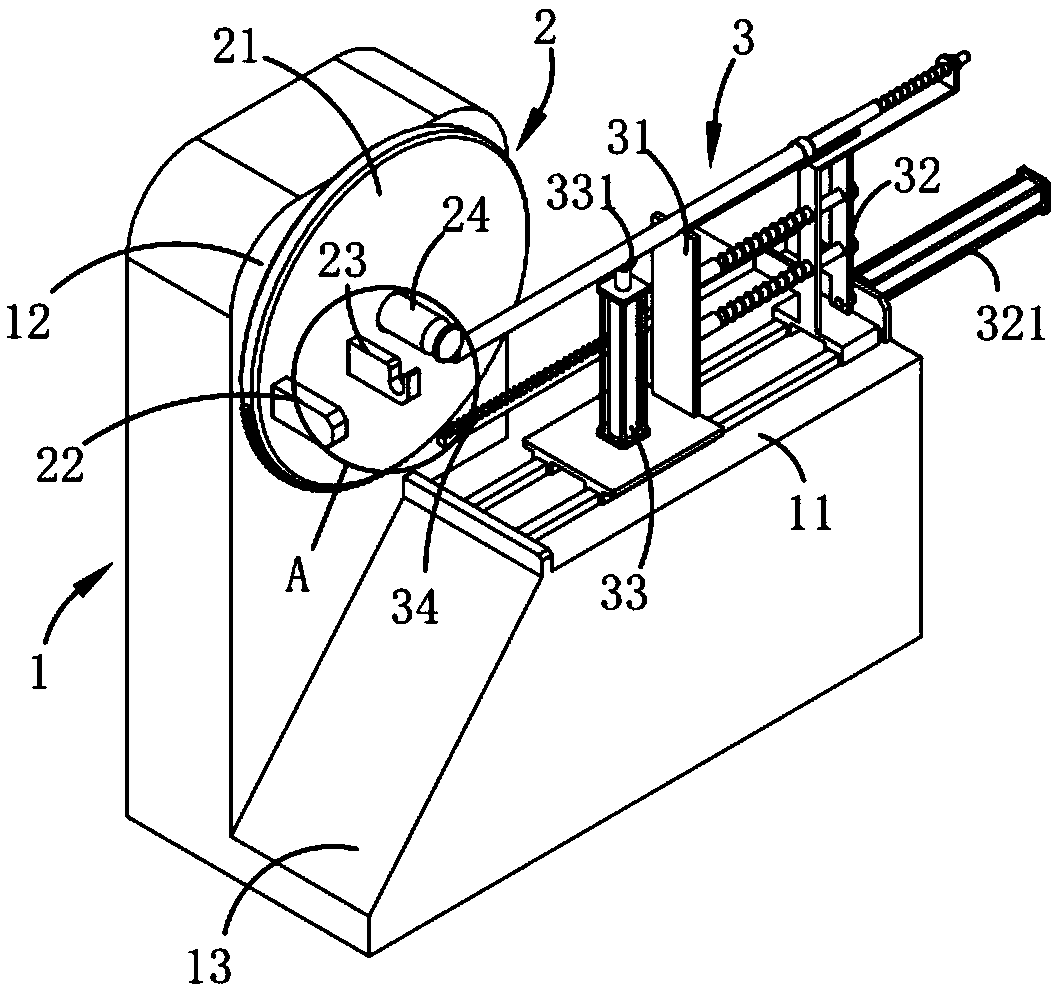

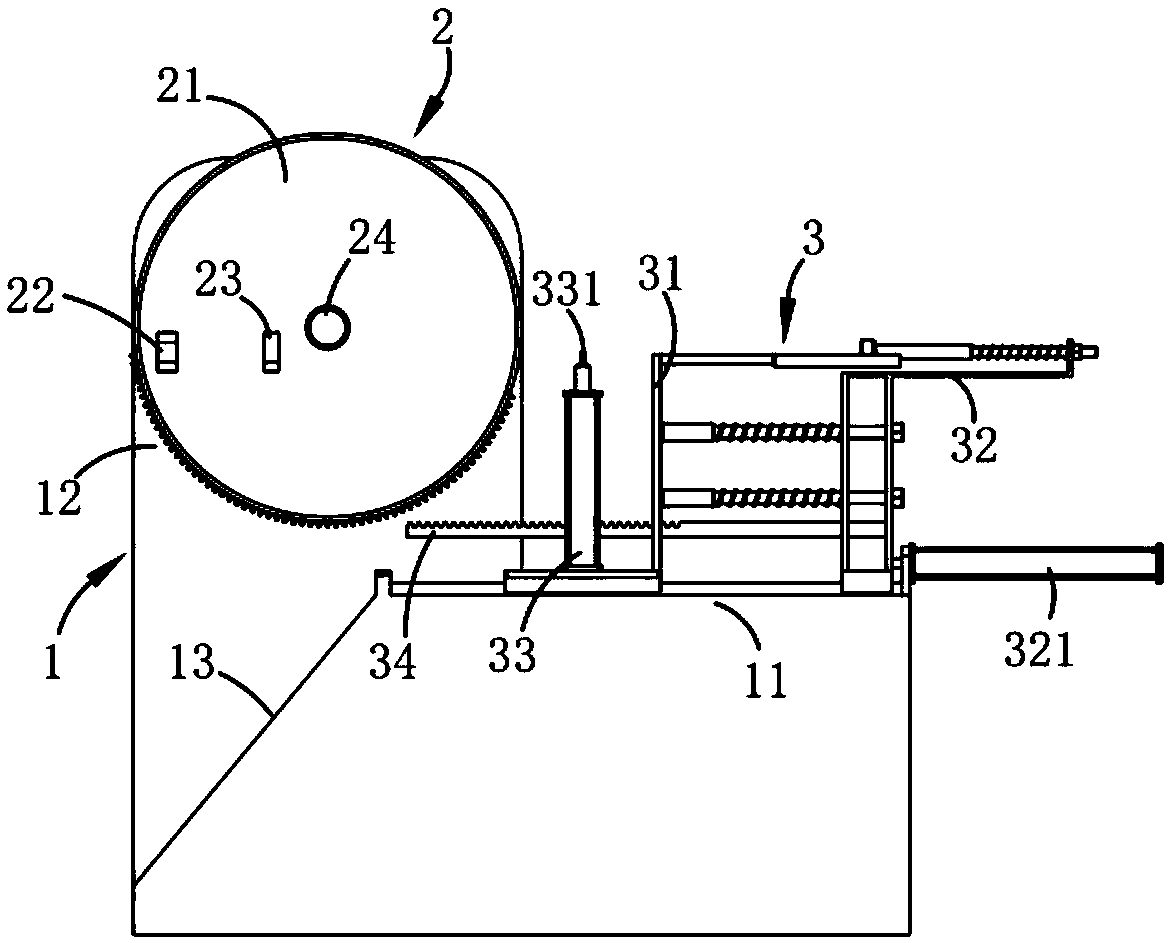

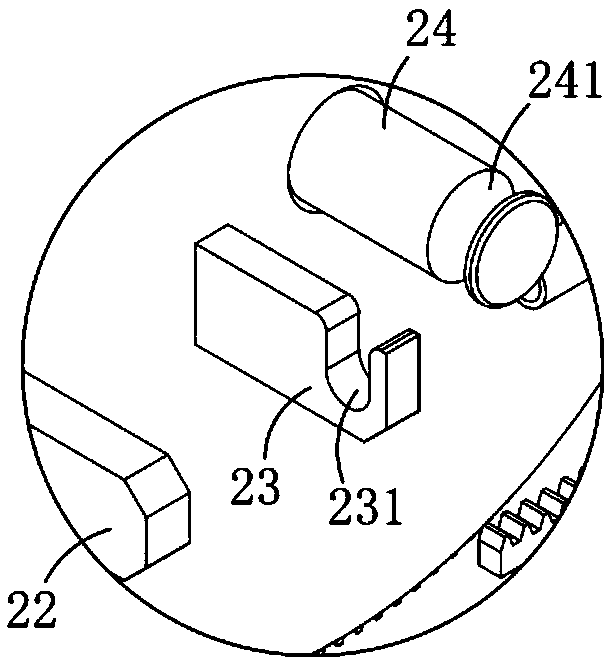

Horizontal bending machine

InactiveCN103121053AIncrease forward momentumEasy to bend multiple timesMetal-working feeding devicesPositioning devicesRelative pressureLayer thickness

The invention relates to a horizontal bending machine which comprises a machine body, a controller, a bending mechanism and a follower plate. The bending mechanism is horizontally arranged on the machine body. The follower plate is arranged in a workpiece feeding direction of the bending mechanism. In time of bending, the controller controls a workpiece to moving into the follower plate and the position of the workpiece is limited by the follower plate and the bending mechanism. The bending mechanism bends the workpiece and acts synchronously with the follower plate. The bending precision is improved, a bending die can rotate independently so that restoring is convenient and multiple bending of the workpiece is facilitated. A whole bending process of the workpiece is fully automatic so that the production efficiency of the bending machine is improved, labor intensity of operators is relived and at the same time, quality and stability of products can be improved. In time of material pressing, the bending machine can be suitable for clamping heat exchangers with different layer thickness and layer numbers so that application range is wide. Synchronous action of the bending mechanism and the follower plate in time of bending can be achieved, friction when the workpiece is bent is reduced and quality of the workpiece is improved. The workpiece can be bended in a delamination mode, required bending moment is little, relative pressure among heat exchanger fins and the bending die and among layers of the heat exchanger is small and the heat exchanger fins are not prone to fall.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

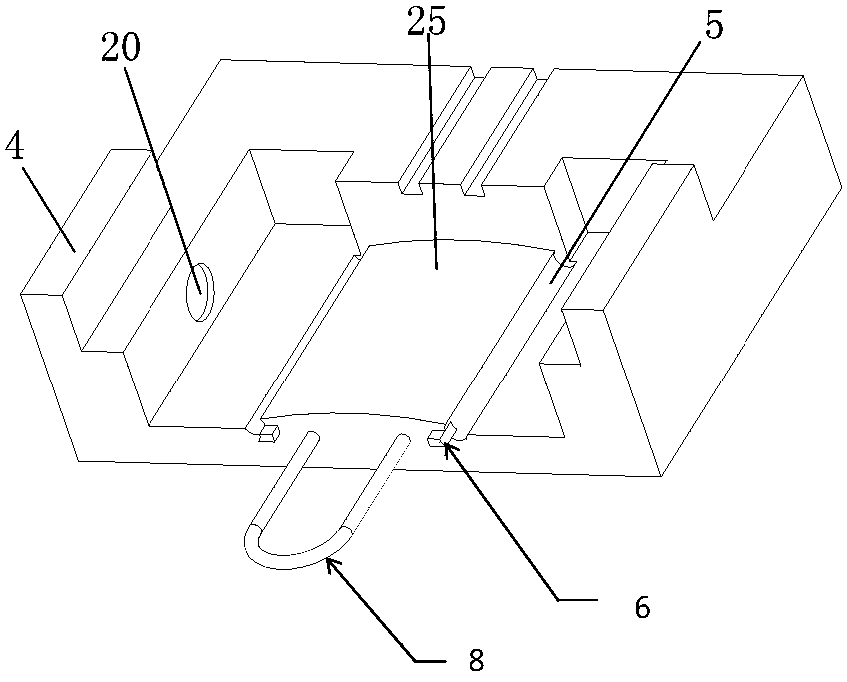

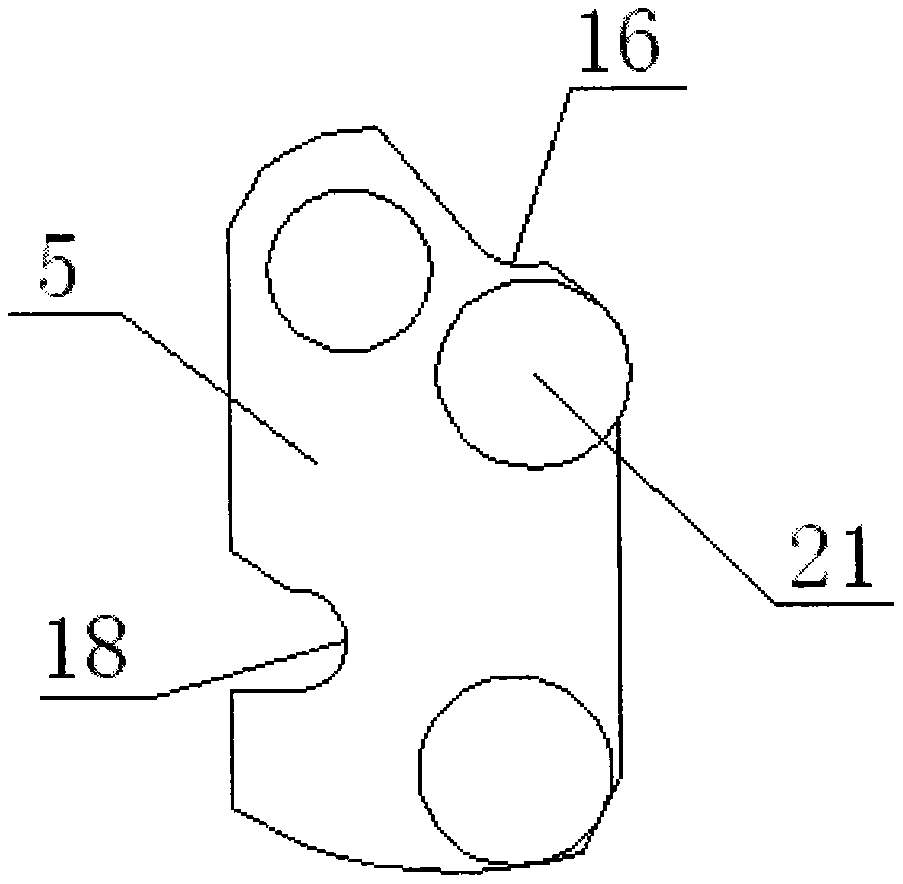

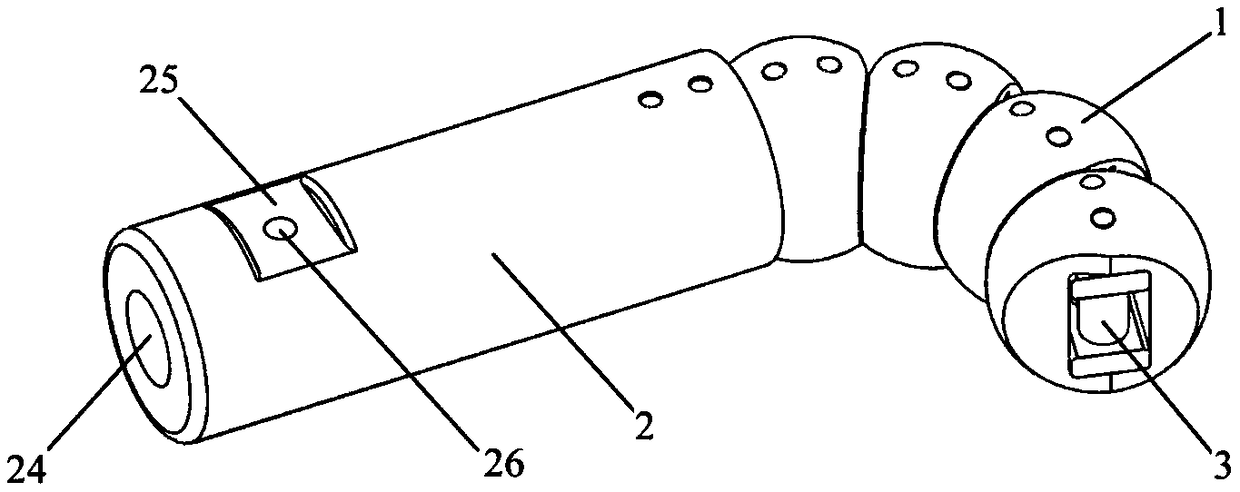

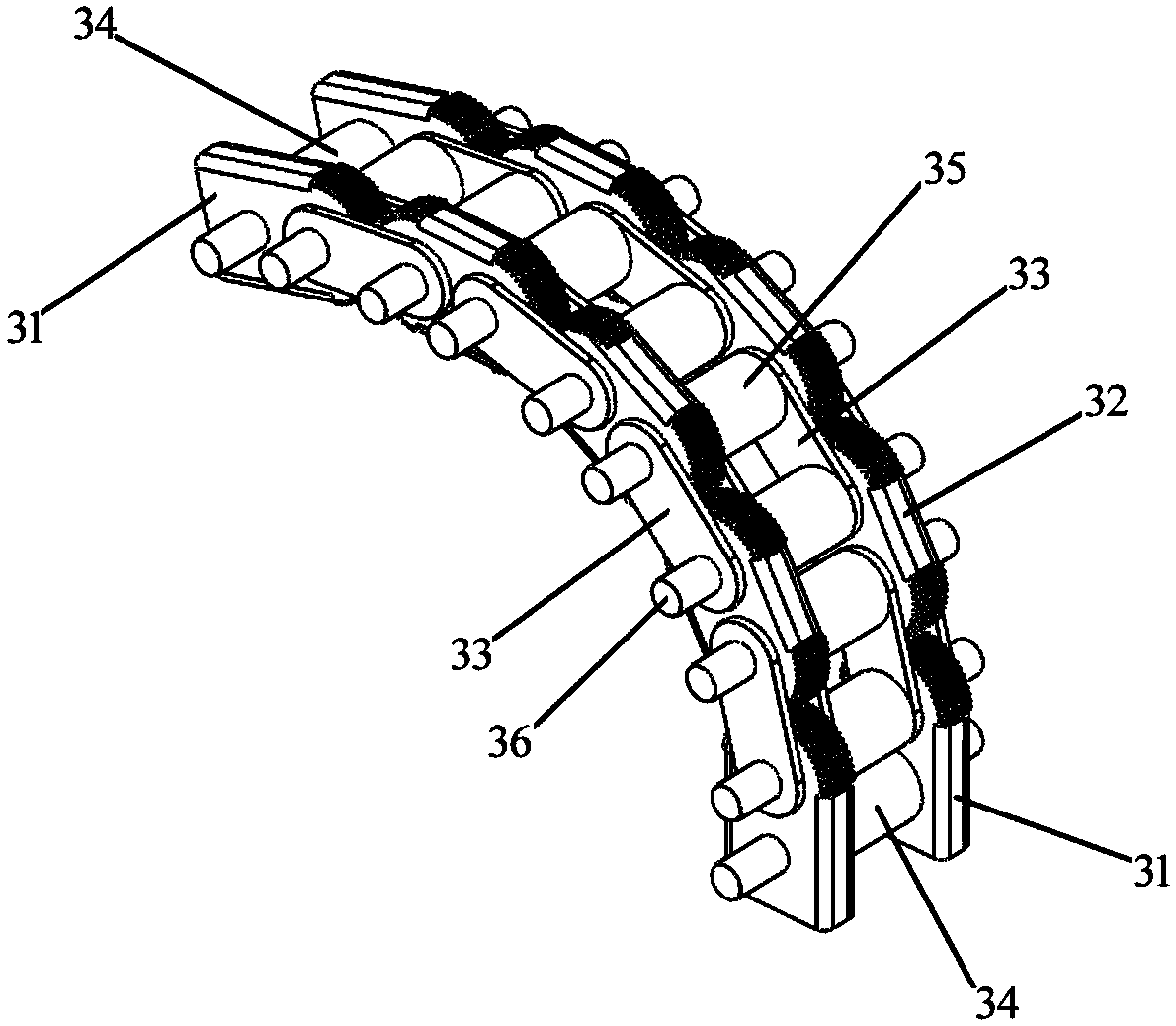

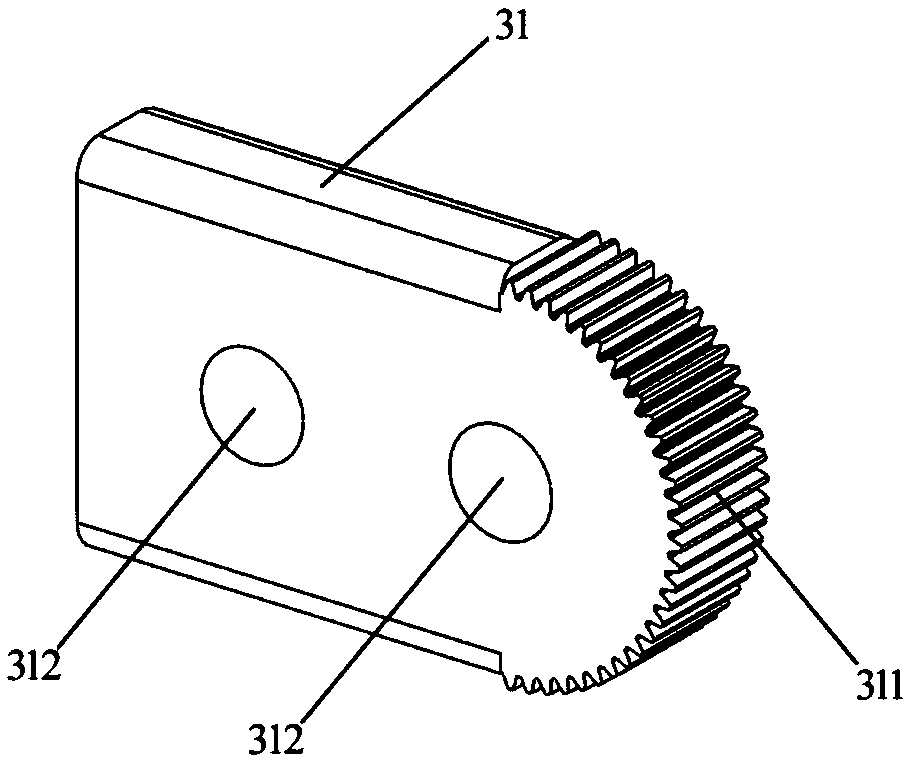

S-shaped joint for surgical robot, surgical instrument and endoscope

InactiveCN106955161AImprove carrying capacityImprove bending accuracyEndoscopesSurgical robotsSurgical robotEngineering

The invention provides an S-shaped joint for a surgical robot. The S-shaped joint comprises at least one joint connector pair and a flexible structure, a first joint connector of each joint connector pair comprises a first spherical surface, a first meshing mechanism is arranged on each first spherical surface, a second joint connector of each joint connector pair comprises a second spherical surface, a second meshing mechanism is arranged on the second spherical surface, each first meshing mechanism is meshed with the corresponding second meshing mechanism, the flexible structure controls the swing direction and the swing angle of the joint connector pair to realize swing of the S-shaped joint. The spherical surfaces are adopted as support structures of the joint connector pair during swing, and the bearing capacity of the S-shaped joint is improved; swing of the at least one joint connector pair is realized through meshing motion of the meshing mechanisms, the meshing precision of the meshing mechanisms is improved, and high bending precision of the S-shaped joint can be realized. A surgical instrument and an endoscope comprise the S-shaped joints, so that the tail end of the instrument or an imaging system can reach the expected position and posture.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

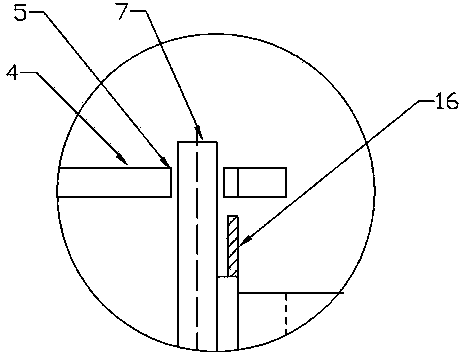

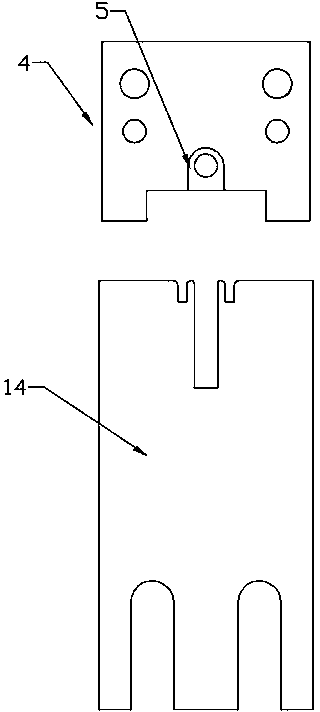

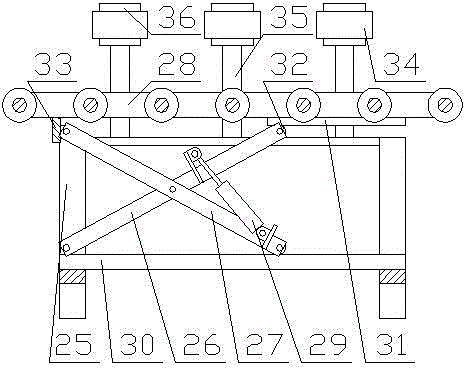

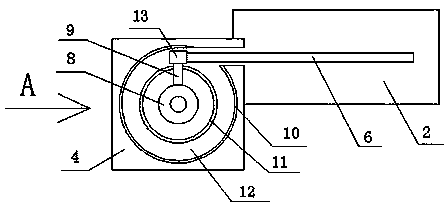

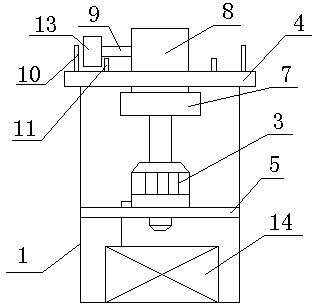

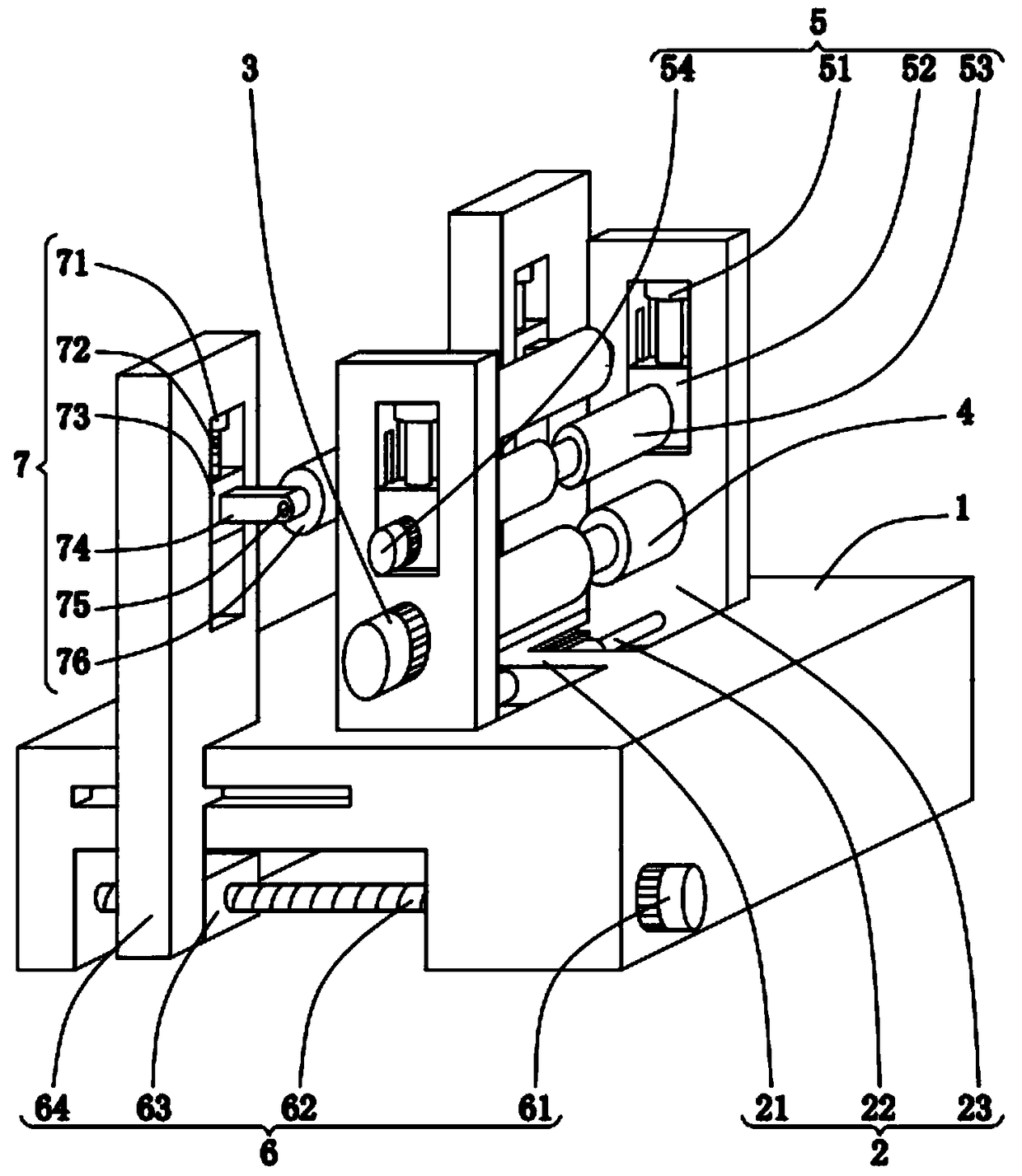

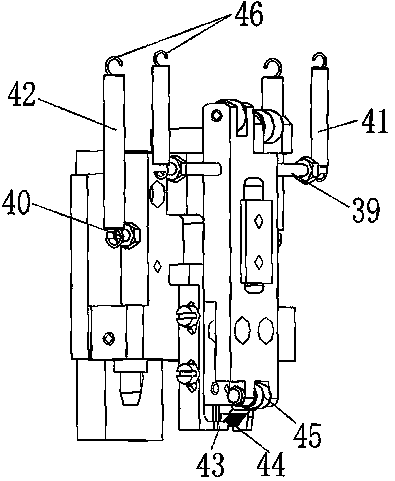

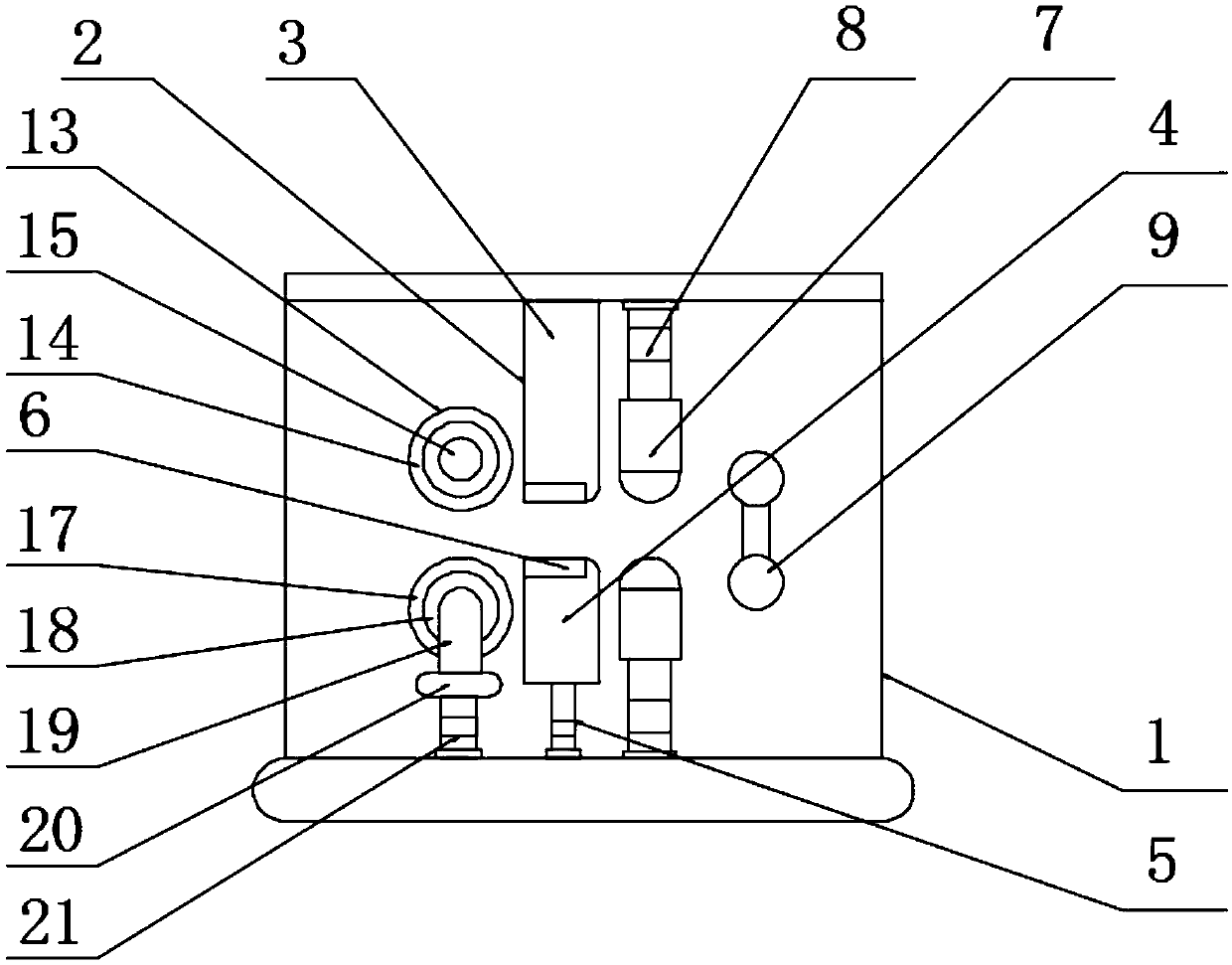

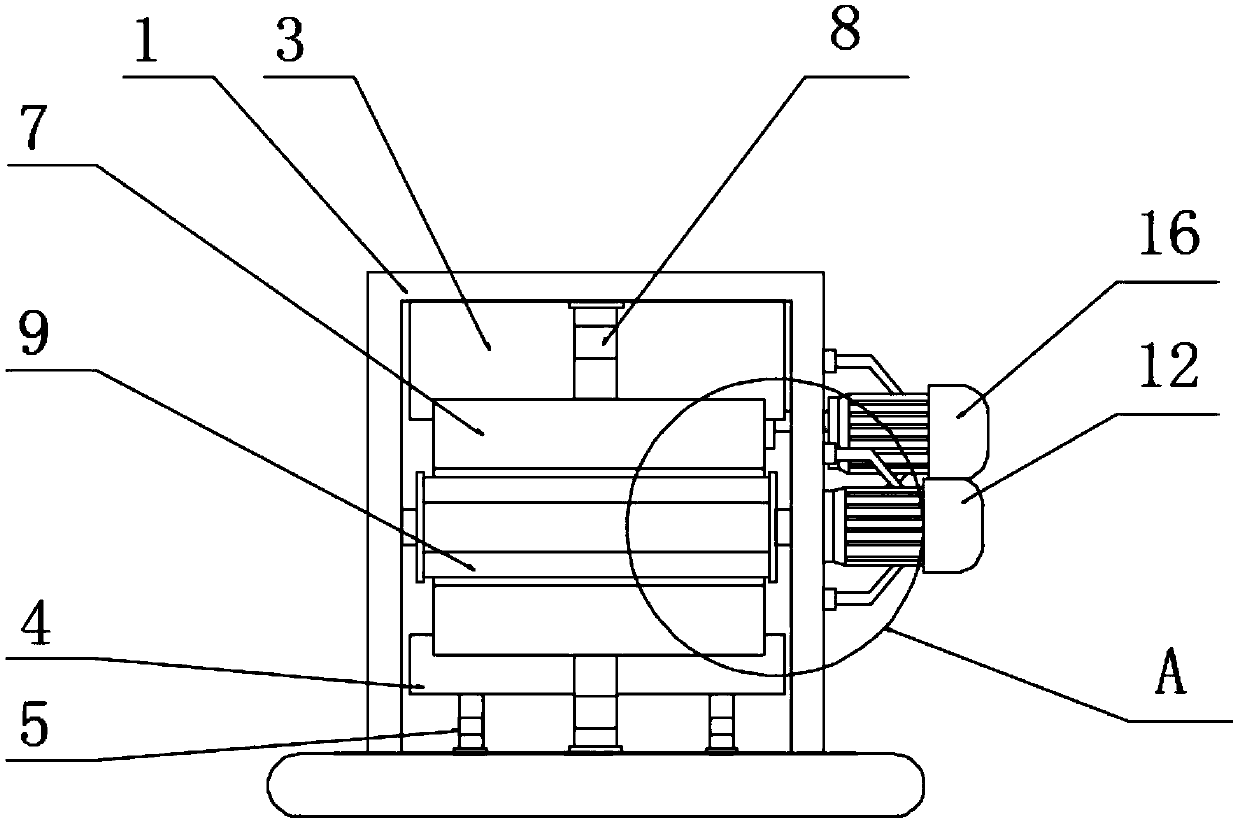

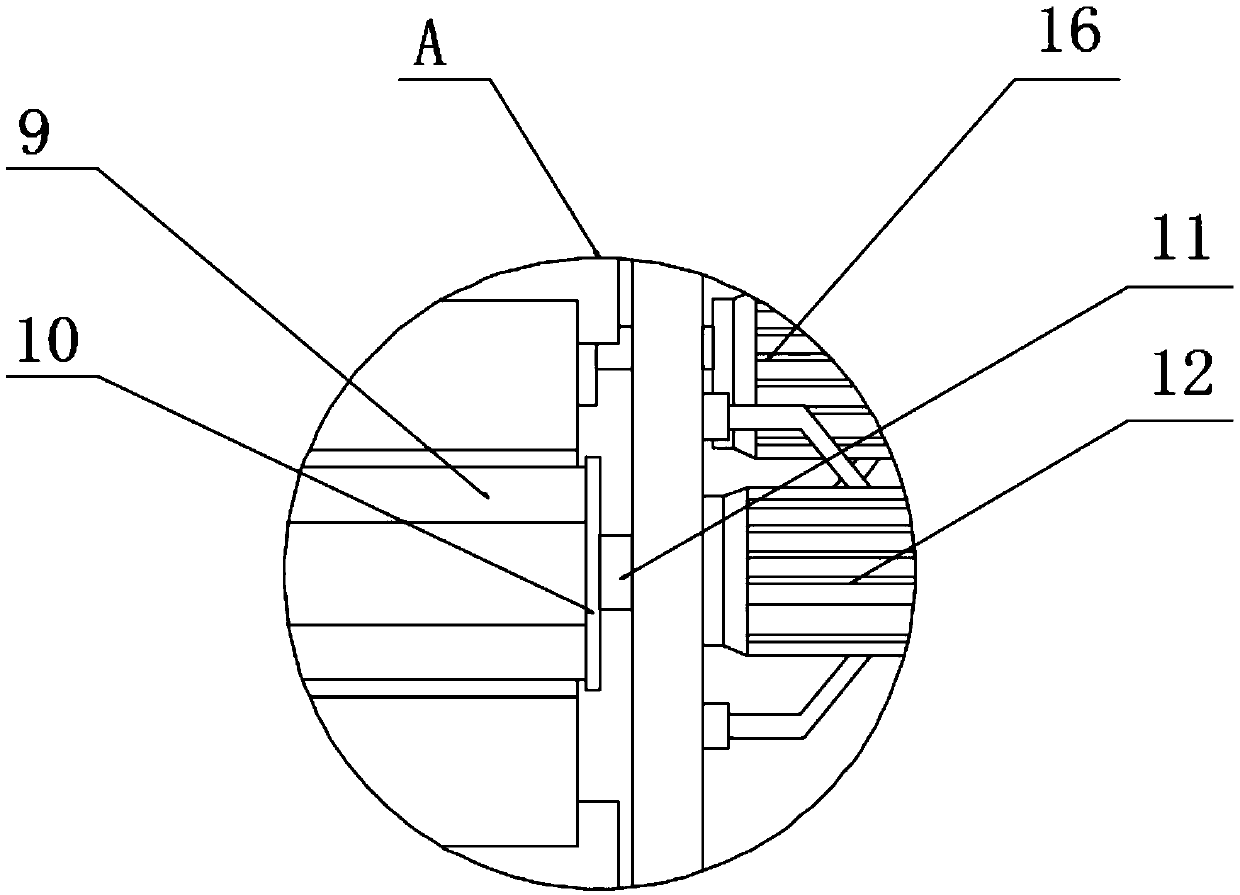

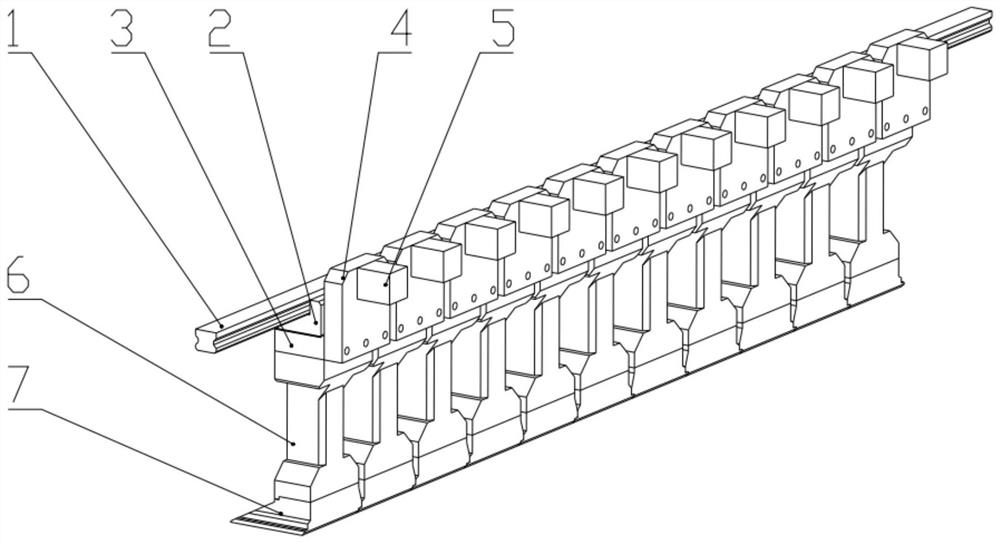

Inductance coil pin bending machine

The invention relates to an inductance coil pin bending machine. The inductance coil pin bending machine comprises a machine base (1), a machine base stand column (2), an inductance coil fixing block (4), an upper pressing module, a lower bending module, a side bending module and a control system. The inductance coil fixing block (4) is arranged on a support in the middle of the machine base support column (2); the middle of the inductance coil fixing block (4) is provided with a through hole (5); a central positioning mandril (7) driven by a first air cylinder (6) is arranged right under the through hole (5). The inductance coil pin bending machine can rapidly bend the pins of an inductance coil, reduces the labor intensity of workers, improves the bending precision, reduces damage of the inductance coil, improves the utilization rate of the inductance coil and further improves the productivity.

Owner:资兴市弘电电子科技有限公司

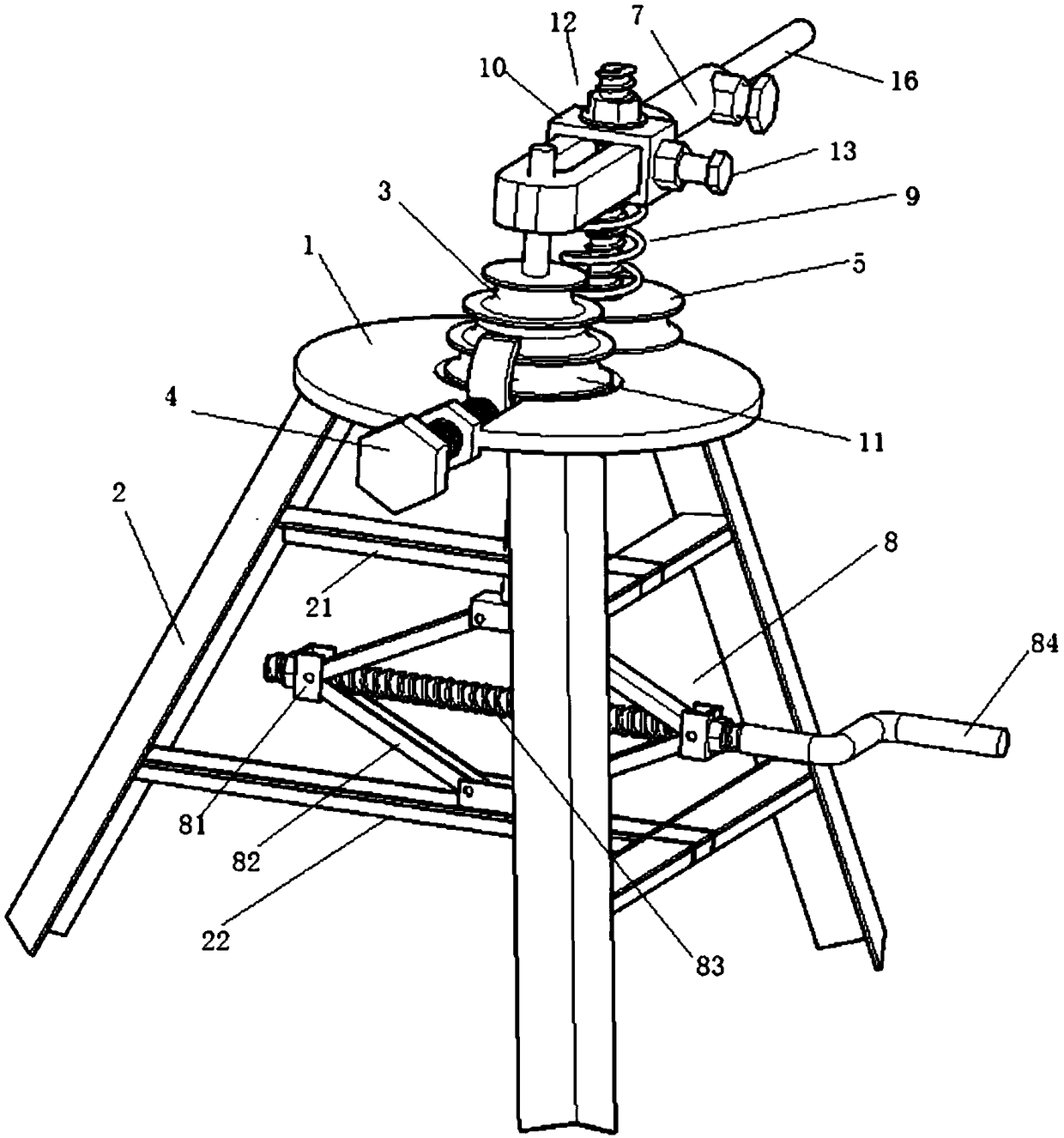

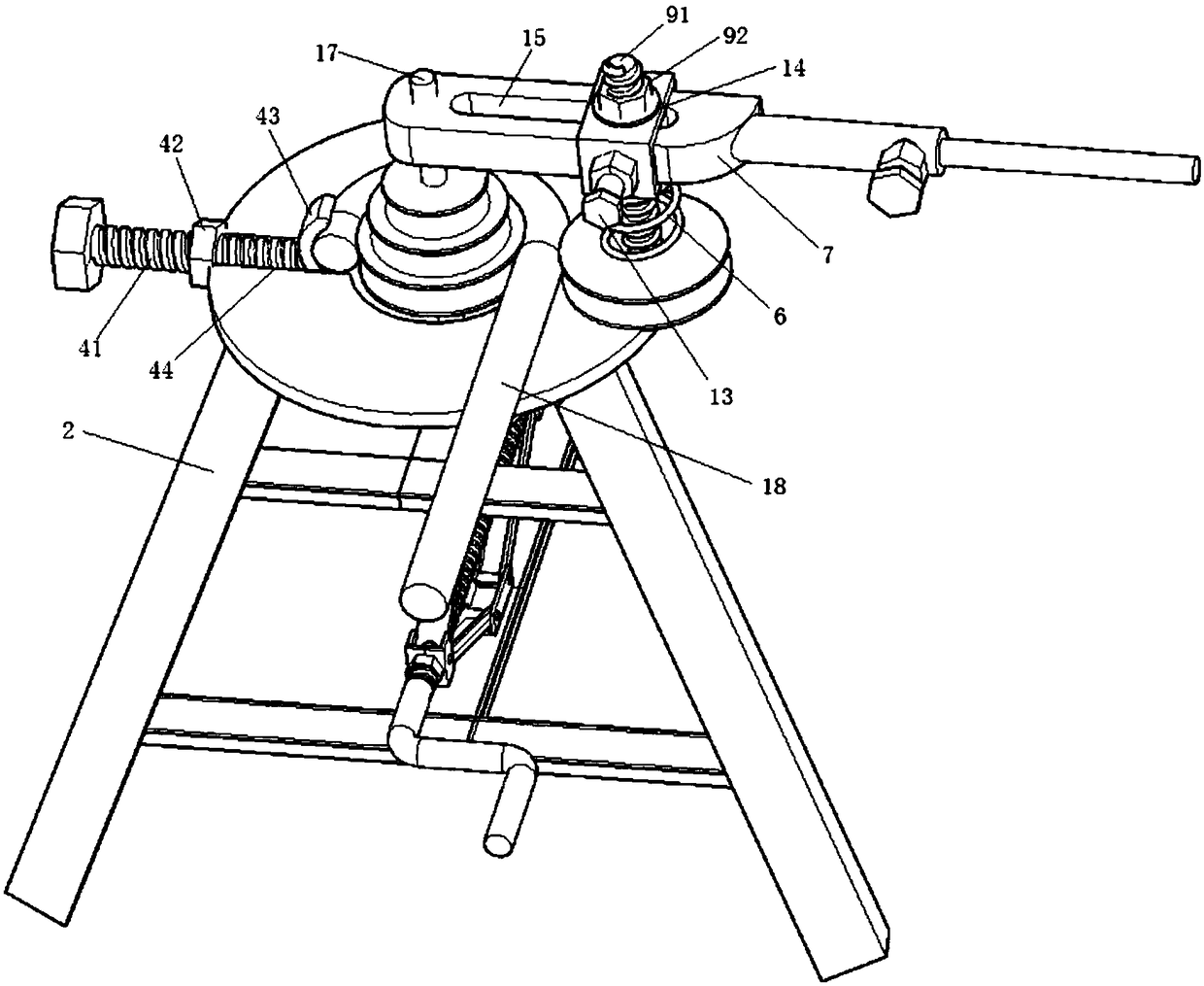

Pipe bending device with radius capable of being adjusted by 360 degrees

InactiveCN108746275APrecise control of bending angle and sizeGuaranteed metal propertiesEngineeringPressure pipe

The invention discloses a pipe bending device with a radius capable of being adjusted by 360 degrees. The pipe bending device comprises a supporting frame, a workbench, a multi-groove pipe bending plate, a torsional plate rod, a pressure pipe device, a pressure pipe adjusting block and a pipe bending locking device. A hole for mounting the multi-groove pipe bending plate is formed in the middle portion of the workbench, the multi-groove pipe bending plate is installed on the supporting frame through a first lifting device, and a plurality of pipe bending grooves with different elbow radii arearranged on the multi-groove pipe bending plate in the upper and lower directions. The pipe bending locking device is arranged on the workbench and is used for pressing and locking the end portion ofa pipe to be bent on the pipe bending grooves of the multi-groove pipe bending plate. The torsional plate rod is mounted on a central shaft of the multi-groove pipe bending plate by a rotating pair, the pressure pipe adjusting block is installed on the torsional plate rod by a transverse translation device, the pressure pipe device is installed at the bottom of the pressure pipe adjusting block through a second lifting device, and the relative position between the pressure pipe device and the multi-groove pipe bending plate is adjusted through the transverse translation device to match the bend radii of the bend grooves. The pipe bending device with the radius capable of being adjusted by 360 degrees is stable in structure, simple in operation and adjustable in pipe bending radius, and usecost is greatly reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

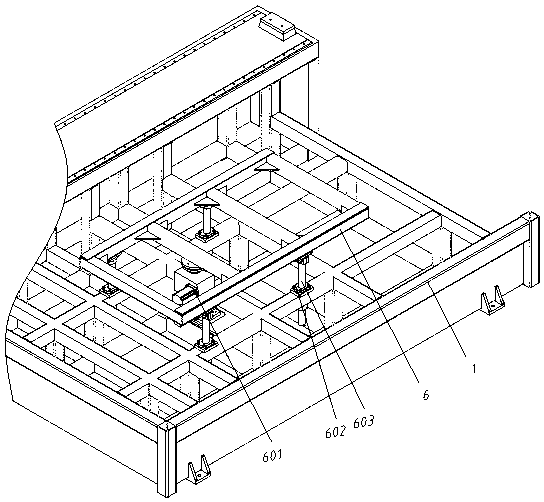

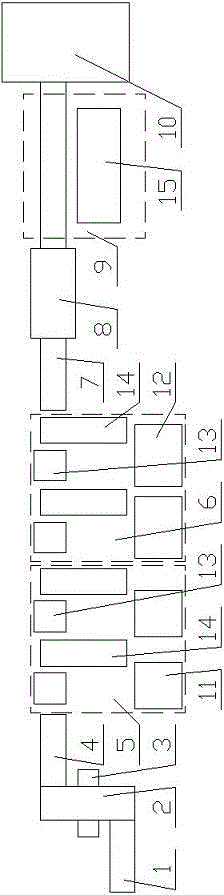

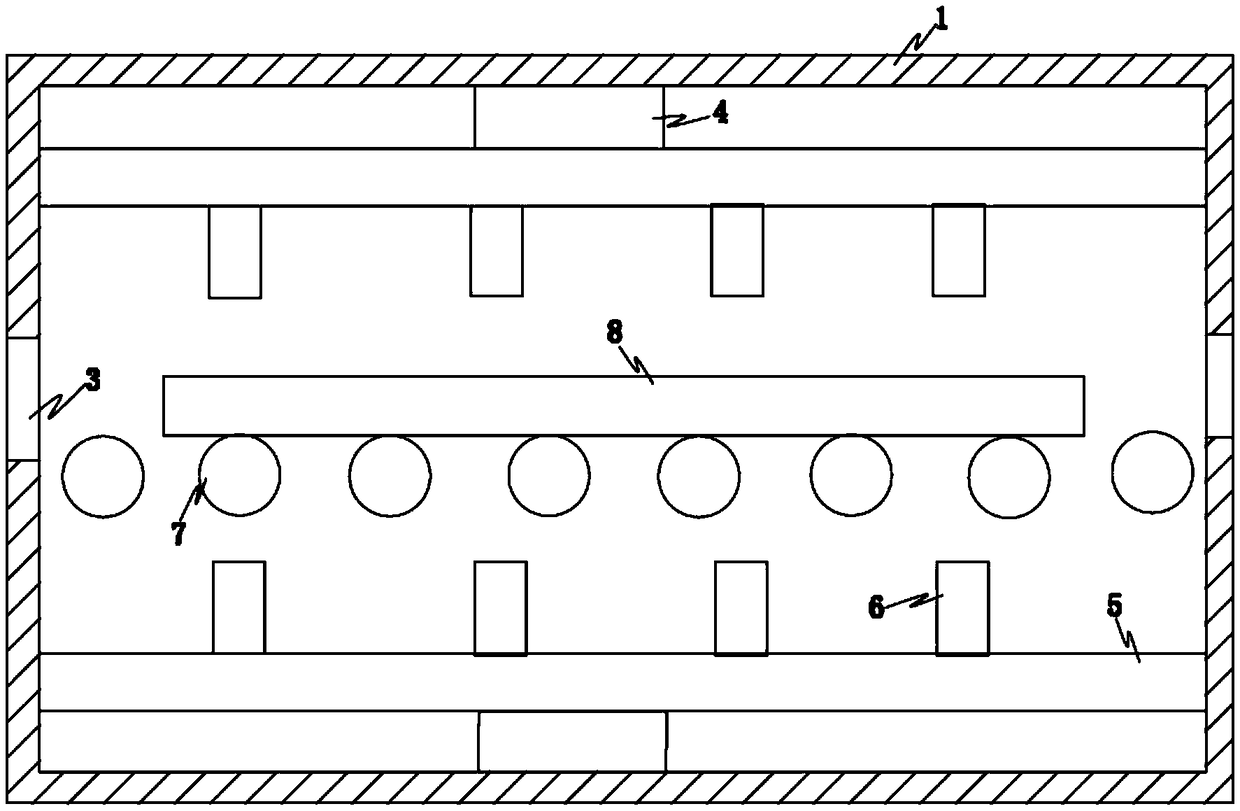

Elevator door plate production line

ActiveCN105728583AFully automatedIncrease productivityMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an elevator door plate production line. The elevator door plate production line sequentially comprises a blank feeding device, a feeding transfer rack, a punching device, a bending device, a riveting device, a rib applying area and a blanking transfer rack. A conveying rack A is disposed between the punching device and the bending device. A conveying rack B is mounted between the bending device and the riveting device. The feeding transfer rack is disposed above the feeding device, the punching device and the conveying rack A. The conveying rack B is connected with the blanking transfer rack through the riveting device and the rib applying area. According to the structure of the elevator door plate production line, automatic production of elevator door plates is achieved, the production efficiency of the elevator door plates is improved, and the labor cost is effectively reduced.

Owner:JIANGYIN FIVE STAR WELDING COPPER

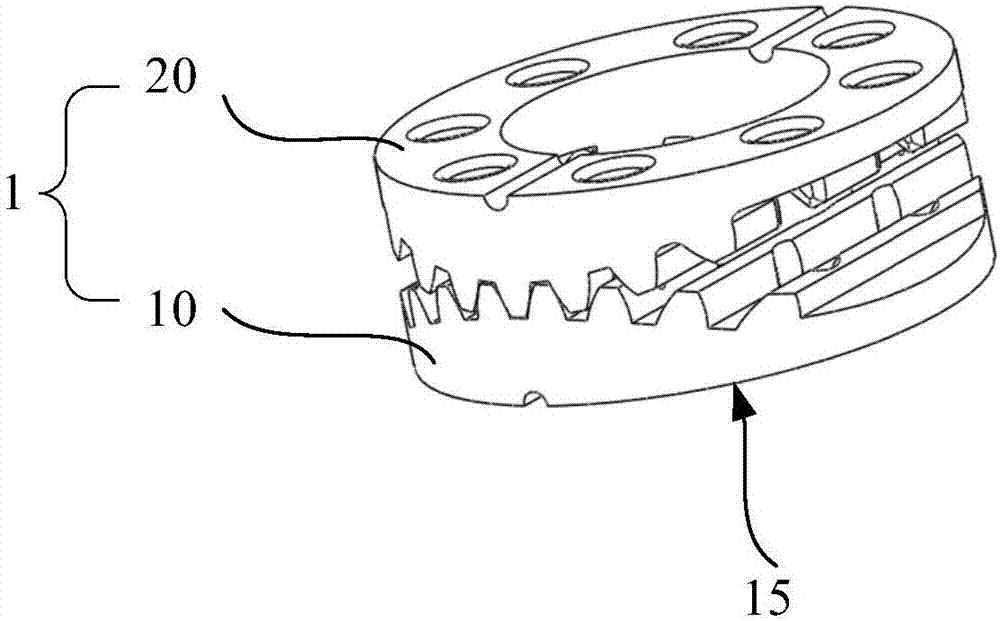

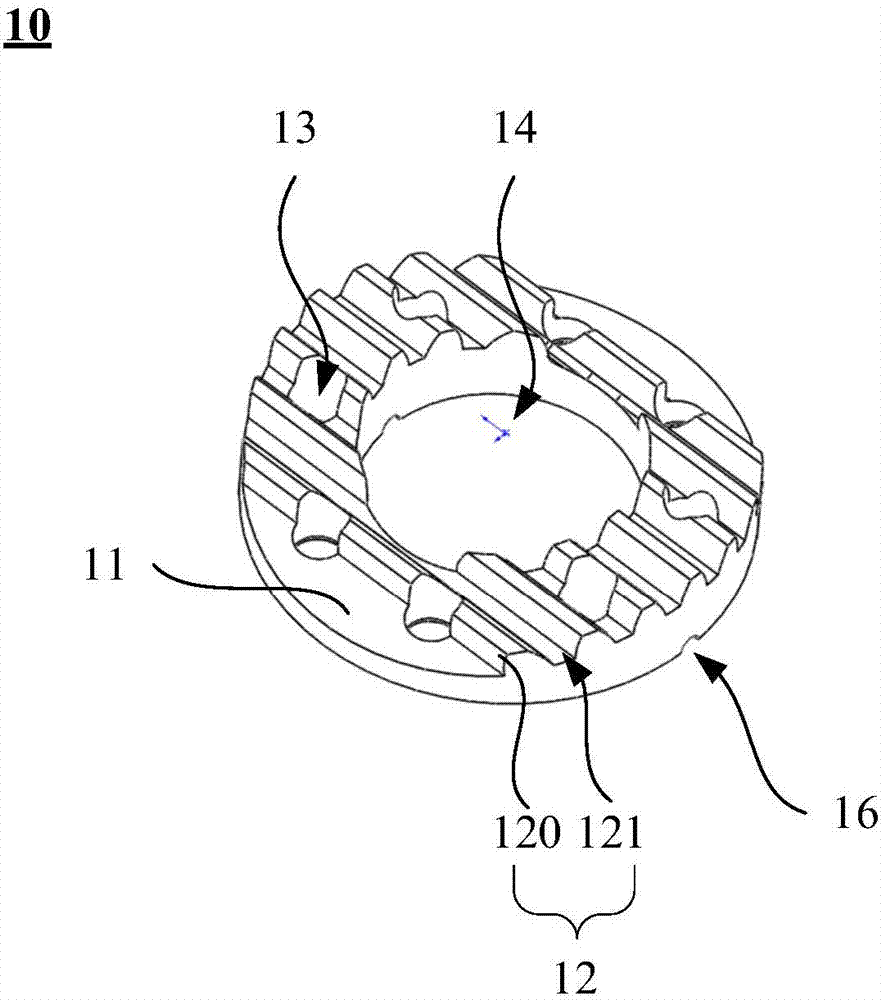

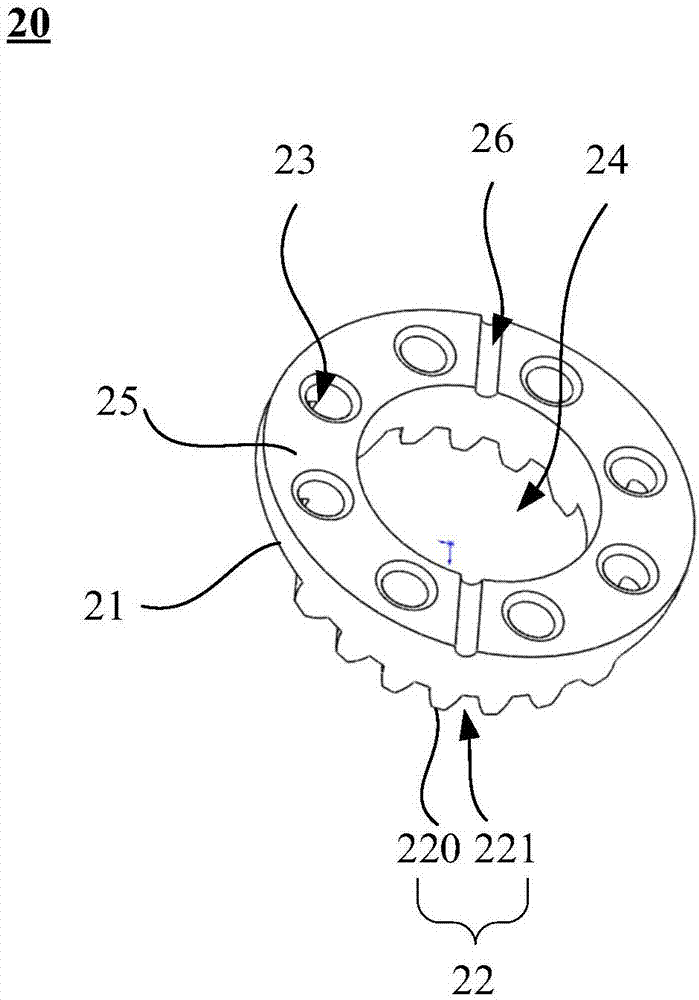

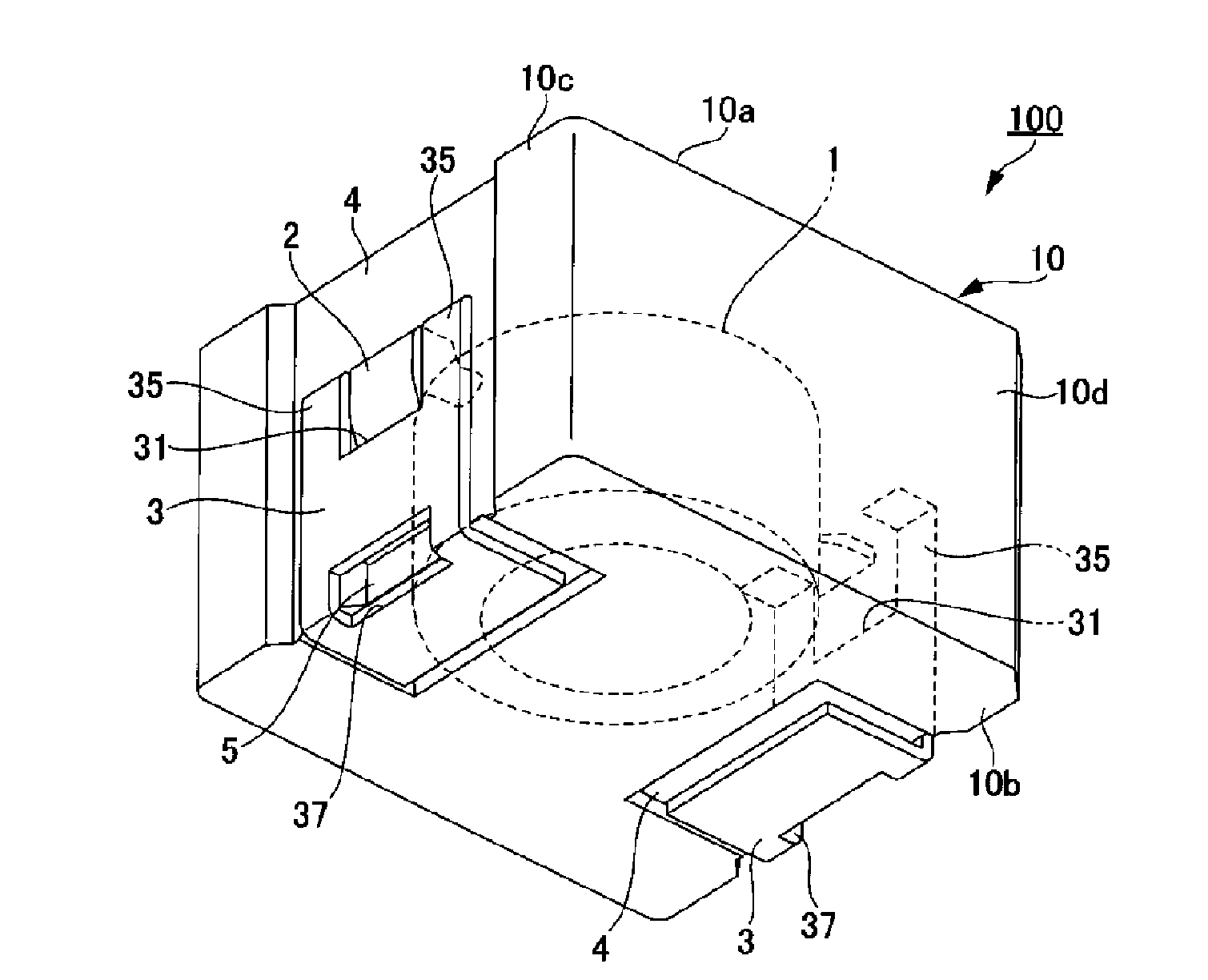

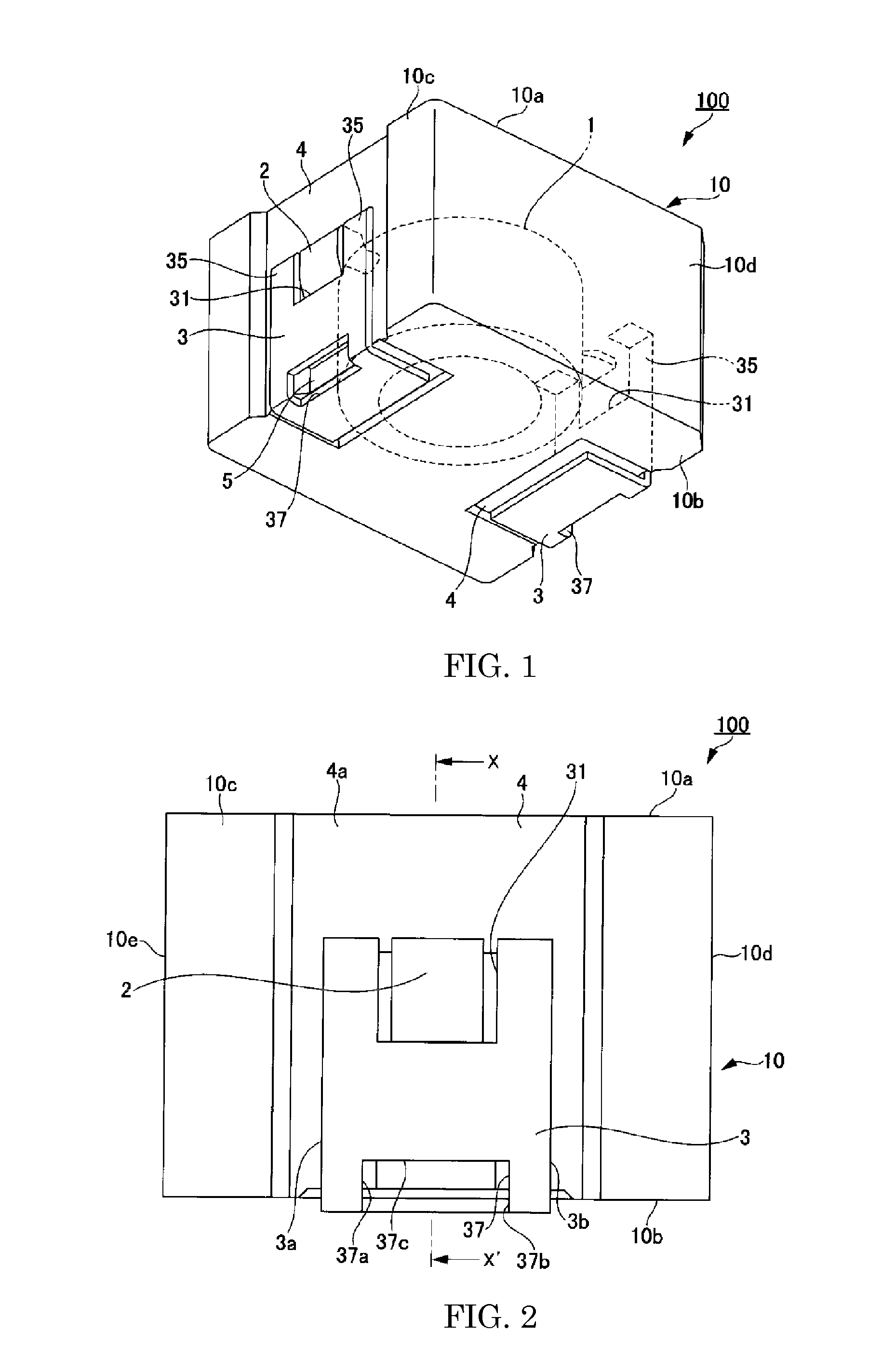

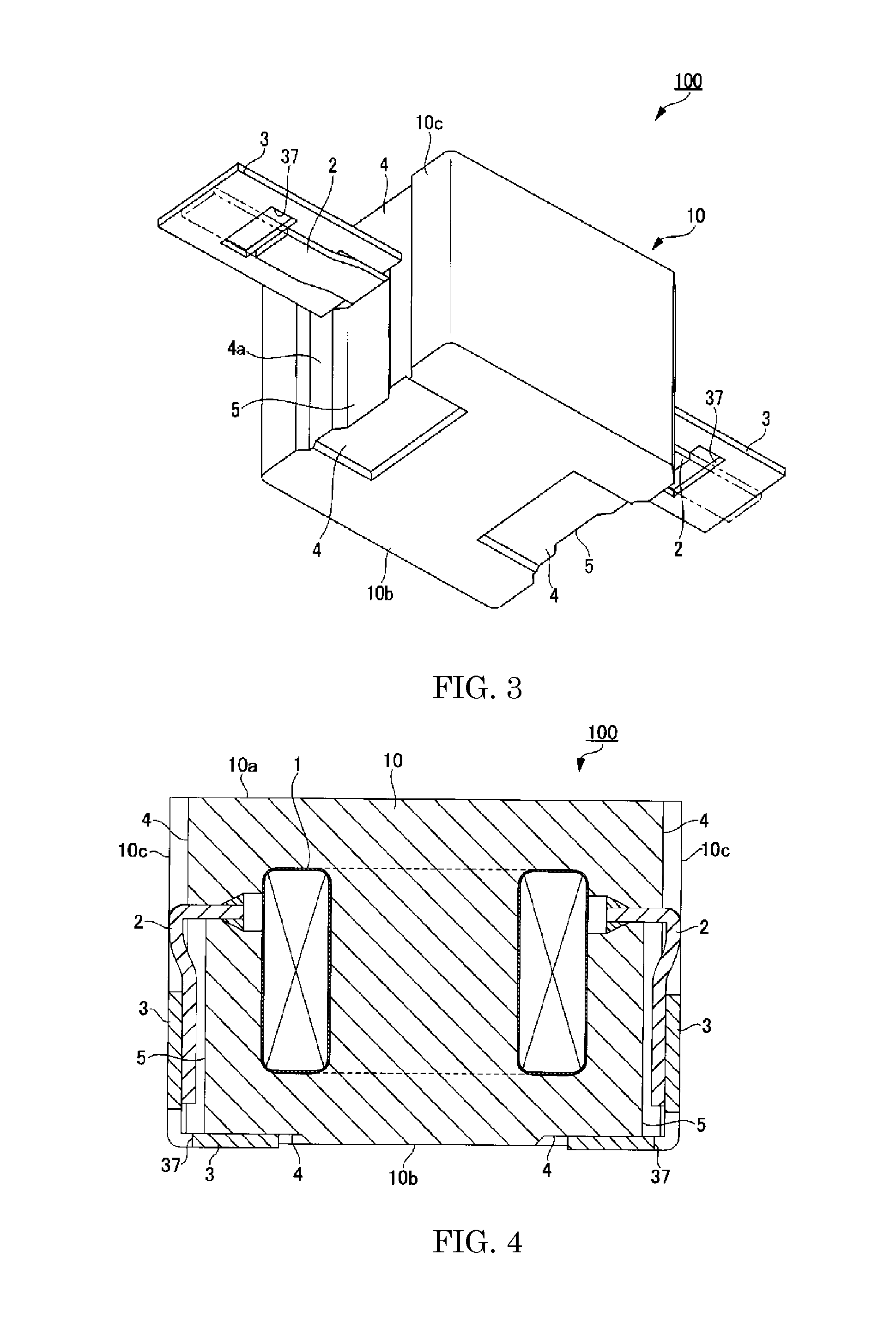

Coil component

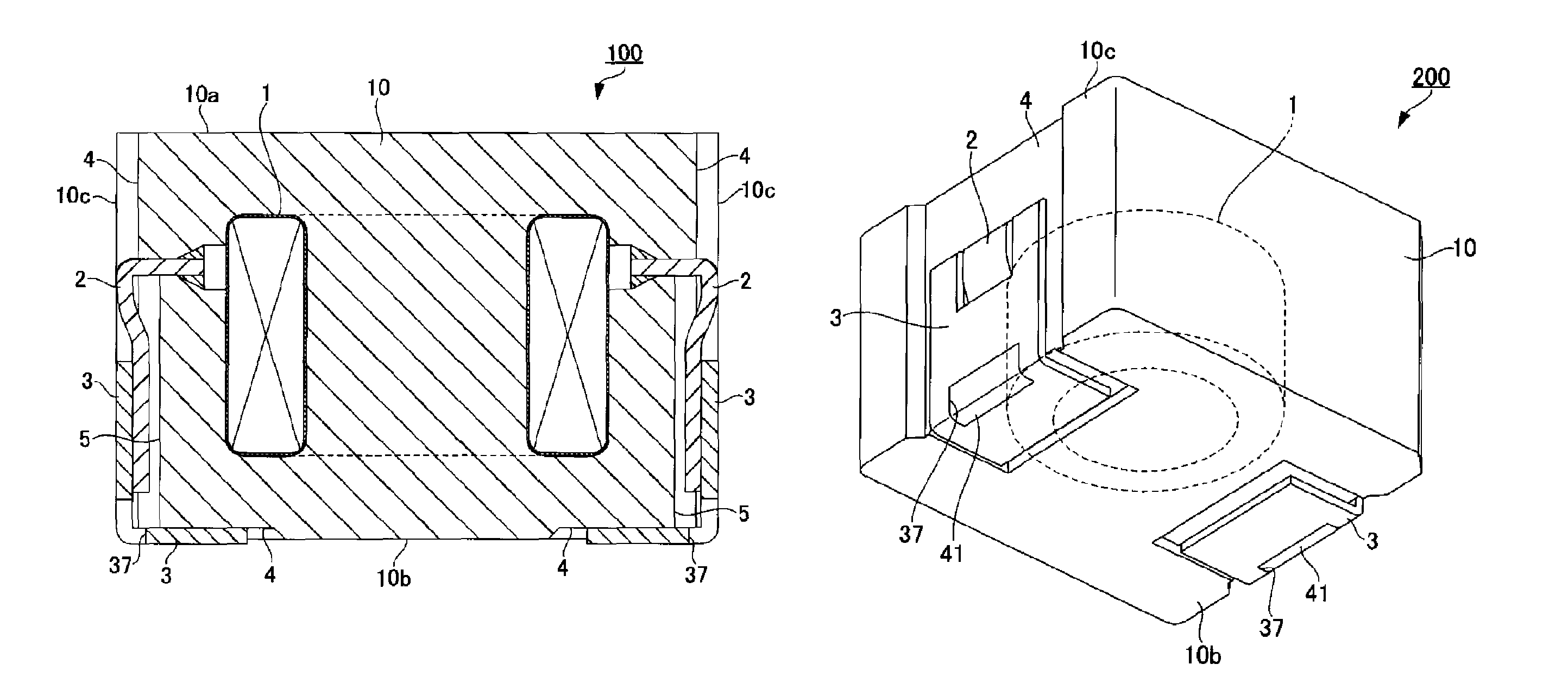

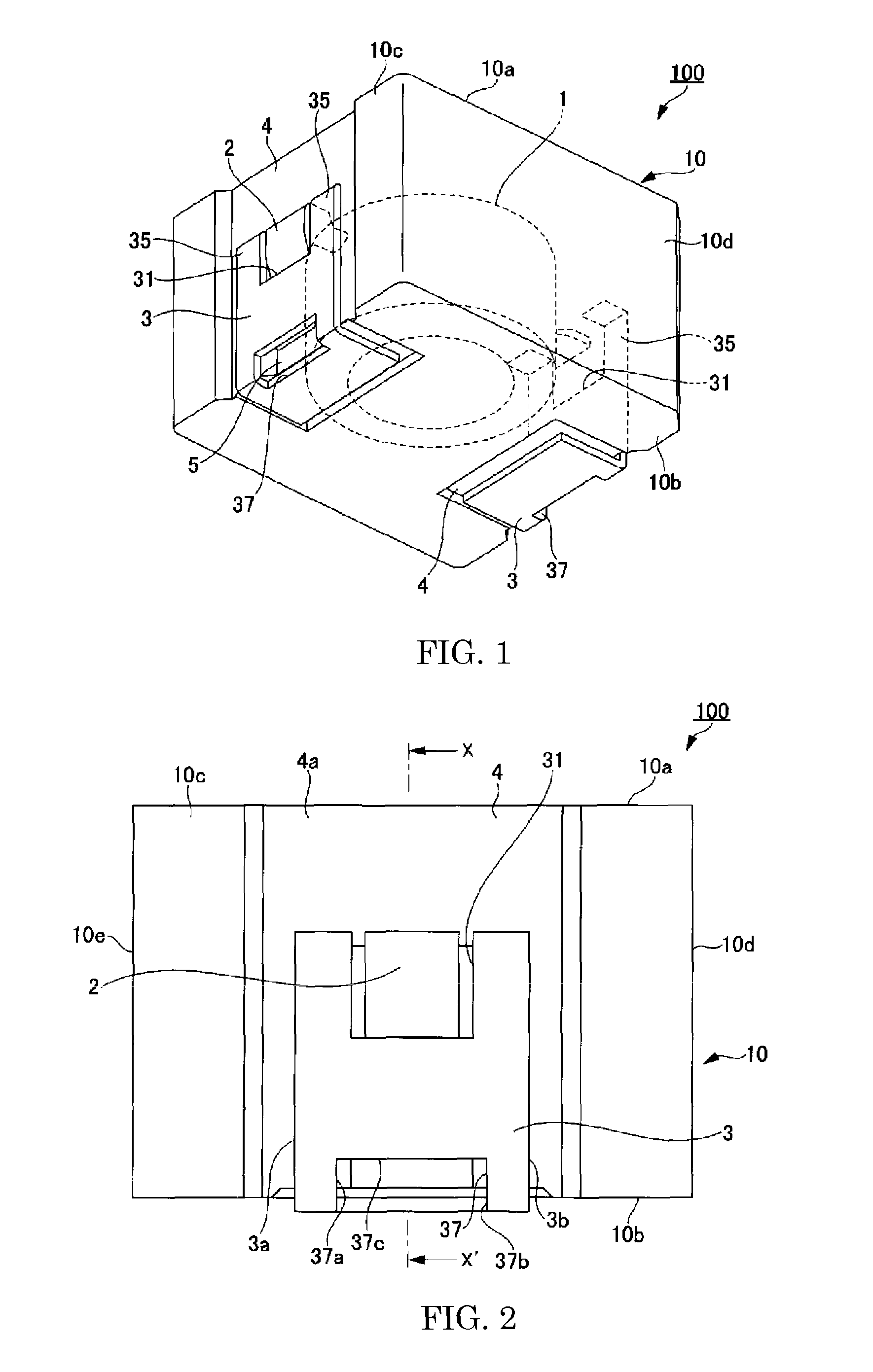

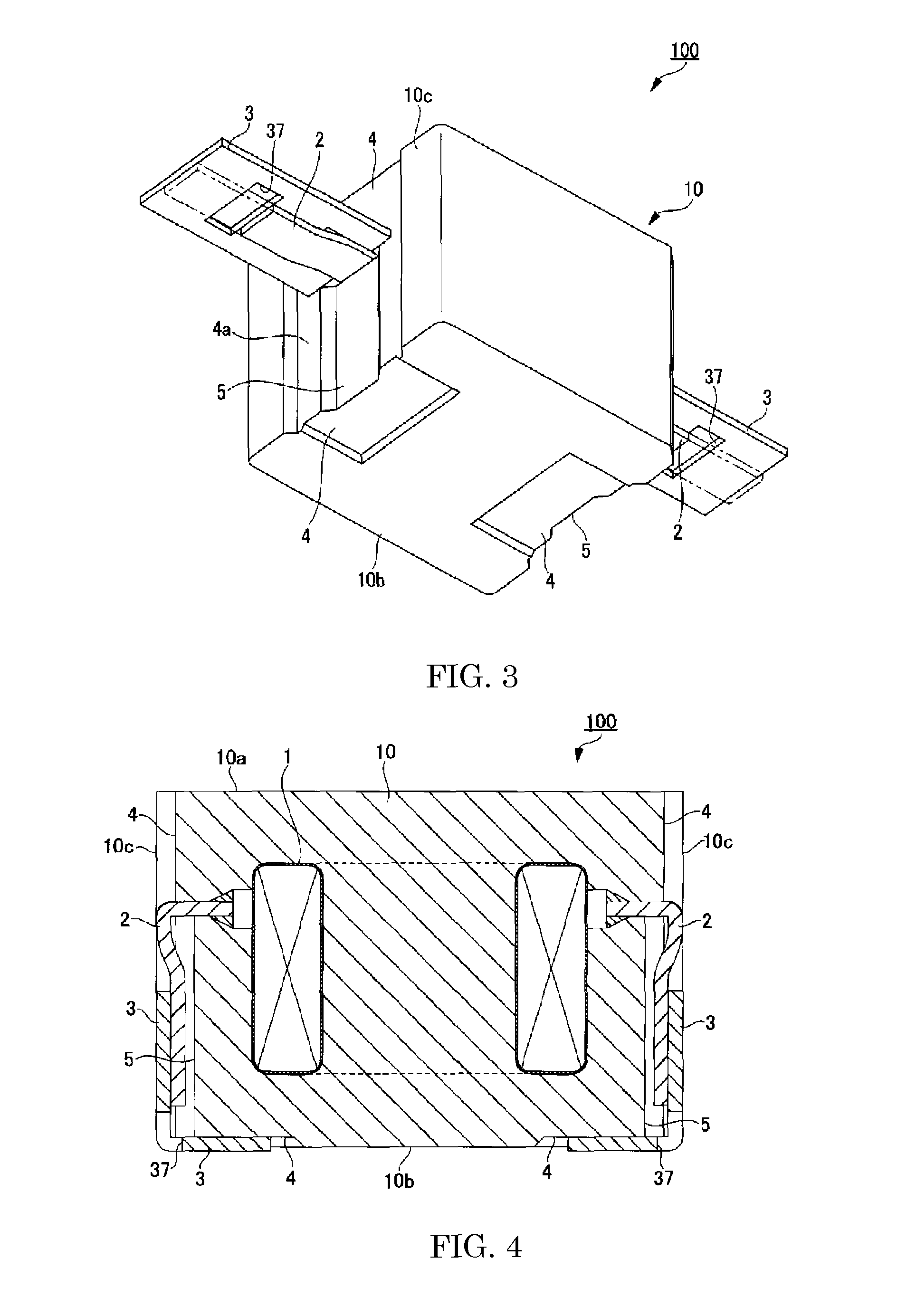

ActiveUS20130154780A1Improve bending accuracyPrecise bendingTransformers/inductances coils/windings/connectionsInductance with magnetic coreCondensed matter physicsMaterials science

A coil component including: a magnetic core which is formed by a magnetic material and which has a top surface, a bottom surface facing the top surface and a side surface continuous approximately perpendicularly to the top surface and the bottom surface; a coil which is buried inside the magnetic core and whose end portion protrudes from the side surface of the magnetic core; a flat-shaped terminal which protrudes from the side surface of the magnetic core, is bent toward the bottom surface of the magnetic core and is connected with the end portion of the coil, wherein there is formed an opening portion at a position corresponding to the place which is bent for the flat-shaped terminal from the side surface to the bottom surface of the magnetic core.

Owner:SUMIDA CORP

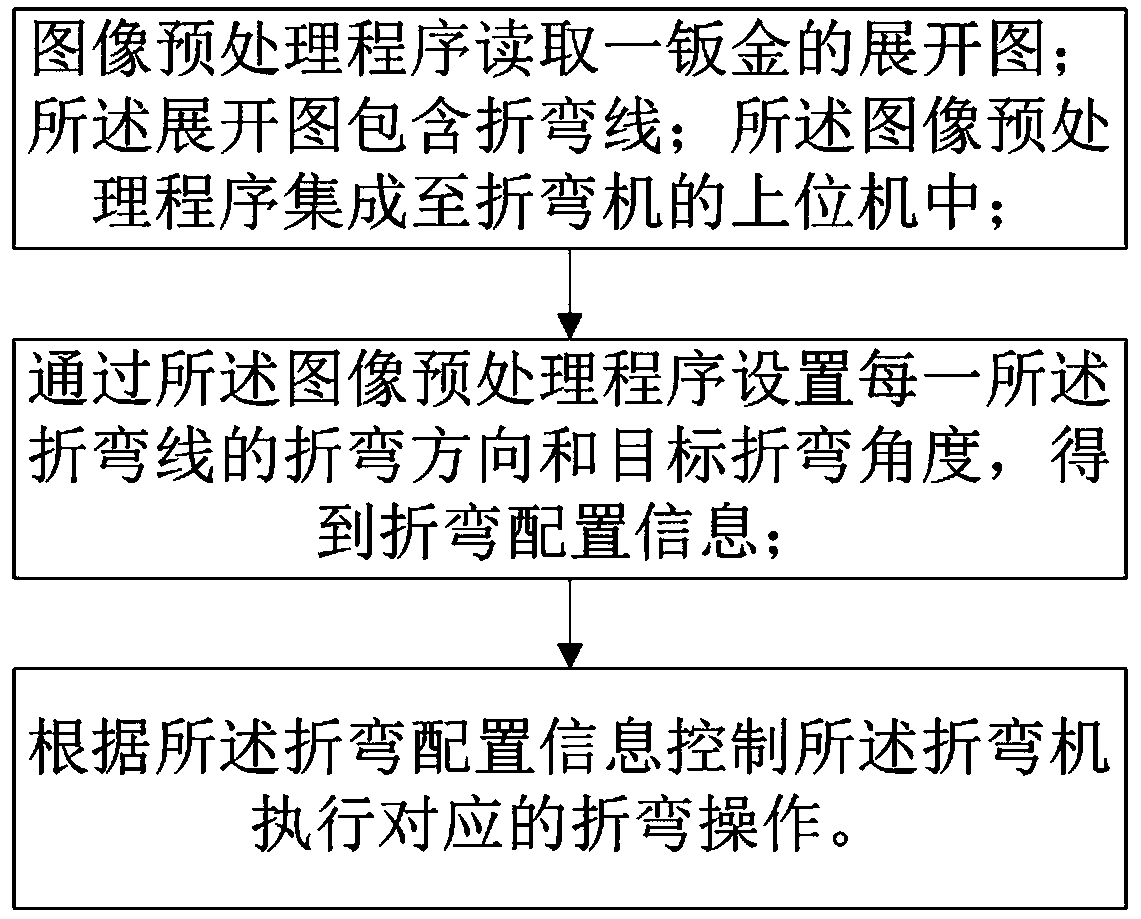

Metal plate bending method and terminal

ActiveCN109590357ALow costImprove efficiencyMetal-working feeding devicesMetal working apparatusEngineeringRead through

The invention relates to a metal plate bending method and terminal and belongs to the field of industrial automation. The metal plate bending method comprises the steps that an expanded view of a metal plate is read through an image preprocessing program, wherein the expanded view comprises bending lines, and the image preprocessing program is integrated into an upper computer of a bending machine; the bending direction and the target bending angle of each bending line are set through the image preprocessing program, so that bending configuration information is obtained; and the bending machine is controlled to implement corresponding bending operation through the bending configuration information. By means of the metal plate bending method, the bending production efficiency of the metal plate is improved, and the production cost is lowered.

Owner:福建渃博特自动化设备有限公司

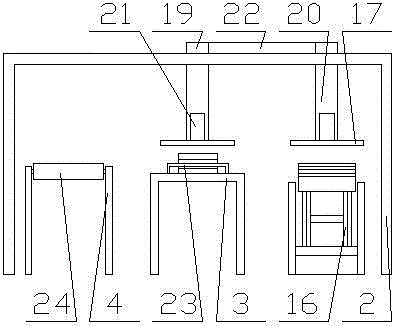

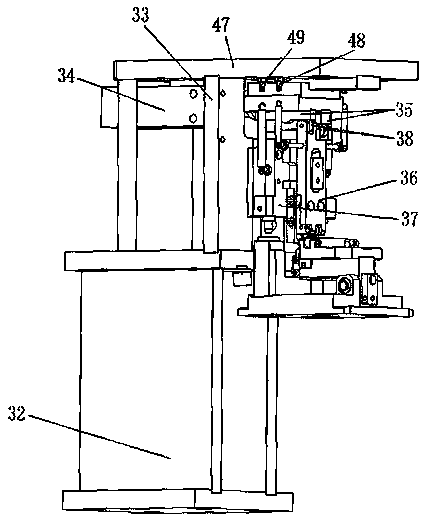

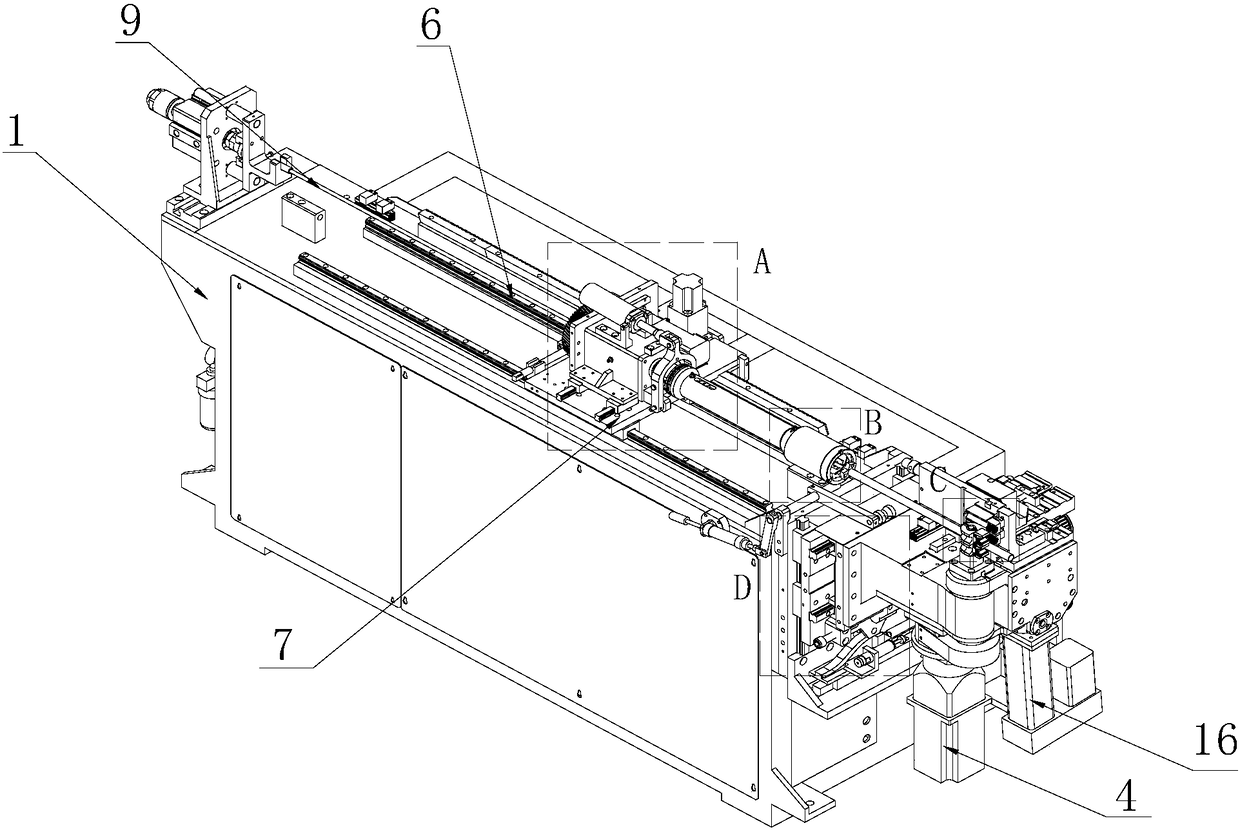

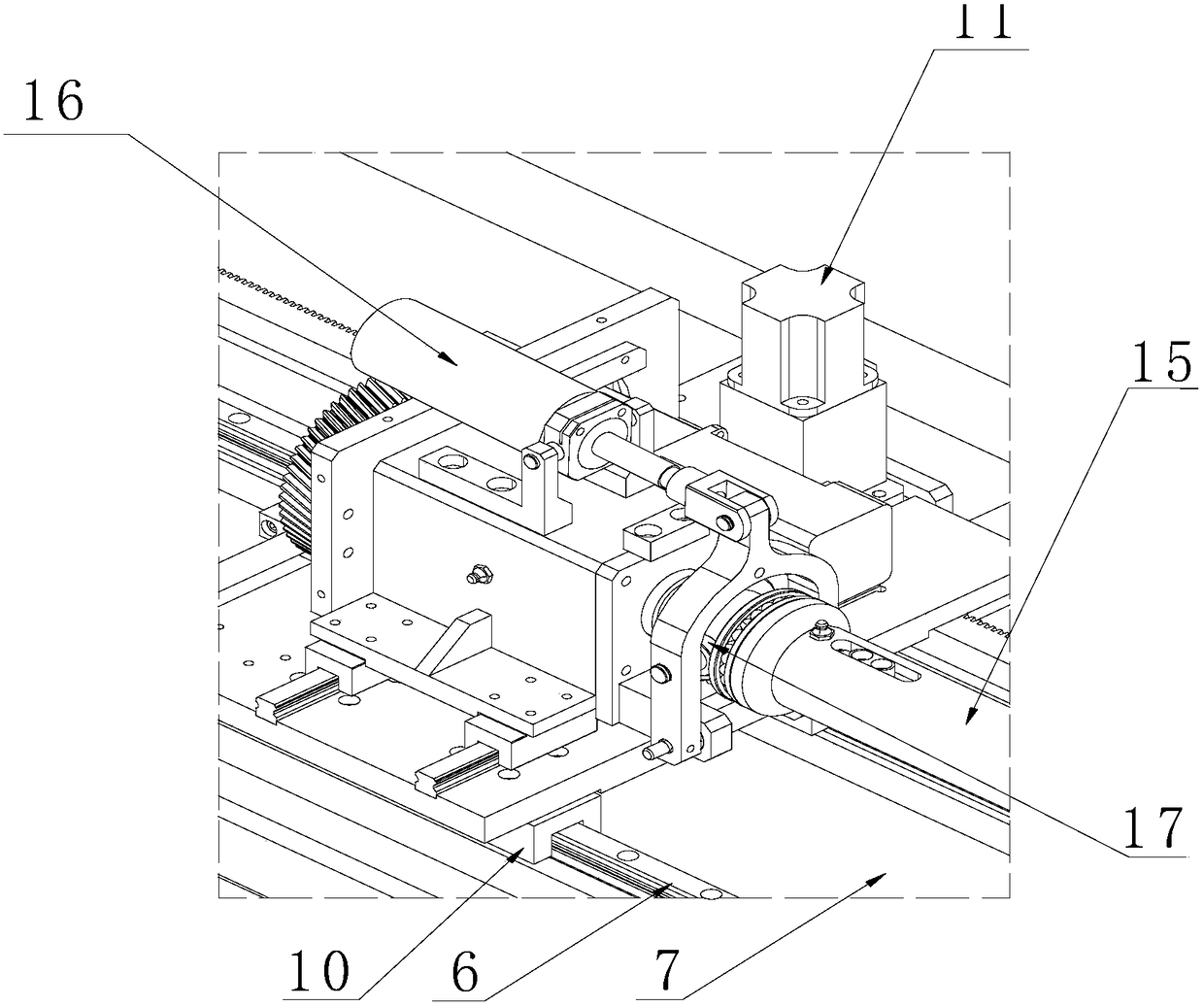

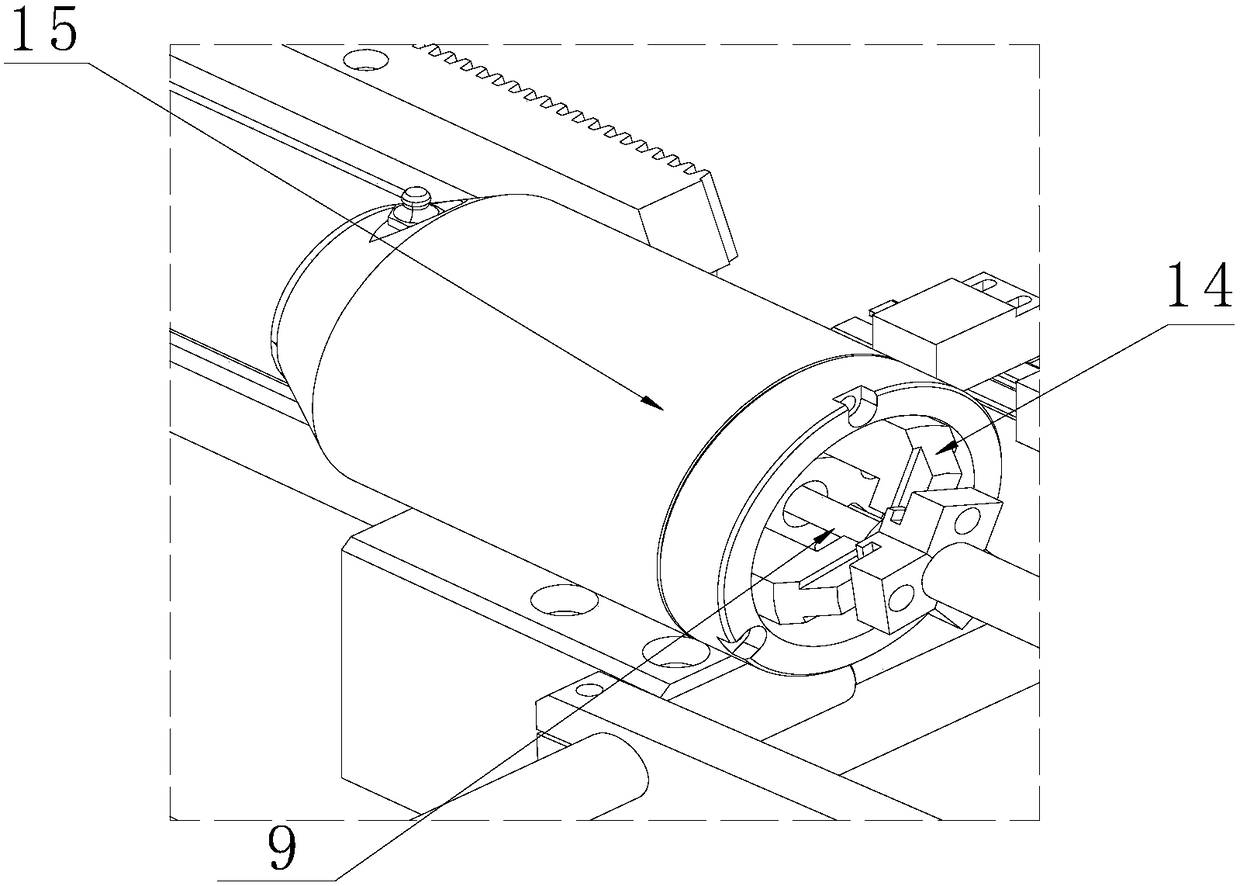

Automatic pipe bender for stainless steel pipes and bending method thereof

InactiveCN107199262AStable and reliable outputIngenious realization of automatic conveyingMetal-working feeding devicesPositioning devicesOutput deviceEngineering

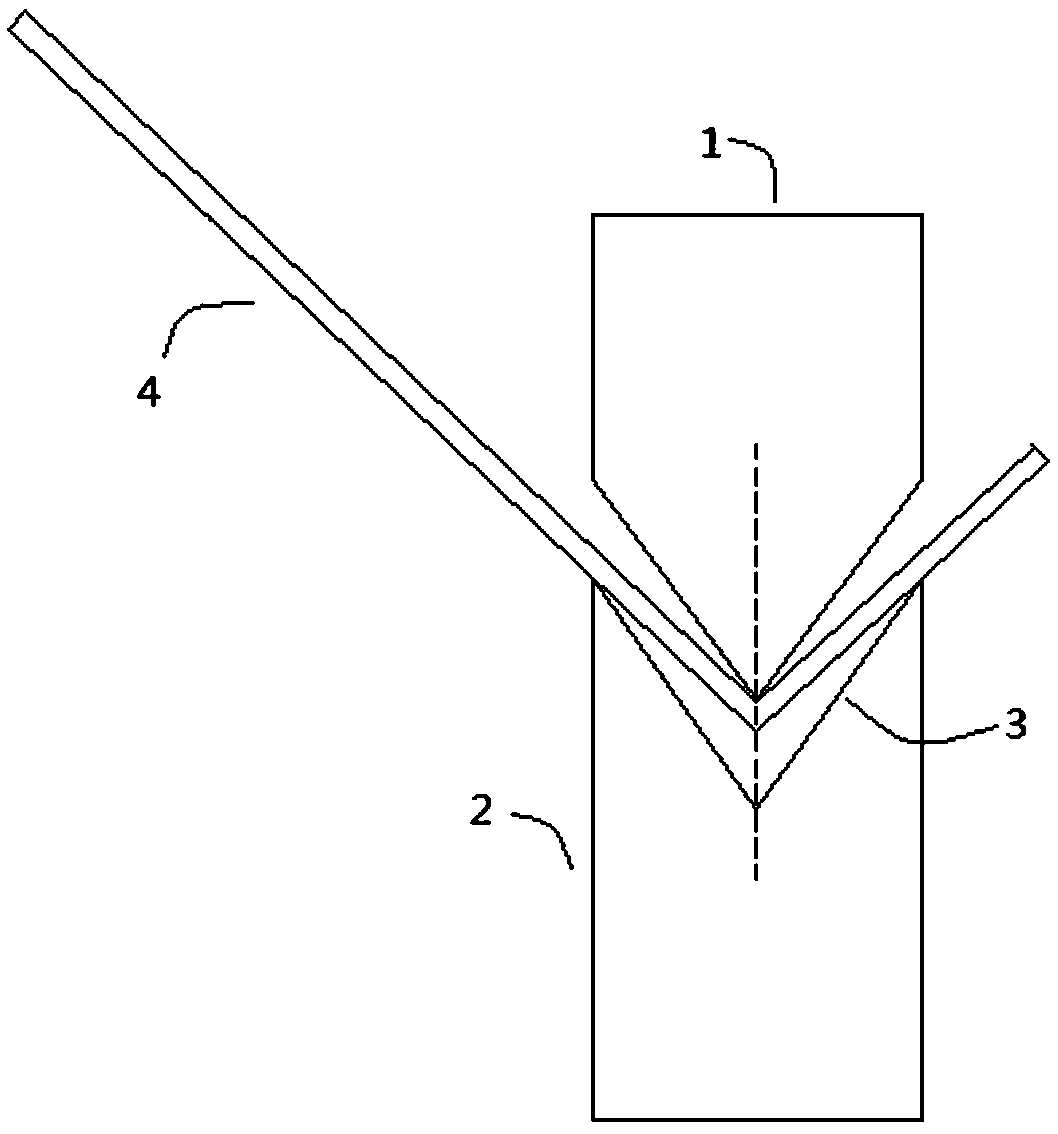

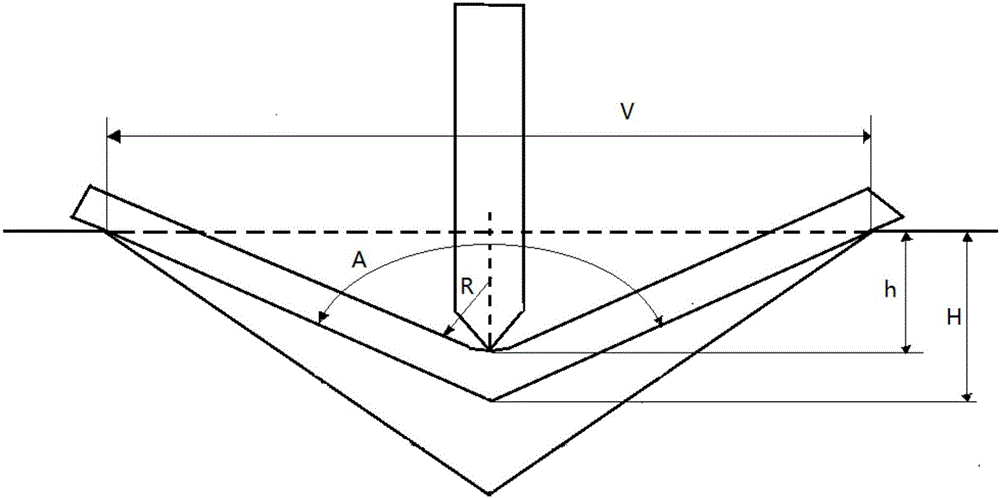

The invention relates to an automatic pipe bender for stainless steel pipes and a bending method thereof. The automatic pipe bender comprises a base, a bending frame, a bending head assembly, a bending seat and a bending driving device, wherein the bending frame is installed on the base, the bending head assembly is fixed to the upper end of the bending frame, the bending seat can vertically slide on the bending frame, the bending driving device is used for driving the bending seat, the bending head assembly comprises a bending head fixed seat which is fixed to the upper end of the bending frame and a bending head which is fixed to the lower part of the bending head fixed seat, and a steel pipe bending groove is formed in the lower end of the bending head; the bending seat comprises a V-shaped bending fixed seat which is installed on the bending frame in a sliding mode through vertical guide wheels on both sides, and a plurality of bending abutting rods are arranged on the V-shaped bending fixed seat; and a steel pipe feeding device, an elbow taking device and an elbow output device are further installed on the base. The automatic pipe bender has the advantages of high bending accuracy, high bending stability, high bending efficiency and low labor intensity.

Owner:HUNAN KUANGCHU TECH CO LTD

Steel bar bender for building

The invention discloses a steel bar bender for building. The steel bar bender comprises a machine frame, a conveying mechanism, a drive device, a workbench board and a supporting board, wherein the workbench board is arranged on the machine frame and the supporting board is arranged on the machine frame. A steel bar is arranged on the conveying mechanism. The drive device is installed on the supporting board. An output shaft of the drive device is provided with a shaft sleeve. A rotary shaft is connected to the upper portion of the shaft sleeve. An operation transverse beam is arranged on the rotary shaft. A first bending operation board and a second bending operation board are arranged on the workbench board. A circular space is formed between the first bending operation board and the second bending operation board. One end of the operation transverse beam stretches into the circular space and the portion, stretching into the circular space, of the operation transverse beam is provided with a fixing device for fixing the steel bar. The steel bar bender for building is simple in structure, convenient to use and install, easy to operate, capable of saving labor, low in cost, capable of conveniently conducting bending, high in bending accuracy and bending quality, capable of being conveniently maintained in the later period, large in application range, long in service life, safe and reliable.

Owner:CHENGDU LYUDI TECH

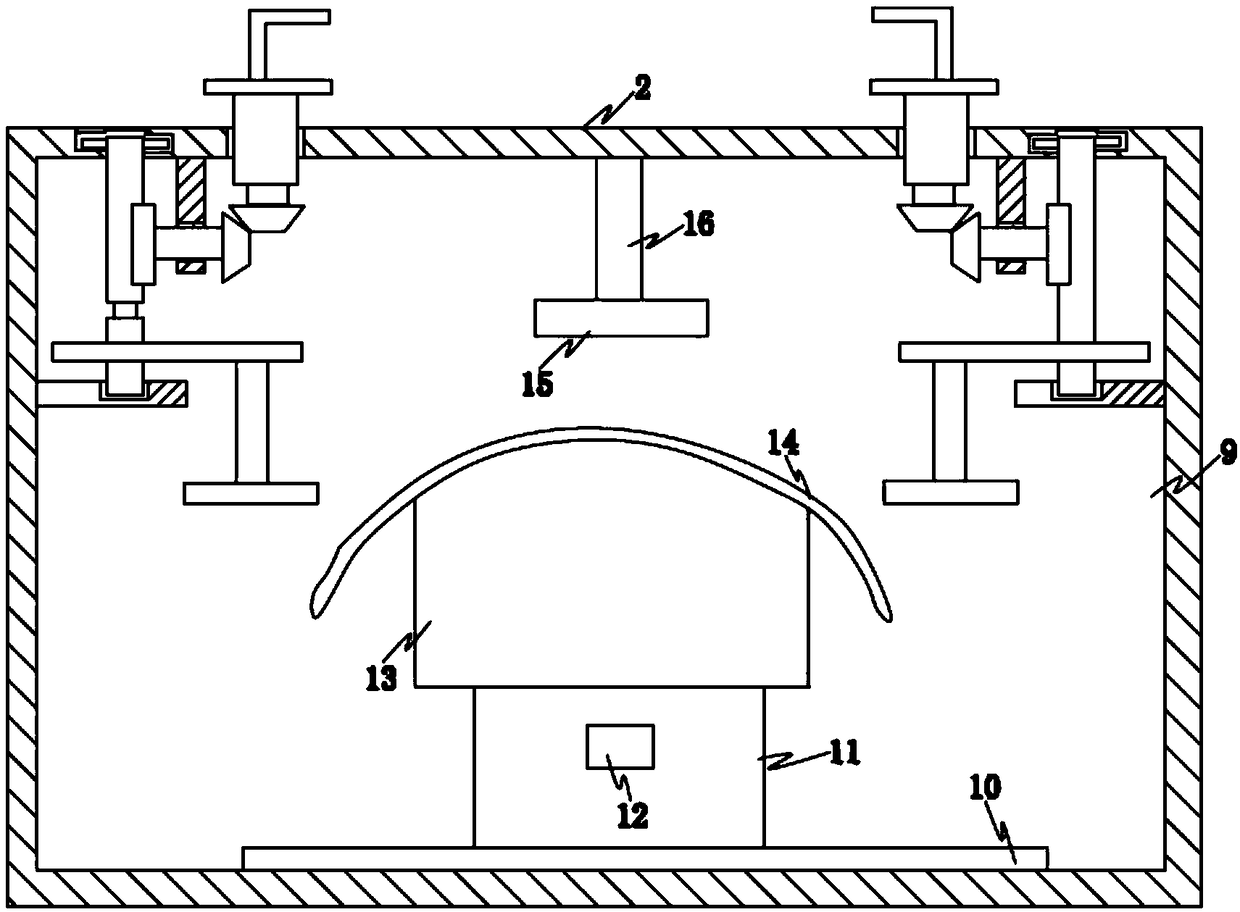

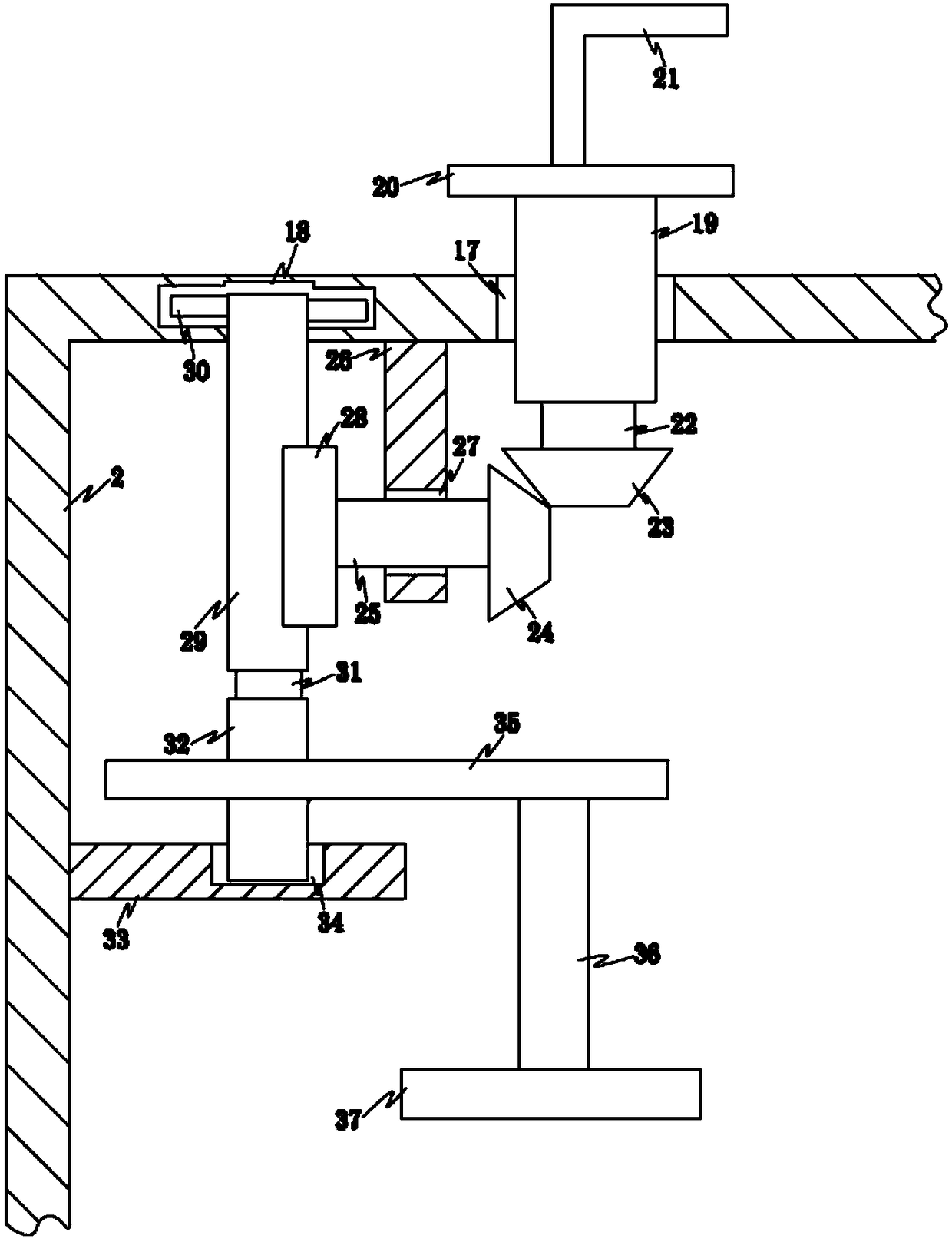

Reverse bending type glass hot-bending furnace

ActiveCN108640488APrevent burstReduce scrap rateGlass reforming apparatusEngineeringElectrical and Electronics engineering

The invention discloses a reverse bending type glass hot-bending furnace which comprises a preheating box and a hot-bending furnace. A hot-bending mold is arranged on a support block; a fixed heatingwire plate is arranged above the hot-bending mold; local telescopic heating devices are symmetrically arranged on inner side walls, close to the fixed heating wire plate, of a hearth; each local telescopic heating device comprises a screw rod; a driven bevel gear is connected with a worm wheel through a connecting rod; the worm wheel is movably arranged on a worm; one side, far away from a rotaryrod, of the worm is connected with the screw rods through connecting blocks; the screw rods penetrate through an operation plate; and a movable heating wire plate is arranged on an extending rod. According to the reverse bending type glass hot-bending furnace provided by the invention, through the built-in preheating box, glass can be fully preheated before hot-bending, so that the hidden danger that the glass is ruptured due to shock heating in the hot-bending chamber is eliminated; and multiple local telescopic heating devices are arranged in the hot-bending furnace, so that the deep-bendinghot-bending glass is promoted to be fit to the mold under the traceless state, and the hot-bending accuracy is improved.

Owner:东莞市宏波光电科技有限公司

Aluminum alloy panel rolling process

The invention relates to the technical field of aluminum alloy processing, in particular to an aluminum alloy panel rolling process. The aluminum alloy panel rolling process comprises a fixed base, astretching mechanism, a rotating mechanism, a panel rolling mechanism, a pushing mechanism, a transmission mechanism, an auxiliary mechanism and a connecting mechanism. The rotating mechanism can drive a first roller in the panel rolling mechanism to rotate to roll the panel. Meanwhile, the panel is rolled in an assisted manner by means of the pushing mechanism, and the thickness of the rolled panel can be adjusted according to the descending distance of a second roller in the pushing mechanism. The length of the first roller in the panel rolling mechanism can be adjusted flexibly, so that thepanel rolling lengths of different panels can be met. A third roller in the auxiliary mechanism can move transversely by means of the transmission mechanism, and meanwhile, the third roller drives asecond lead screw to rotate by means of a fourth motor to move up and down, so that the third roller not only can move in the horizontal direction, but also move in the vertical direction, and therefore, the panel bending precision in the panel rolling process is improved.

Owner:宁波信豪铝业有限公司

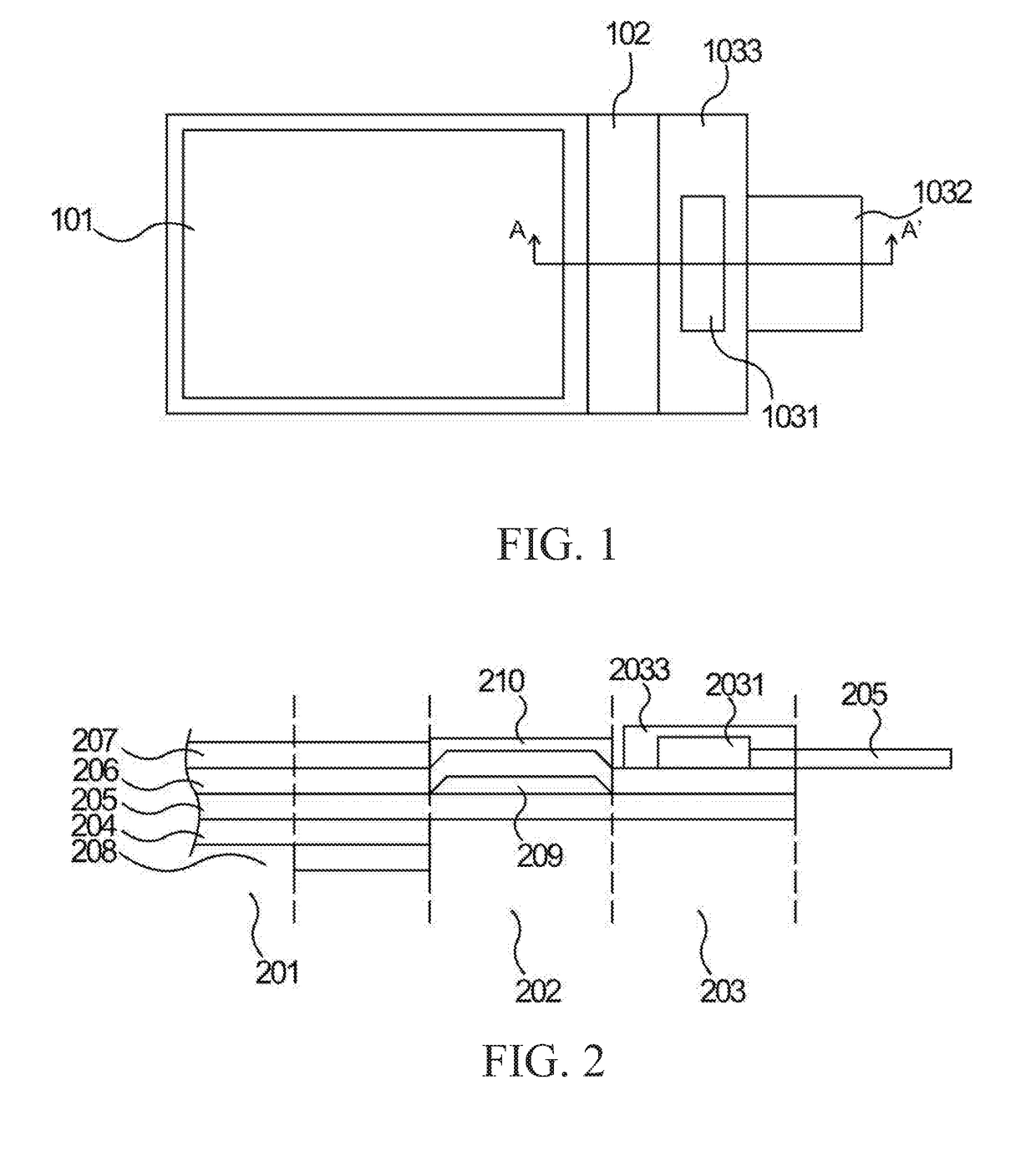

OLED display panel and display device thereof

ActiveUS20190036075A1Improve toughnessImprove bending accuracySolid-state devicesSemiconductor/solid-state device manufacturingFlexible circuitsDisplay device

An OLED display panel is provided and defined as: a display region, a bending region, and a driving bonding region, wherein the driving bonding region has: a driving chip; a flexible circuit board configured to achieve a connection between the driving chip and a motherboard; and a reinforcing plate disposed on and covered with a surface of the substrate wiring layer of the driving bonding region, wherein a chamber is formed in a bottom portion of the reinforcing plate, and the driving chip is located in the chamber.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

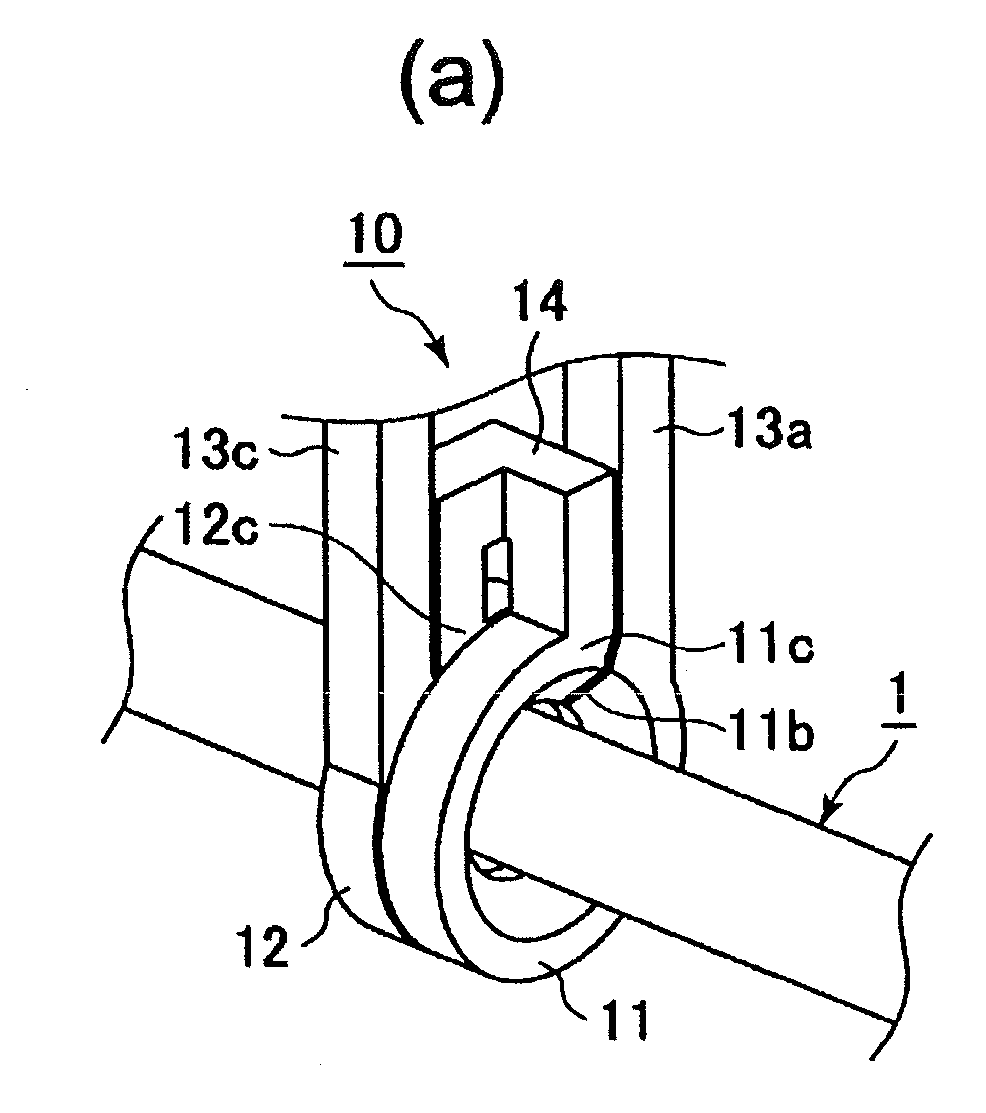

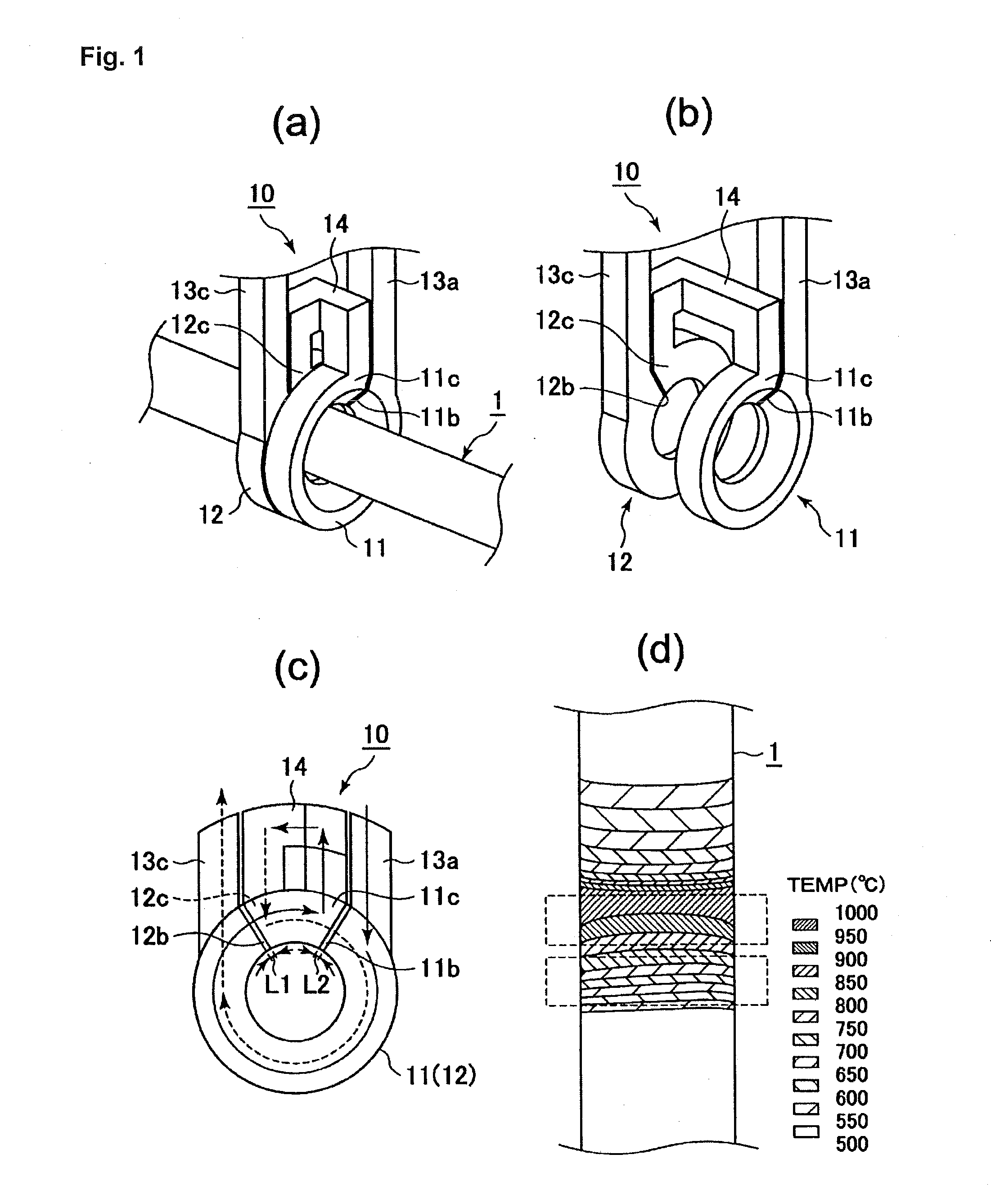

Induction heating coil, and an apparatus and method for manufacturing a worked member

ActiveUS20120325806A1High dimensional accuracyReliable manufacturingCoil arrangementsIncreasing energy efficiencyNarrow rangeSteel tube

An induction heating coil for stably heating a steel tube which is being fed in its axial direction without rotating, the heating being uniform in the circumferential direction and in a narrow range in the axial direction has at least two 1-turn coils in the form of a first turn coil body and a second turn coil body. The inner peripheral length Ln (the non-effective coil length) where the effective number of coil turns is less than the total number of coil turns when the coil is projected in the axial direction and the inner peripheral length L0 of the projected coil bodies (the inner coil length) satisfy Ln / L0<0.05. First and second coil bodies have insulating portions on their connecting portions, and the insulating portions are present in locations separated by a central angle of 5-45° measured from the center of the coil bodies.

Owner:NIPPON STEEL CORP

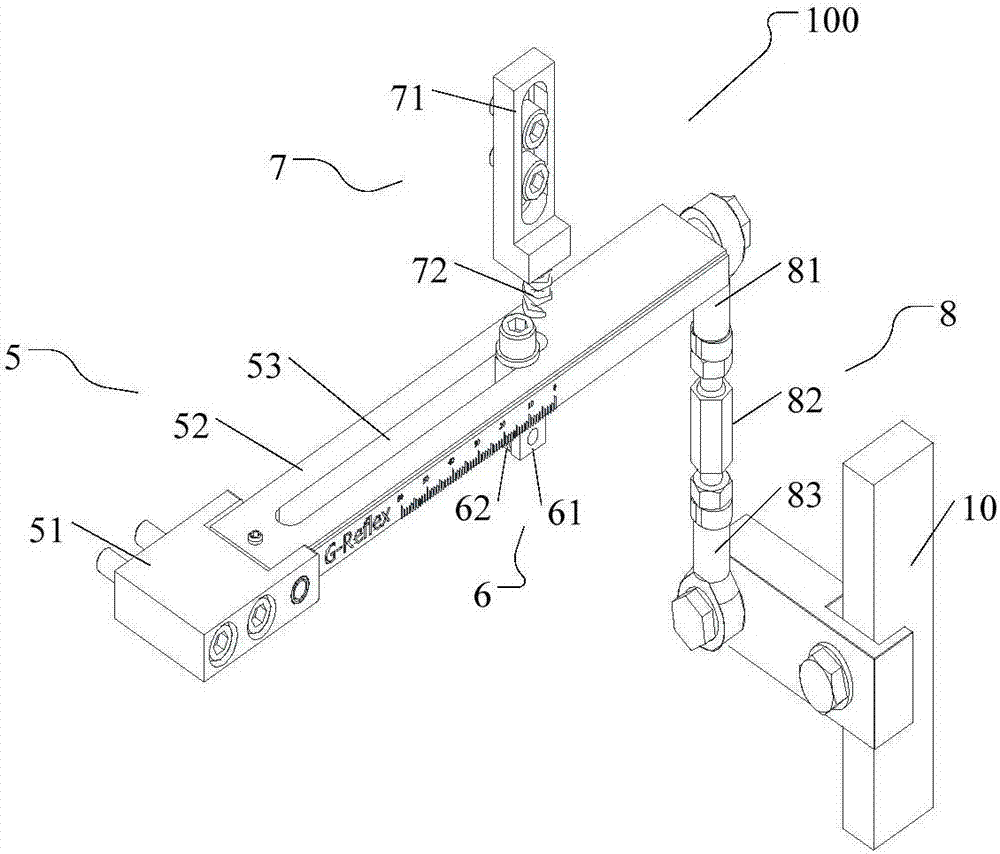

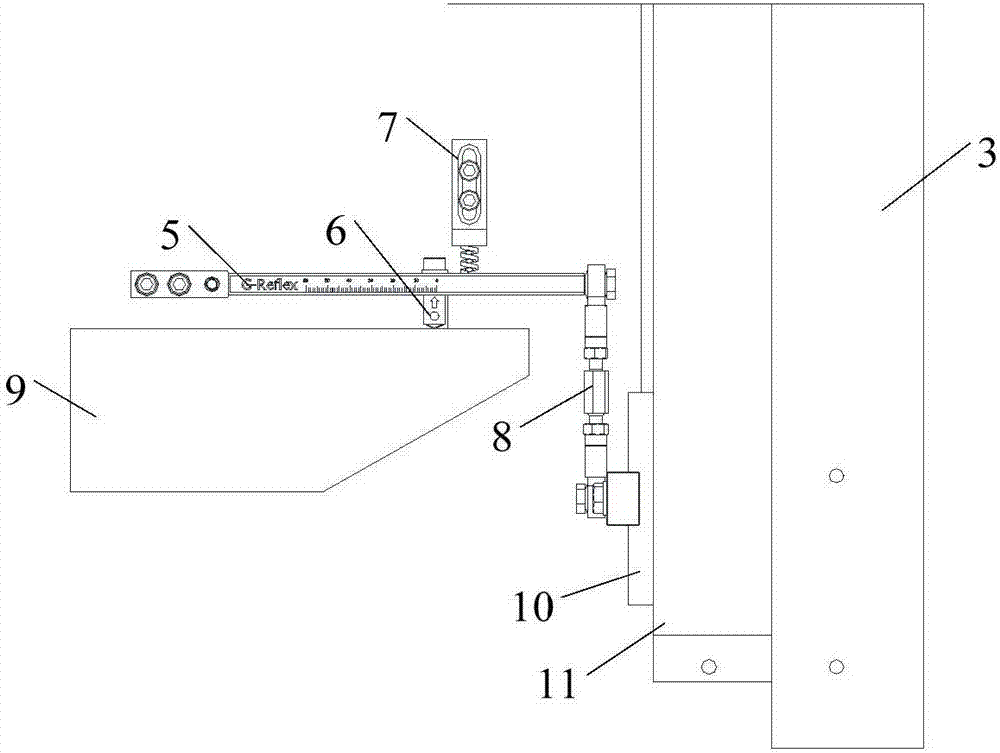

Rack deformation compensation device and bending machine

The invention provides a rack deformation compensation device and a bending machine. The technical problem that the bending degree error of a bending machine is large in the prior art is solved. The rack deformation compensation device comprises a fulcrum assembly and a lever assembly. The lever assembly is movably connected with the fulcrum assembly and can make lever type swinging with the fulcrum assembly as a fulcrum. The first end of the lever assembly is used for being connected with a lateral plate of the bending machine. The second end of the lever assembly is connected with a grating reading head. The fulcrum assembly is used for being connected with a lower beam of the bending machine.

Owner:山东嘉意机械有限公司

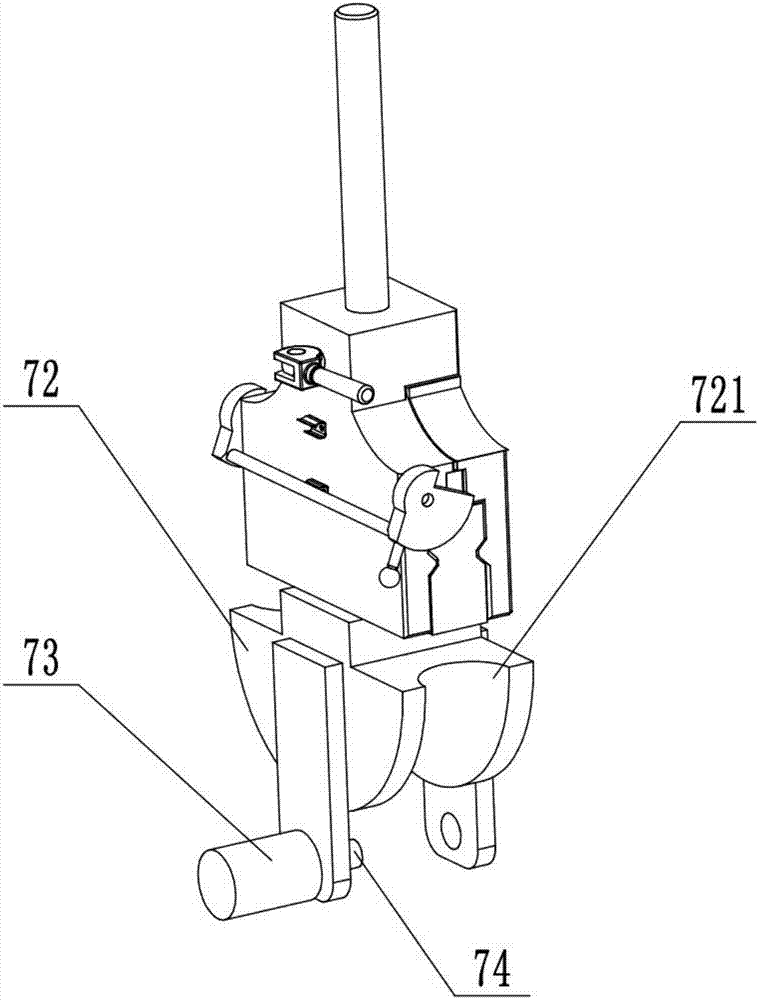

Bending mechanism for flexible flat cable assembly device

InactiveCN103736874ASo as not to damageNo displacement deviation will occurLine/current collector detailsEngineeringCam

The invention discloses a bending mechanism for a flexible flat cable assembly device. The bending mechanism comprises a base, a rear plate, a top plate and a cylinder. The bending mechanism is characterized by further comprising two cams, two inclined blocks, a front movable plate, a rear movable plate and a bending knife. The rear plate is arranged above the base, the top plate is arranged at the top end of the rear plate, the two inclined blocks capable of moving are arranged below the top plate, a cylinder rod of the cylinder penetrates through the rear plate to be connected with the inclined blocks, the front movable plate and the rear movable plate are arranged below the two inclined blocks respectively, the cams matched with inclined planes of the corresponding inclined blocks are installed at the top of the front movable plate and the top of the rear movable plate, pressing wheels are arranged at the bottom of the front movable plate, and the bending knife is arranged at the bottom of the rear movable plate. The bending mechanism for the flexible flat cable assembly device is simple in structure and convenient to use and can press a flexible flat cable, and the flexible flat cable is conveniently accurately bent in a piece groove.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

Mobile phone curved glass hot bending composite die with temperature regulation function and control method

The invention discloses a mobile phone curved glass hot bending composite die with a temperature regulation function and a control method thereof. The mobile phone curved glass hot bending composite die comprises a compression die and a bottom die, wherein a cavity is formed in the bottom die; grooves are respectively formed in two sides of the compression die; bosses meshed with the grooves are arranged at two sides of the bottom die; edges of the grooves and the bosses are in the same curved surface; a compression die curved surface is arranged at the center of the compression die; a cavitycurved surface is arranged in the cavity; the compression die curved surface and the cavity curved surface are curved surfaces with the same curvature; when the compression die is in pressing with the bottom die, the bosses are inserted in the grooves, the surfaces of the bosses are in fit with the surfaces of the grooves, the compression curved surface is pressed towards the cavity curved surface, a zone, which faces towards the cavity curved surface, in the bottom die and a zone, which faces towards the compression die curved surface, in the compression die are respectively provided with ametal heating tube, and the metal heating tubes are connected with a temperature controller after being connected with a power supply through guide lines. According to the mobile phone curved glass hot bending composite die disclosed by the invention, the bending accuracy of glass is increased, the consistency during bending of the glass is ensured, and the quality of a product is increased.

Owner:GUANGDONG HUST IND TECH RES INST

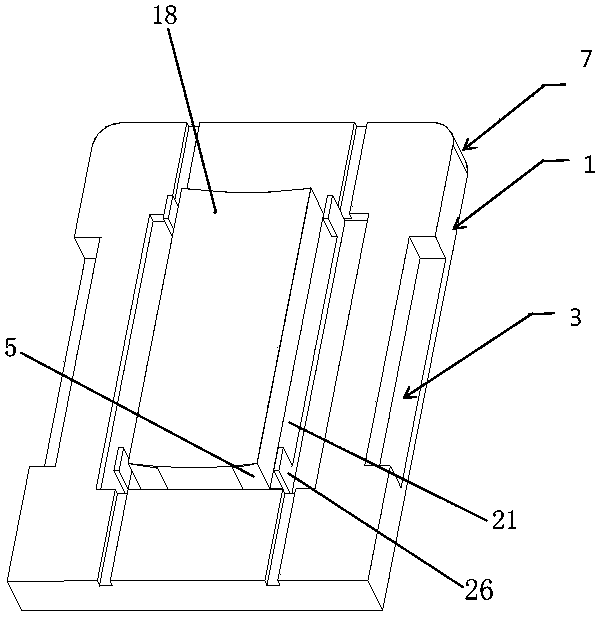

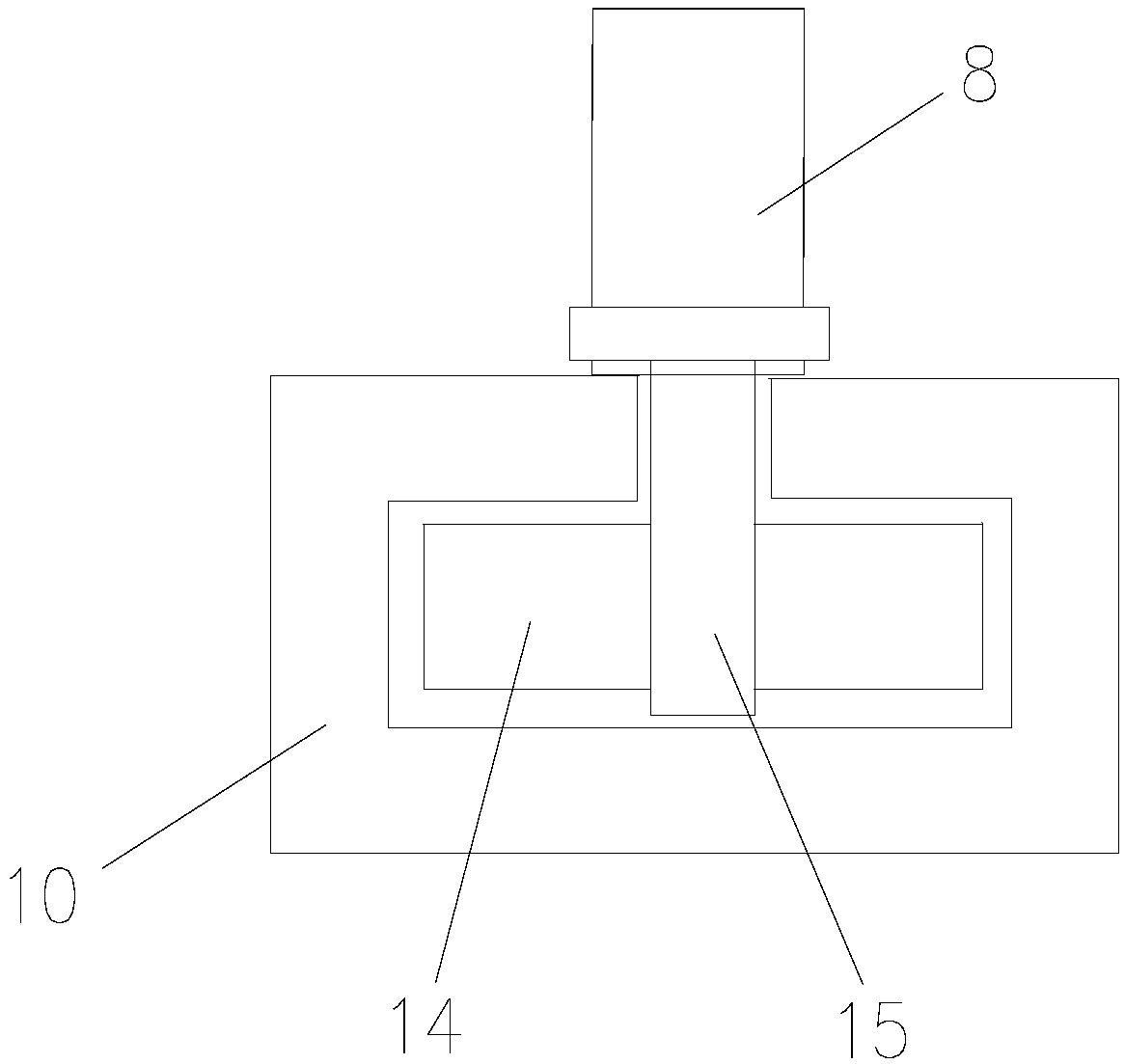

Bending mechanism

InactiveCN108801818AConsistent bending operationGood repeatabilityMaterial strength using repeated/pulsating forcesFlexible circuitsEngineering

The embodiment of the invention relates to mechanical equipment and discloses a bending mechanism. The bending mechanism is used for bending an FPC (Flexible Printed Circuit) board and comprises a test tabletop, an operation panel, a hold-down part, a driving device and a master control unit, wherein the operation panel is opposite to the test tabletop and is used for crossing over the test tabletop and the operation panel; the test tabletop and the operation panel jointly bear the FPC; the PFC comprises a first part extending towards the direction of the operation panel and a second part extending towards the direction of the test tabletop; the first driving device drives the operation panel to turn over around a preset axis; the operation panel bends the first part of the FPC round the hold-down part during turnover; the master control unit controls the first driving device to drive the operation panel to be turned over to a preset angle. Compared with the prior art, bending operation of the FPC is kept consistent and the repeatability efficiency is higher; the positions of the FPC are unified in the bending process, so that a test result is more reliable, labor force is reducedand the test cost is reduced.

Owner:SHANGHAI YUDE COMM TECH

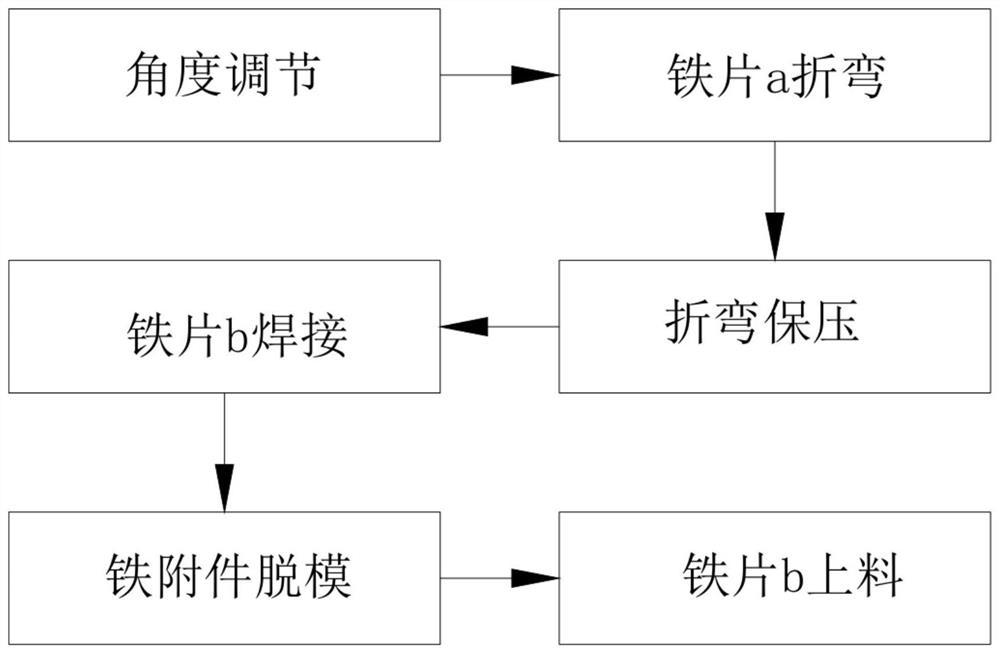

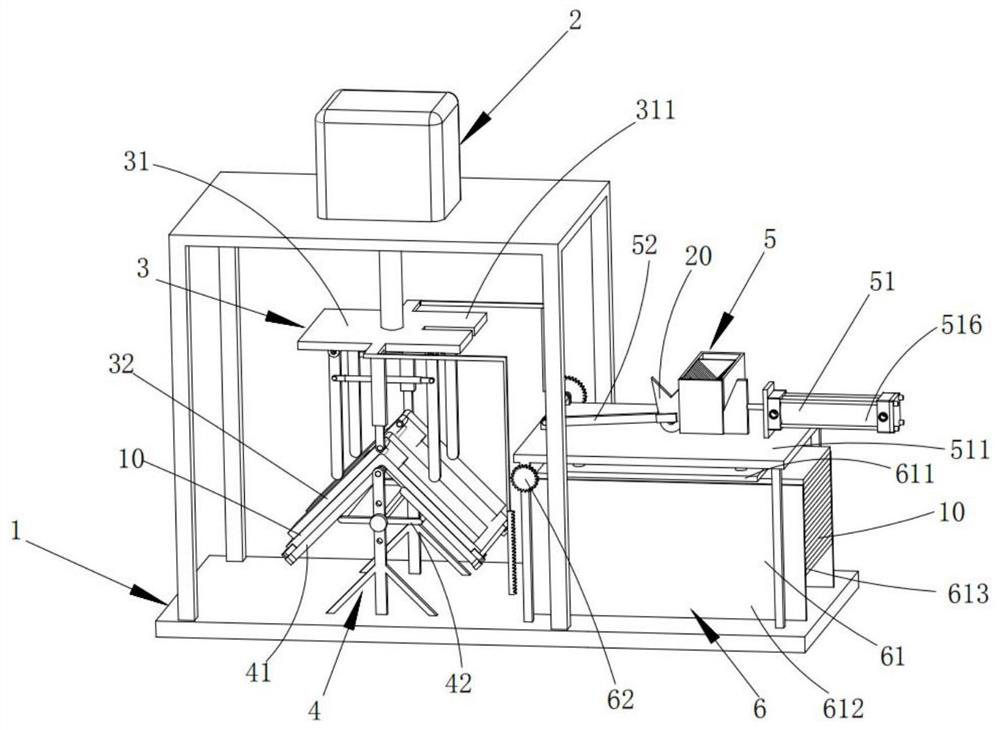

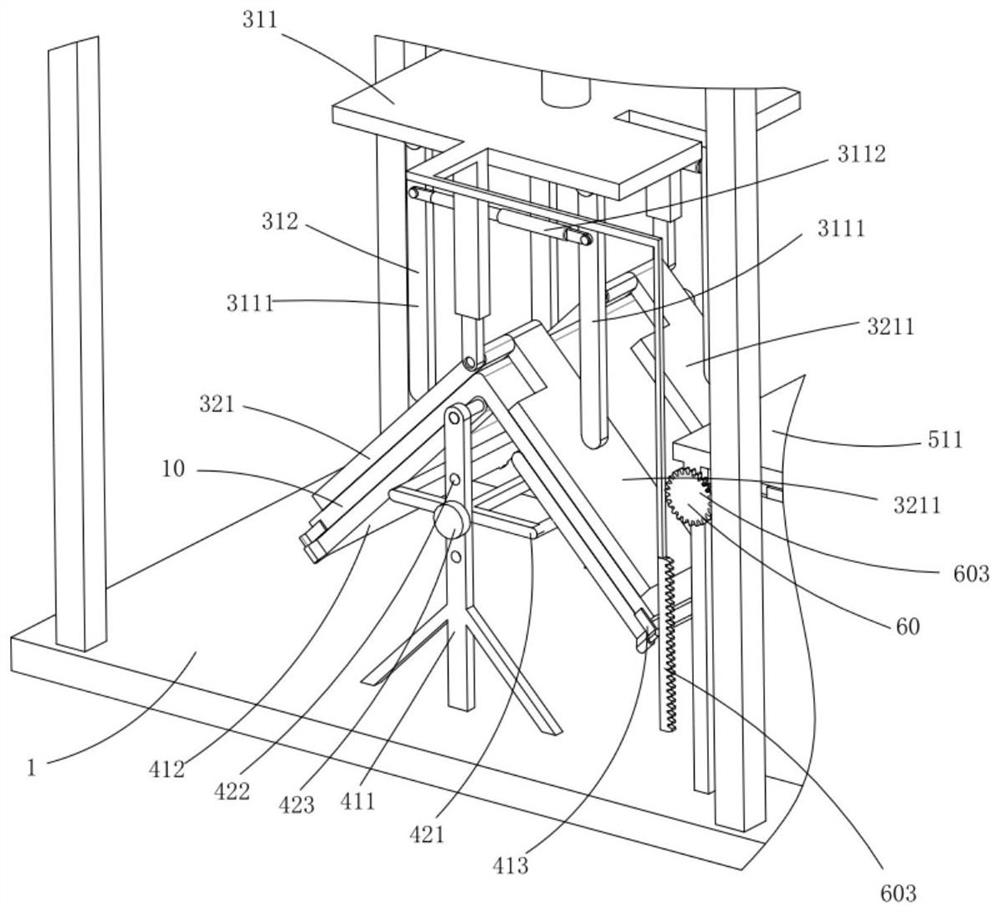

Iron accessory multi-angle bending method

ActiveCN112828084AImprove bending accuracyAvoid displacementMetal-working feeding devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention relates to an iron accessory multi-angle bending method. The method comprises the following steps that angle adjustment is conducted, and a pin is inserted into a corresponding limiting hole according to the bending angle so as to change the height of a limiting frame matched with the pin on a support; an iron sheet a is bent, a fixing plate moves downwards, pressing plates make contact with the iron sheet a, and then ejector rods drive the pressing plates and bottom plates to rotate at the same time to bend the iron sheet a till the bottom plates abut against the limiting frame; bending and pressure maintaining are conducted, the fixing plate continues to move downwards, the ejector rods rotate, and the ends move along the upper surfaces of the pressing plates; an iron sheet b is welded, a transmission assembly a acts to drive a swing arm to rotate, a gripper places the iron sheet b on the iron sheet a, and then the iron sheet a and the iron sheet b are welded to form an iron accessory; a welded part is demolded, the fixing plate moves upwards, the pressing plates and the swing arm rotate and reset, and then a roll shaft rotates to drive the iron sheet a to move to the bottom plate and eject the iron accessory away; and the iron sheet b is fed, and an air cylinder drives the iron sheet b to be clamped into the gripper. By means of the iron accessory multi-angle bending method, continuous production of the iron accessory can be achieved.

Owner:HUZHOU COLLEGE

Plate bending machine and method

PendingCN109079006AGuaranteed bending qualityImprove bending accuracyShaping toolsMetal-working feeding devicesAgricultural engineeringPress brake

The invention discloses a plate bending machine and method. The plate bending machine comprises a case, a bending device is arranged in the case, the bending device comprises an upper fixing block, the upper fixing block is fixedly connected with the case, a lower fixing block is arranged at the bottom of the upper fixing block, a first hydraulic rod is arranged at the bottom of the lower fixing block, an output shaft of the first hydraulic rod is fixedly connected with the lower fixing block, a heater is arranged on the surface of each of the upper fixing block and the lower fixing block, a bending block is arranged on one side of the upper fixing block and the lower fixing block, a second hydraulic rod is arranged at one end of the bending block, and an output shaft of the second hydraulic rod is fixedly connected with the bending block. The bending device is provided, the heaters heat the plate to ensure the plate at a high temperature, the bending block is driven by the second hydraulic rod to bend the plate up or down as needed to ensure the bending quality of a right angle, and the bending block is also driven by the second hydraulic rod to fix the plate.

Owner:大连绿云科技有限公司

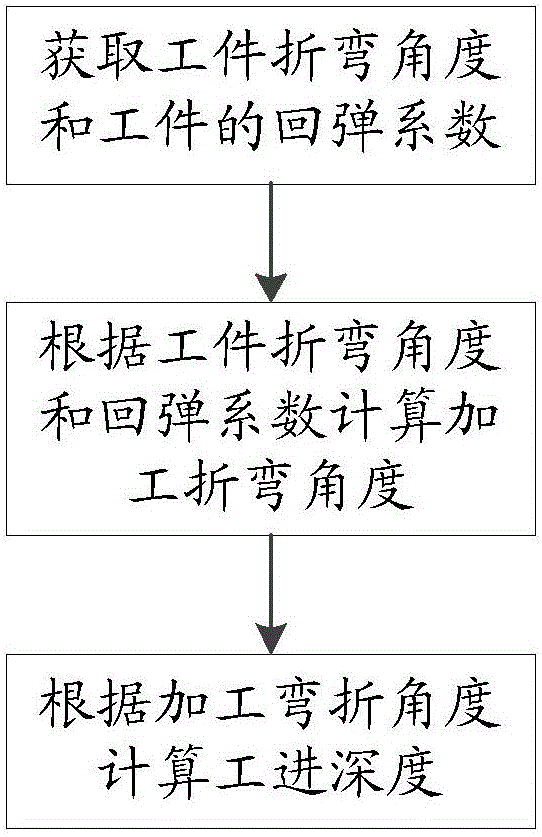

Computing method for bending-machine part-processing feeding depth

InactiveCN105975786AImprove work efficiencyLow costInformaticsSpecial data processing applicationsPress brakeWaste material

The invention discloses a computing method for the bending-machine part-processing feeding depth. The computing method includes the steps that the bending angle of a workpiece and the rebound coefficient of the workpiece are obtained; the processing bending angle is computed according to the bending angle and the rebound coefficient of the workpiece; the feeding depth of a bending-machine processing part is obtained according to the processing bending angle. The bending accuracy is improved through the feeding depth obtained by computing and amending, bending rebound and multiple other factors capable of influencing the bending accuracy are considered, common bending requirements can be met through direct processing, and under the condition of requiring the high accuracy, only once adjustment is required, and working efficiency is improved; meanwhile, the feeding depth can be directly computed according to parameters, the position of a memory does not need to be adjusted before memorizing, waste materials generated in the testing process and the adjustment process are reduced, and cost is saved.

Owner:QIAOHONG NUMERICAL CONTROL TECH SHANGHAI

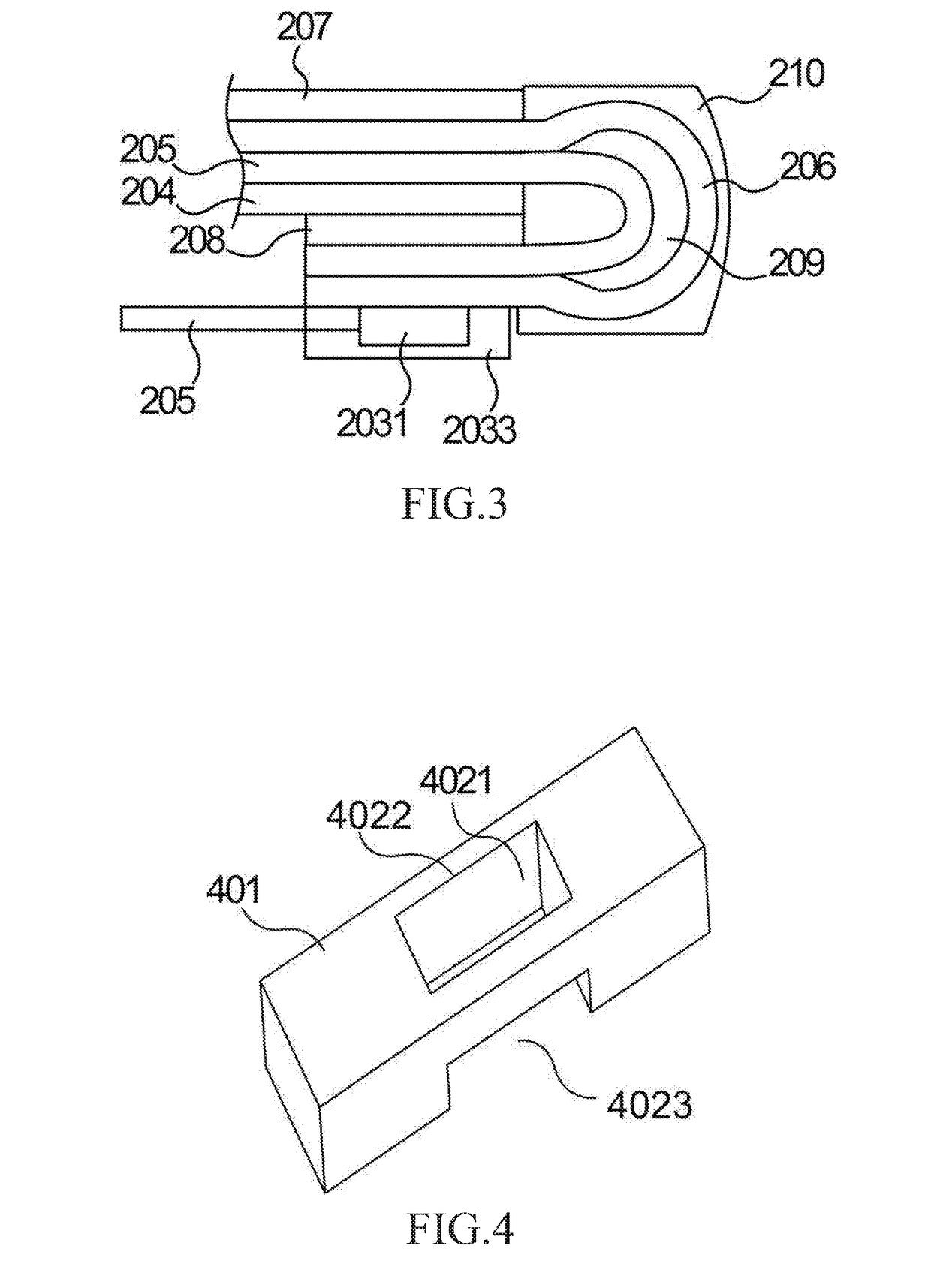

Coil component

ActiveUS8922317B2Improve accuracyImprove bending accuracyTransformers/reacts mounting/support/suspensionTransformers/inductances casingsEngineeringElectrical and Electronics engineering

A coil component including: a magnetic core which is formed by a magnetic material and which has a top surface, a bottom surface facing the top surface and a side surface continuous approximately perpendicularly to the top surface and the bottom surface; a coil which is buried inside the magnetic core and whose end portion protrudes from the side surface of the magnetic core; a flat-shaped terminal which protrudes from the side surface of the magnetic core, is bent toward the bottom surface of the magnetic core and is connected with the end portion of the coil, wherein there is formed an opening portion at a position corresponding to the place which is bent for the flat-shaped terminal from the side surface to the bottom surface of the magnetic core.

Owner:SUMIDA CORP

Pipe bending tooling

The invention relates to the technical field of pipe processing, and particularly discloses a pipe bending tooling, which comprises a processing table, a positioning table and adjusting blocks are arranged on the processing table, and a placing channel for placing a pipe is formed between the adjusting blocks and the positioning table; the number of the adjusting blocks is two, and the two adjusting blocks are in sliding connection with the processing table; a positioning hole is formed in the lower part of each adjusting block; the end part of each adjusting block is provided with an arc-shaped groove; a sliding hole is arranged in the positioning table, a sliding block is slidably connected in the sliding hole, and a spring is fixed between the sliding block and the sliding hole wall; asliding cavity and a positioning cavity are arranged in the processing table; a positioning column used for being inserted in a positioning hole is slidably connected in the positioning cavity, the two ends of the sliding cavity are respectively communicated with the sliding hole and the positioning cavity; a push rod is slidably connected in the sliding cavity, the two ends of the push rod are bent and fixedly connected with the sliding block and the positioning column. According to the scheme, the problem that the distance between the two bending parts of the pipe is difficult to control when the two ends of the pipe are bent in the prior art, which causes low qualification rate of the bent pipe, is solved.

Owner:重庆祥越管道配件制造有限公司

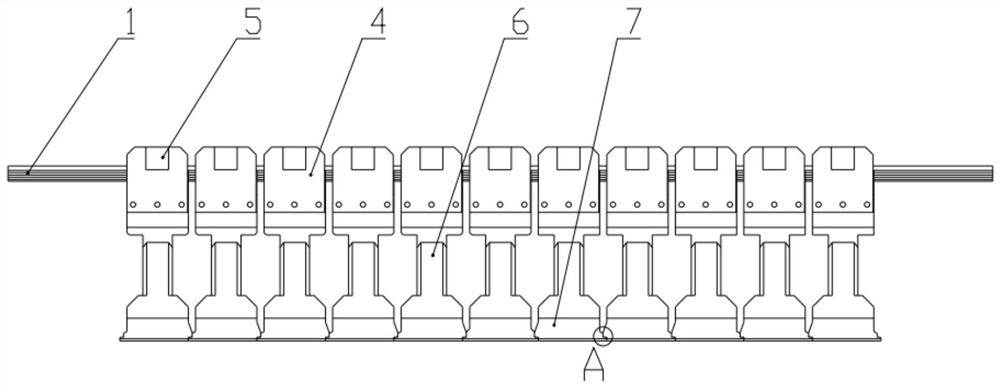

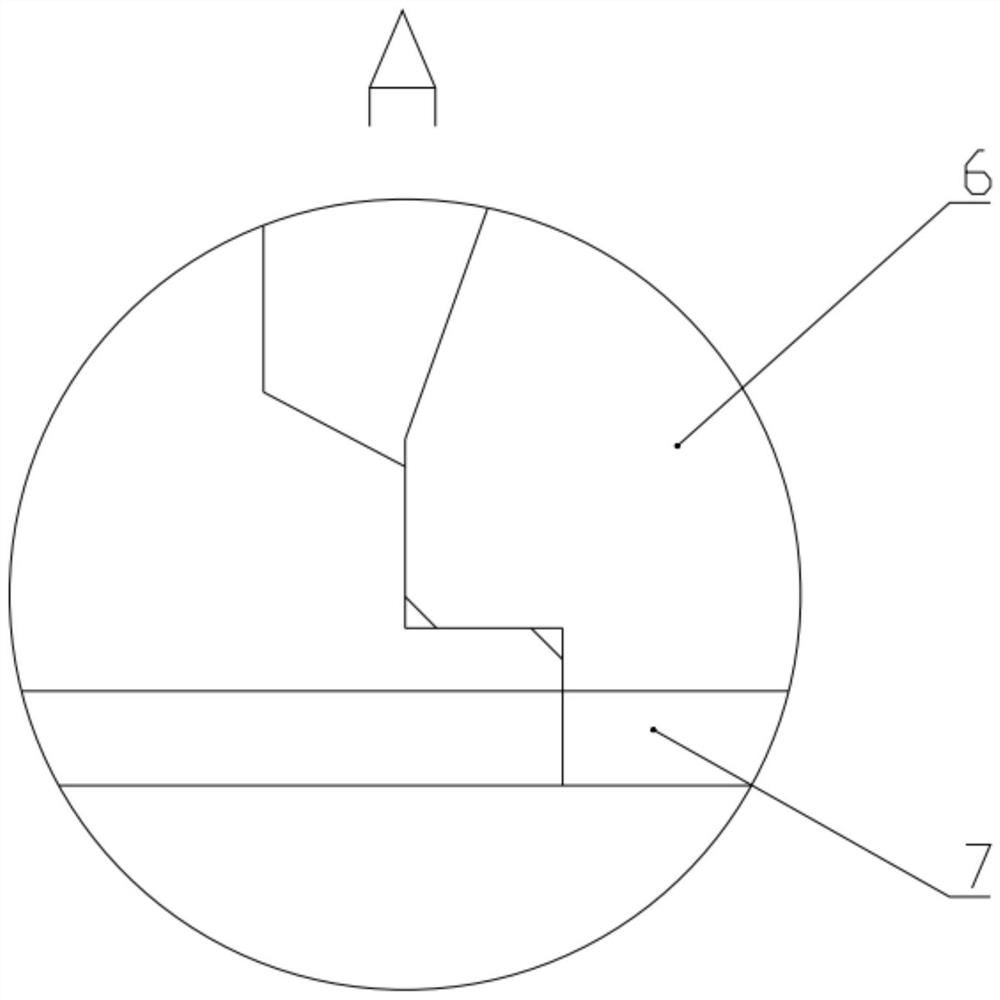

Flexible bending center pressing cutter mechanism

InactiveCN111687245AReduce wearExtended service lifeShaping toolsMechanical engineeringIndustrial engineering

The invention relates to the field of bending equipment, in particular to a flexible bending center pressing cutter mechanism. The flexible bending center pressing cutter mechanism comprises a linearguide rail, a guide rail sliding block, a sliding block base plate and pressing cutters which are sequentially connected in the longitudinal direction, the pressing cutters comprise pressing cutter upper parts and pressing cutter main bodies, the linear guide rail is fixedly connected with a positioning wallboard, one end, away from the positioning wallboard, of the sliding block base plate is fixedly connected with a limiting air cylinder block, a limiting air cylinder is installed on the limiting air cylinder block, an air cylinder jacking column of the limiting air cylinder stretches out and abuts against the positioning wallboard; and step-shaped clamping tables are arranged between every two adjacent pressing cutter main bodies. According to the flexible bending center pressing cuttermechanism, the linear sliding rail and the sliding block are adopted, so that the friction resistance is reduced, and meanwhile, the abrasion degree of the pressing cutters is reduced; automaticallylocking the pressing cutters is carried out by adopting the positioning air cylinder, the positioning accuracy and stability of the pressing cutters are guaranteed, and therefore the bending accuracyis improved; mutually stacked step-shaped clamping tables are arranged between the adjacent pressing cutters, so that the pressing cutter deflection caused by non-uniform stress of the pressing cutters at the edge of a plate is avoided; and a split type design structure is adopted, so that overall replacement of the pressing cutters is avoided, and the replacement cost is reduced.

Owner:青岛艾特智能装备有限公司

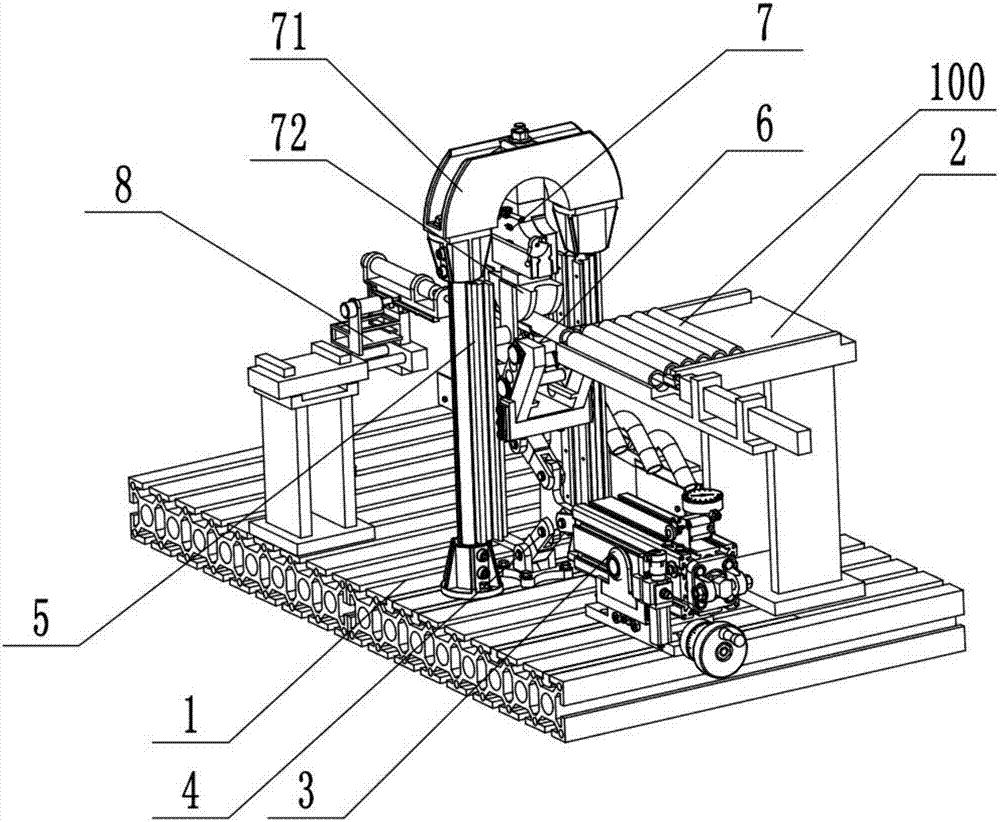

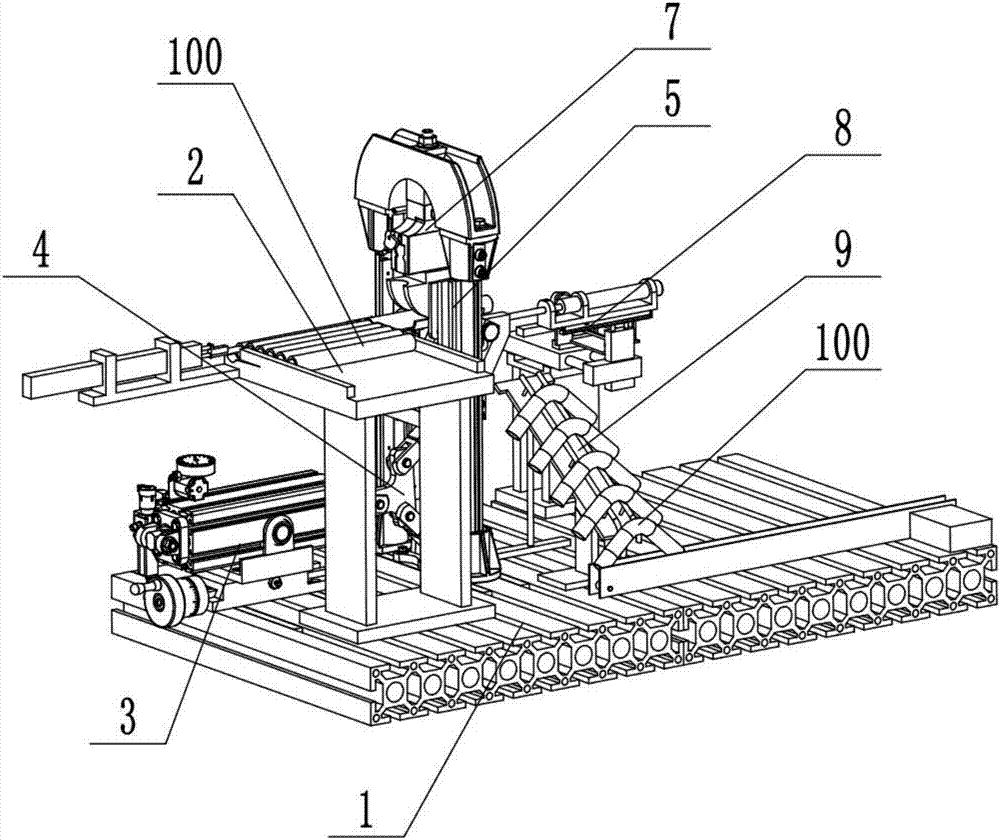

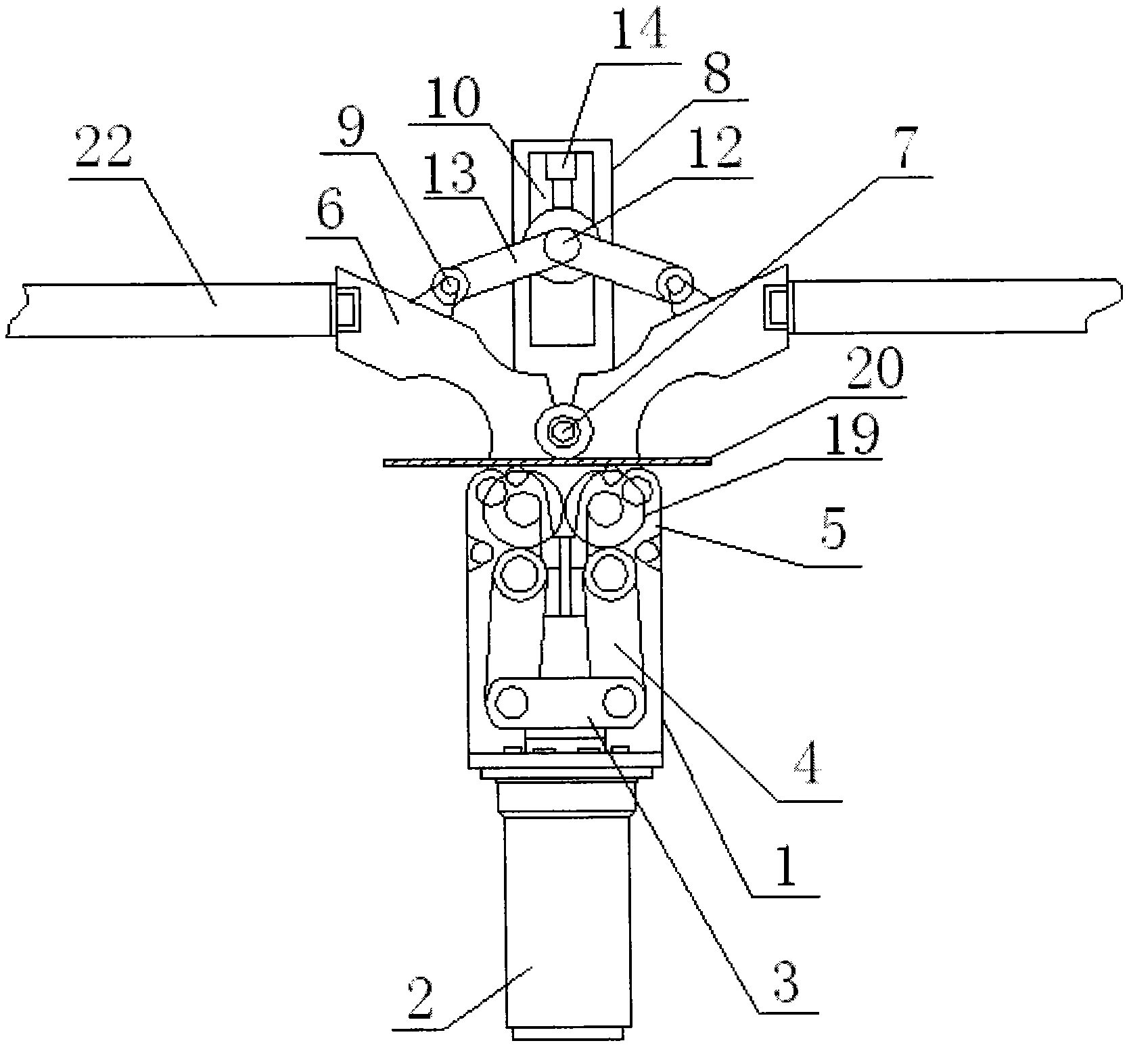

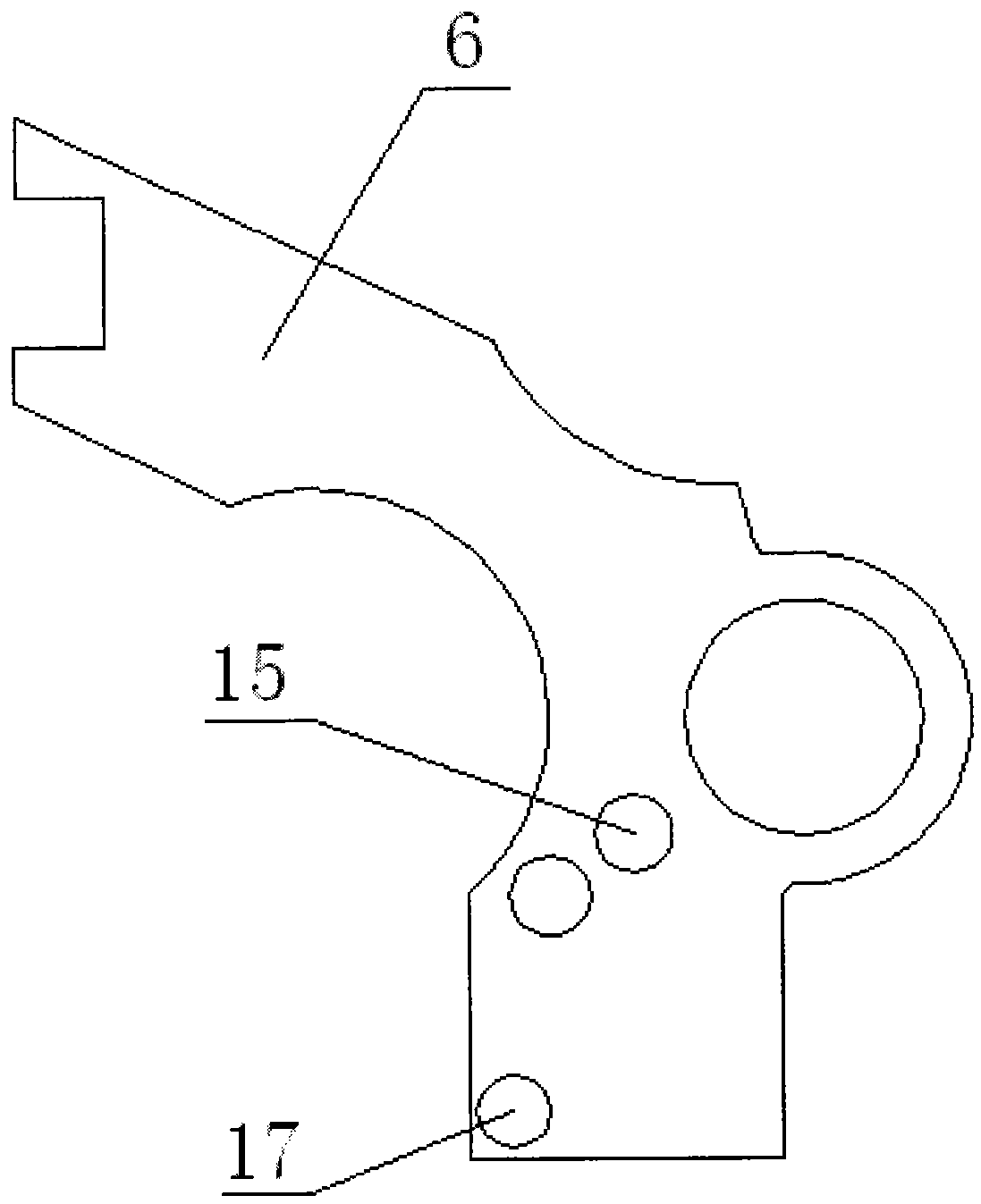

Connecting rod type bending device used for reinforcement forming machine to bend reinforcement

The invention discloses a connecting rod type bending device used for a reinforcement forming machine to bend a reinforcement. The connecting rod type bending device comprises a base, an oil cylinder, a push rod, a connecting rod, a hinge pin thrust bearing, a hinged plate, an articulated hinge pin and a fixed plate, wherein the oil cylinder is arranged on the base; the push rod is arranged on the base; the connecting rod is arranged on the base; the hinge pin thrust bearing is arranged on the base; the hinged plate is arranged on the base; the articulated hinge pin is arranged on the base; the fixed plate is arranged above the base; a fixed hinge is arranged on the hinged plate; the fixed plate is provided with a chute; a sliding block is arranged in the chute; a movable hinge is arranged on the sliding block; a connecting rod is arranged on the movable hinge; the connecting rod is connected with the fixed hinge; a hydraulic rod is arranged in the chute; the hydraulic rod is connected with the sliding block; the push rod is connected with the oil cylinder; an inner limiting pin for limiting an internal rotation distance of the hinge pin thrust bearing is arranged on the hinged plate; an outer limiting pin for limiting an external rotation distance of the hinge pin thrust bearing is arranged on the hinged plate.

Owner:湖州佳灏信息技术有限公司

Pipe bending machine

The invention discloses a pipe bending machine which comprises a frame, a pipe bending outputting mechanism and a pipe bending molding mechanism, wherein the pipe bending outputting mechanism is arranged on the frame; and the pipe bending molding mechanism is arranged on one side of the pipe bending outputting mechanism, comprises a pipe bending molding die for holding a to-be-processed pipe, andis characterized in that the pipe bending molding die comprises a plurality of vertical bending dies and clamping dies, which are overlapped; each clamping die is connected with a servo electric cylinder; and cavities are formed by closing the bending dies and the clamping dies; the pipe bending molding die is characterized in that the clamping dies are connected with first driving motors for driving the clamping dies to rotate; a supporting assembly used for supporting the to-be-processed pipe is arranged on the frame, and comprises a supporting block for supporting the to-be-processed pipe and a driving device for switching the working states of the supporting block; the output end of the driving device is connected with the supporting block; and a supporting position used for supportingthe to-be-processed pipe is arranged on the supporting block. The pipe bending machine has the advantages of being high in bending precision, low in cost, high in reliability and having no hydraulicoil pollution.

Owner:佛山市佳锐智能装备有限公司

High-precision metal pipe bending system and method thereof

InactiveCN108971289ARealize multi-stage bendingRealize automatic adjustmentMetal-working feeding devicesPositioning devicesEngineeringMetal

The invention relates to the technical field of metal pipe bending production, in particular to a high-precision metal pipe bending system and a method thereof. The system comprises a frame, a positioning mechanism and a conveying mechanism. The frame comprises a horizontal mounting table, a vertical mounting table and a discharging sliding table; the positioning mechanism comprises a rotating disc, a limiting portion, a supporting portion and a bearing portion; the conveying mechanism comprises a placement component, a pushing component, a bending component and a transmission component, and the transmission component is connected with the pushing component and the rotating disc. A to-be-bent steel pipe in a positioning groove is preliminarily bent through the pushing component which drives the rotating disc to rotate, and the steel pipe is then subjected to secondary bending through the bending component. By cooperation of the pushing component and the positioning mechanism, automaticpreliminary bending of the to-be-bent steel pipe is realized after directional transferring. By special structural setup of the placement component and the pushing component, automatic adjustment offeed amount in a steel pipe bending process is realized, high-precision steel pipe bending is realized, and the technical problem of low bending precision in the prior art is solved.

Owner:湖州添泽管业有限公司

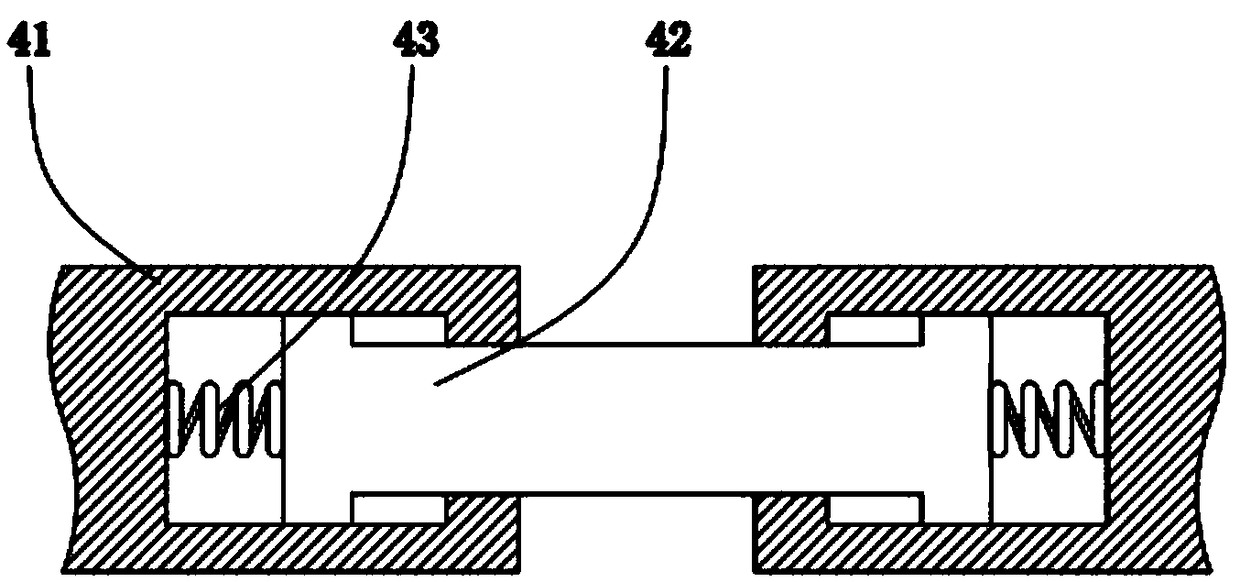

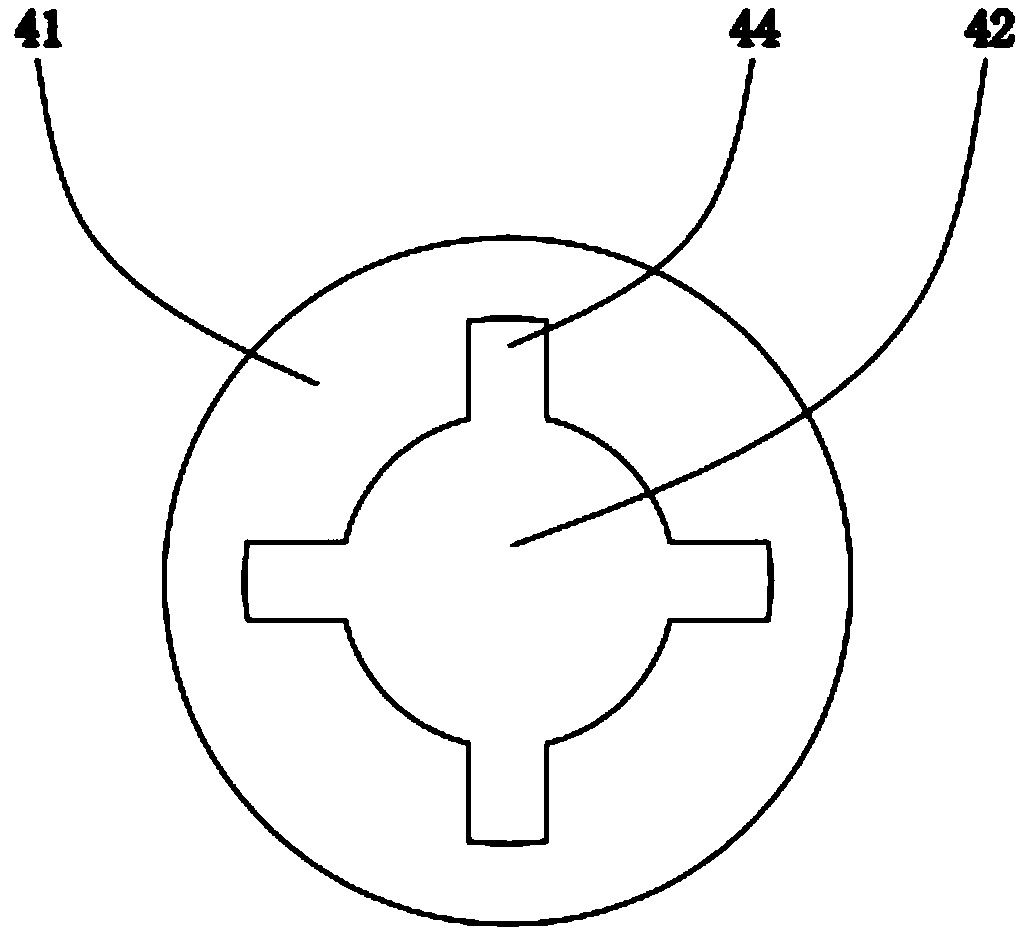

Gear chain type core rod for round pipe bending forming

ActiveCN109201807AImprove support accuracyImprove bending accuracyGlass productionChain typeSpherical shaped

The invention discloses a gear chain type core rod for round pipe bending forming. The gear chain type core rod comprises one or more core balls used for supporting a round pipe bent pipe segment, a core shaft used for supporting a round pipe straight segment and gear chain type connecting bodies used for connecting the core balls and connecting the core balls with the core shaft. Each gear chaintype connecting body comprises single-side gear plates, dual-side gear plates, connecting pieces, long limiting rings, short limiting rings and shafts. The core balls are shells of spherical structures. A first mounting cavity is formed in each shell. The core shaft is of a cylinder shaft. The gear chain type core rod has certain university, can be suitable for bending forming of thin-wall pipes large in radius-thickness ratio and small in bending radius and is high in supporting precision.

Owner:ZHEJIANG KING MAZON MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com