Patents

Literature

43results about How to "Improve support accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

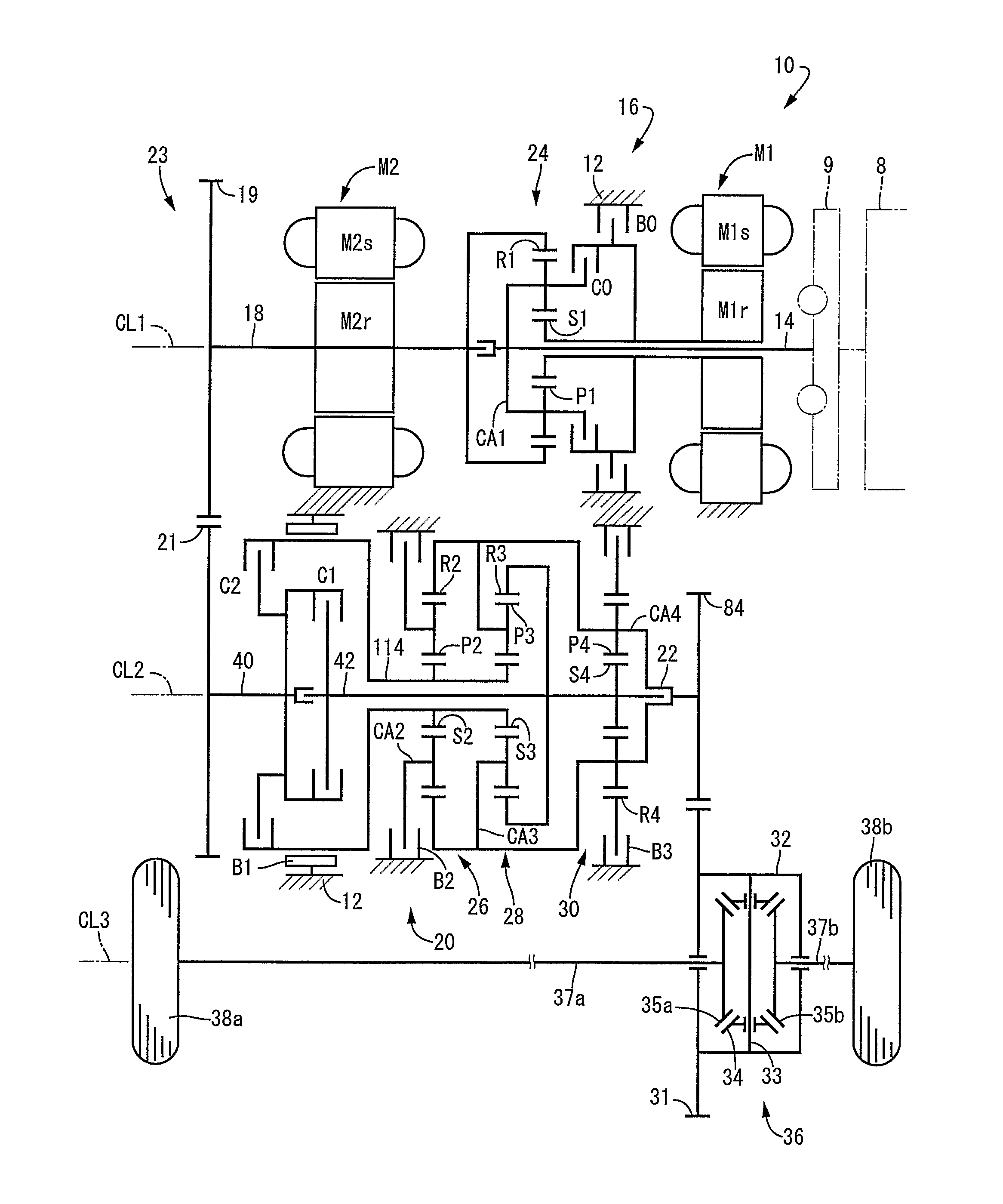

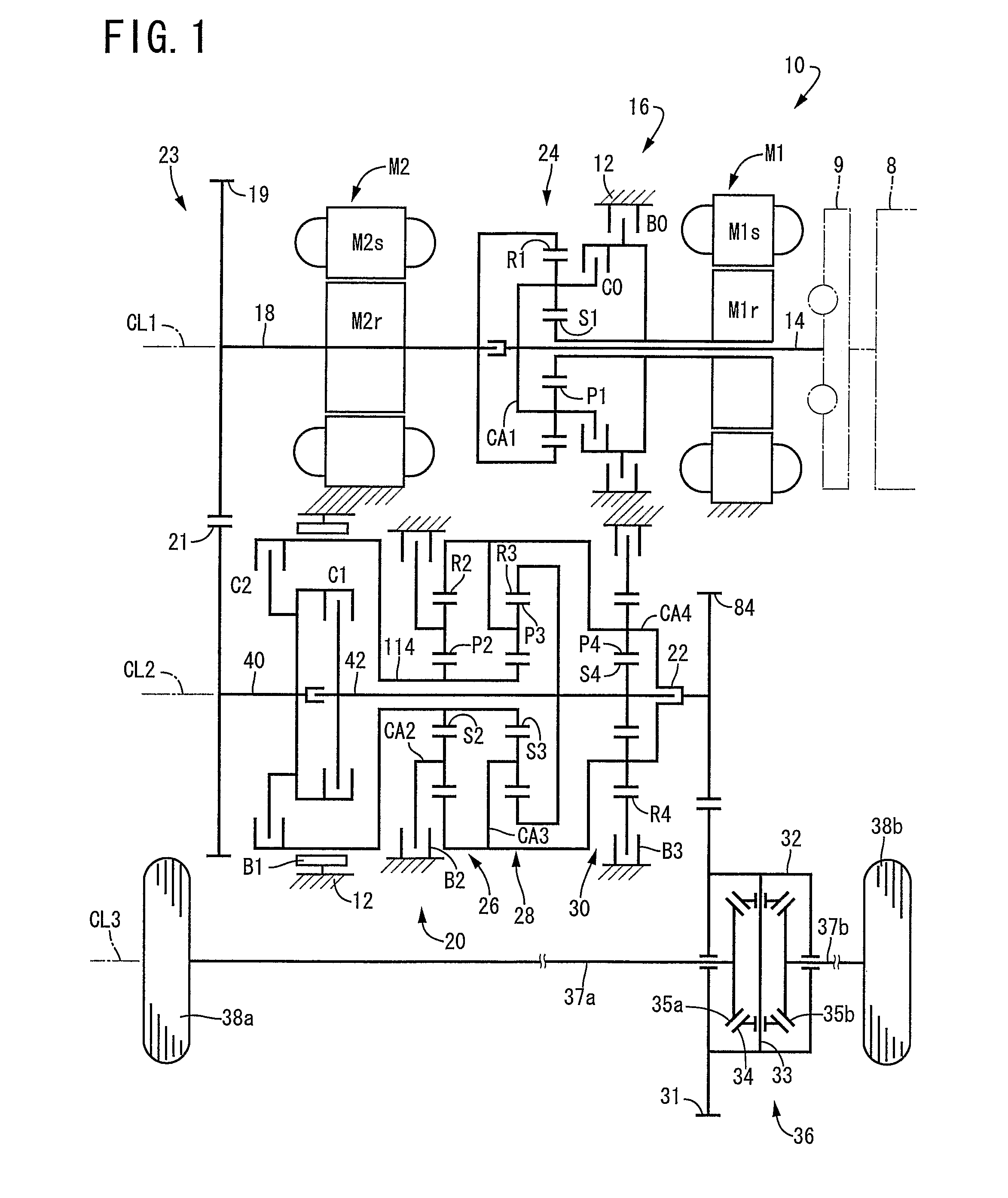

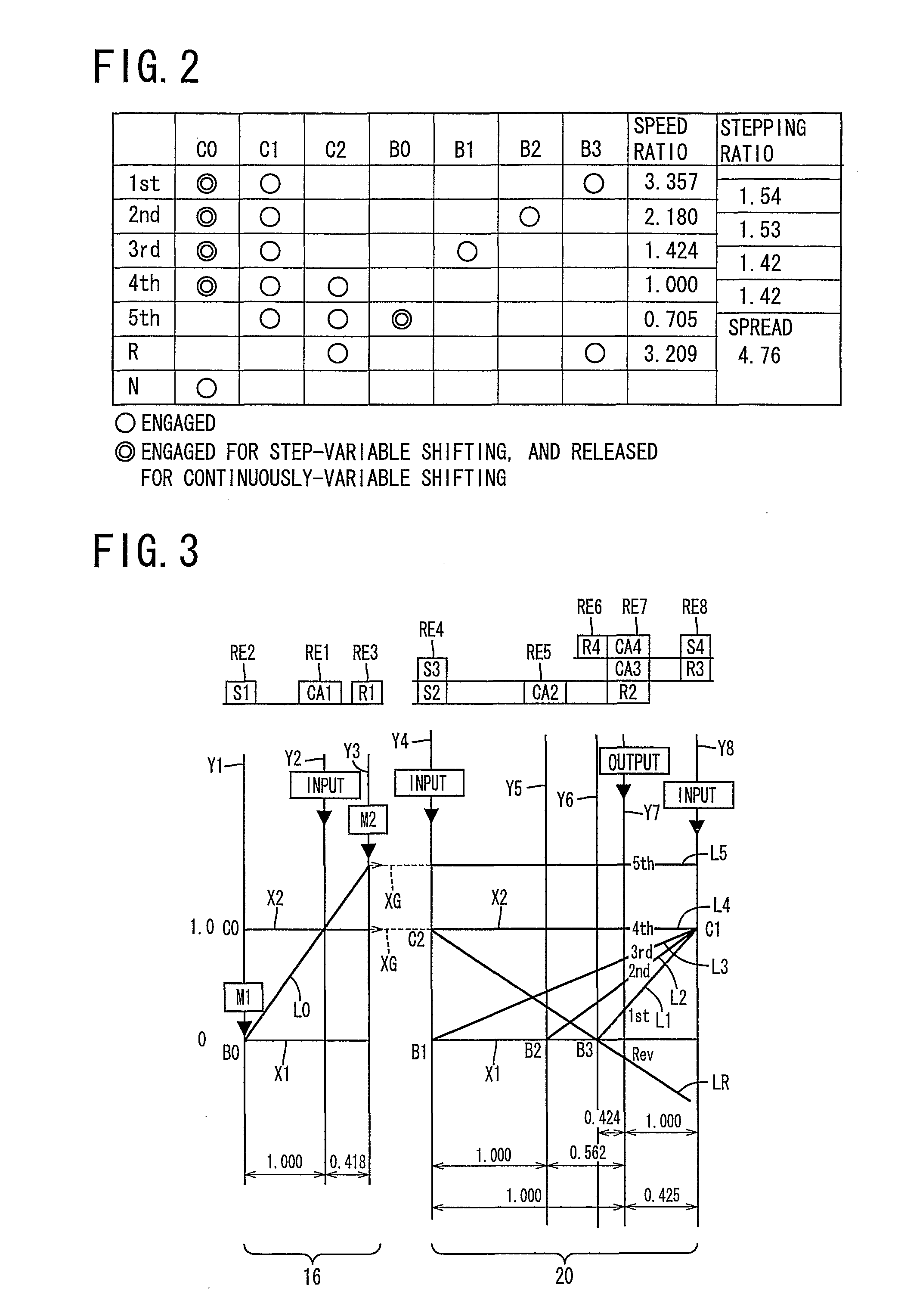

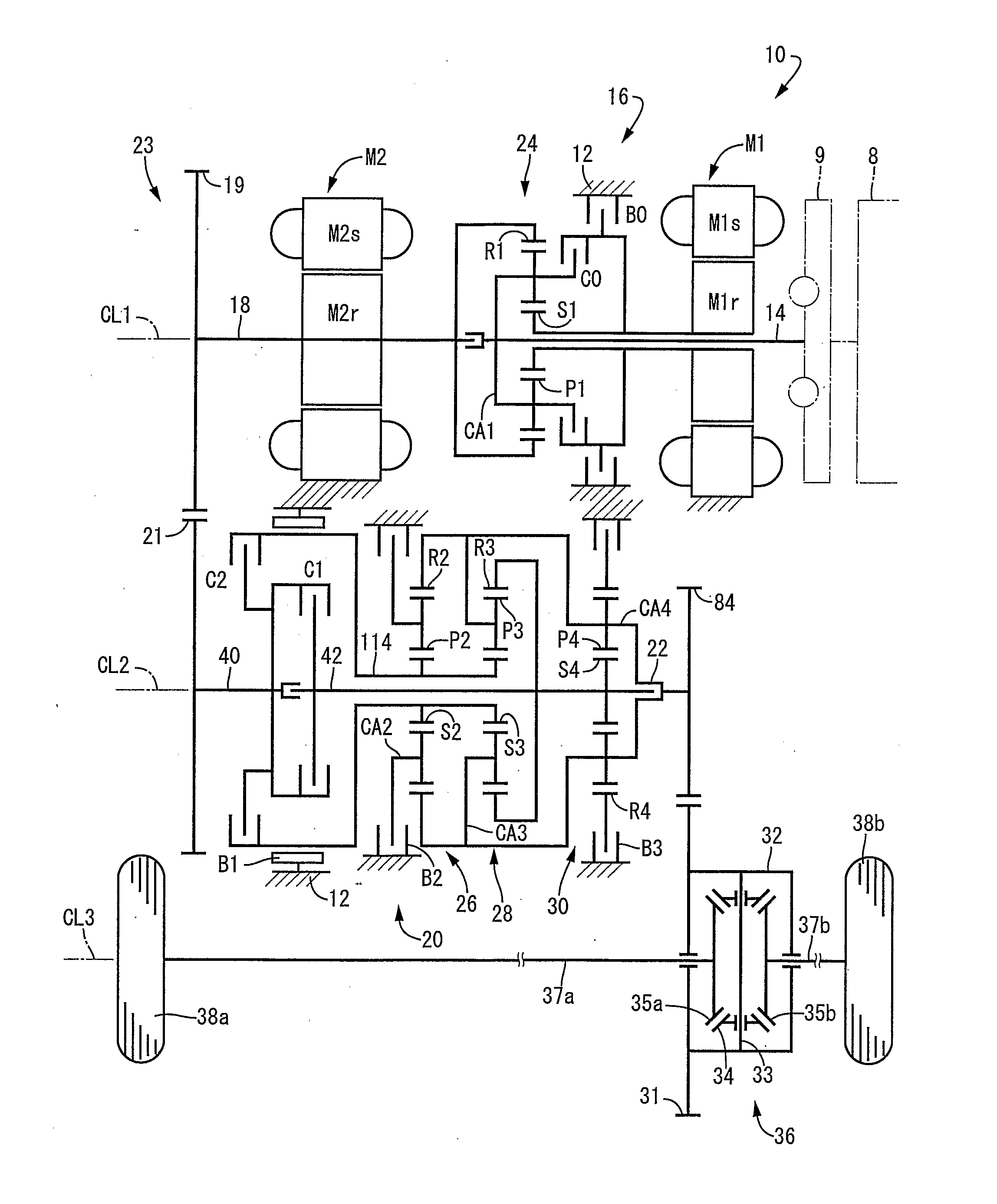

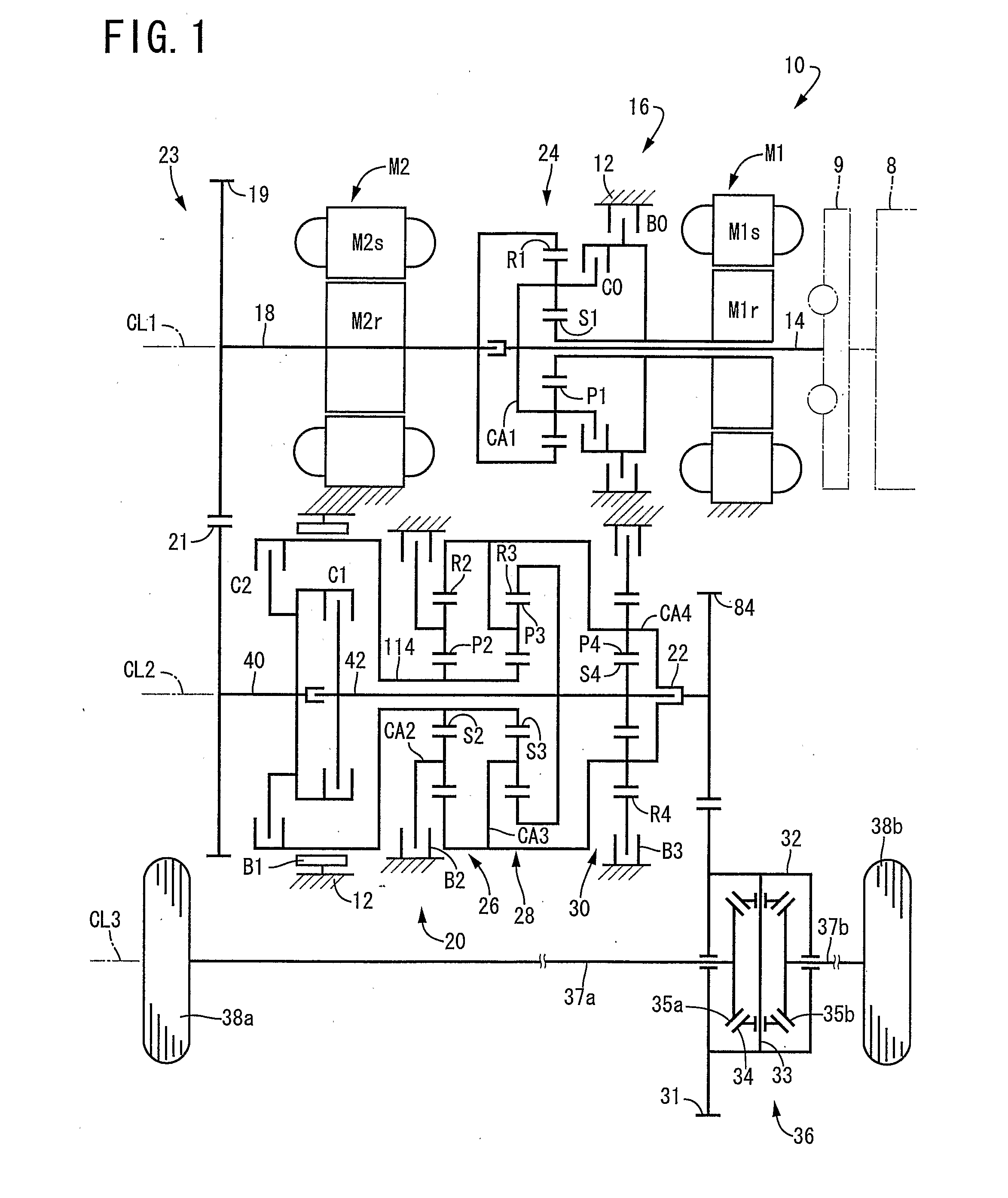

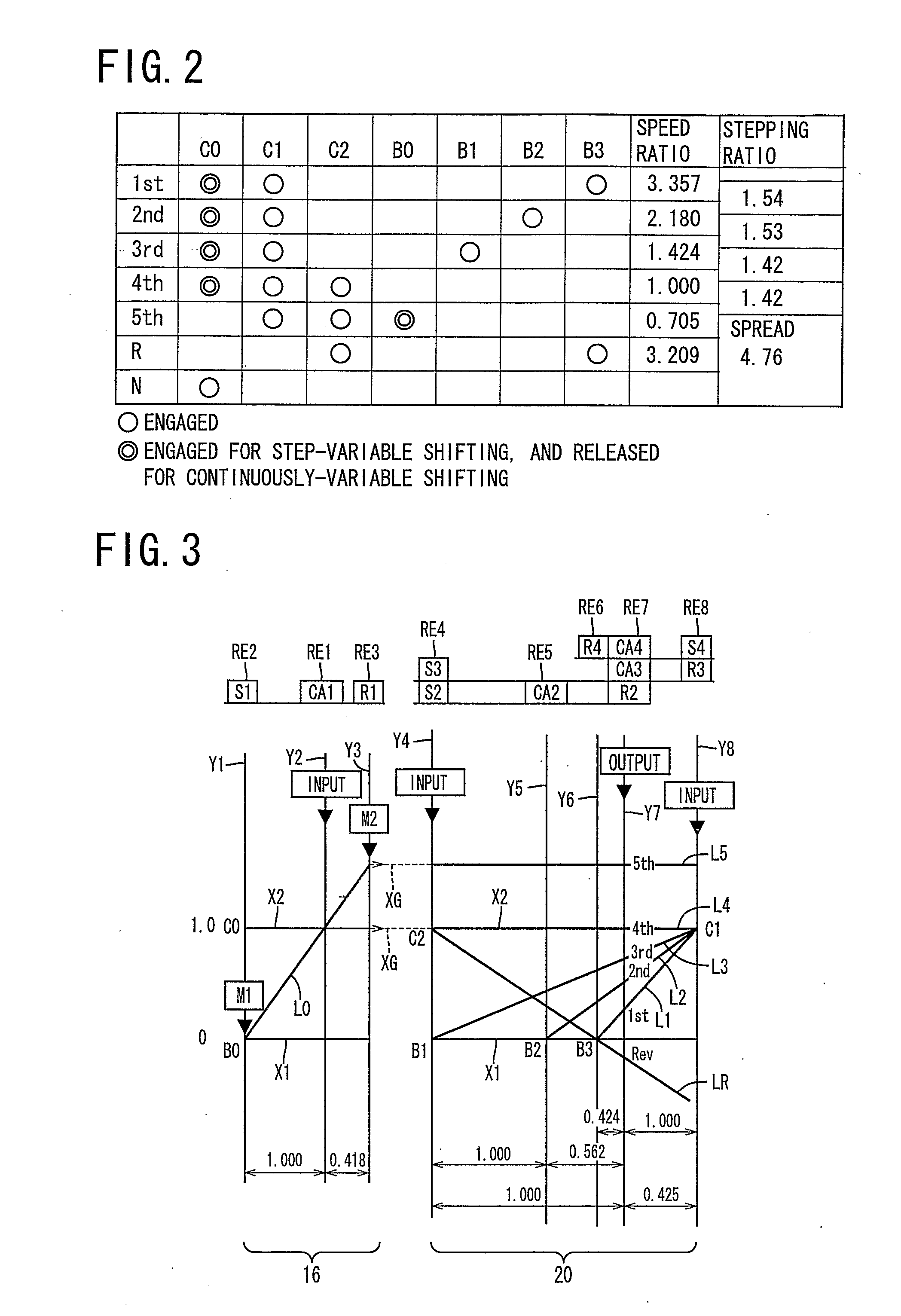

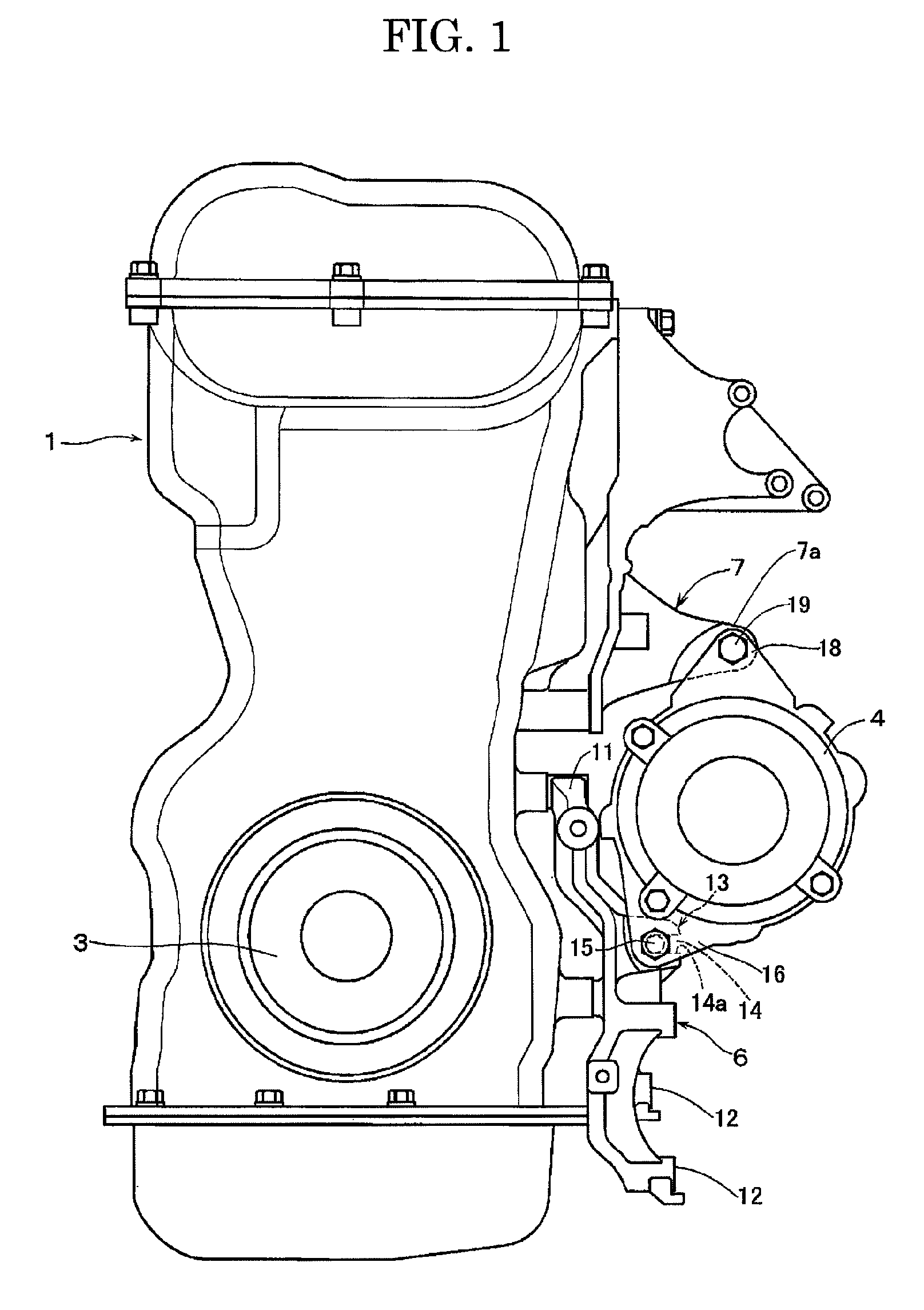

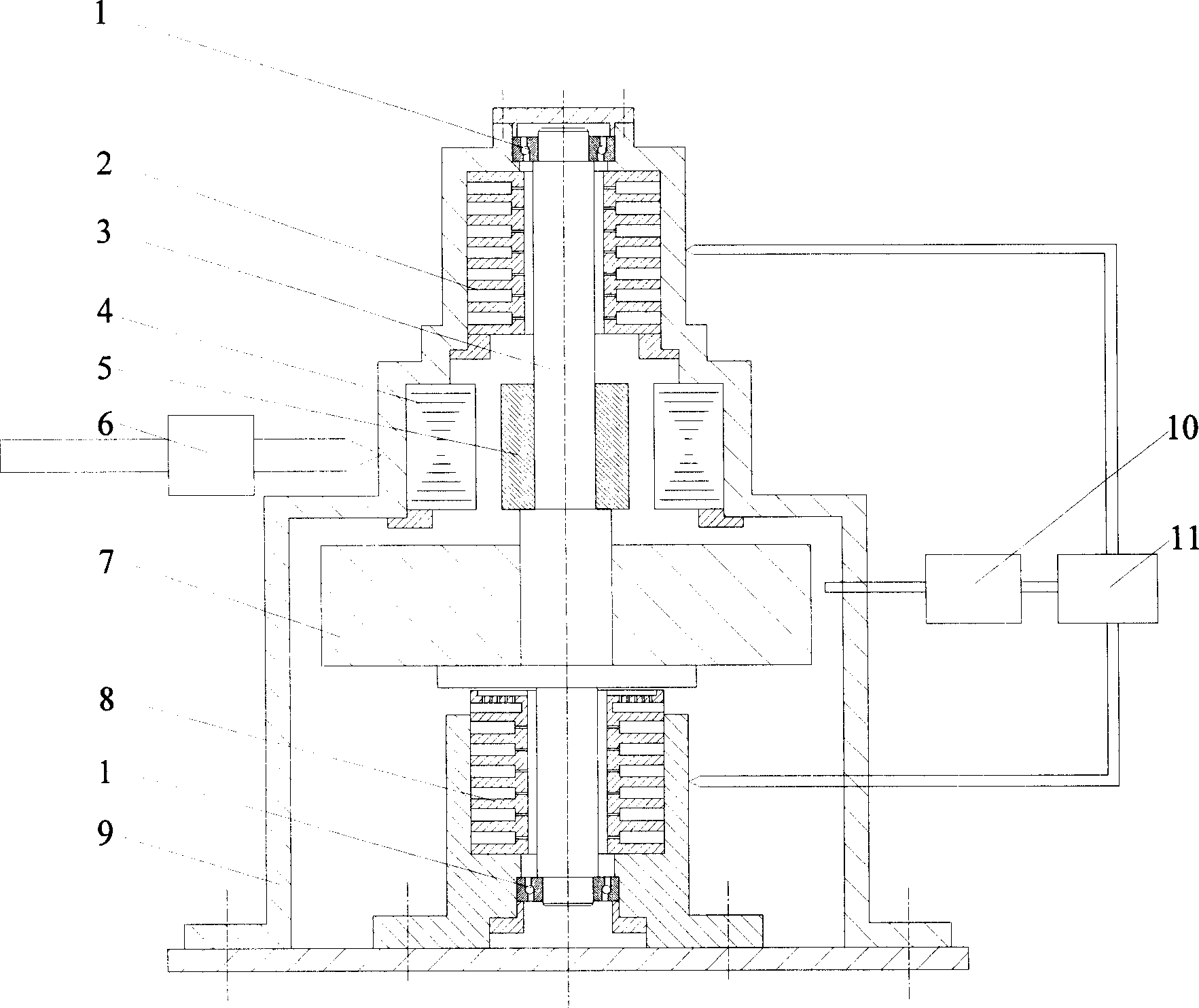

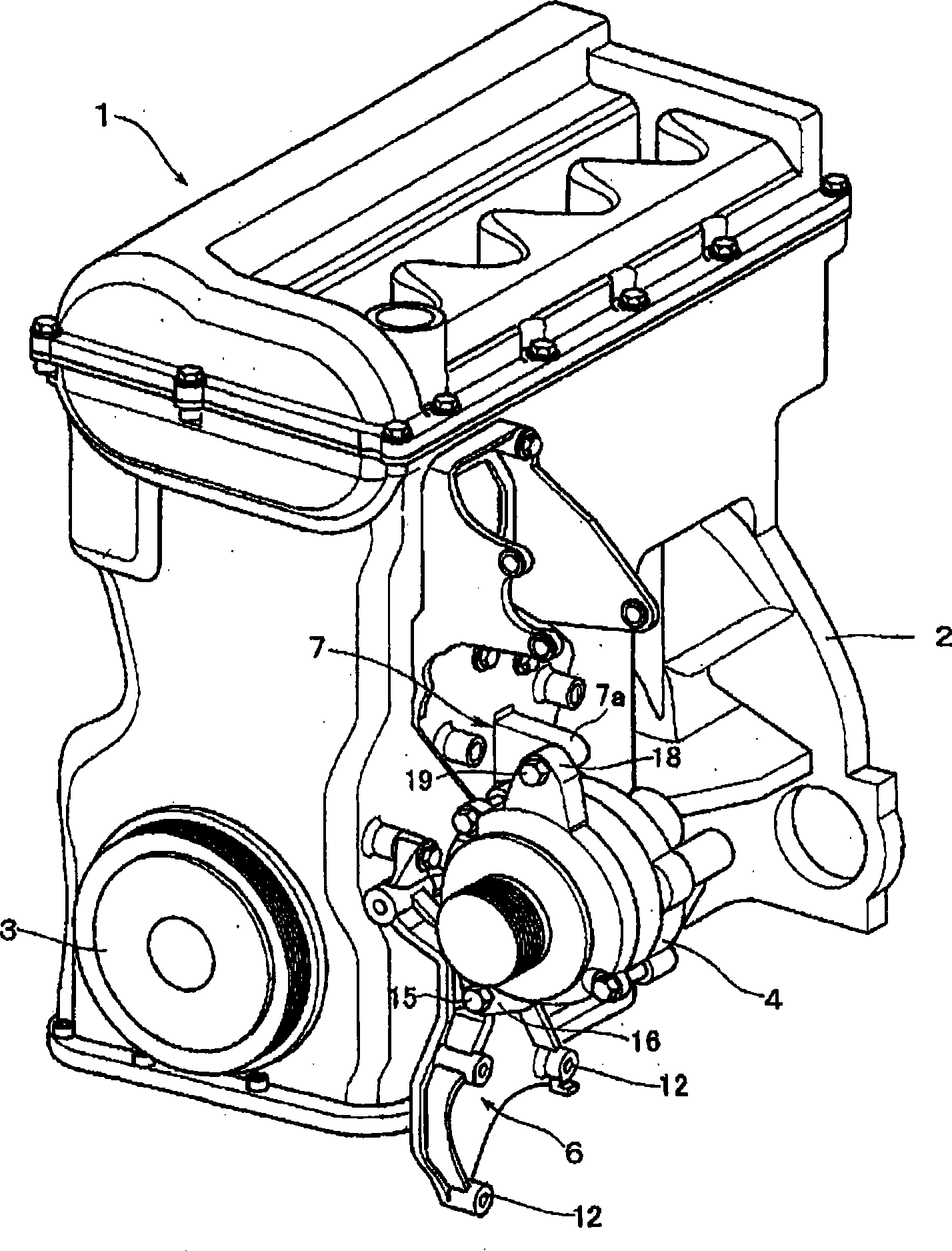

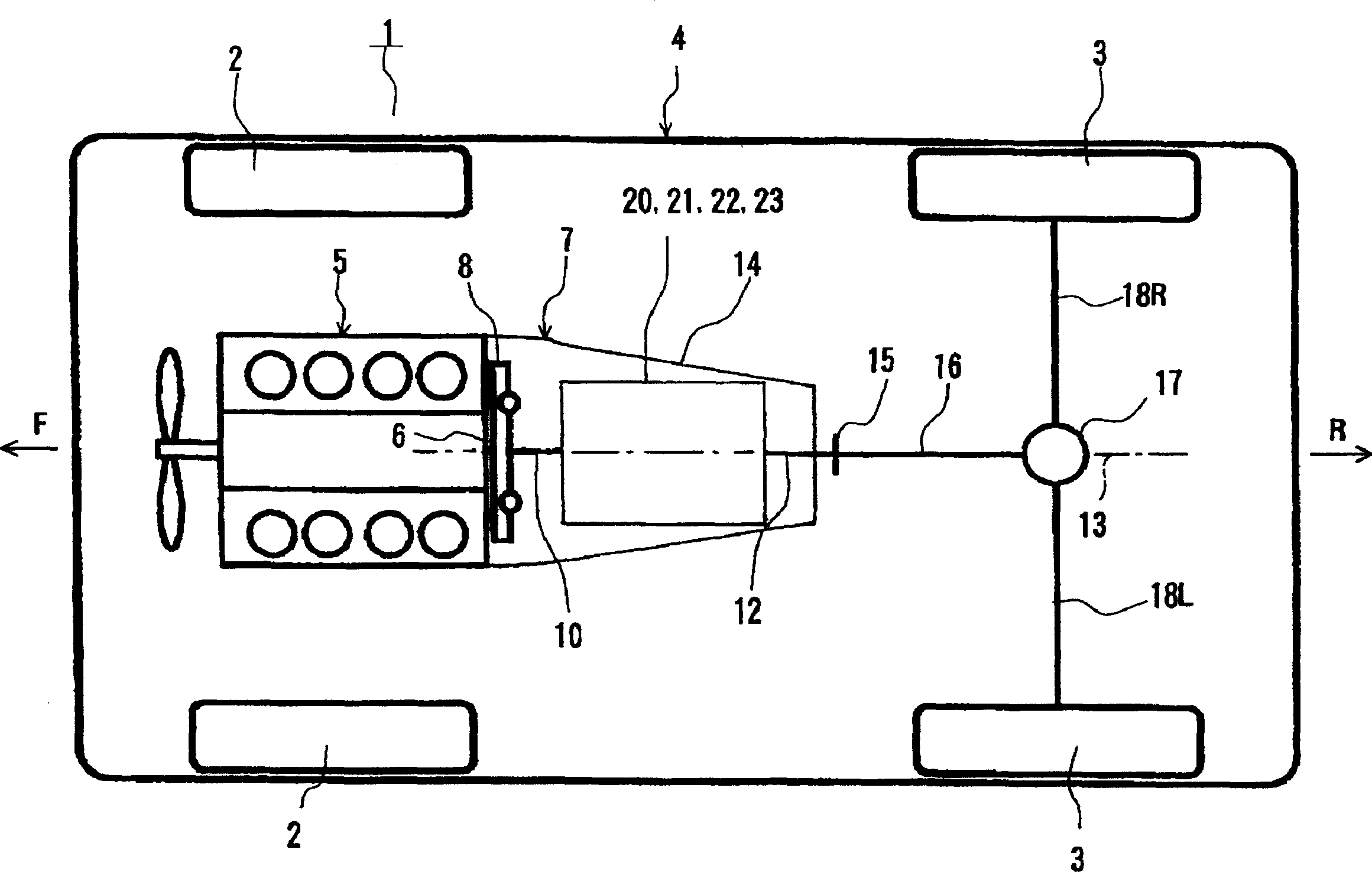

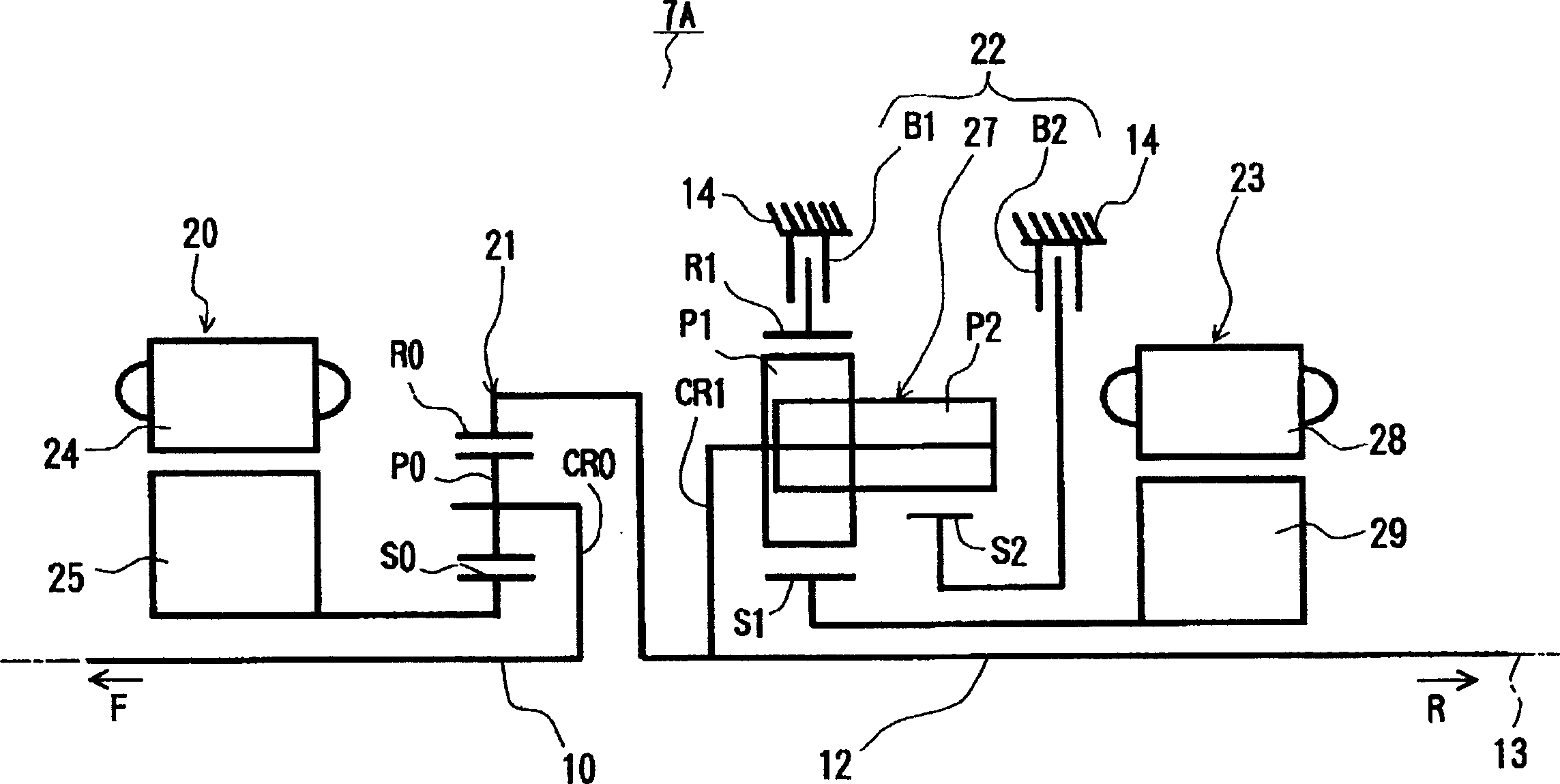

Vehicular drive system

InactiveUS7988579B2Reduce axial sizeImprove support accuracyHybrid vehiclesGearboxesControl theoryElectric motor

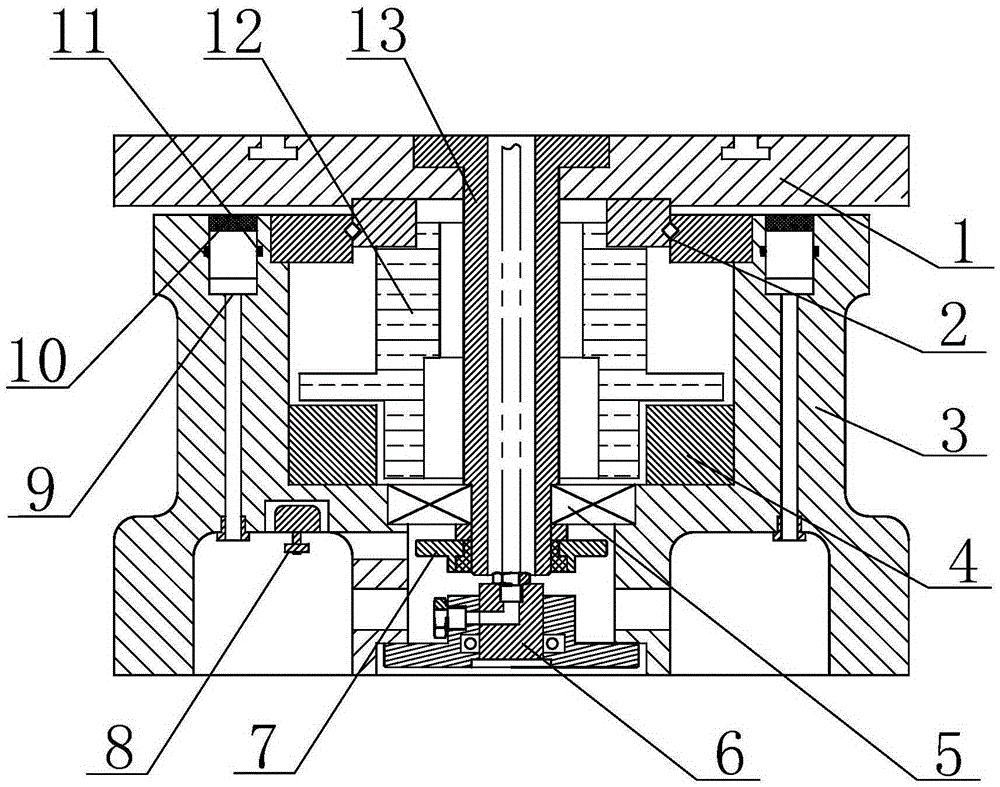

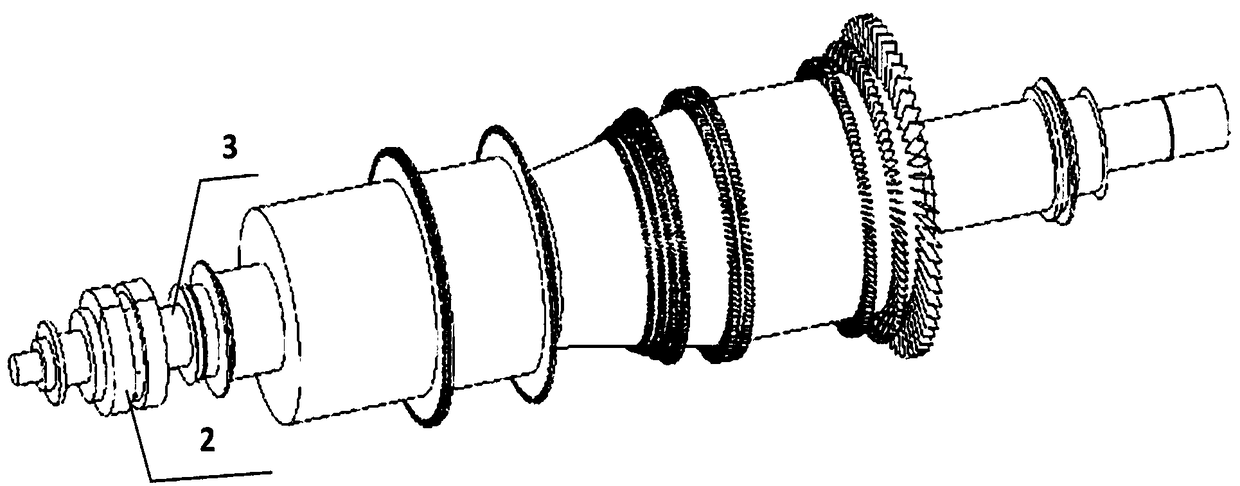

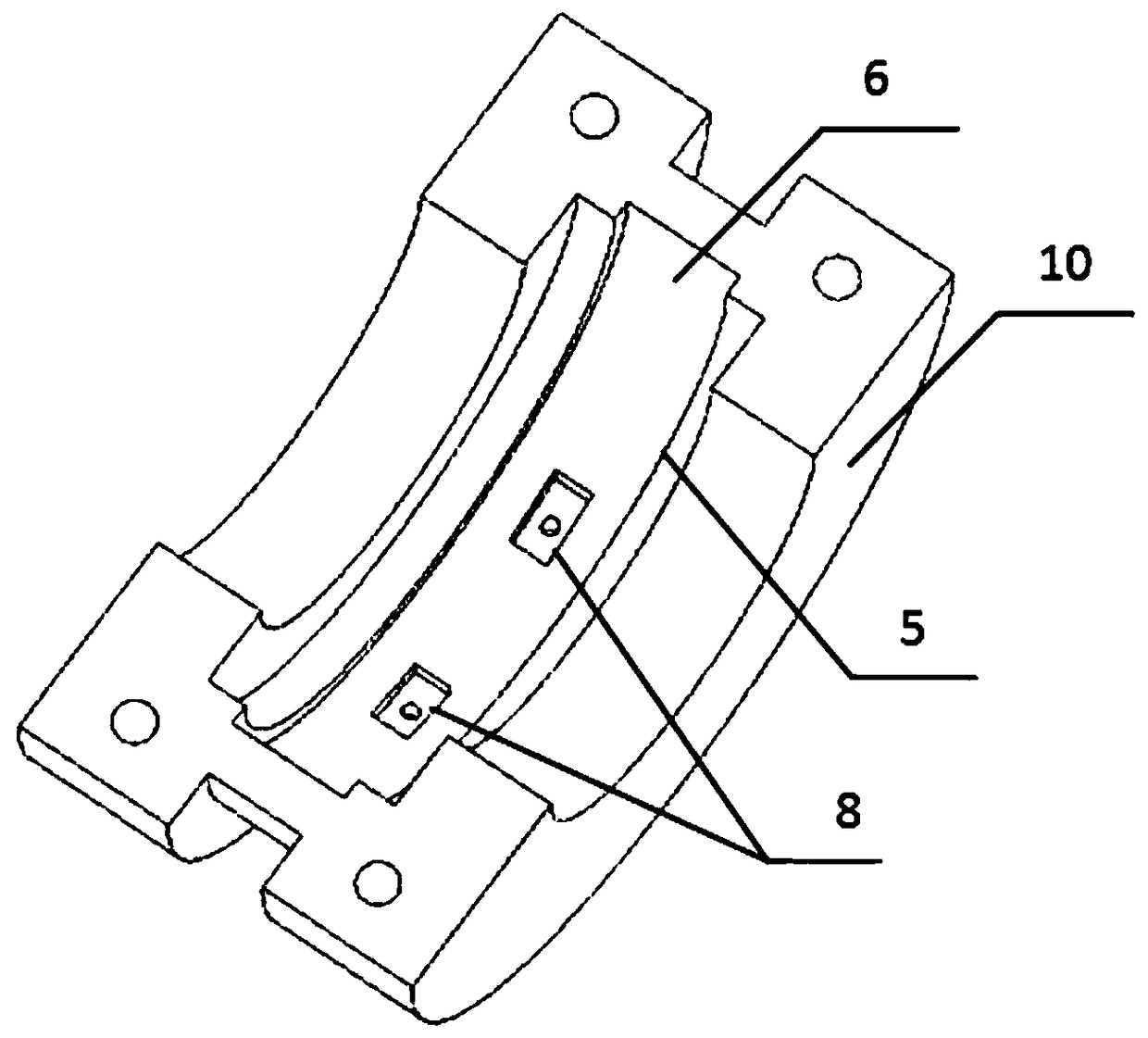

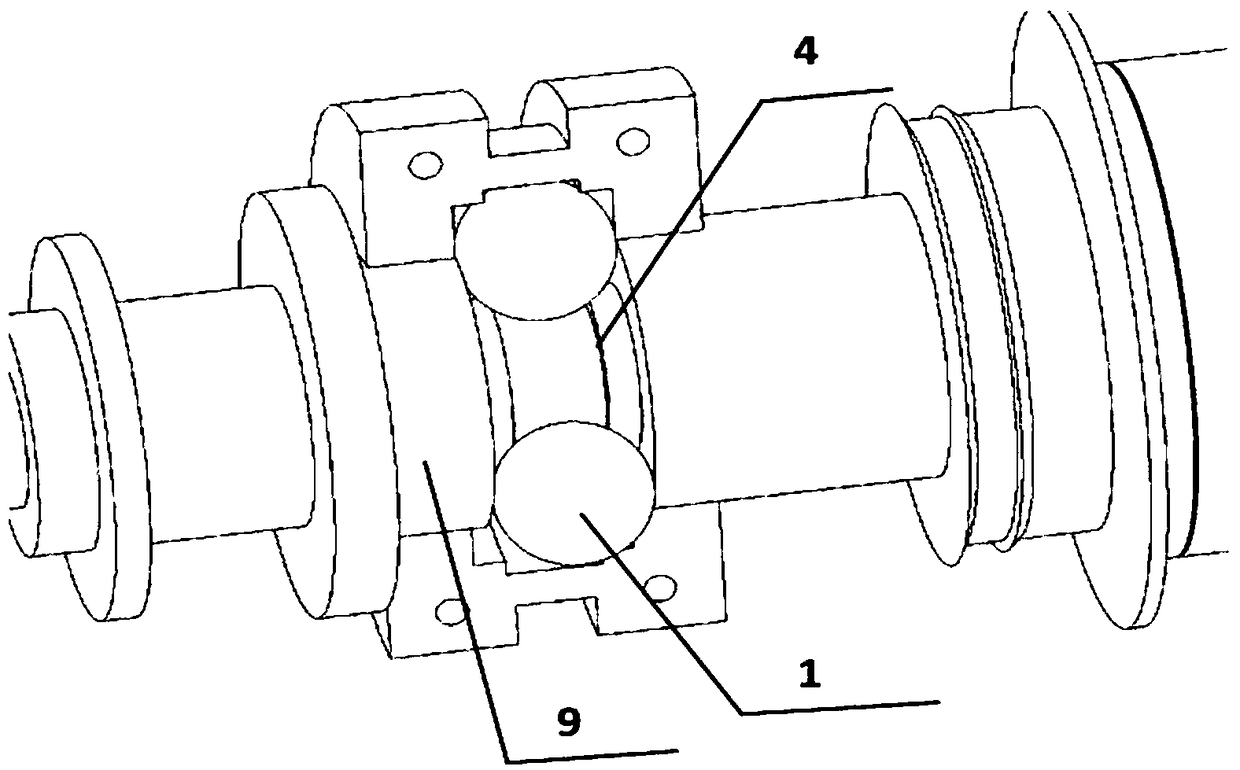

A vehicular drive system accommodated in a housing and including a first input shaft that receives a vehicle drive force generated by a vehicle drive power source, and a differential mechanism operable to distribute the vehicle drive force received from the first input shaft to a first electric motor and a second input shaft. The first and second input shafts are disposed coaxially with a first axis such that the second input shaft is disposed downstream of the first input shaft. The first input shaft is rotatably supported by a first support portion provided on the housing and an axial end portion of the second input shaft, and the second input shaft is rotatably supported by a third support portion and a fourth support portion that are provided on the housing.

Owner:TOYOTA JIDOSHA KK

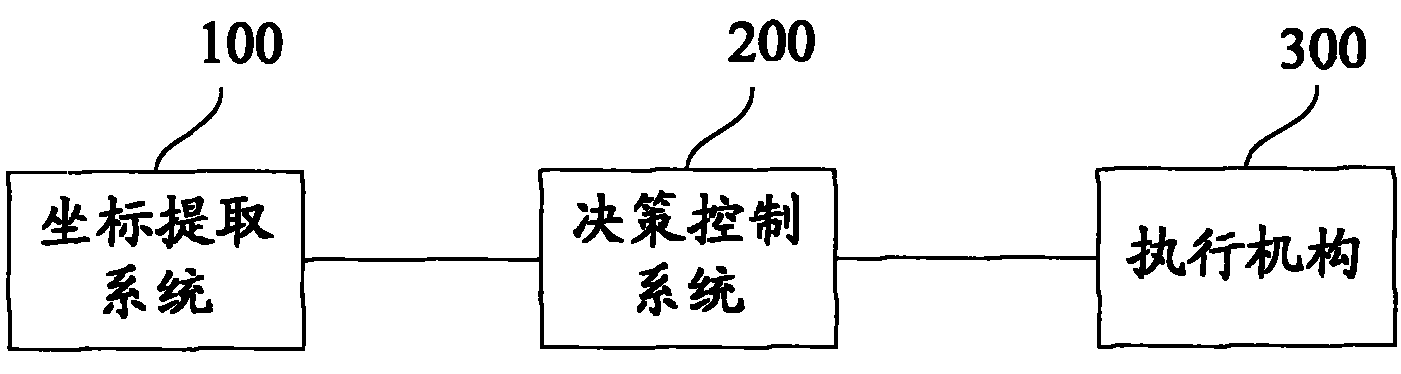

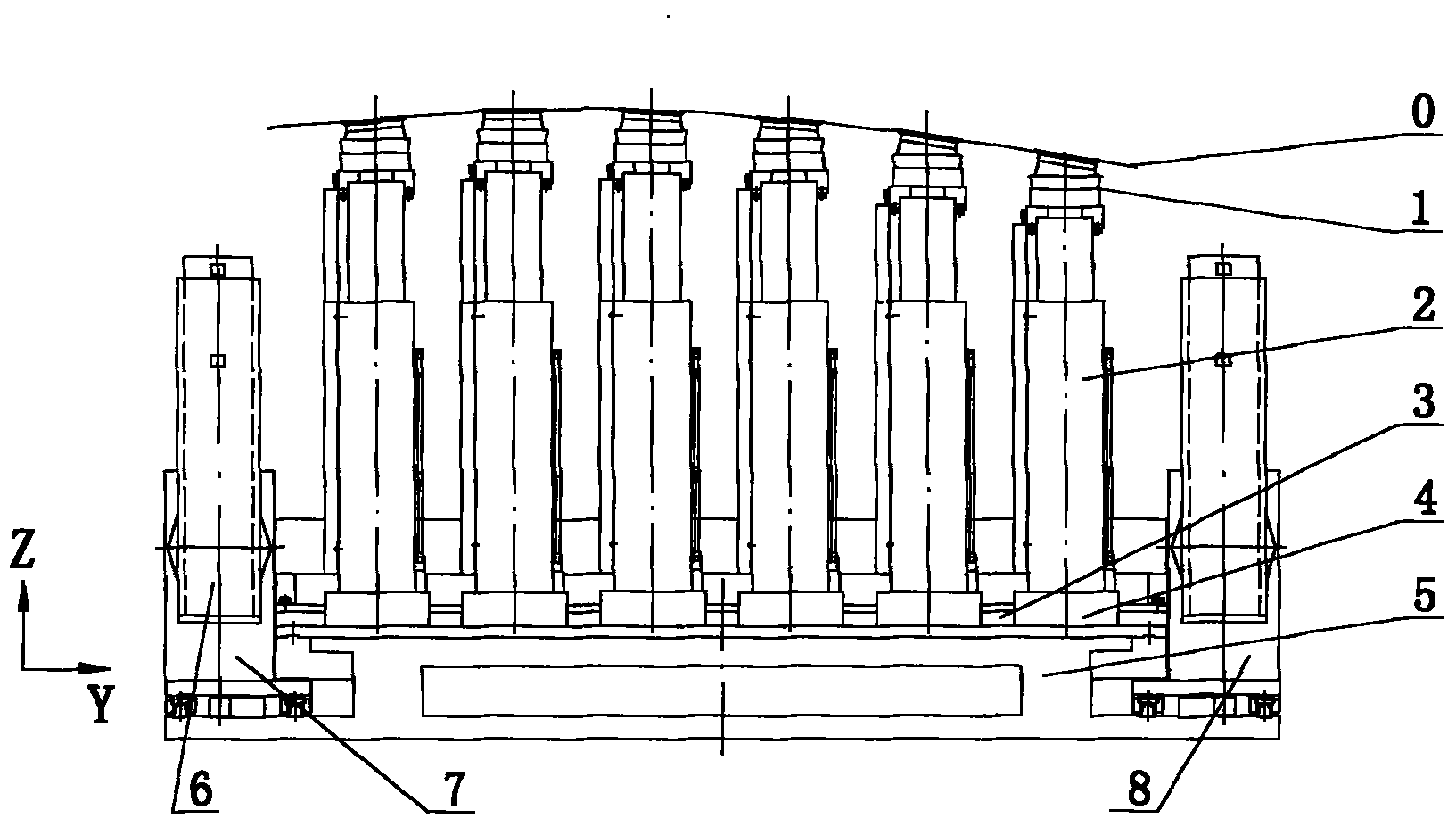

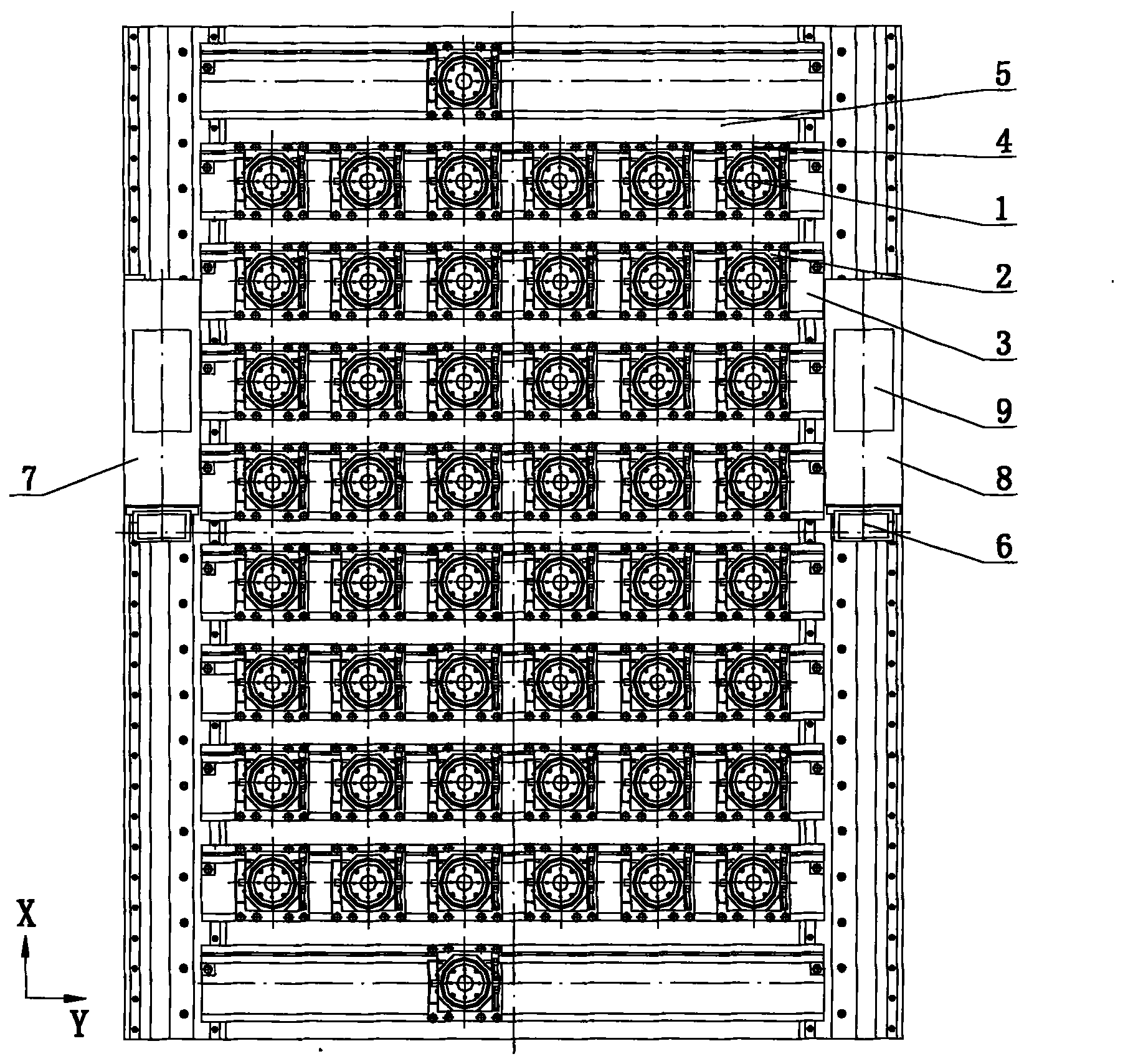

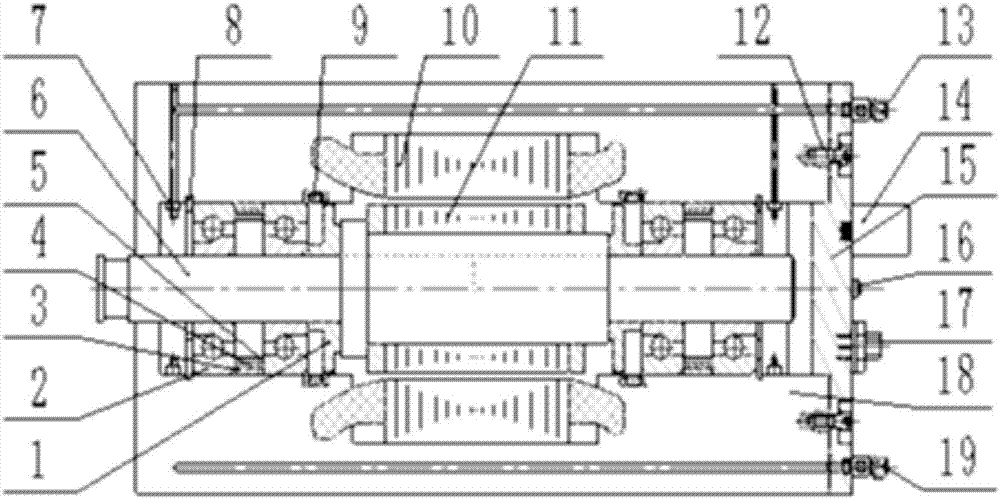

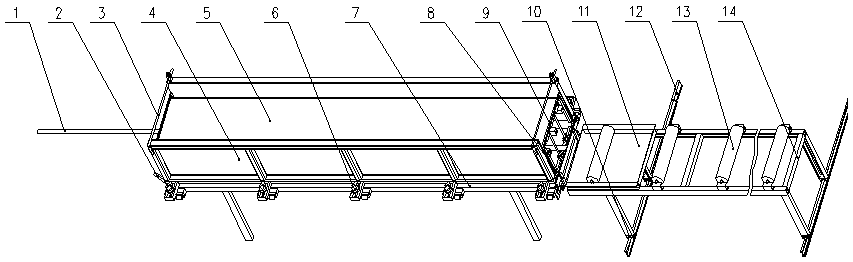

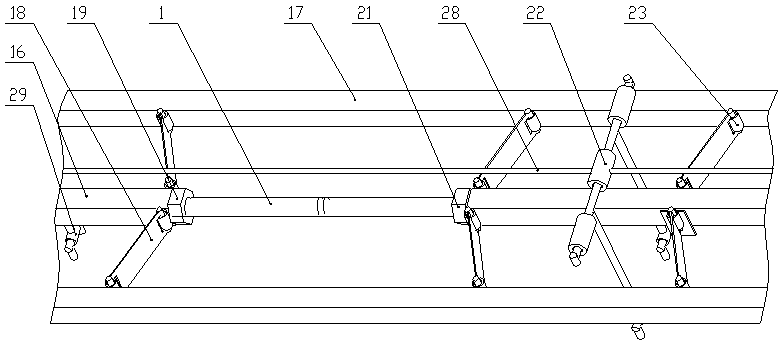

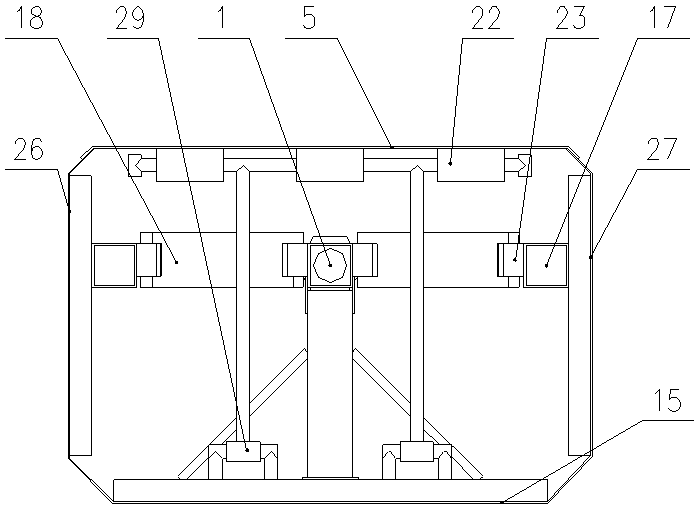

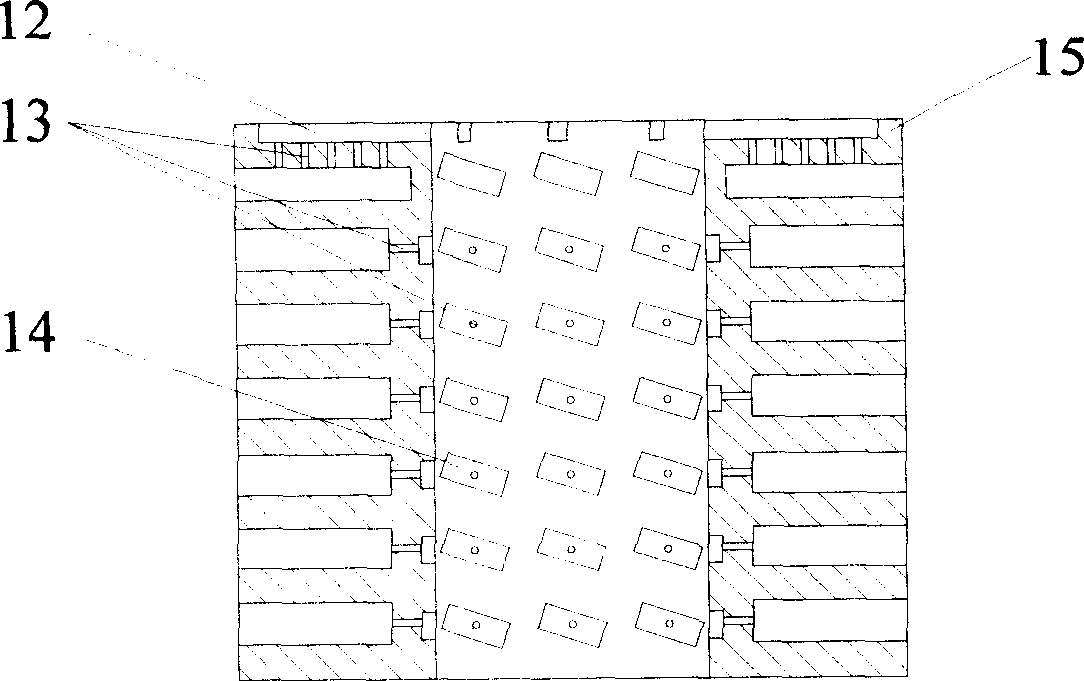

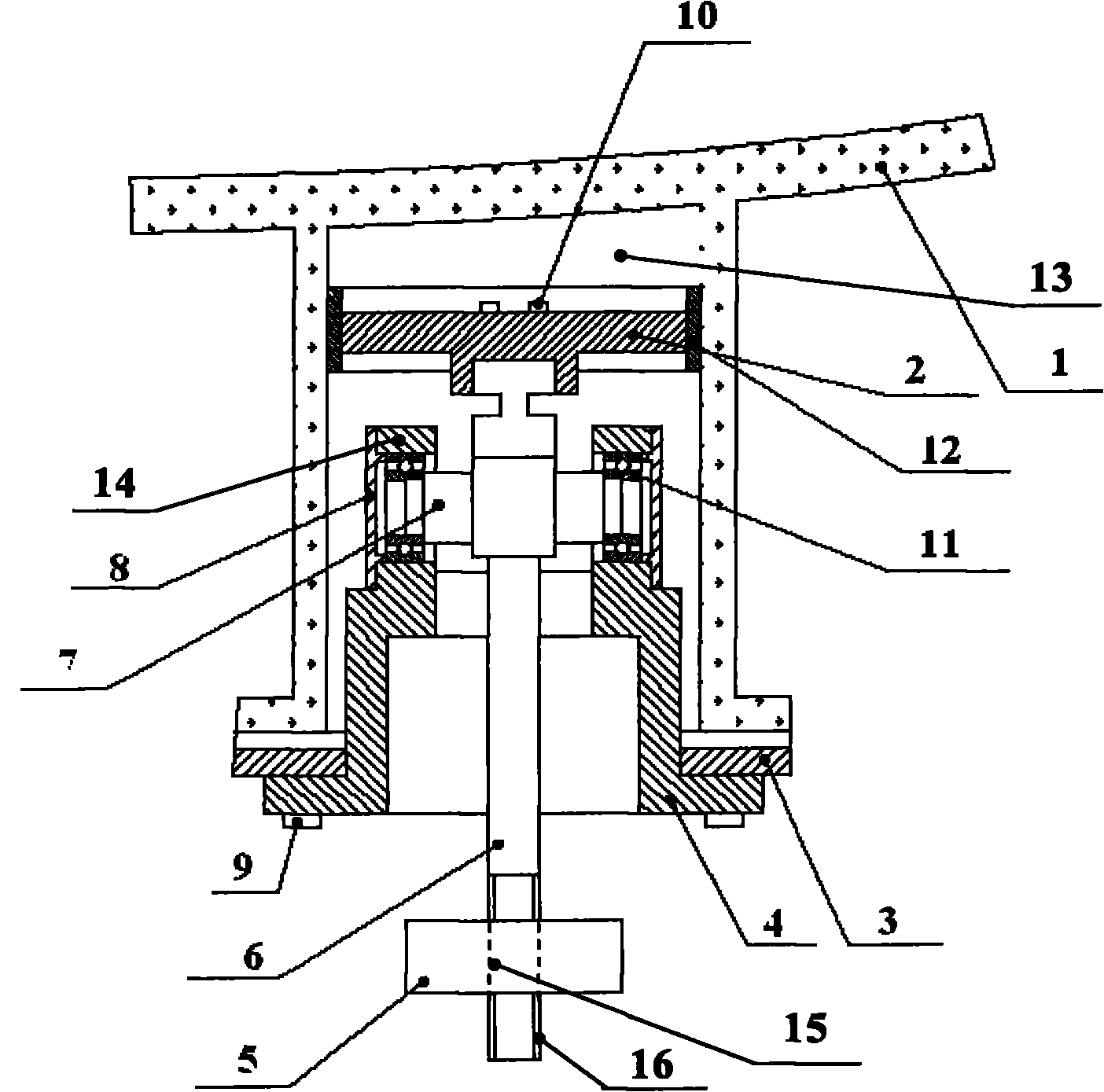

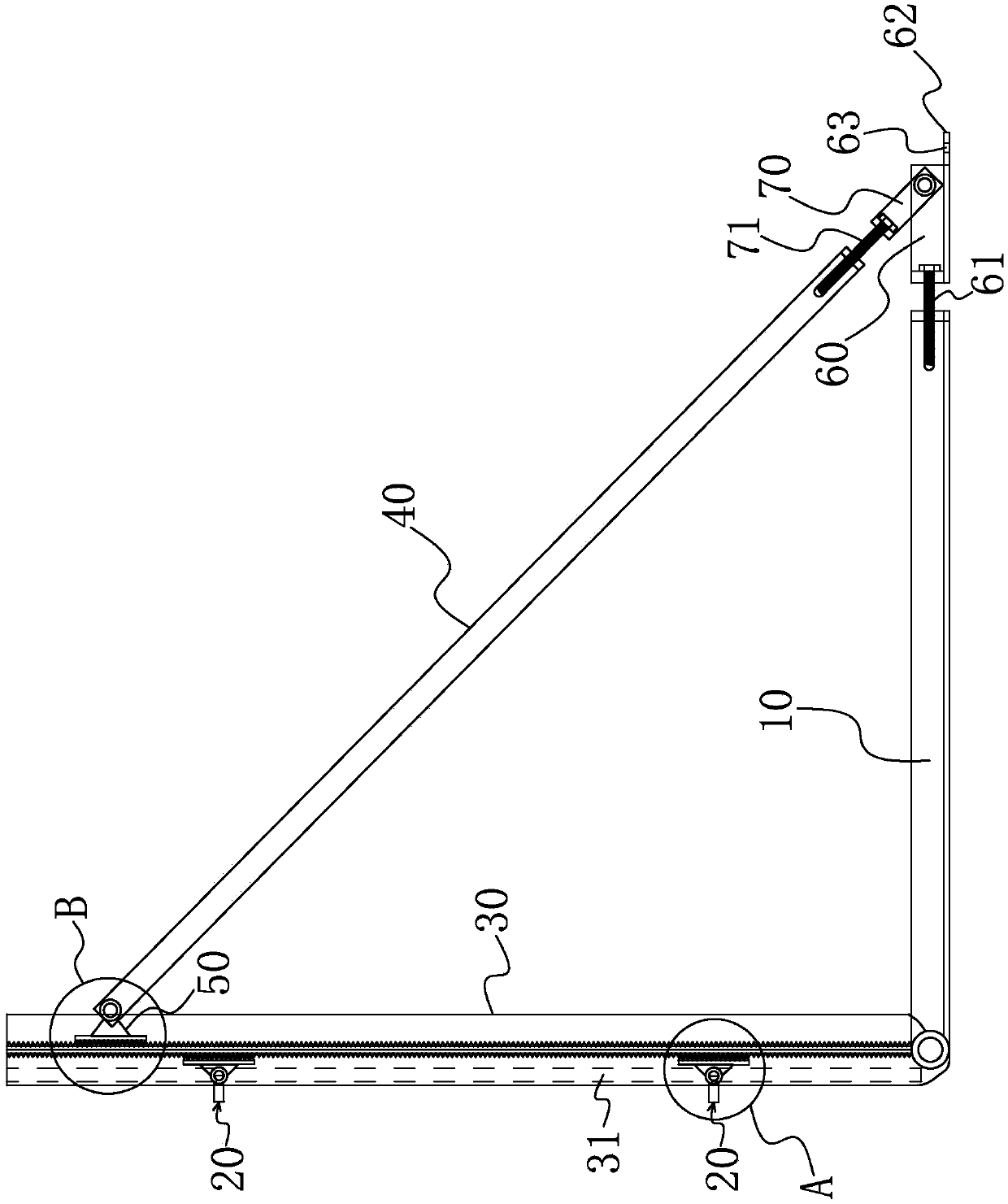

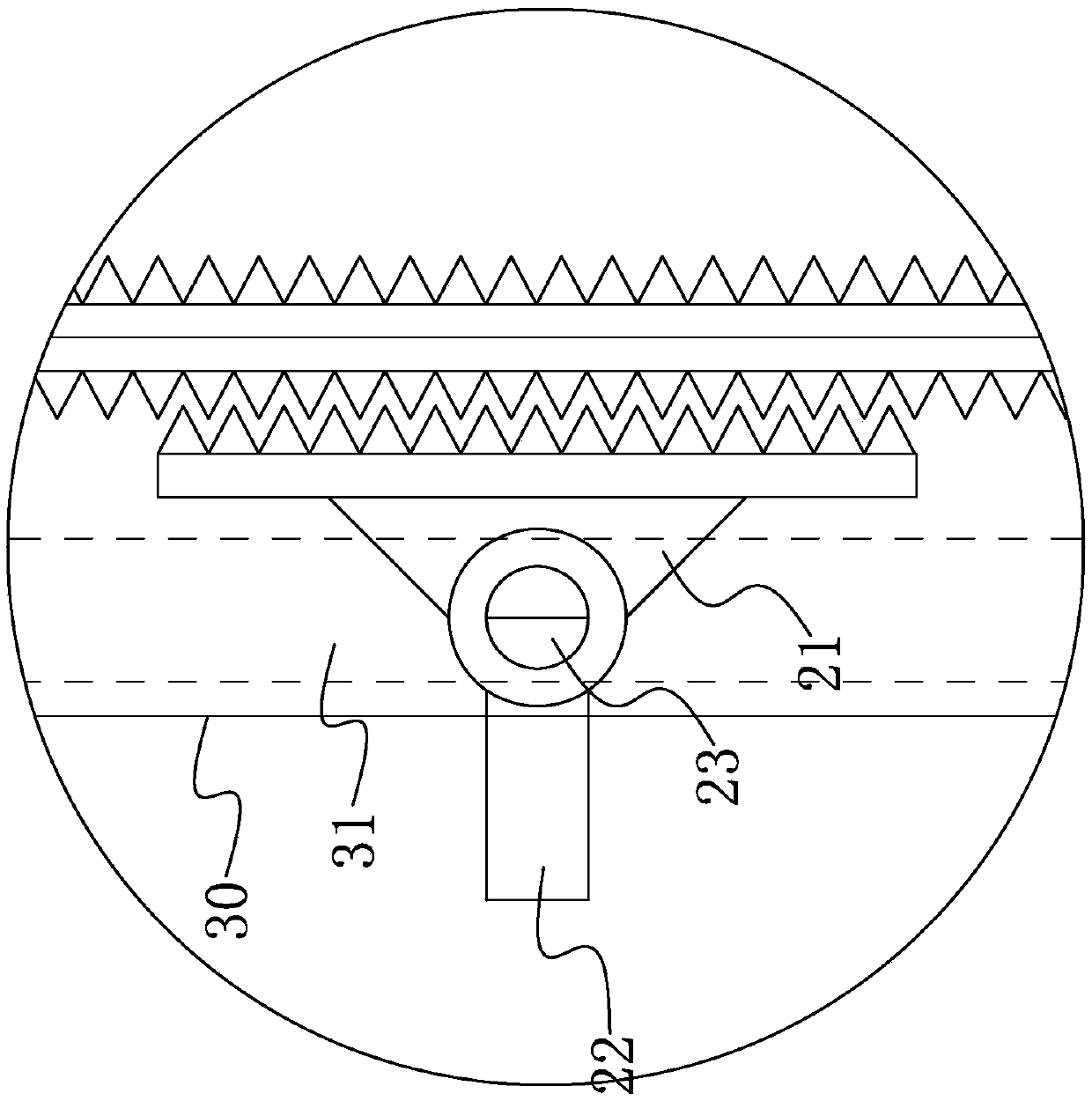

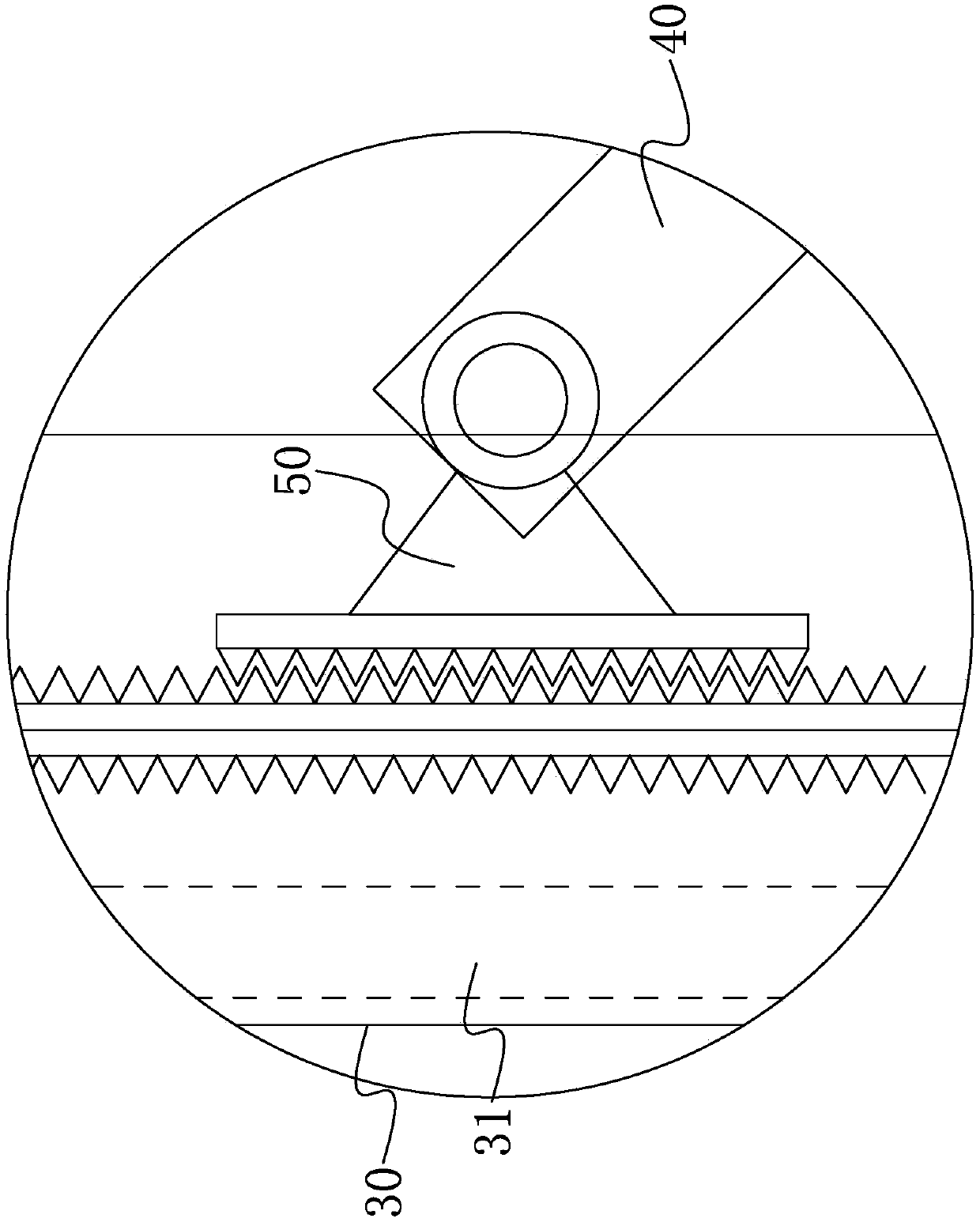

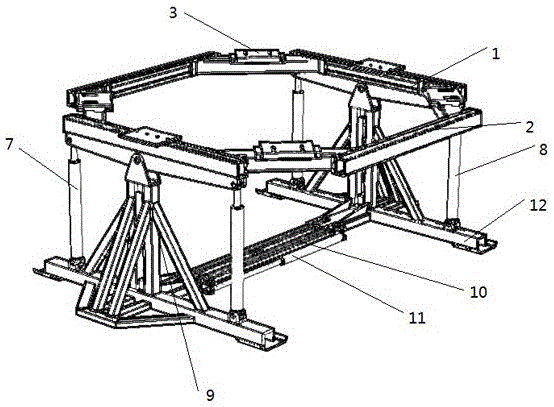

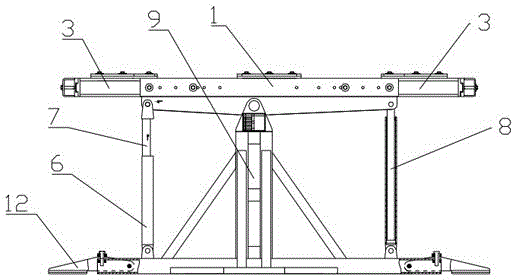

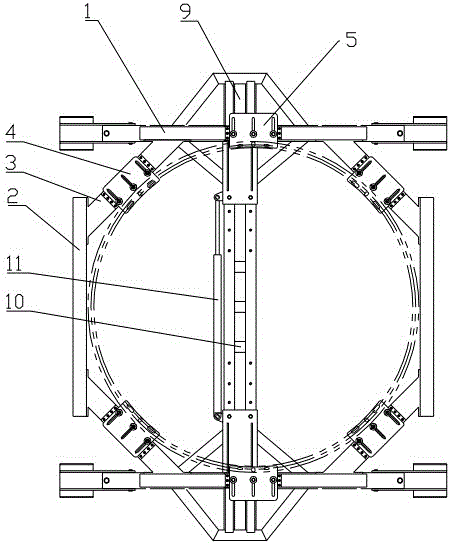

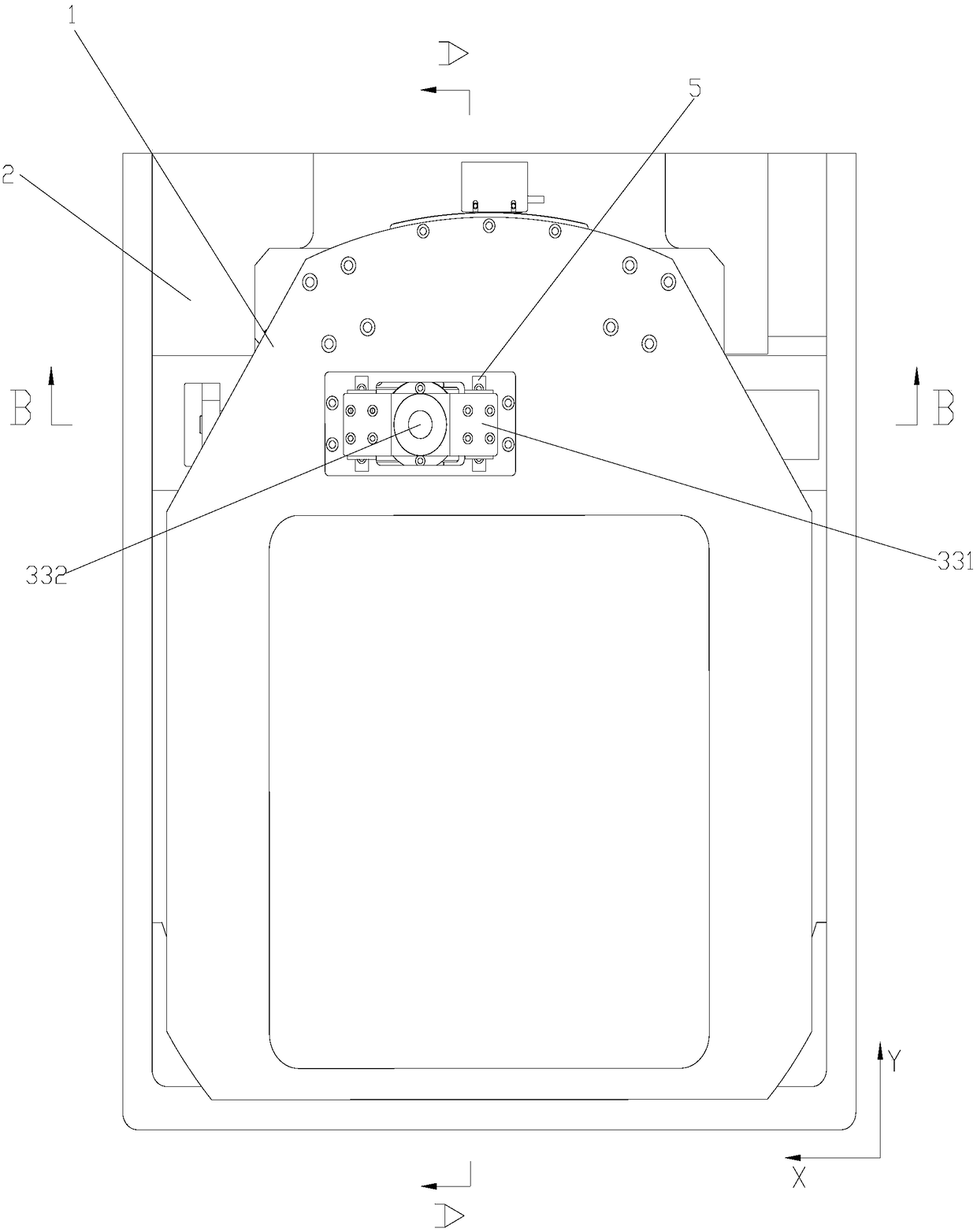

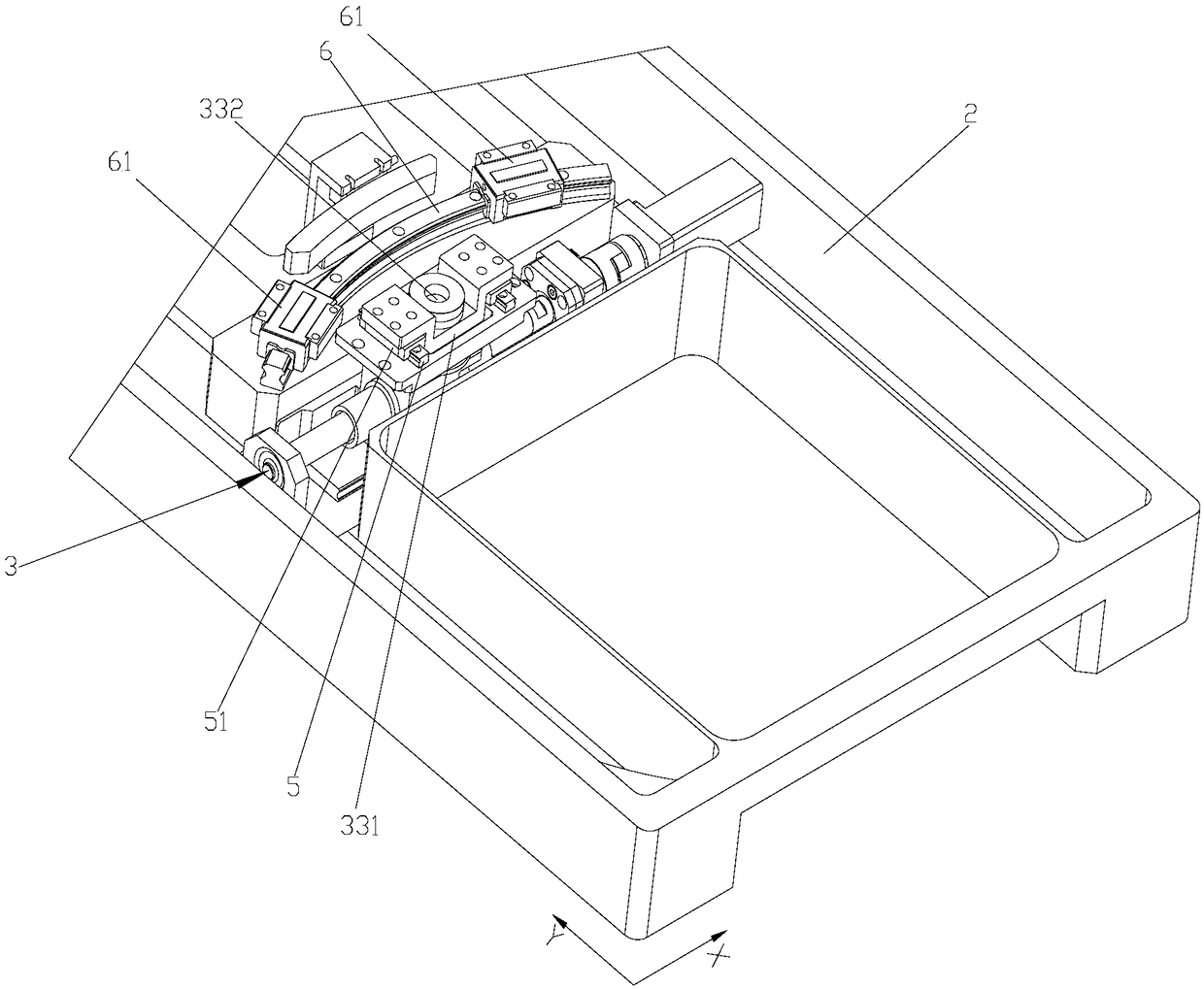

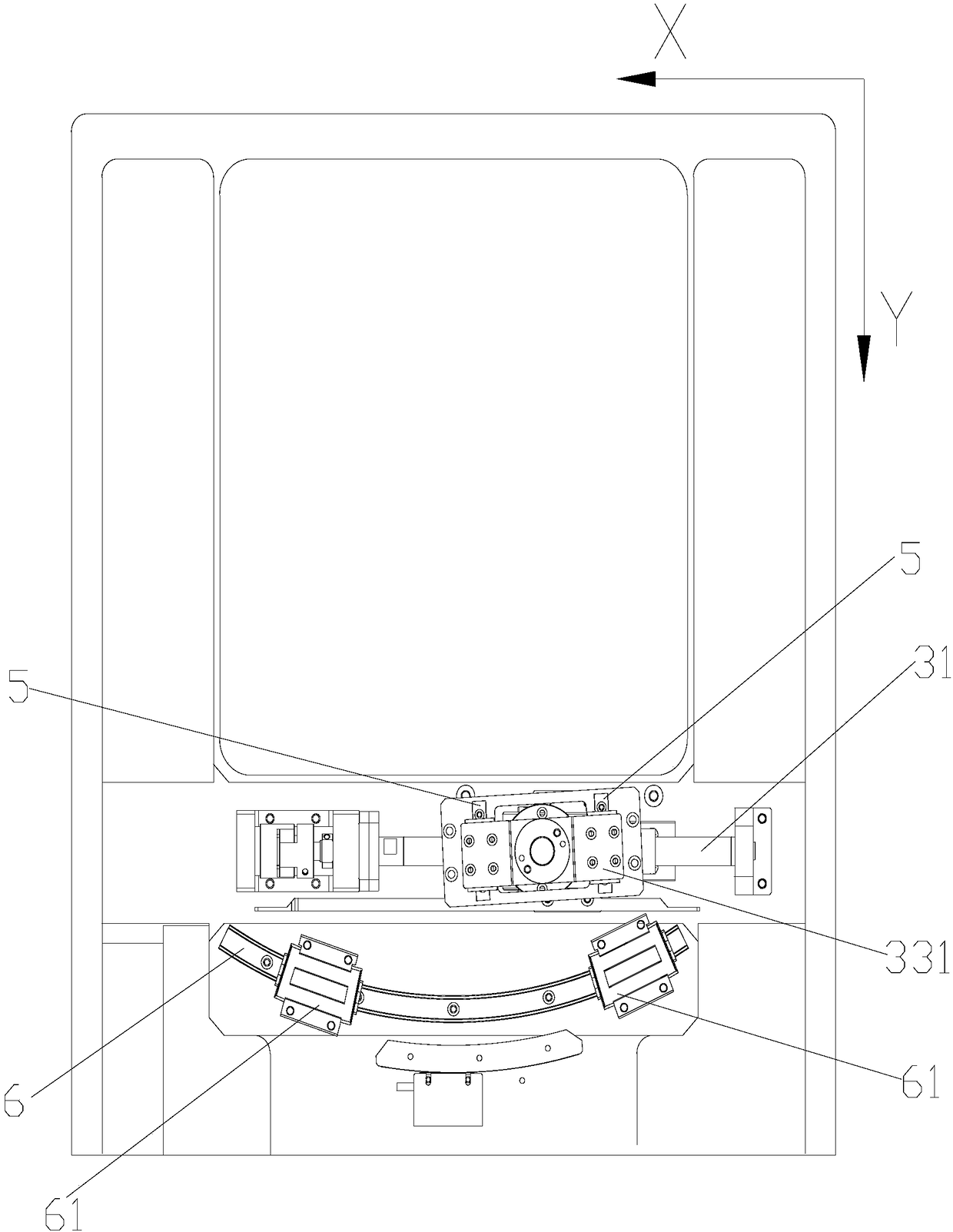

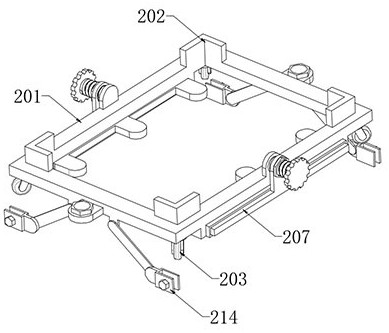

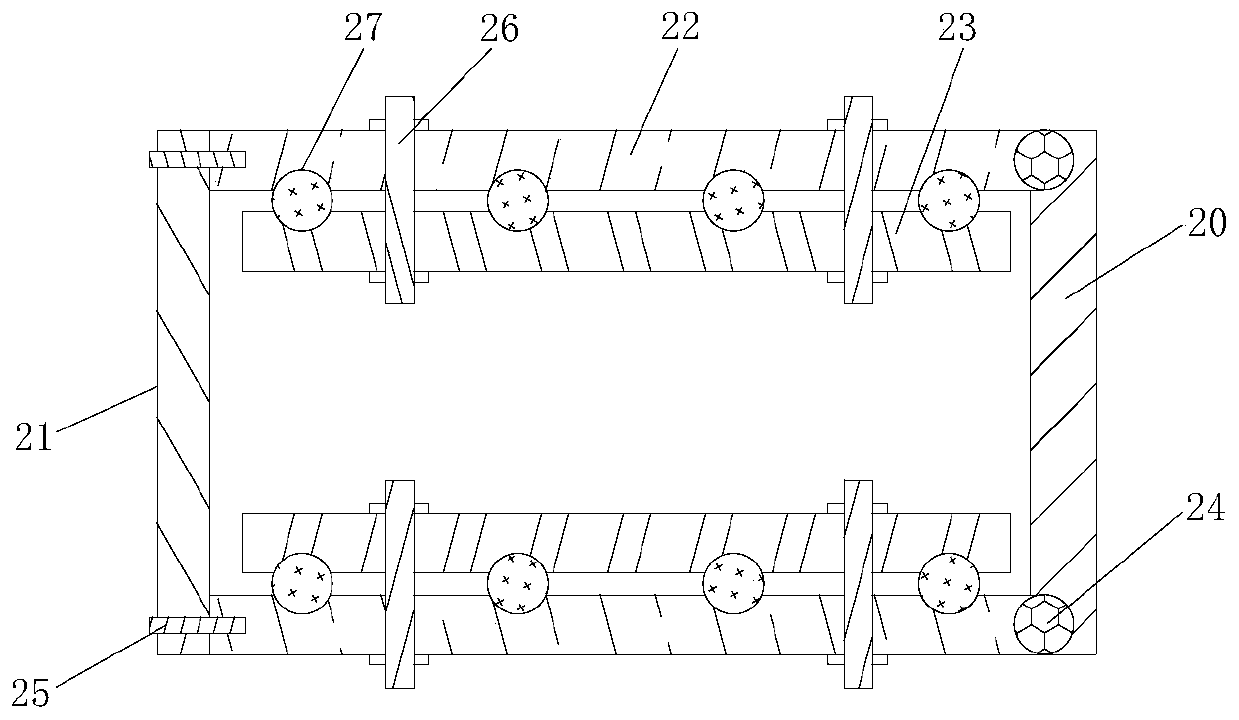

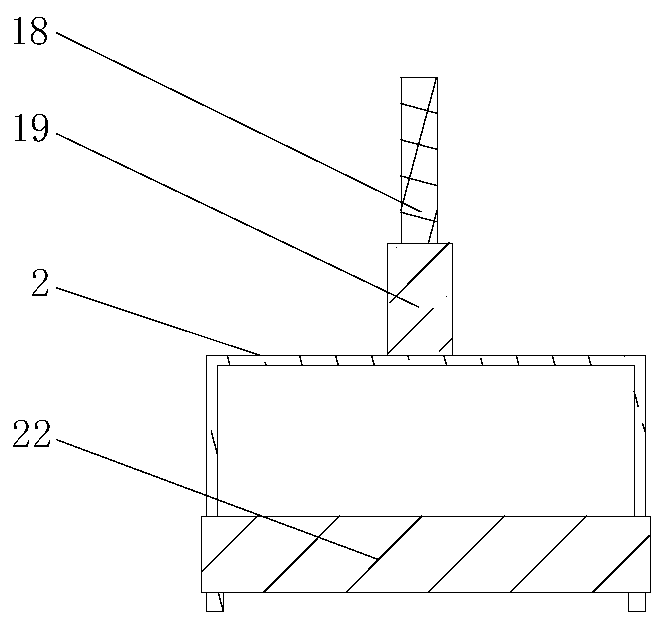

Flexible tool equipment intelligent control system of aircraft

InactiveCN101804867ASimple mechanical structureReduce the burden onAircraft assemblyNumerical controlDecision controlMovement control

The invention provides a flexible tool equipment intelligent control system of an aircraft, which comprises a coordinate extracting system, a decision control system and an executing mechanism, wherein the coordinate extracting system is used for carrying out curve digital modeling on a workpiece to be processed, extracting the support point coordinate information of the workpiecce and generatingand transmitting a workpiece coordinate information file to the decision control system; and the decision control system is used for planning and deciding the action of the executing mechanism according to the workpiece coordinate information file and generating and transmitting a corresponding control command to the executing mechanism. The invention provides a flexible tool equipment intelligent control system for realizing clamping and positioning in the processing of a large curve thin wall part of an aircraft, carries out calculation and control by adopting a high-performance industrial control computer as a core and realizes the synergy movement control on double robots by an intelligent control main board and the reasonable and uniform distribution of all support units on a flexible tool equipment machine tool by the moving operation on all the support units on the flexible tool equipment.

Owner:TSINGHUA UNIV

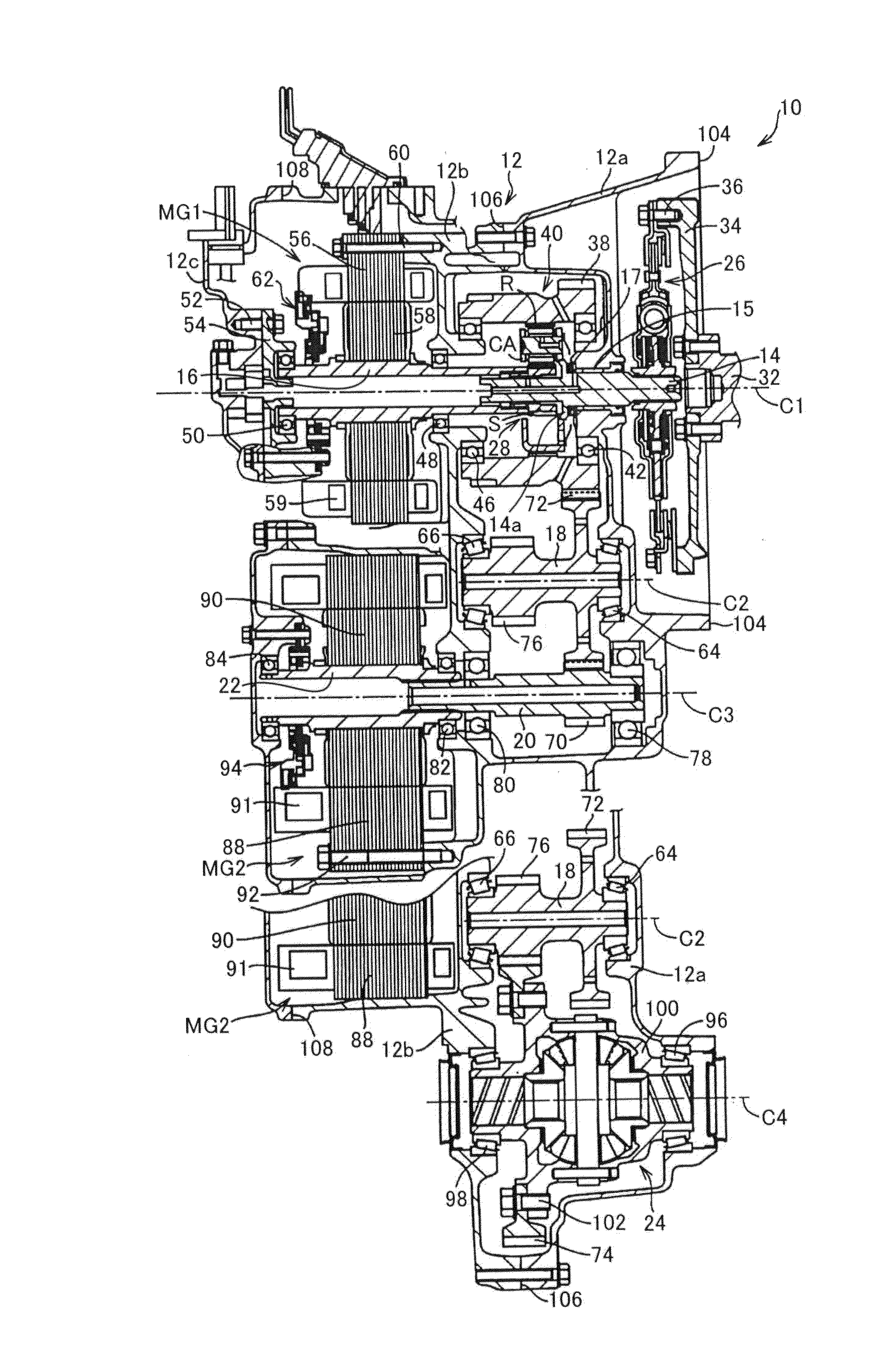

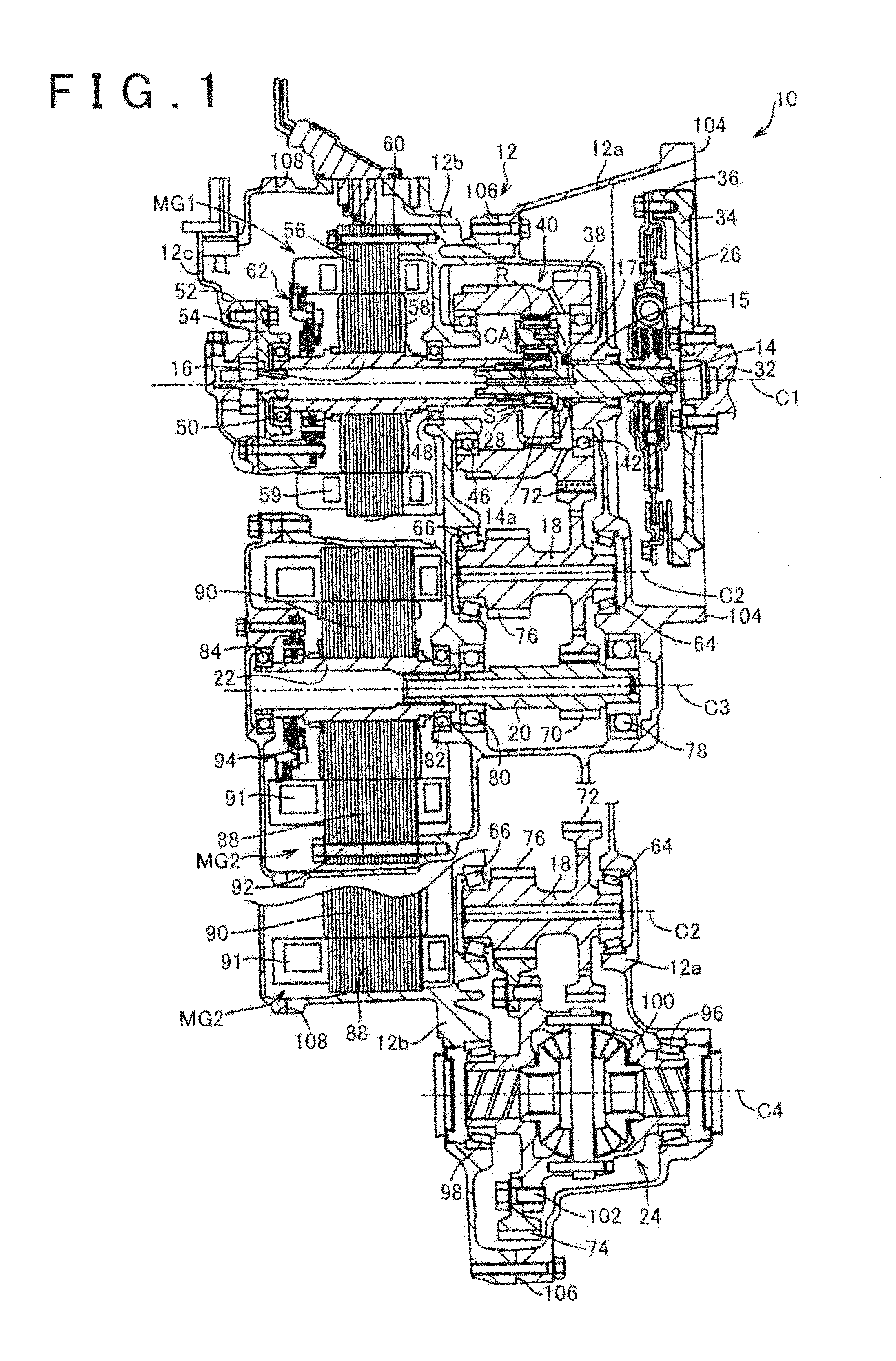

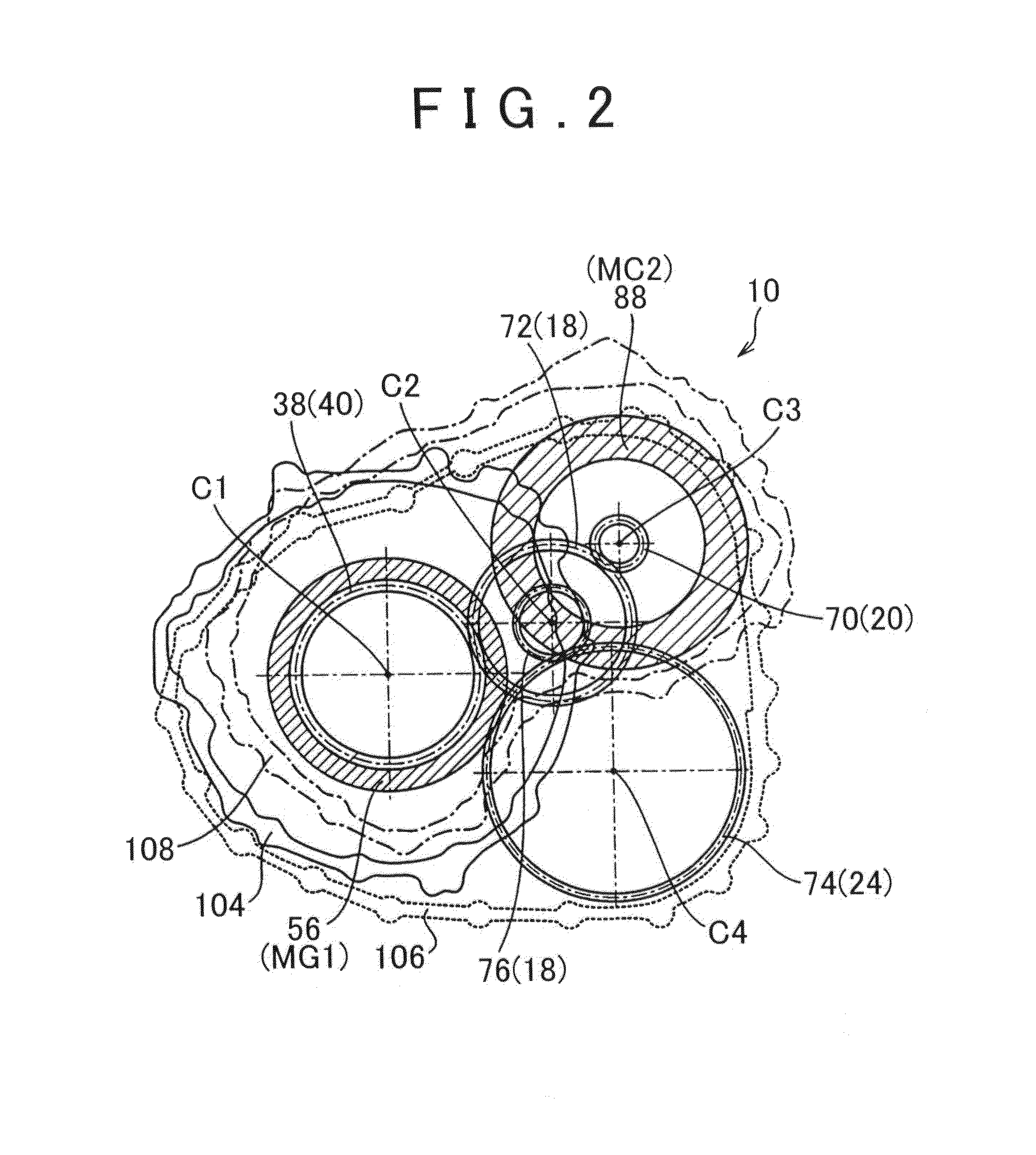

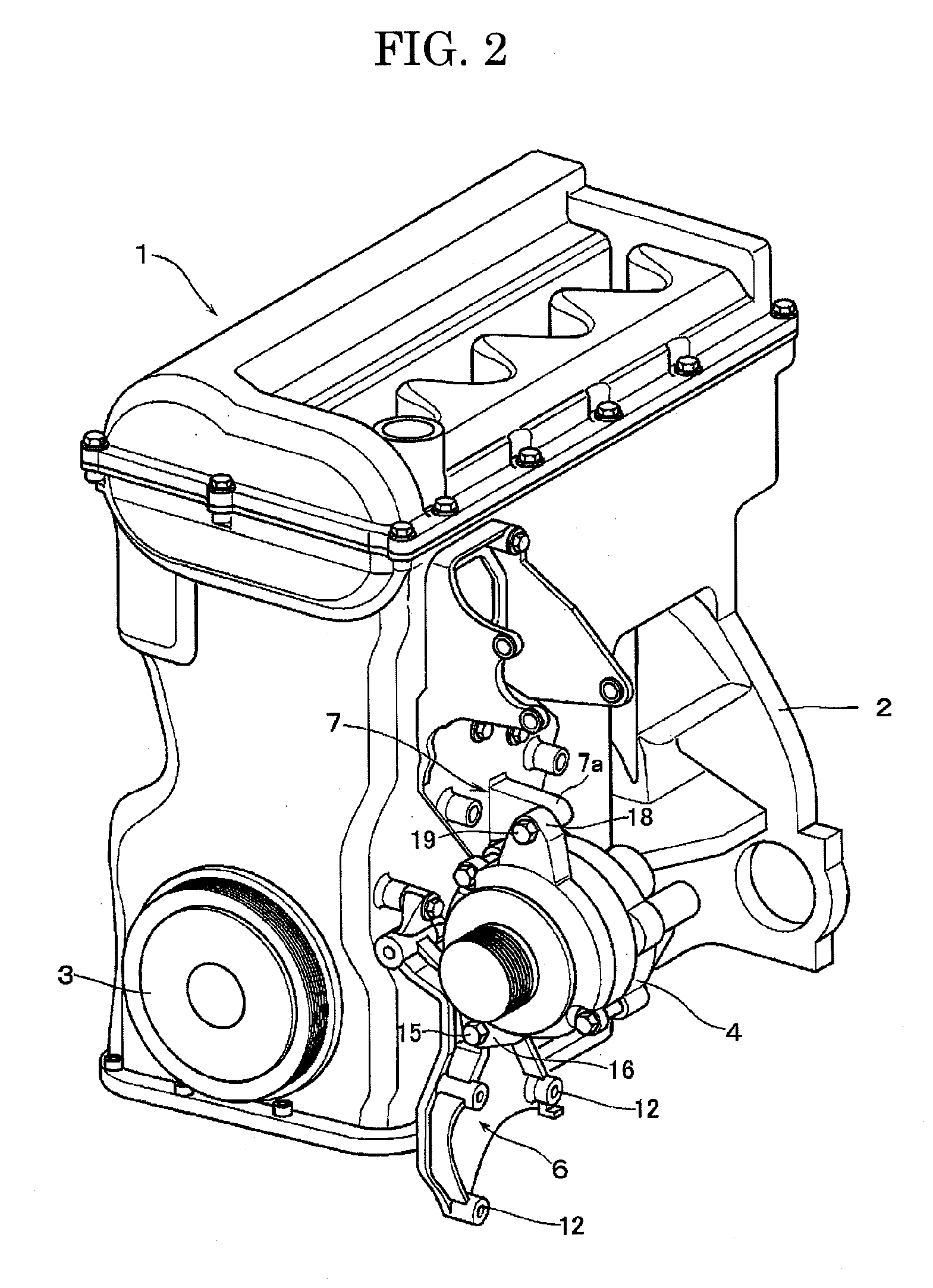

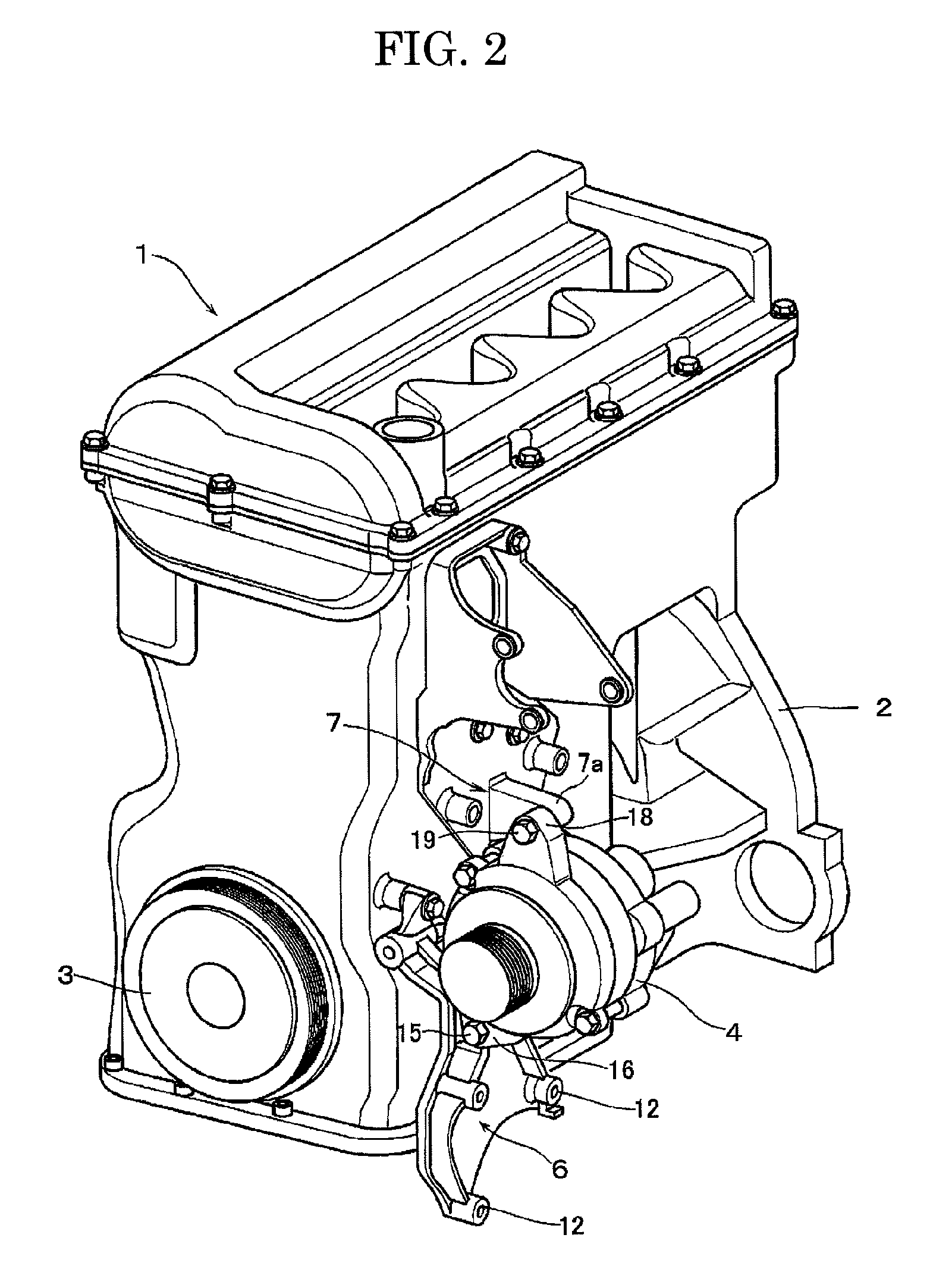

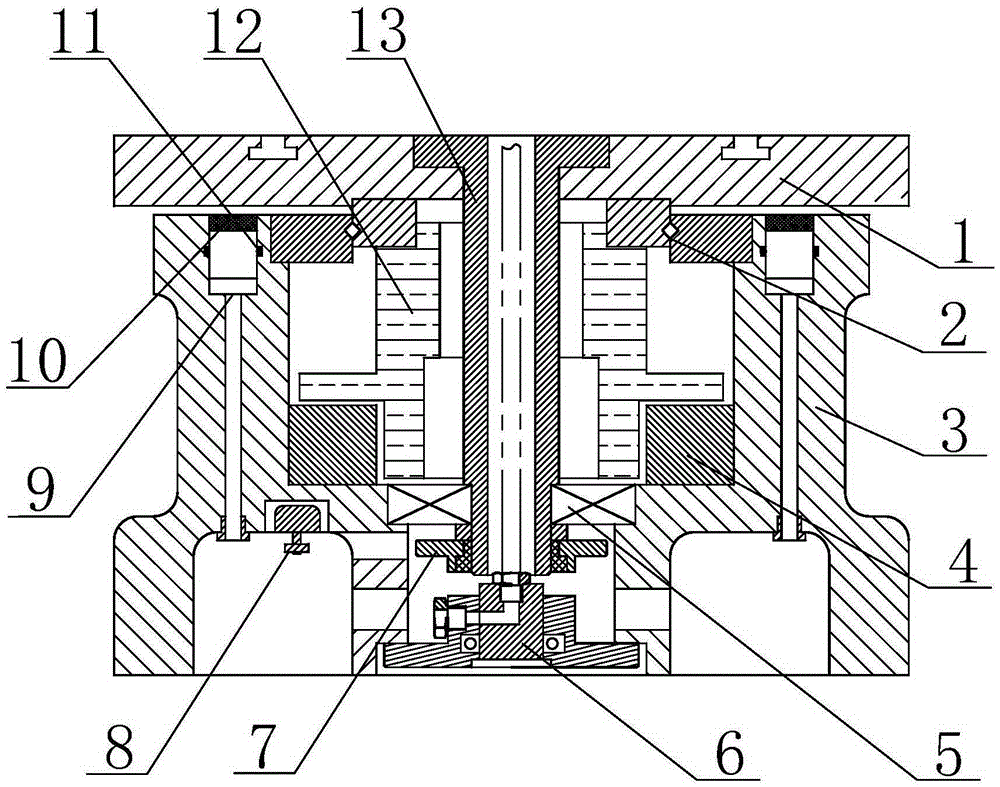

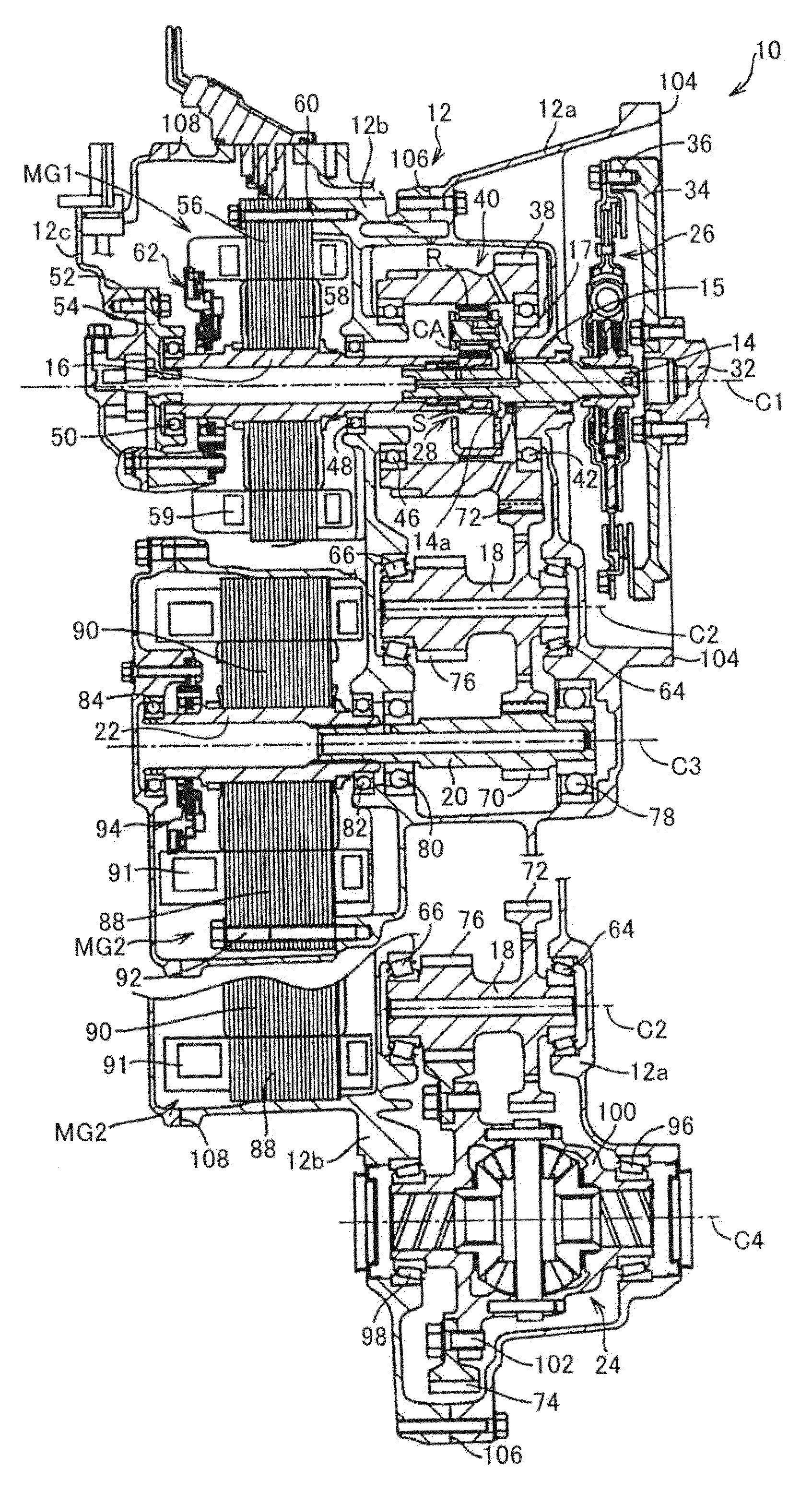

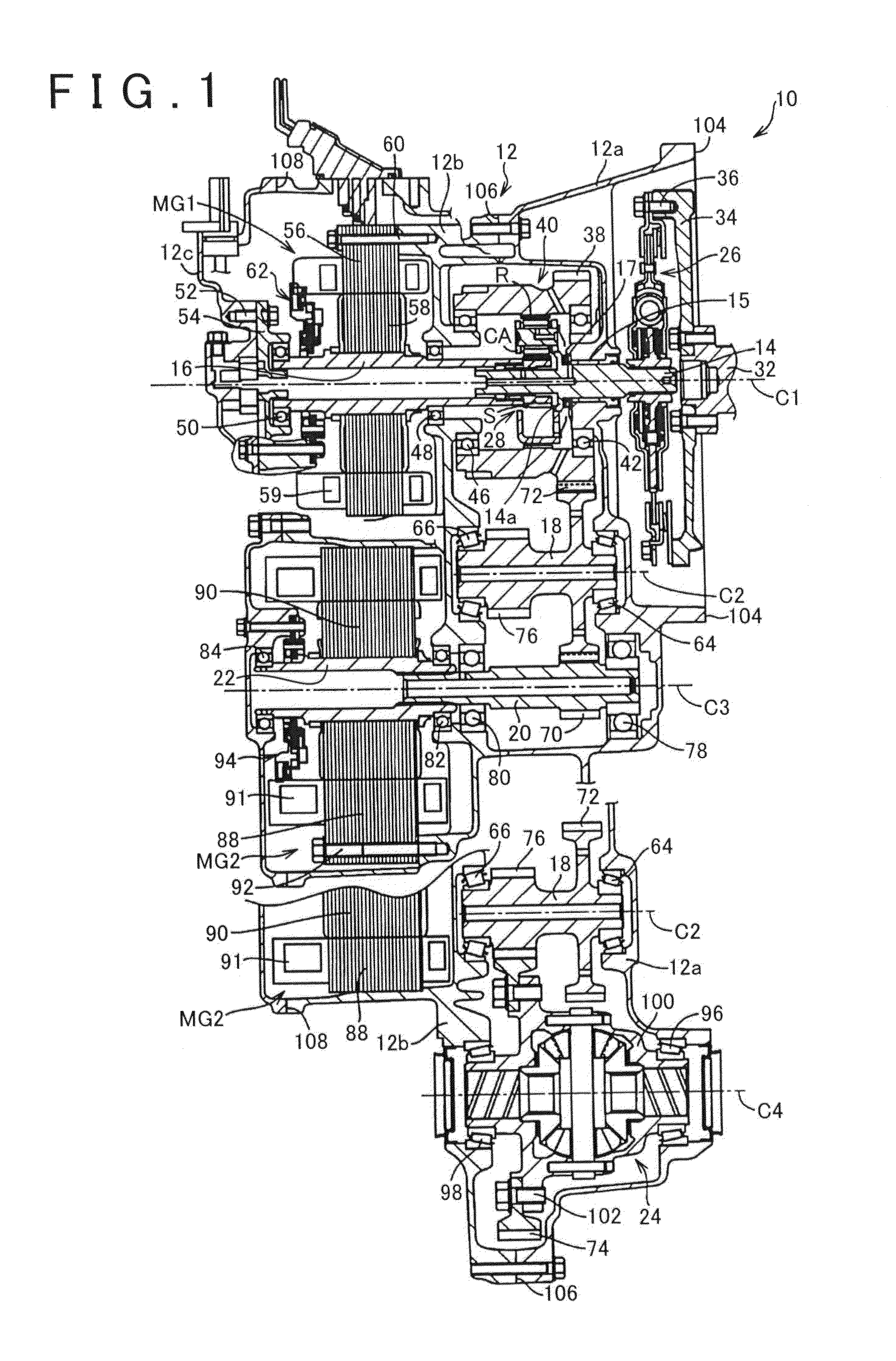

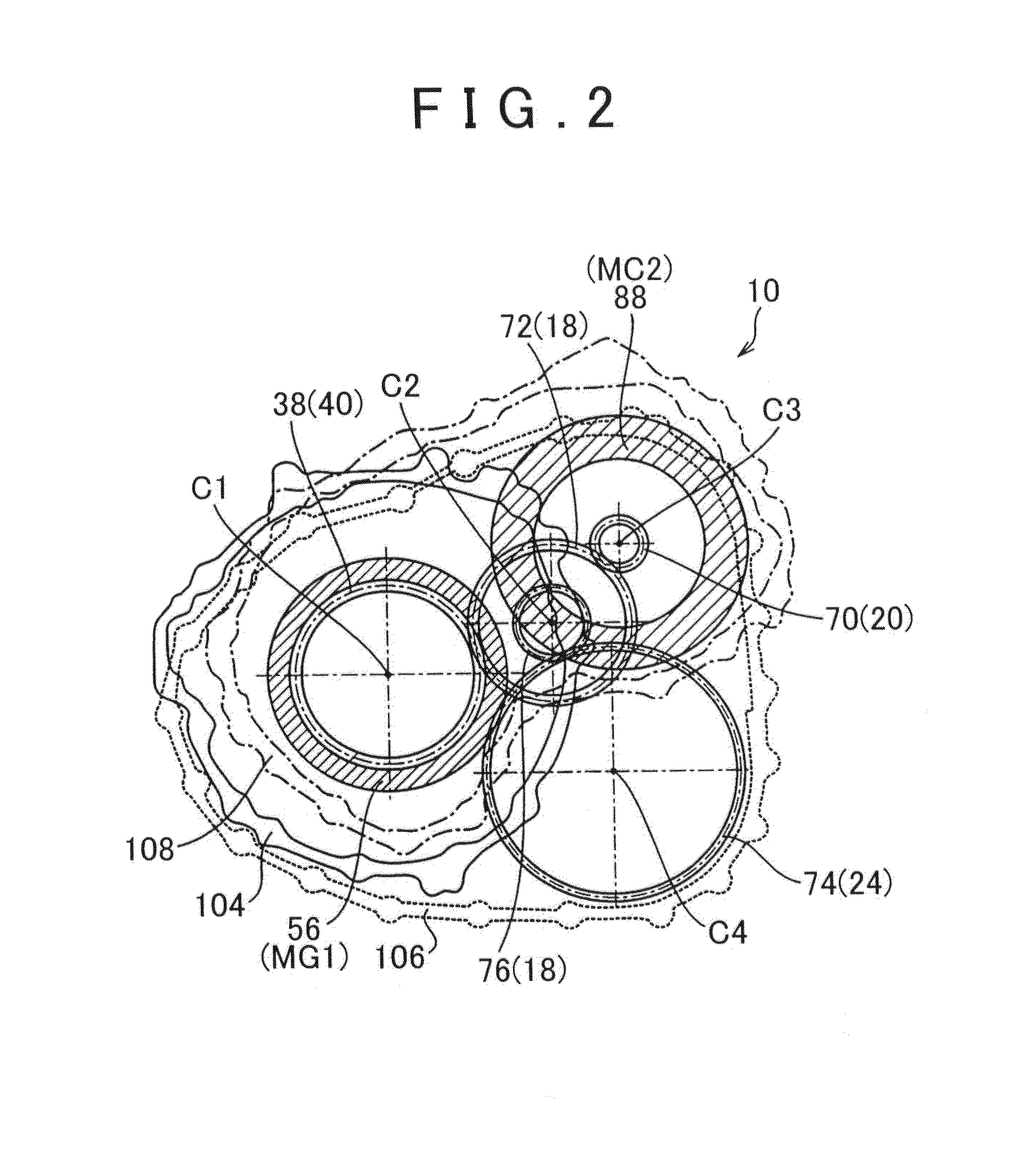

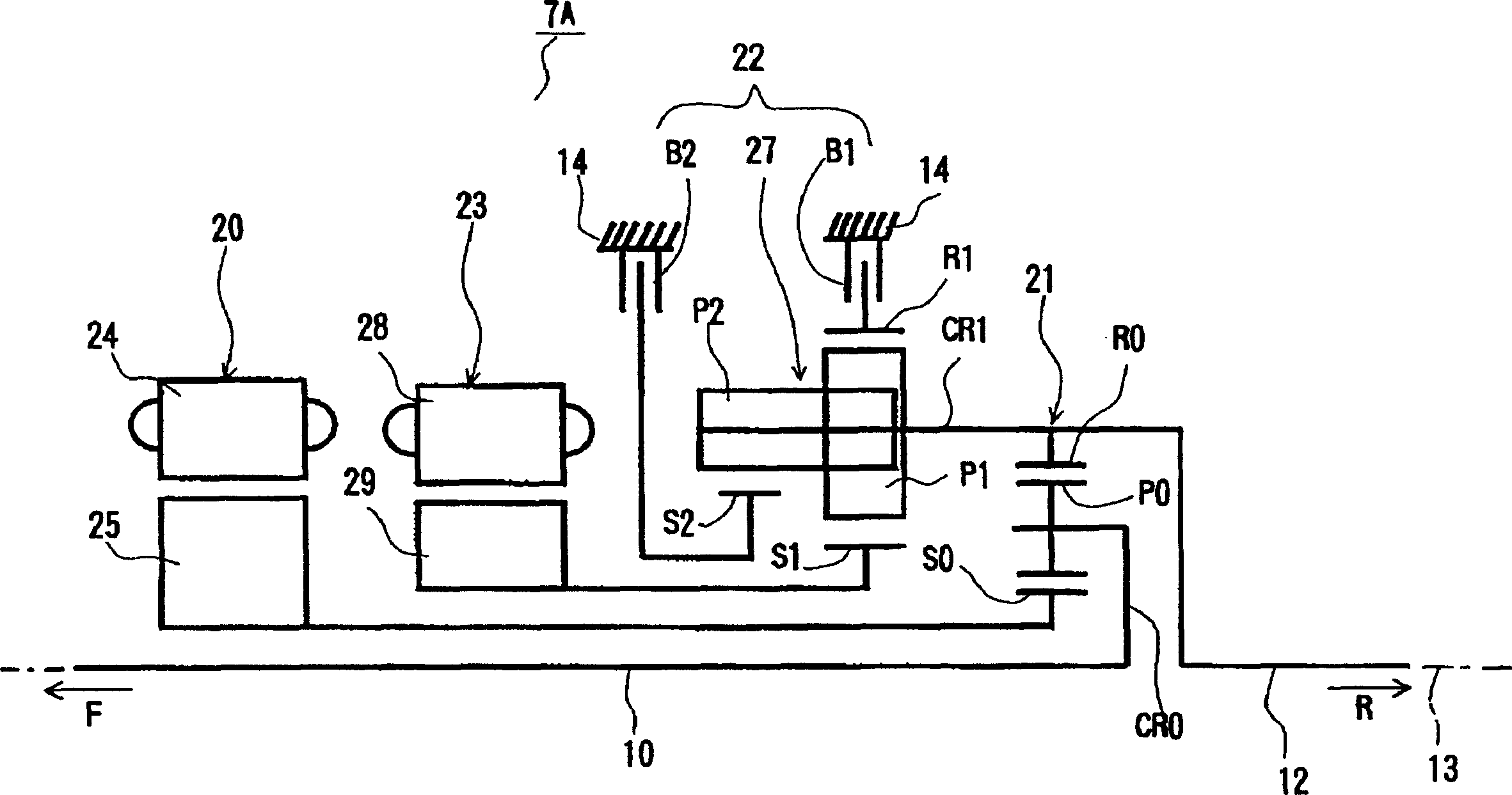

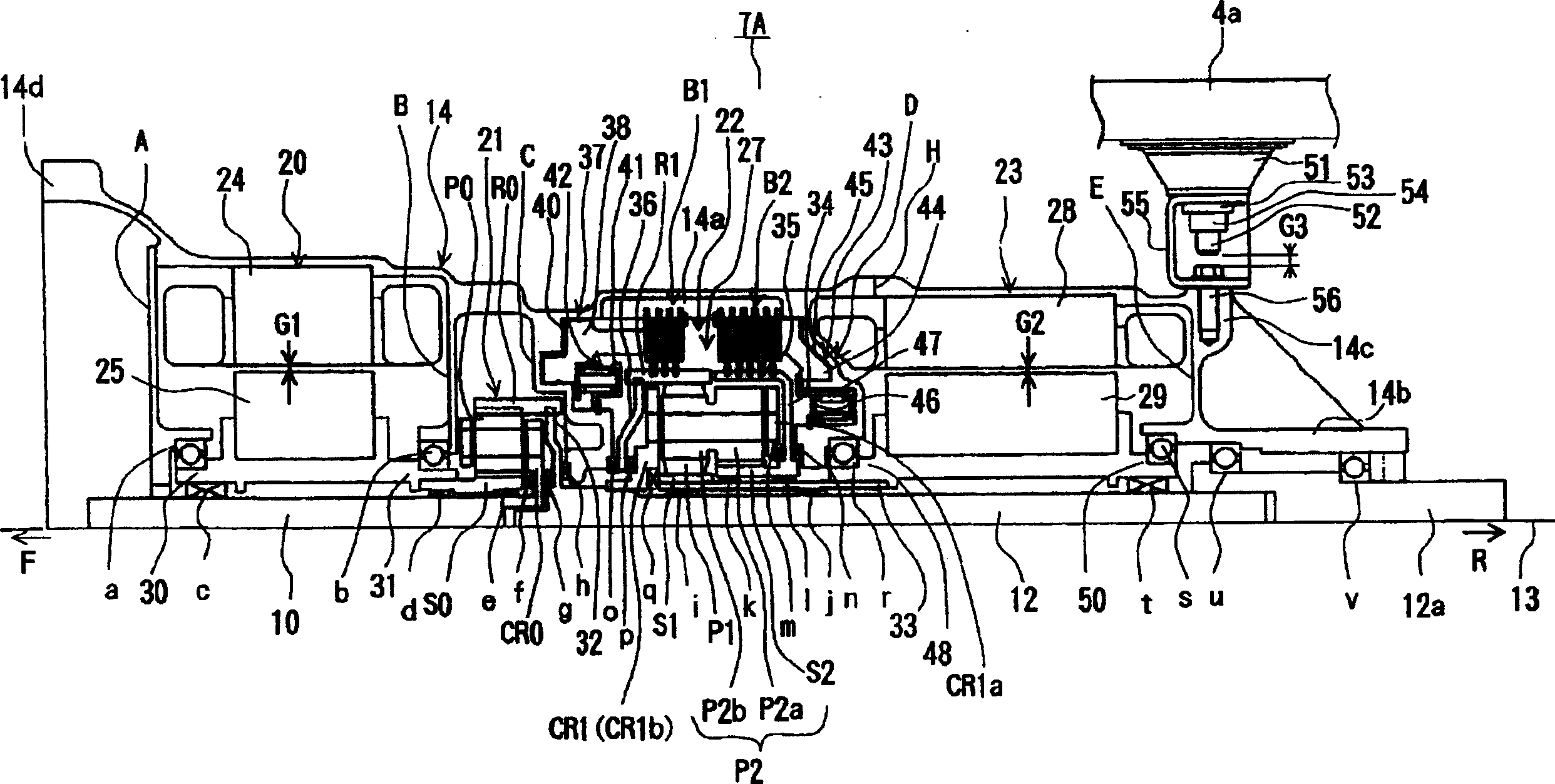

Hybrid vehicle driving apparatus

ActiveUS20130184111A1Improve support accuracyIncrease the number ofHybrid vehiclesToothed gearingsEngineeringHybrid vehicle

A hybrid vehicle driving apparatus includes: a first rotor shaft of a first electric motor, the first electric motor being disposed on a first axis; a power distribution mechanism that includes a planetary gear device and is disposed on the first axis; an output gear shaft that serves as an output member of the power distribution mechanism and is disposed on the first axis; a counter shaft disposed on a second axis; a second rotor shaft of a second electric motor disposed on a third axis; a power transmission shaft disposed on the third axis; a differential gear disposed on a fourth axis; and a casing that includes a plurality of case members. The output gear shaft, the power transmission shaft, the counter shaft, the differential gear, the first rotor shaft, and the second rotor shaft are rotatably supported by a common case member that is one of the plurality of case members.

Owner:TOYOTA JIDOSHA KK +1

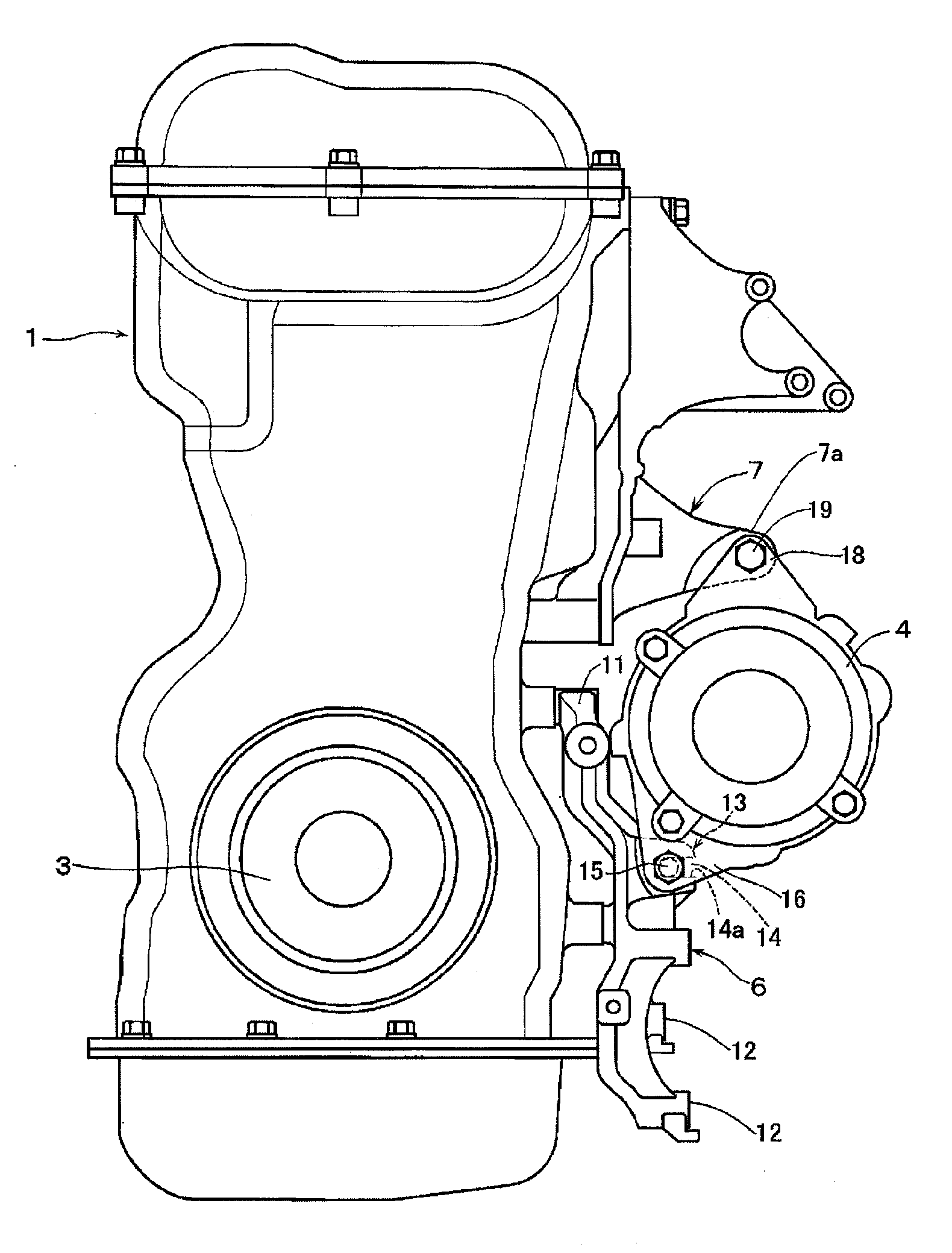

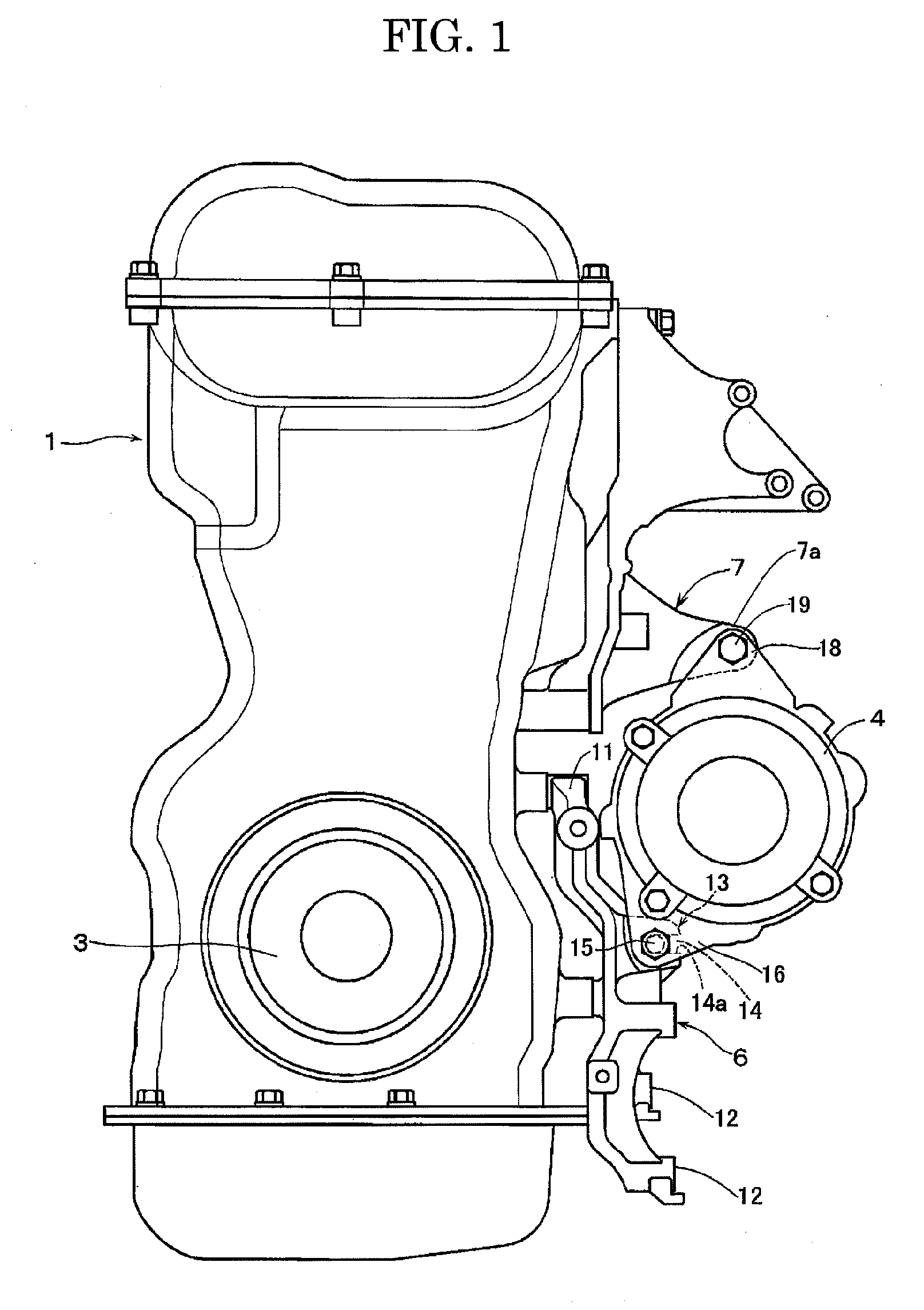

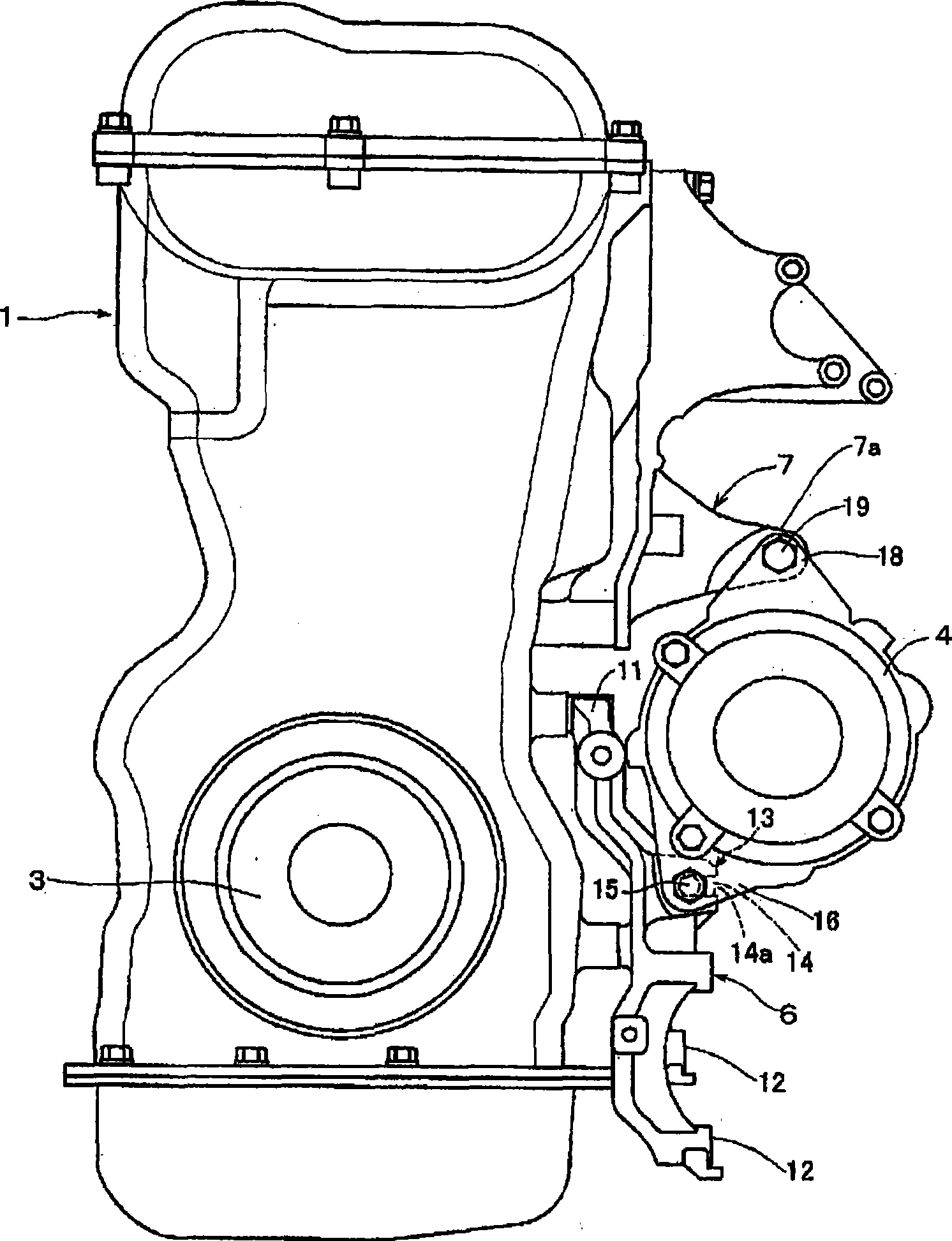

Vehicular drive system

InactiveUS20100222171A1Reduce axial sizeImprove support accuracyHybrid vehiclesGearboxesControl theoryElectric motor

A vehicular drive system accommodated in a housing and including a first input shaft that receives a vehicle drive force generated by a vehicle drive power source, and a differential mechanism operable to distribute the vehicle drive force received from the first input shaft to a first electric motor and a second input shaft. The first and second input shafts are disposed coaxially with a first axis such that the second input shaft is disposed downstream of the first input shaft. The first input shaft is rotatably supported by a first support portion provided on the housing and an axial end portion of the second input shaft, and the second input shaft is rotatably supported by a third support portion and a fourth support portion that are provided on the housing.

Owner:TOYOTA JIDOSHA KK

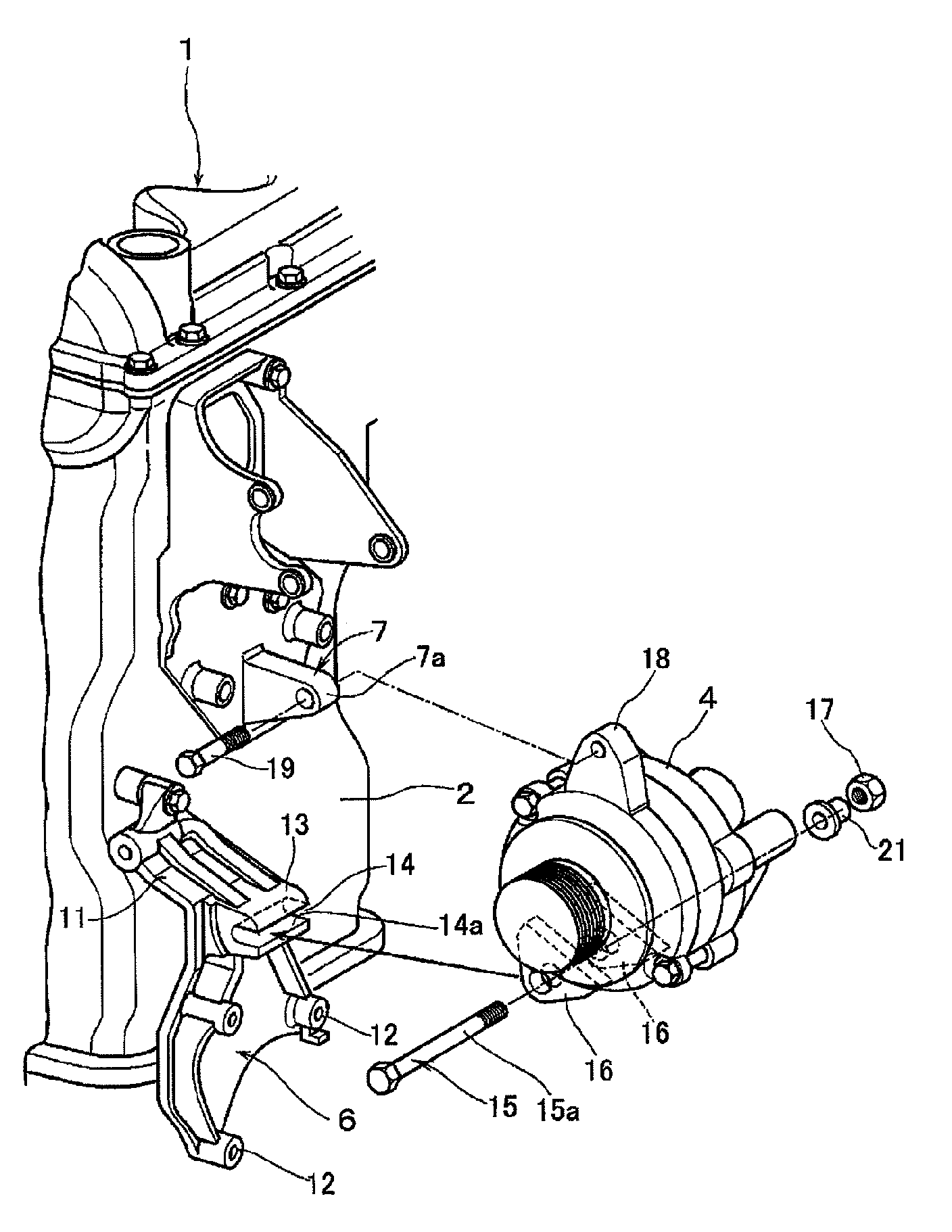

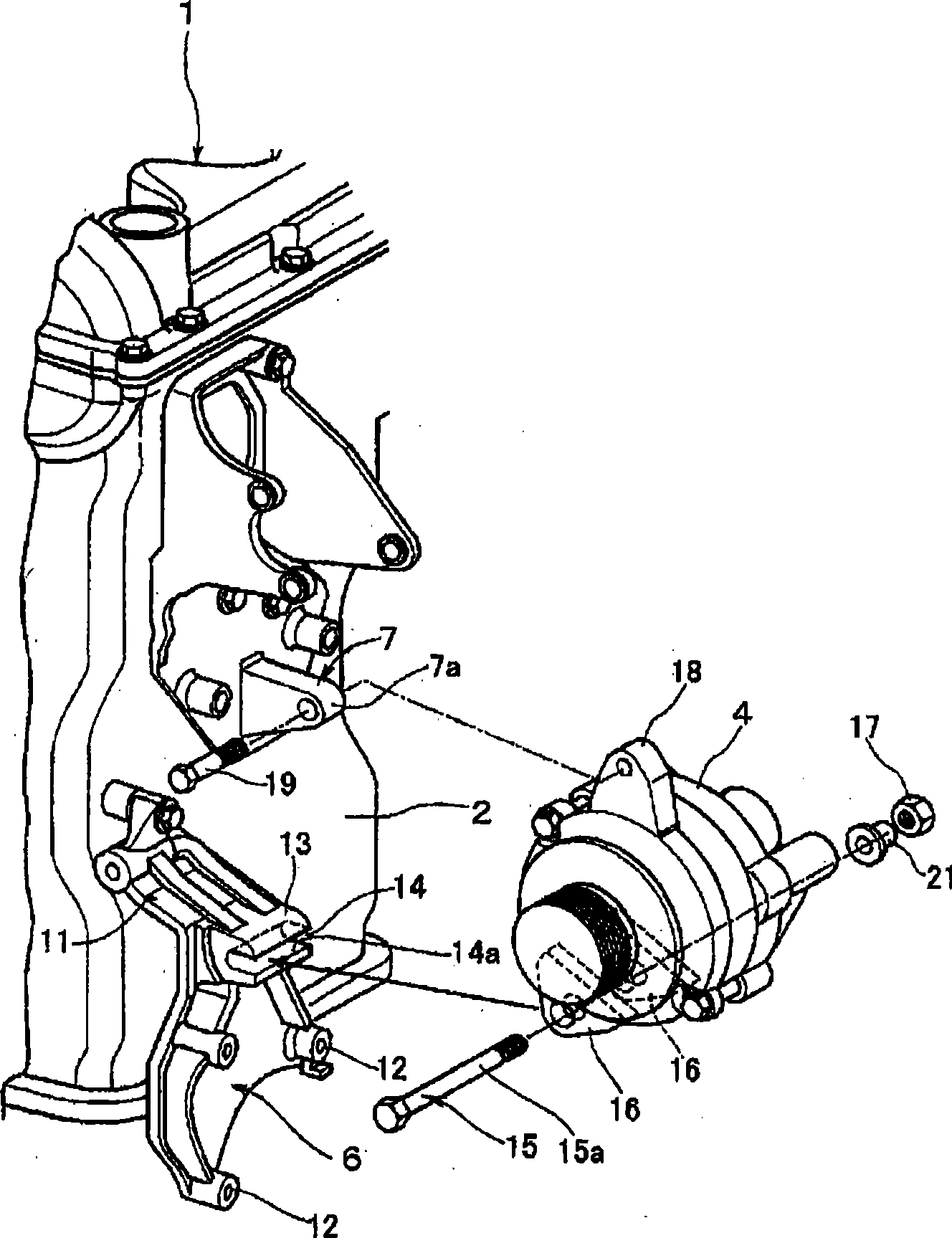

Accessory mounting structure

ActiveUS20090159038A1Stably heldImprove support accuracyCasingsMachine framesElectric generatorCylinder block

A horizontal groove extending horizontally when an alternator bracket is fixed to a cylinder block of a vehicle engine is formed in the alternator bracket. A shank of a bolt inserted through mounting pieces of an alternator is inserted into the horizontal groove from a horizontally lateral direction toward the cylinder block to support the bolt on a lower surface of the horizontal groove. After insertion, the bolt is restrained from moving toward an opening of the horizontal groove. Since the insertion of the bolt into the horizontal groove is facilitated, and the weight of the alternator is borne by the lower surface of the horizontal groove, a burden on a fixing portion is reduced, and it becomes easy to position the alternator and hold it when it is fixed. Thus, the accessory can be mounted on the cylinder block with satisfactory work efficiency and with support accuracy kept high.

Owner:MITSUBISHI MOTORS CORP

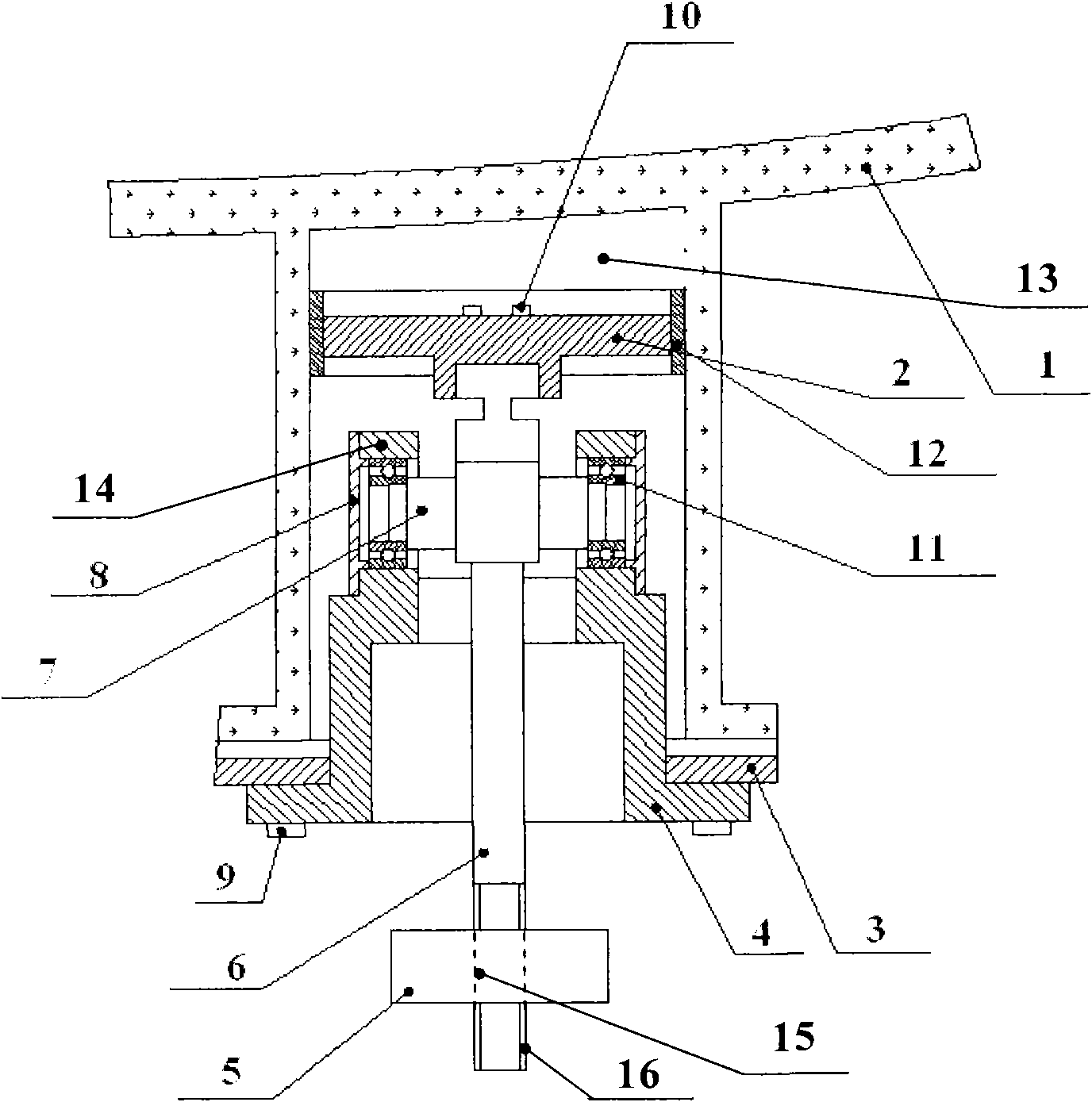

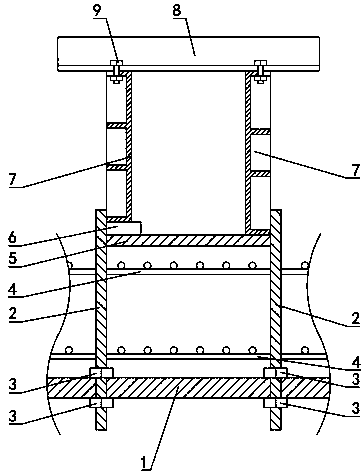

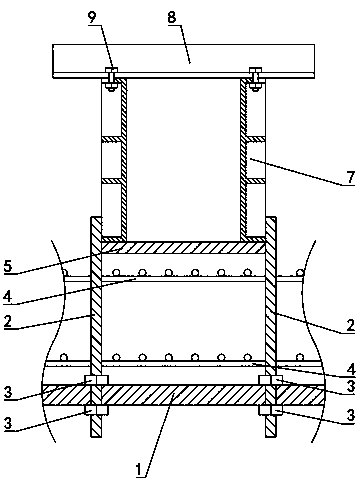

Electric spindle angular contact ball bearing pre-tightening force regulating mechanism

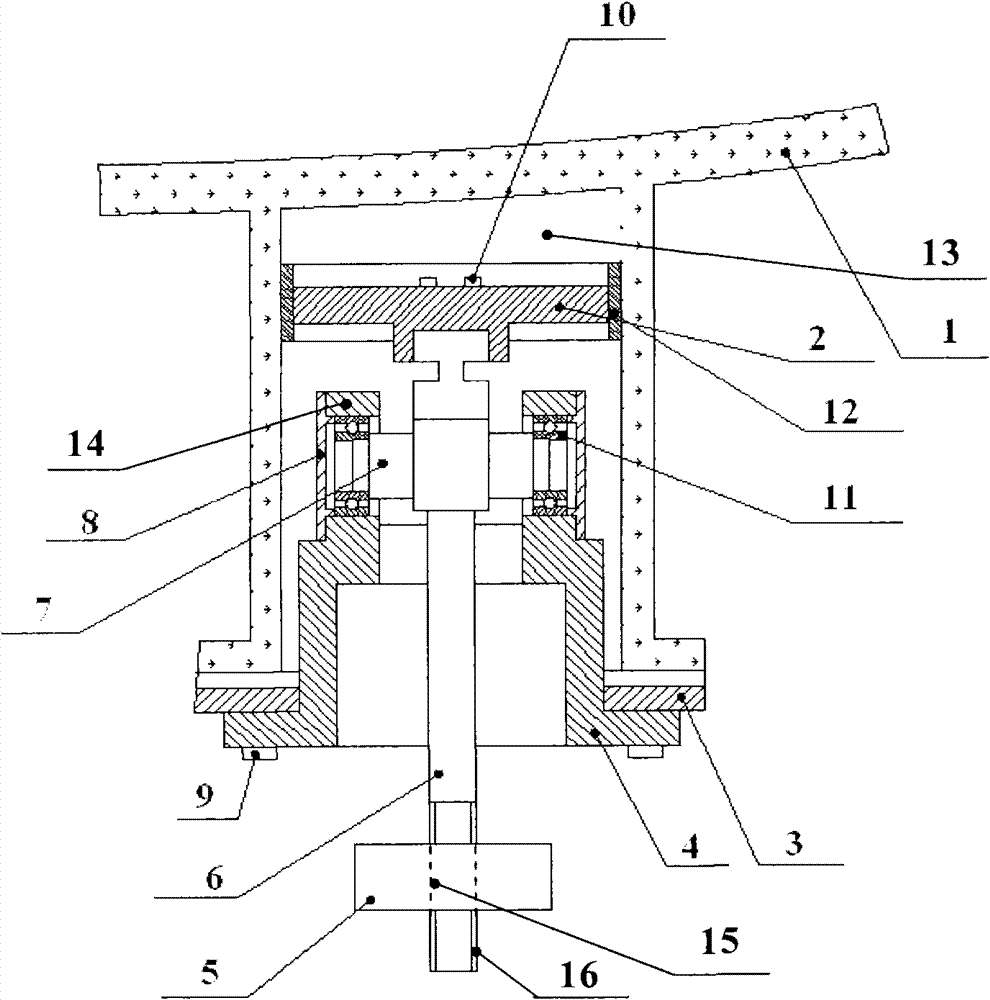

ActiveCN107344245AImprove support accuracyHigh rotation accuracyLarge fixed membersBall bearingInjector nozzle

The invention exposes an electric spindle angular contact ball bearing pre-tightening force regulating mechanism. An elastic check ring for a hole, angular contact ball bearings and an oil stopping ring are sequentially arranged on a spindle in a sleeving manner; three layers of sleeves are installed between the bearings installed in pairs; a non-contact type temperature sensor is installed between the bearings and the oil stopping ring; an angular acceleration vibration sensor is installed at the tail end of the electric spindle; and an oil spraying nozzle is installed on the face of the outer side of the bearings. A piezoelectric ceramic driving power source, a connector assembly, an oil receiving nozzle and a water receiving nozzle are installed on an end cover on the tail portion of the electric spindle. The piezoelectric ceramic driving power source is connected with two annularly stacked piezoelectric ceramic sleeves through a circuit. According to the technical scheme, by means of a good automatic pre-tightening force regulating technology, the pre-tightening force of the electric spindle bearings is effectively regulated, the electric spindle temperature rise is regulated and controlled, noise is lowed, the supporting precision and the rotating precision of the bearings are improved, the service life of the bearings is prolonged, and therefore the dynamic performance of the electric spindle is improved, and the machining precision and the work efficiency of a machine tool adopting an electric spindle unit are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Accessory mounting structure

ActiveUS8511272B2Guaranteed to workImprove support accuracyCasingsMachine framesAlternatorEngineering

A horizontal groove extending horizontally when an alternator bracket is fixed to a cylinder block of a vehicle engine is formed in the alternator bracket. A shank of a bolt inserted through mounting pieces of an alternator is inserted into the horizontal groove from a horizontally lateral direction toward the cylinder block to support the bolt on a lower surface of the horizontal groove. After insertion, the bolt is restrained from moving toward an opening of the horizontal groove. Since the insertion of the bolt into the horizontal groove is facilitated, and the weight of the alternator is borne by the lower surface of the horizontal groove, a burden on a fixing portion is reduced, and it becomes easy to position the alternator and hold it when it is fixed. Thus, the accessory can be mounted on the cylinder block with satisfactory work efficiency and with support accuracy kept high.

Owner:MITSUBISHI MOTORS CORP

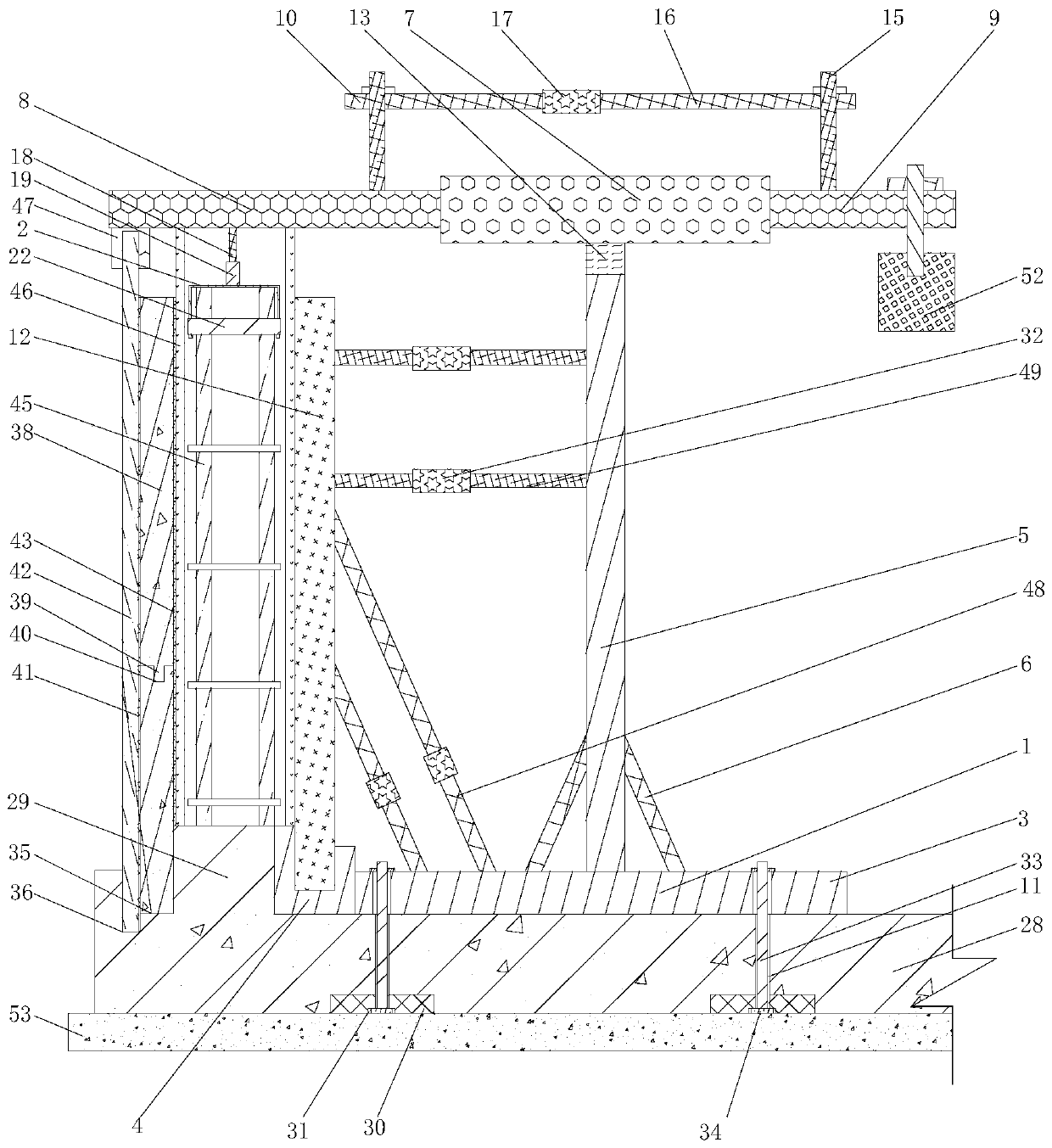

Two-panel retractable internal mold flue gas channel vibration casting machine

The invention relates to a vibrating casting machine for producing flue gas ducts for buildings. The vibrating casting machine comprises a handle, an internal mold mechanism, an external mold mechanism, an external mold rack, a mold-out rack, a vibrating pump and an elastic support, wherein a molding mechanism of the internal mold mechanism consists of an upper panel and a lower panel; the upper panel is linear, and the left end and the right end of the upper panel are turned downwards; the lower panel consists of a front surface, a rear surface and a bottom surface which are formed by bending a panel, the lower panel is U-shaped, and the tops of the left end and the right end of the lower panel are turned inwards to be in clearance fit with the downwardly turned parts of the upper panel; a retractable mechanism in the internal mold mechanism adopts a left-handed nut and a right-handed nut which form a pair and a plurality of sets of pull rods to realize contraction and spreading of an internal mold; a sealing strip is arranged between a side plate and a baseplate of an external mold; guiding blocks, limiting blocks and bearings are arranged at the two ends of the external mold rack; and carrier rollers are arranged at the upper part of the mold-out rack, and rollers are arranged at the lower part of the mold-out rack and are in clearance fit with guide rails.

Owner:朱志强

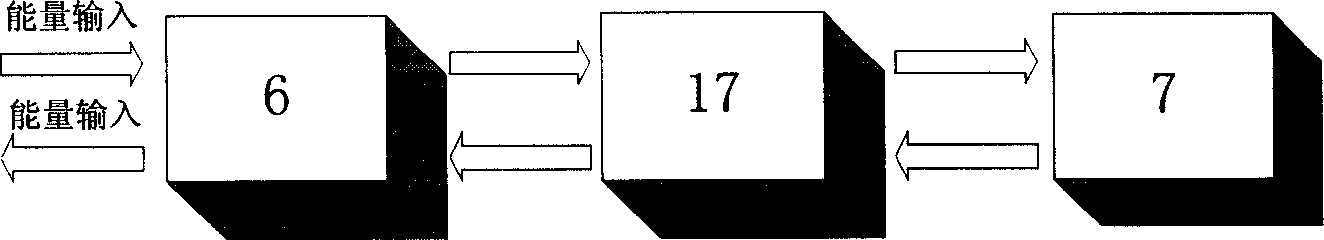

High pressure gas support flying wheel battery

InactiveCN1750364AImprove efficiencyExtended service lifeMechanical energy handlingBearingsElectrical batteryGas cylinder

This invention discloses a high pressure gas supported flywheel cell, which takes a high pressure gas bottle as the gas source to input an inert gas into a gas bearing via a regulator and a filter to float the flywheel. When charging, the power supply drives the motor via a power electronic conversion device to drive the flywheel rotate at high speed and convert the electric energy to dynamic energy to be stored. When discharging, the motor becomes a generator to generate electricity driven by the flywheel to return electric energy to the power supply. The vacuum pump extracts the inert gas from the flywheel sealed protection shade and transports it to the gas source.

Owner:XI AN JIAOTONG UNIV

Integrated high-accuracy servo revolving platform

InactiveCN105382558ACompact structureHigh rotation accuracyLarge fixed membersBall bearingEngineering

The invention relates to an integrated high-accuracy servo revolving platform which comprises a working table facet, a motor stator, a rotor, a crossed roller revolving bearing, a deep-groove-ball bearing and a machine base. The center of the working table facet is fixedly provided with a centering shaft, the rotor is fixed to the middle of the outer wall of the centering shaft, the crossed roller revolving bearing is arranged between the working table facet and the machine base, the motor stator is fixed to the middle of the inner wall of the machine base, an outer ring of the deep-groove-ball bearing is fixed to the lower portion of the inner wall of the machine base, an inner ring of the deep-groove-ball bearing is fixed to the lower portion of the centering shaft, and a synchronous pulley is further fixed to the position, located below the inner ring of the deep-groove-ball bearing, of the centering shaft; an encoder feedback detection device is fixed to the position, corresponding to the synchronous pulley, of the lower portion of the machine base, the side wall of the machine base is further internally provided with cylindrical locking levers, and the lower end of the centering shaft is further connected with a hydraulic revolving connector. The integrated high-accuracy servo revolving platform is high in supporting accuracy, high in rigidity, electromechanically integrated and free of mechanical transmission error.

Owner:浙江博雷重型机床制造有限公司

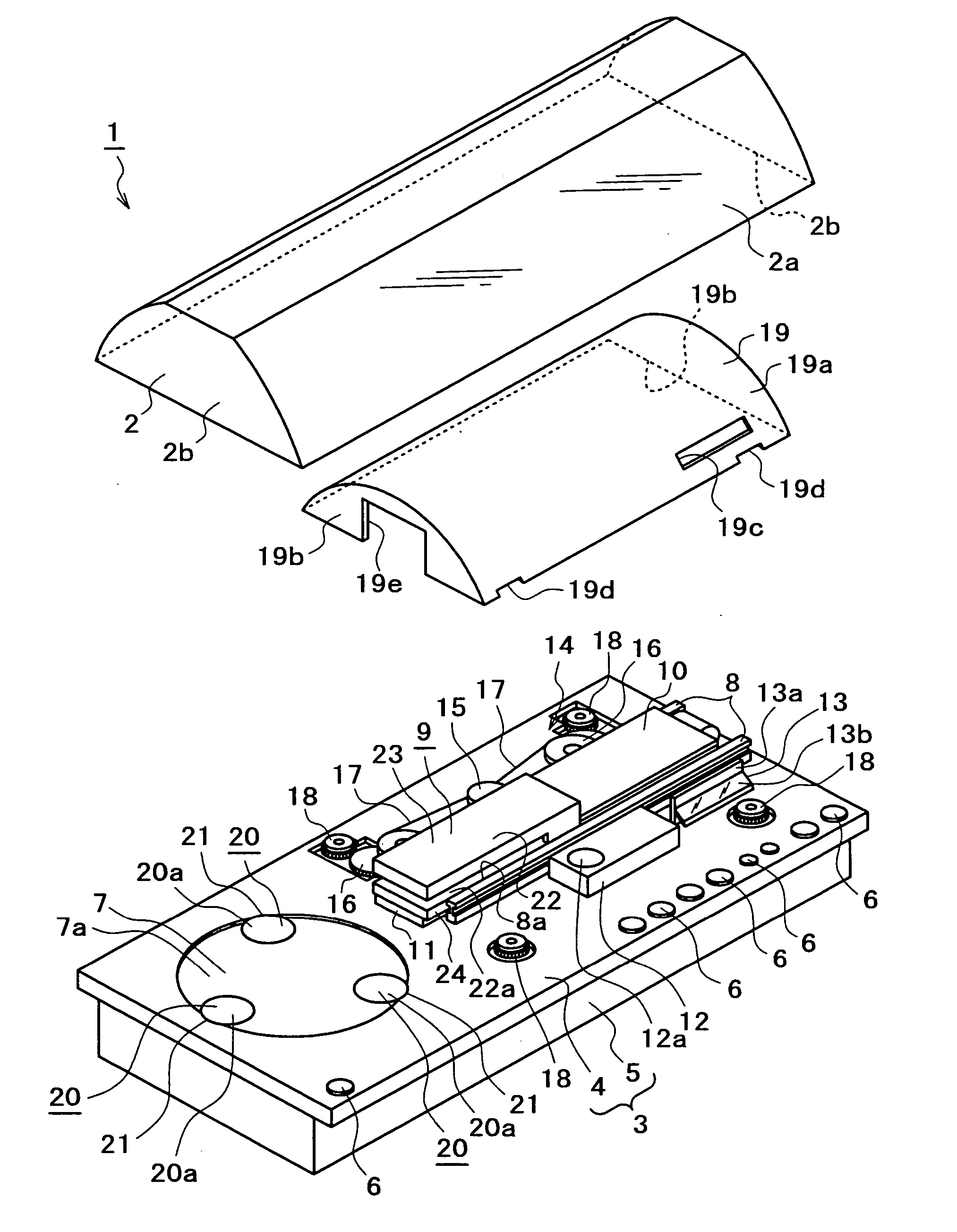

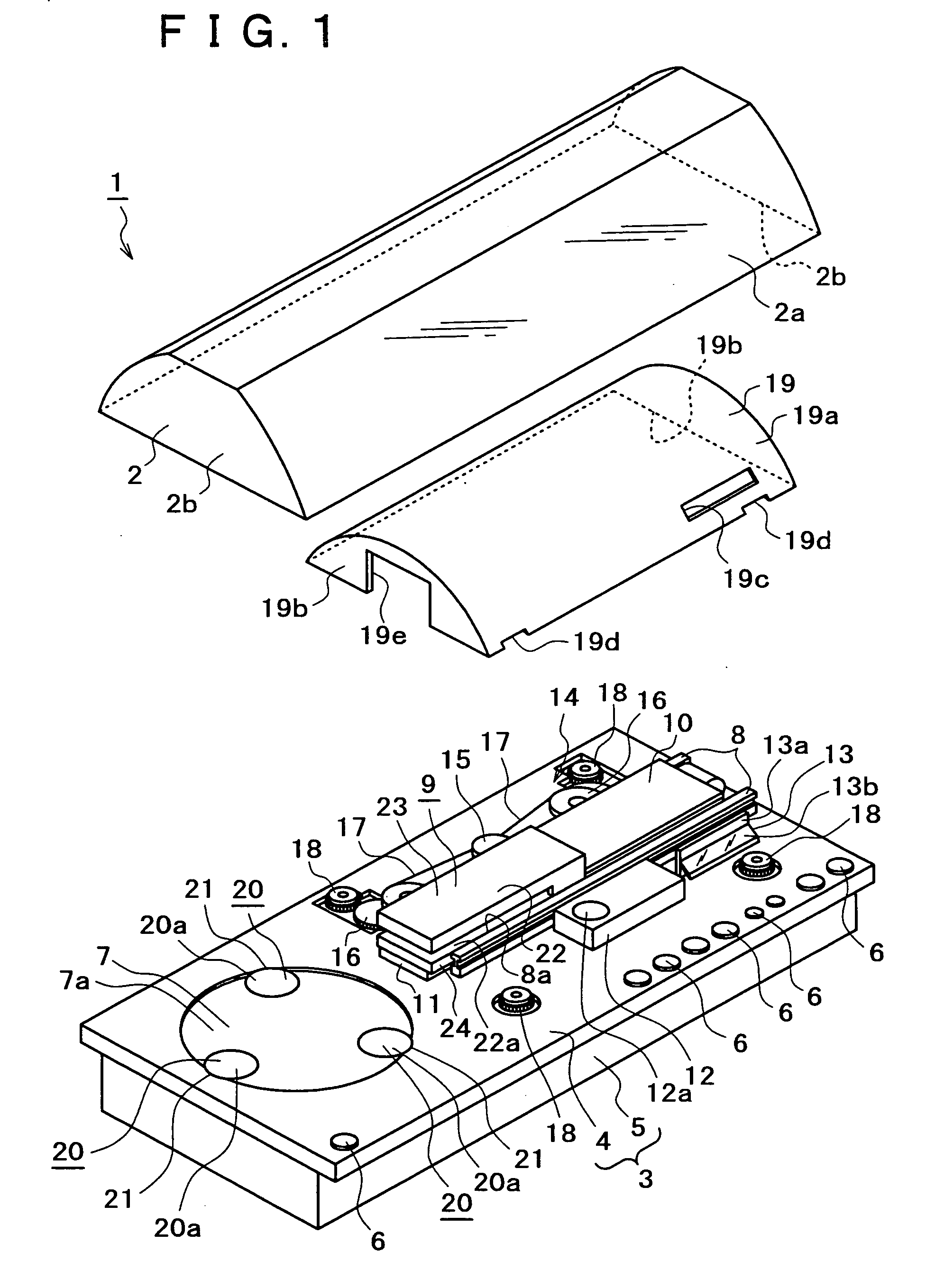

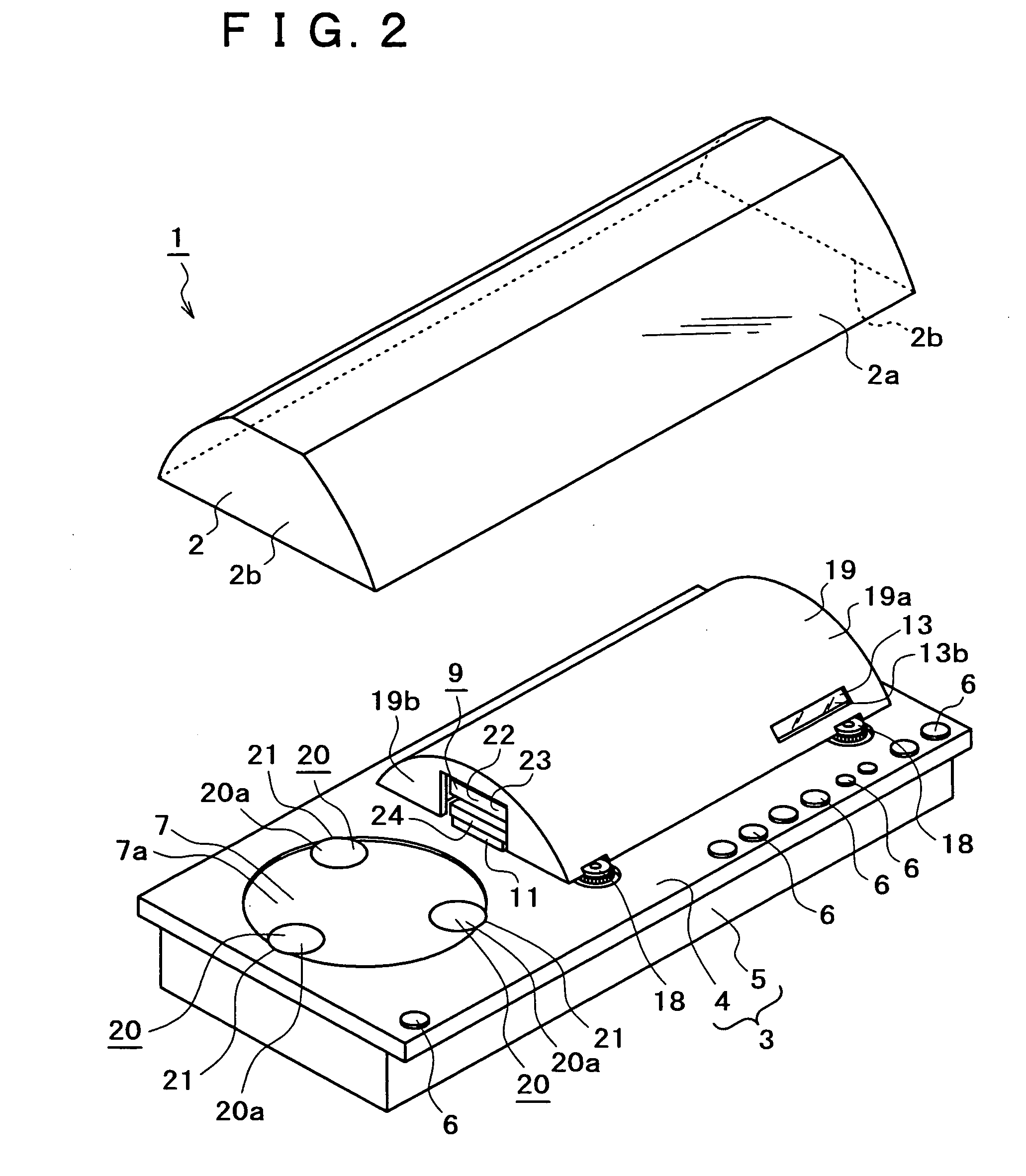

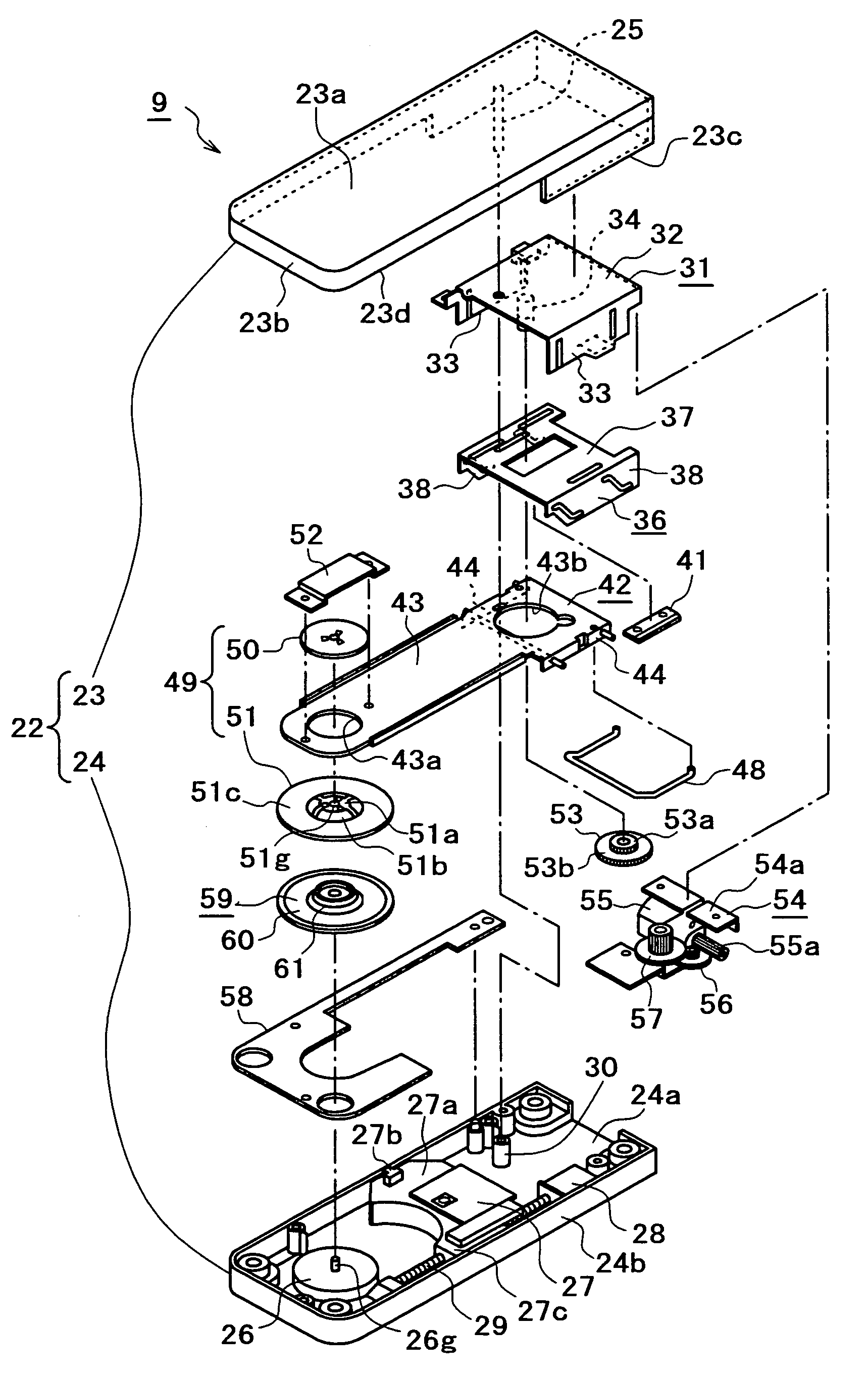

Disk chucking mechanism and disk drive device

InactiveUS20050060733A1Low-profile structureHigh positioning accuracyRecord information storageRecording on magnetic disksEngineeringPulley

A chucking pulley clamps and chucks a disk-shaped recording medium in coaction with a disk table, the chucking pulley having a rotary slide knob. The chucking pulley is rotatably supported on a support arm. The support arm has first lifting / lowering pins and second lifting / lowering pins. A holder is fixedly mounted on the support arm for pressing the chucking pulley toward the disk table while being held in contact with a distal end of the rotary slide knob when the disk-shaped recording medium is in rotation. A bias spring is resiliently held against the first lifting / lowering pins. Moving members are arranged to move the chucking pulley toward and away from the disk table. The moving members have retainers for retaining the first lifting / lowering pins in an acting position when the disk-shaped recording medium is chucked. The first lifting / lowering pins retained in the acting position elastically deform the bias spring to bias the support arm and the holder to move toward the disk table.

Owner:SONY CORP

Radial support mechanism of primary mirror of large aperture telescope for eliminating temperature stress

The invention provides a radial support mechanism of a primary mirror of a large aperture telescope for eliminating the temperature stress, which consists of a radial support base, a lever bracket, clump weights, a lever, a lower pair slider bar, rolling bearings and an indium steel sleeve. The indium steel sleeve is sleeved on the radial support base which is located in the middle of the indium steel sleeve. Silica gel is dotted at a gap fit position between the radial support base and indium steel sleeve so that the indium steel sleeve is fixed on the radial support base. The lever is connected to the radial support base via two mounting screws. The pivot end of the lever is connected to the lever bracket by two rolling bearings through the lower pair slider bar. The clump weights are screwed in the lower end part of the lever in threaded connection. Two bearing cover plates cover the bearing holes on the lever bracket. When the radial support mechanism of the primary mirror works, the radial support mechanism is connected to and fixed on the primary mirror base by means of two mounting screws via the lever bracket, and the radial support base extends to the radial support holesof the primary mirror to be mounted.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

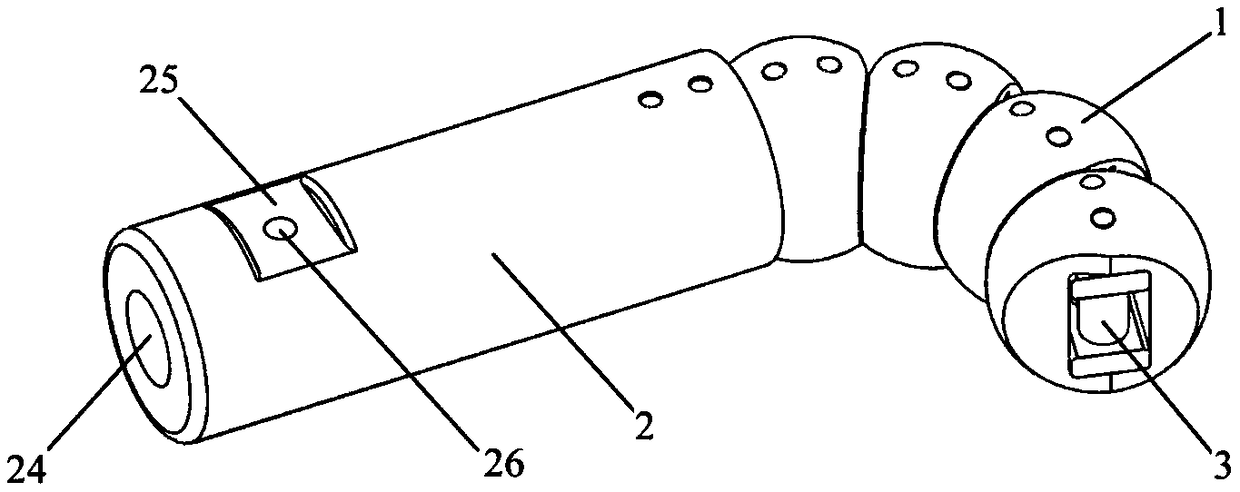

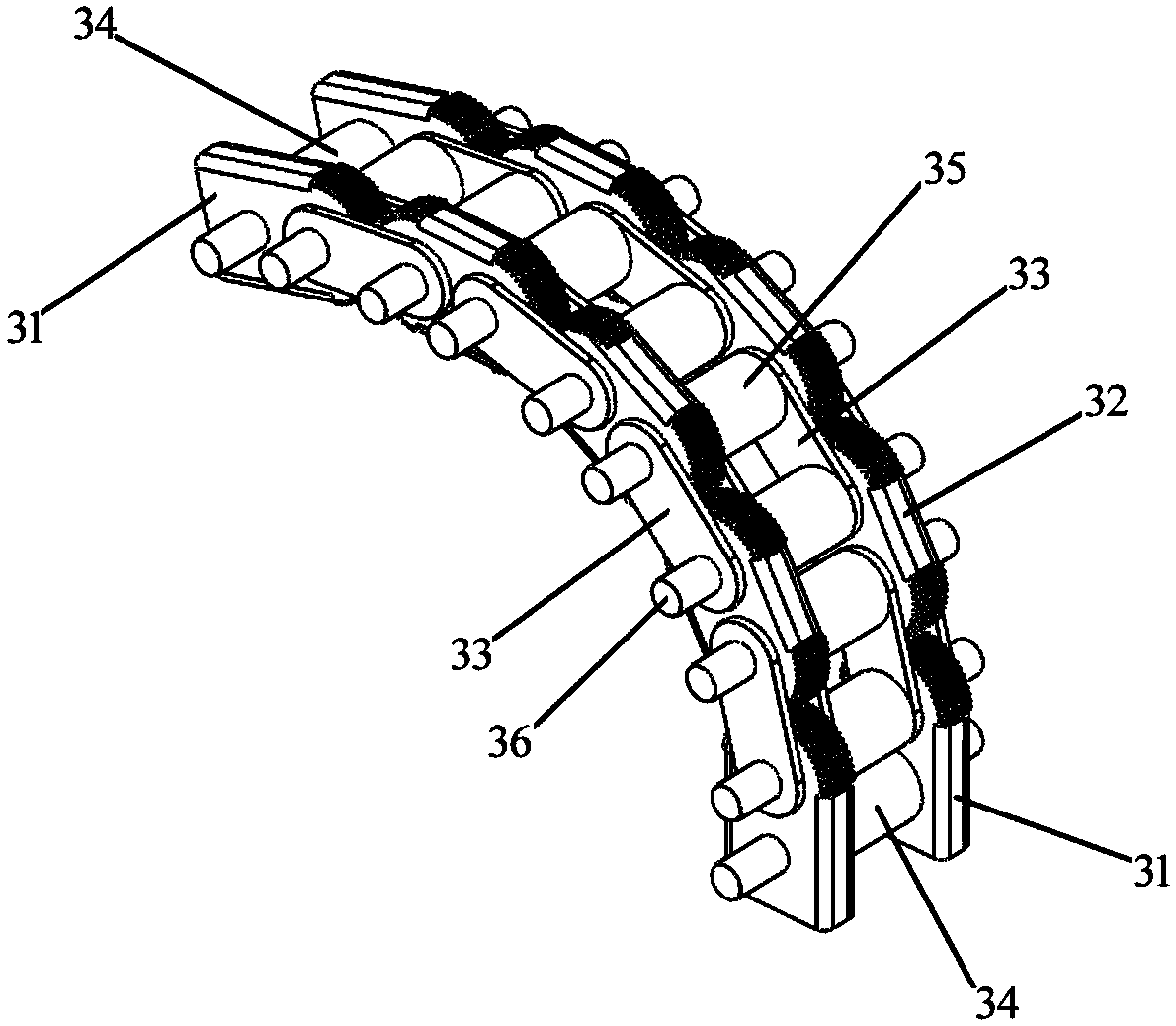

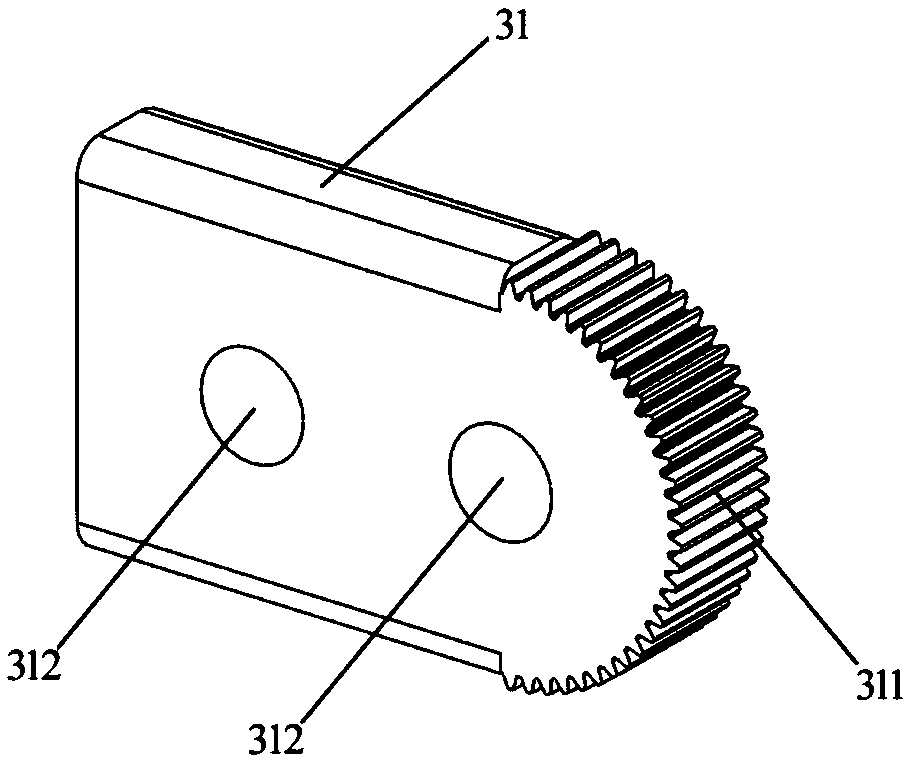

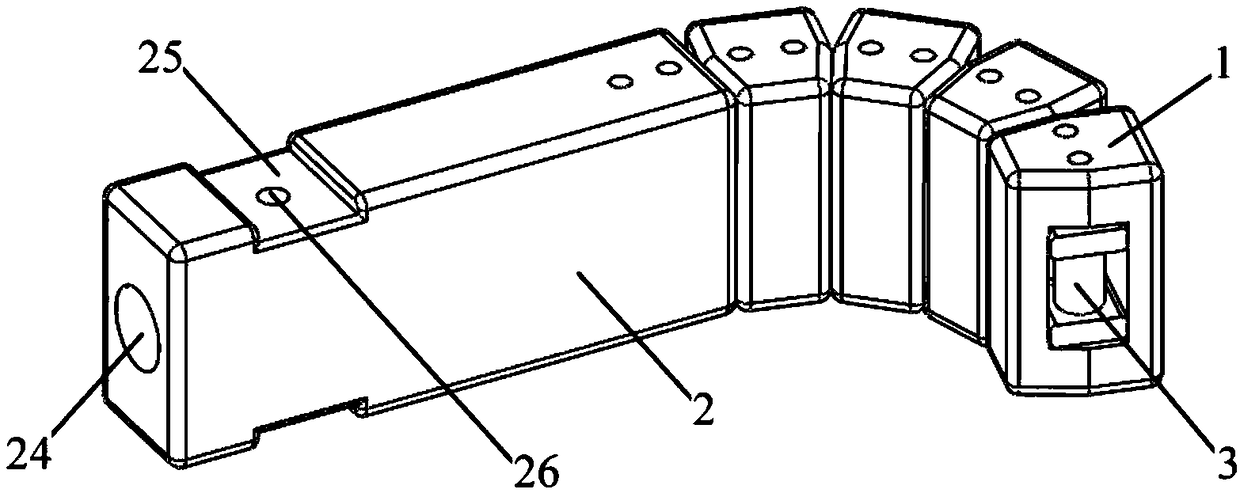

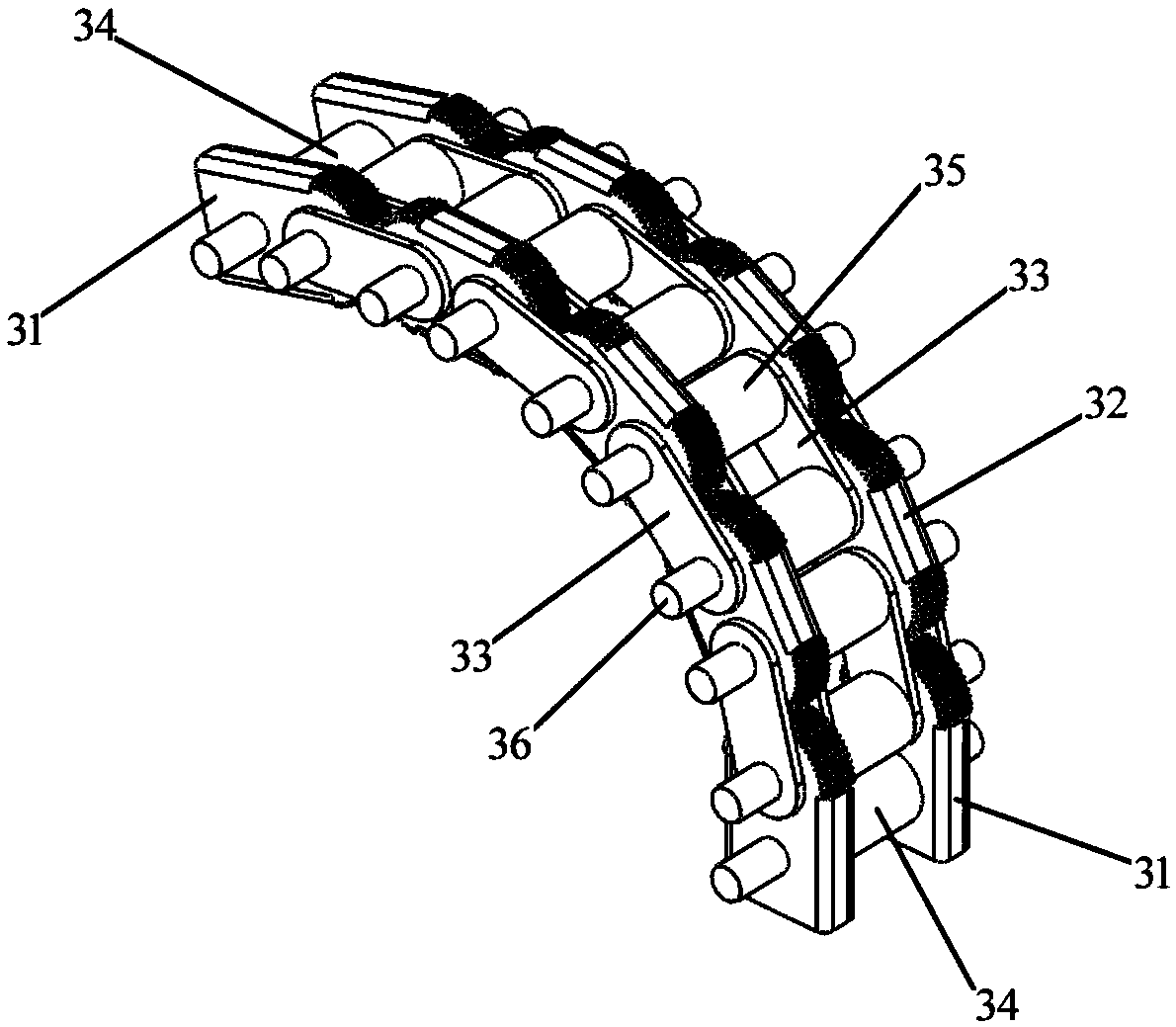

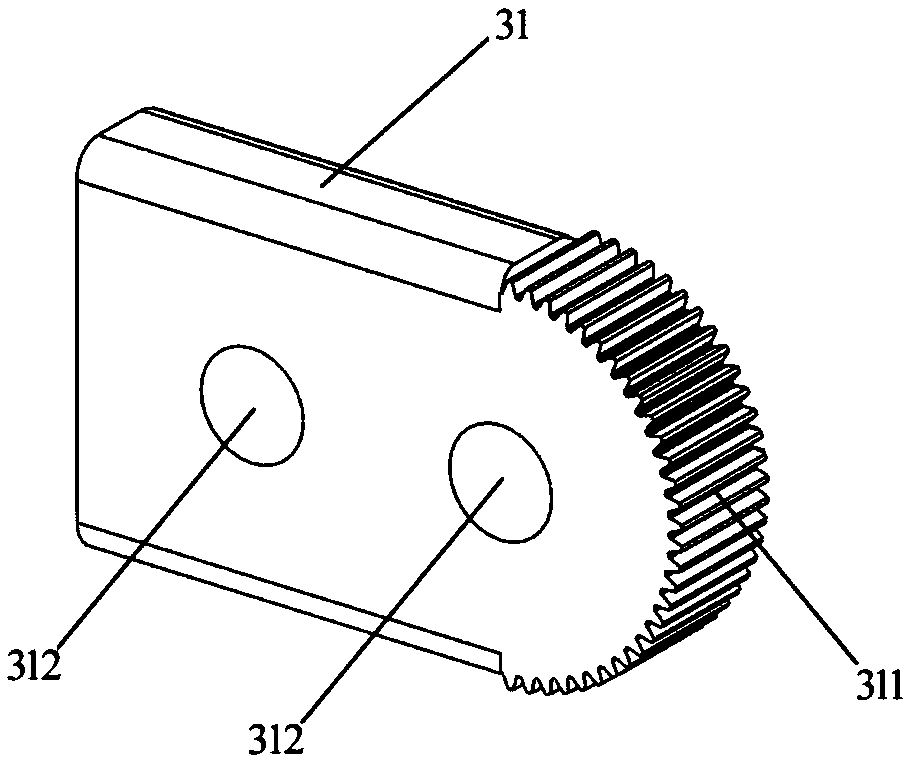

Gear chain type core rod for round pipe bending forming

ActiveCN109201807AImprove support accuracyImprove bending accuracyGlass productionChain typeSpherical shaped

The invention discloses a gear chain type core rod for round pipe bending forming. The gear chain type core rod comprises one or more core balls used for supporting a round pipe bent pipe segment, a core shaft used for supporting a round pipe straight segment and gear chain type connecting bodies used for connecting the core balls and connecting the core balls with the core shaft. Each gear chaintype connecting body comprises single-side gear plates, dual-side gear plates, connecting pieces, long limiting rings, short limiting rings and shafts. The core balls are shells of spherical structures. A first mounting cavity is formed in each shell. The core shaft is of a cylinder shaft. The gear chain type core rod has certain university, can be suitable for bending forming of thin-wall pipes large in radius-thickness ratio and small in bending radius and is high in supporting precision.

Owner:ZHEJIANG KING MAZON MACHINERY

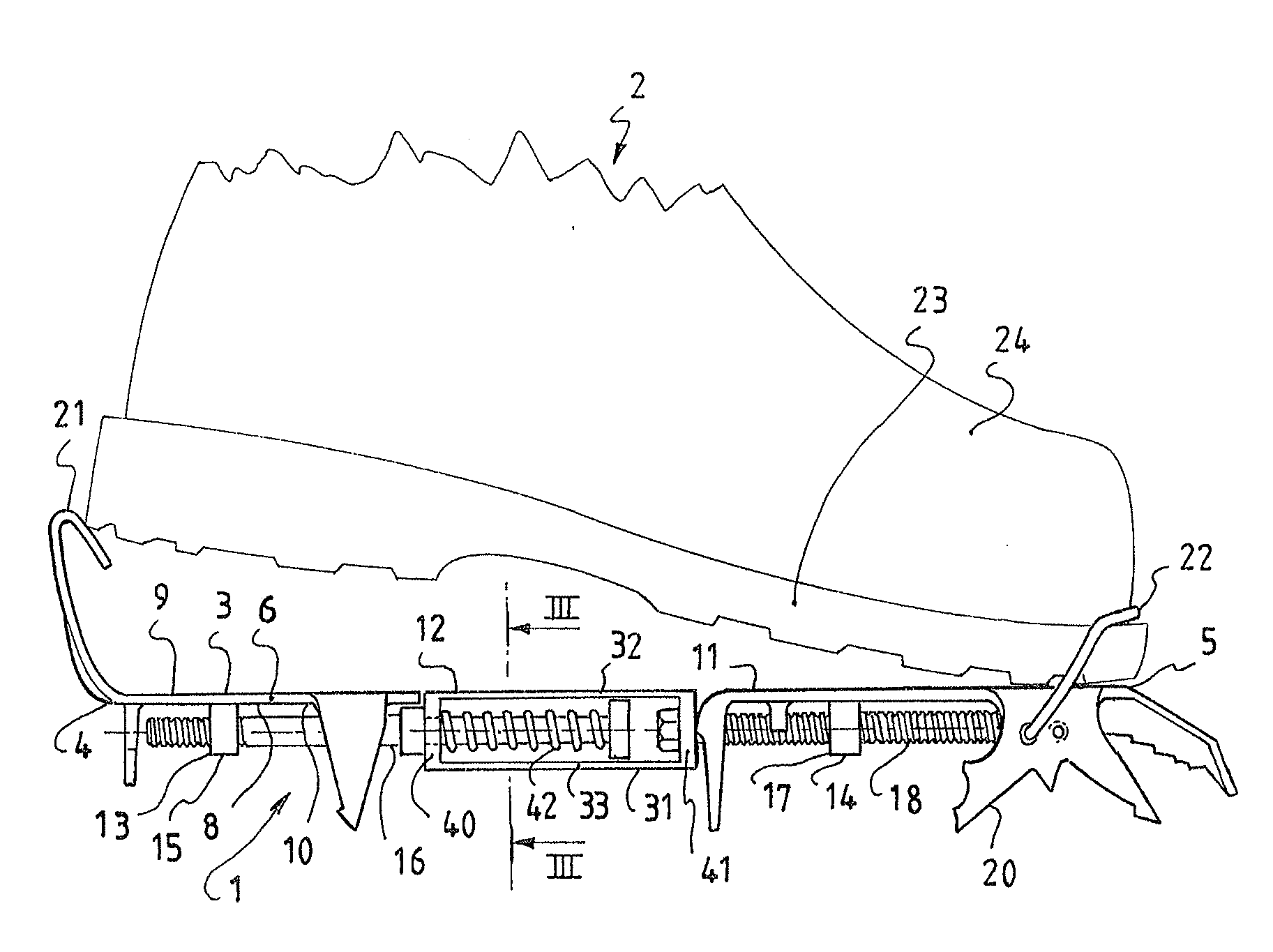

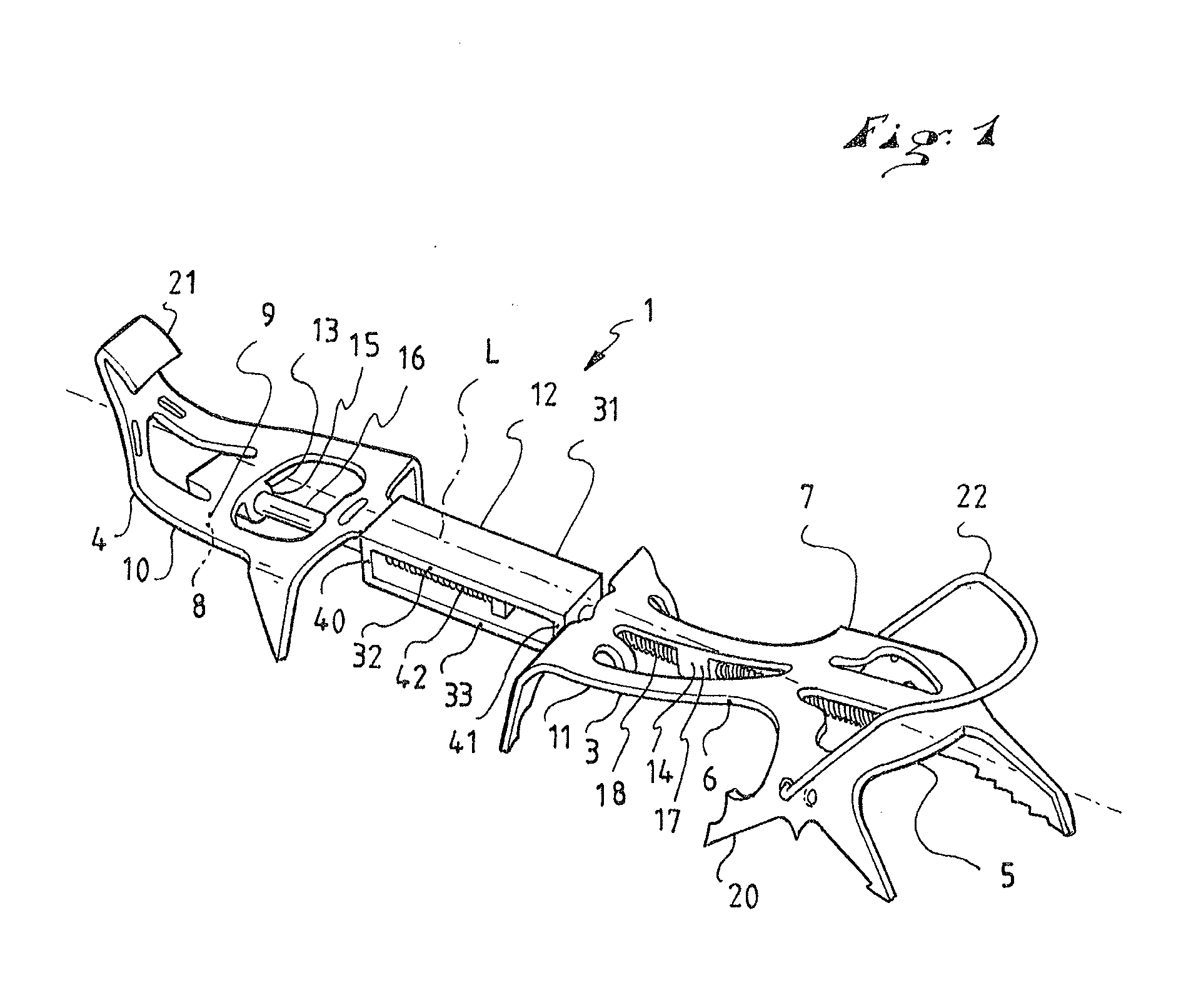

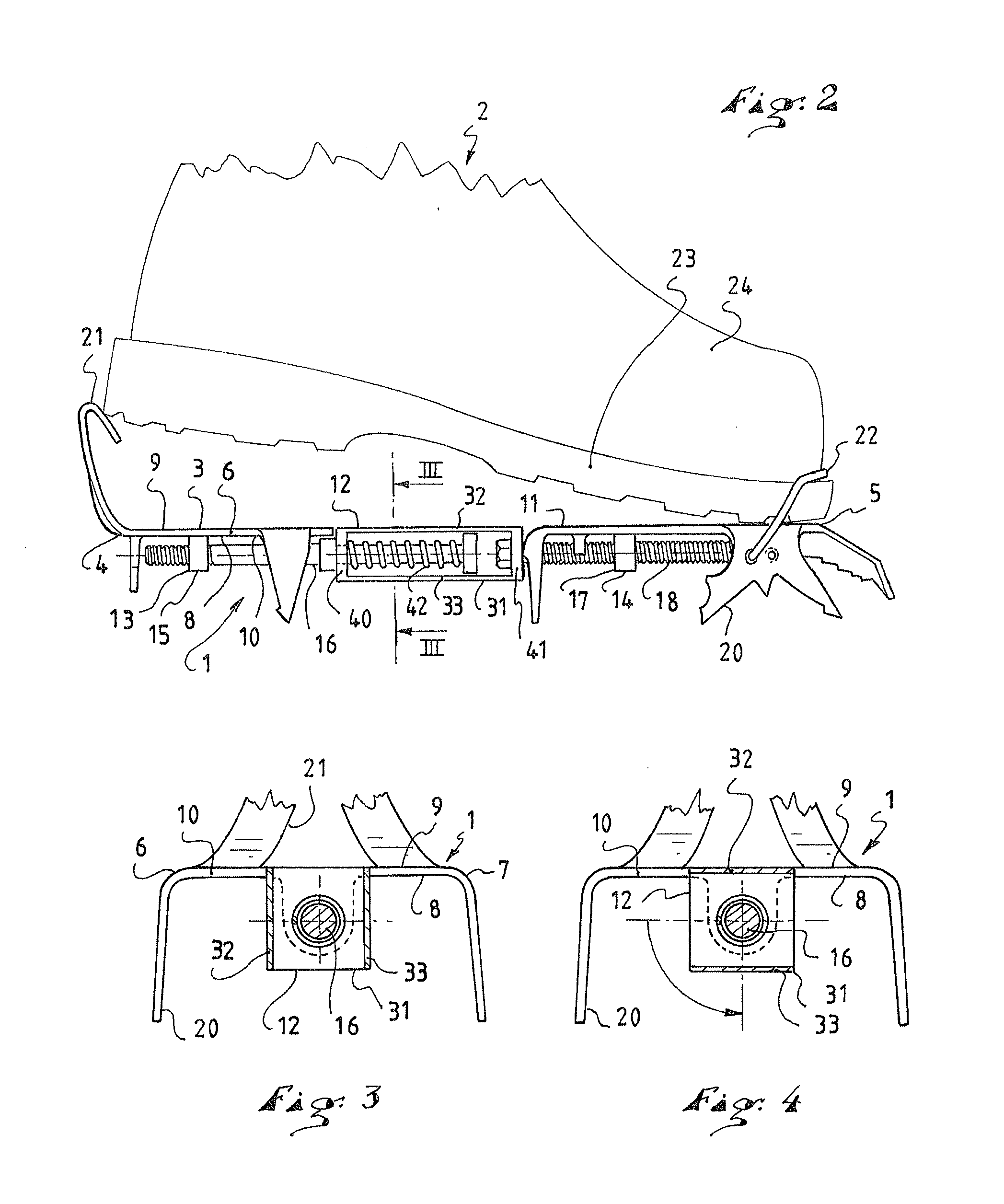

Footwear crampon

InactiveUS20130312281A1Increase and reduce rigidityImprove support accuracyFasteningsFlexural strengthEngineering

Owner:SALOMON SA

Aluminum alloy formwork inclined-supporting device and construction method

PendingCN109667422AImproved Support Stability NewDifficult to moldAuxillary members of forms/shuttering/falseworksUltimate tensile strengthMaterials science

The invention provides an aluminum alloy formwork inclined-supporting device and a construction method, belongs to the technical field of building template construction, and solves the technical problems of low support strength and high construction cost of an existing construction structure and method. The aluminum alloy formwork inclined-supporting device comprises a horizontal support rod arranged horizontally and capable of being fixed with a basic plane, a vertical support rod arranged vertically and one end of which is rotatably connected with the end part of the horizontal support rod,at least two support pieces movably connected with the vertical support rod, an inclined support rod, and an adjusting piece, wherein the support pieces can vertically move relative to the vertical support rod and are fixed to any positions of the vertical support rod; the support pieces are used for connecting with an aluminum alloy formwork; one end of the inclined support rod is rotatably connected with the horizontal support rod; and the adjusting piece is rotatably connected with the other end of the inclined support rod and is movably connected with the vertical support rod. The whole structure is not easy to move and has good supporting and fixing effects; the support stability of the aluminum alloy formwork is improved; and the casting and molding quality of concrete is improved.

Owner:浙江二十冶建设有限公司 +1

Integrated revolving platform

InactiveCN105397507ACompact structureHigh rotation accuracyMachine tool componentsFeeding apparatusBall bearingEngineering

The invention relates to an integrated revolving platform which comprises a working table, motor stators, rotors, crossed roller revolving bearings, deep groove ball bearings and a machine base, wherein a spigot shaft is fixed in the center of the working table; the rotors are fixed at the middle part of the outer wall of the spigot shaft; the crossed roller revolving bearings are arranged among the working table, the rotors and the machine base; the motor stators are fixed at the middle part of the inner wall of the machine base; the outer rings of the deep groove ball bearings are fixed to the lower part of the inner wall of the machine base; the inner rings of the deep groove ball bearings are fixed to the lower part of the spigot shaft; a synchronous pulley is fixed in the position, below the inner rings of the deep groove ball bearings, on the spigot shaft; and an encoder feedback detection device is fixed in the position, corresponding to the synchronous pulley, of the lower part of the machine base. According to the integrated revolving platform, the supporting precision is high, the rigidity is high, the mechanical and electrical integration is achieved, and the mechanical transmission error is avoided.

Owner:浙江博雷重型机床制造有限公司

Turbine rotor online dynamic balance disc active adjustment system

PendingCN109443642ASimple structureImprove support accuracyStatic/dynamic balance measurementDynamic balanceEngineering

The invention discloses a turbine rotor online dynamic balance disc active adjustment system. The system comprises dynamic balance blocks, electromagnetic strips, a radial sliding bearing, non-contacttemperature sensors and angular acceleration vibration displacement sensors; a turbine rotor is surrounded by the radial sliding bearing and rotates in the bearing under oil film lubrication protection. The system of the invention has the advantages of simple structure, high practicability, high reliability, automaticity, high precision and dynamic feedback. When a rotor system suffers a dynamicbalance problem, the dynamic balance blocks with electromagnetic forces and the circumferential electromagnetic strips laid at the innermost surface of the slide way of the slot-in-slot structure of ajournal and the innermost surface of the slide way of the slot-in-slot structure of the inner ring of the bearing attract each other through the unbalanced signals of a high-speed rotation rotor component which are fed back by the circumferentially-arranged angular acceleration vibration displacement sensors, and the dynamic balance blocks start working; and the dynamic balance blocks slide in aclosed slide way formed by the slot-in-slot structure of the inner ring of the bearing and the slot-in-slot structure of the rotator journal so as adjust the overall dynamic balance of the system.

Owner:NORTH HUAJIN CHEM IND CO LTD

Accessory mounting structure

ActiveCN101463756ASatisfied with work efficiencyImprove support accuracyCasingsMachines/enginesAlternatorCylinder block

A horizontal groove extending horizontally when an alternator bracket is fixed to a cylinder block of a vehicle engine is formed in the alternator bracket. A shank of a bolt inserted through mounting pieces of an alternator is inserted into the horizontal groove from a horizontally lateral direction toward the cylinder block to support the bolt on a lower surface of the horizontal groove. After insertion, the bolt is restrained from moving toward an opening of the horizontal groove. Since the insertion of the bolt into the horizontal groove is facilitated, and the weight of the alternator is borne by the lower surface of the horizontal groove, a burden on a fixing portion is reduced, and it becomes easy to position the alternator and hold it when it is fixed. Thus, the accessory can be mounted on the cylinder block with satisfactory work efficiency and with support accuracy kept high.

Owner:MITSUBISHI MOTORS CORP

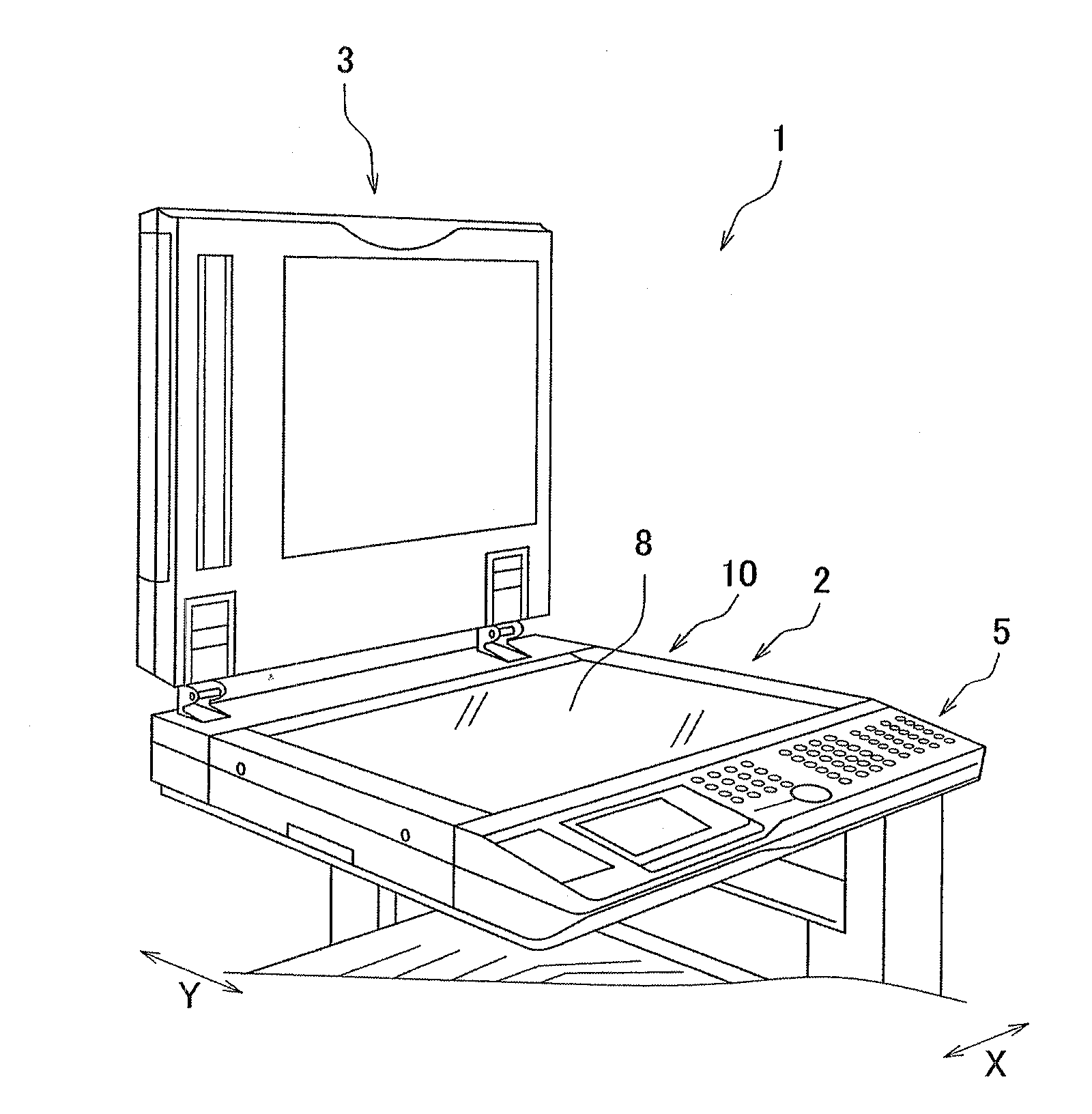

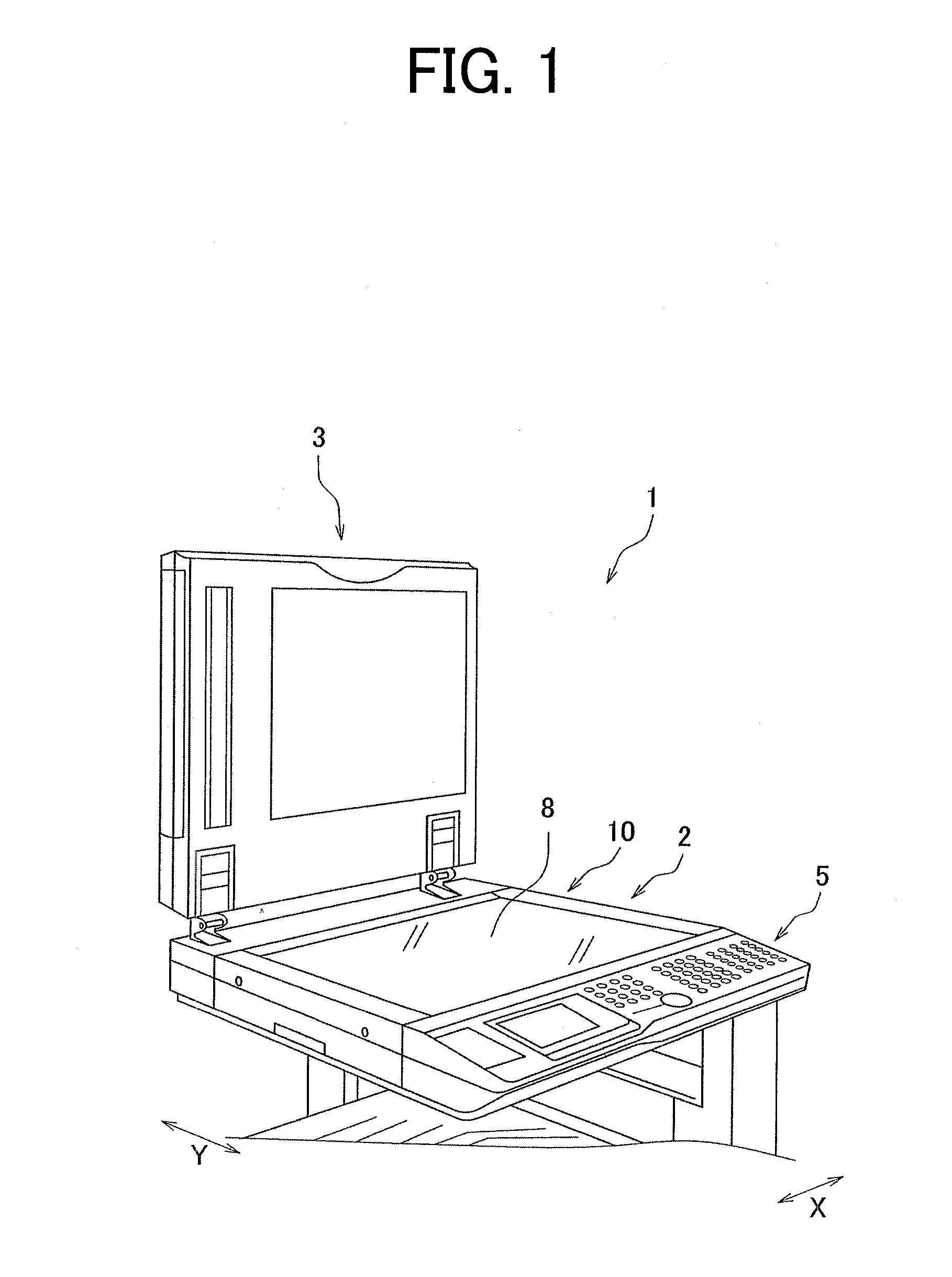

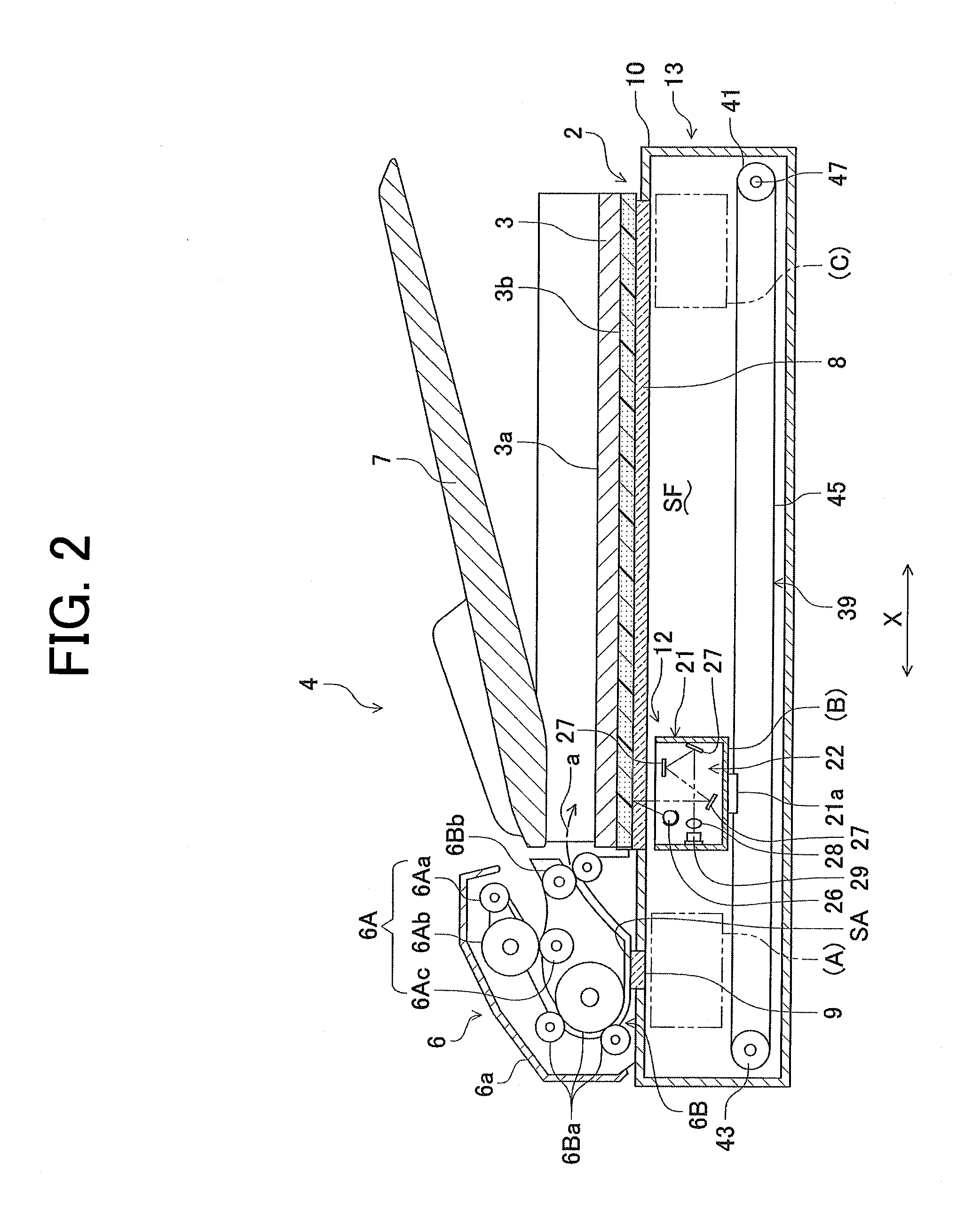

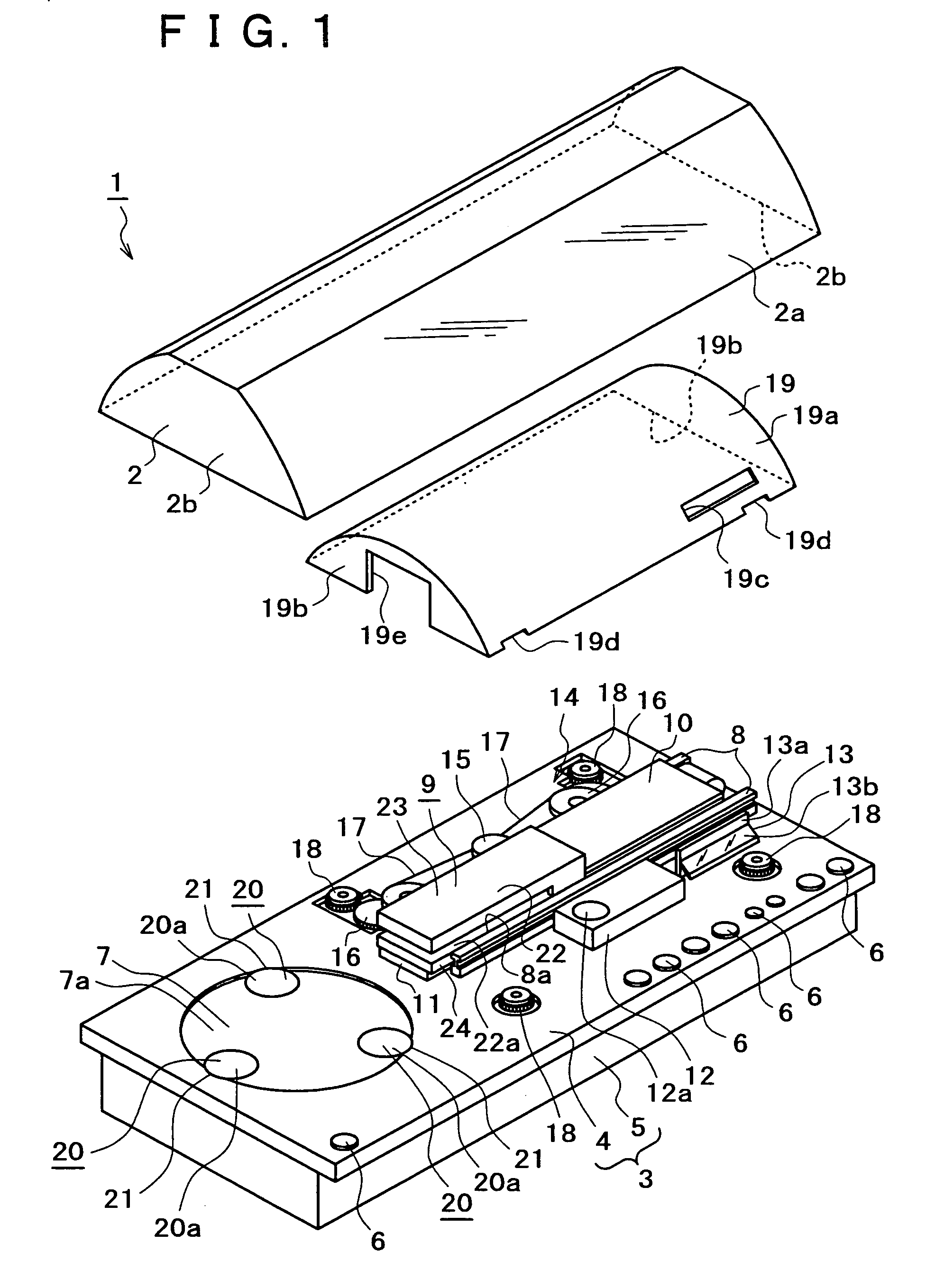

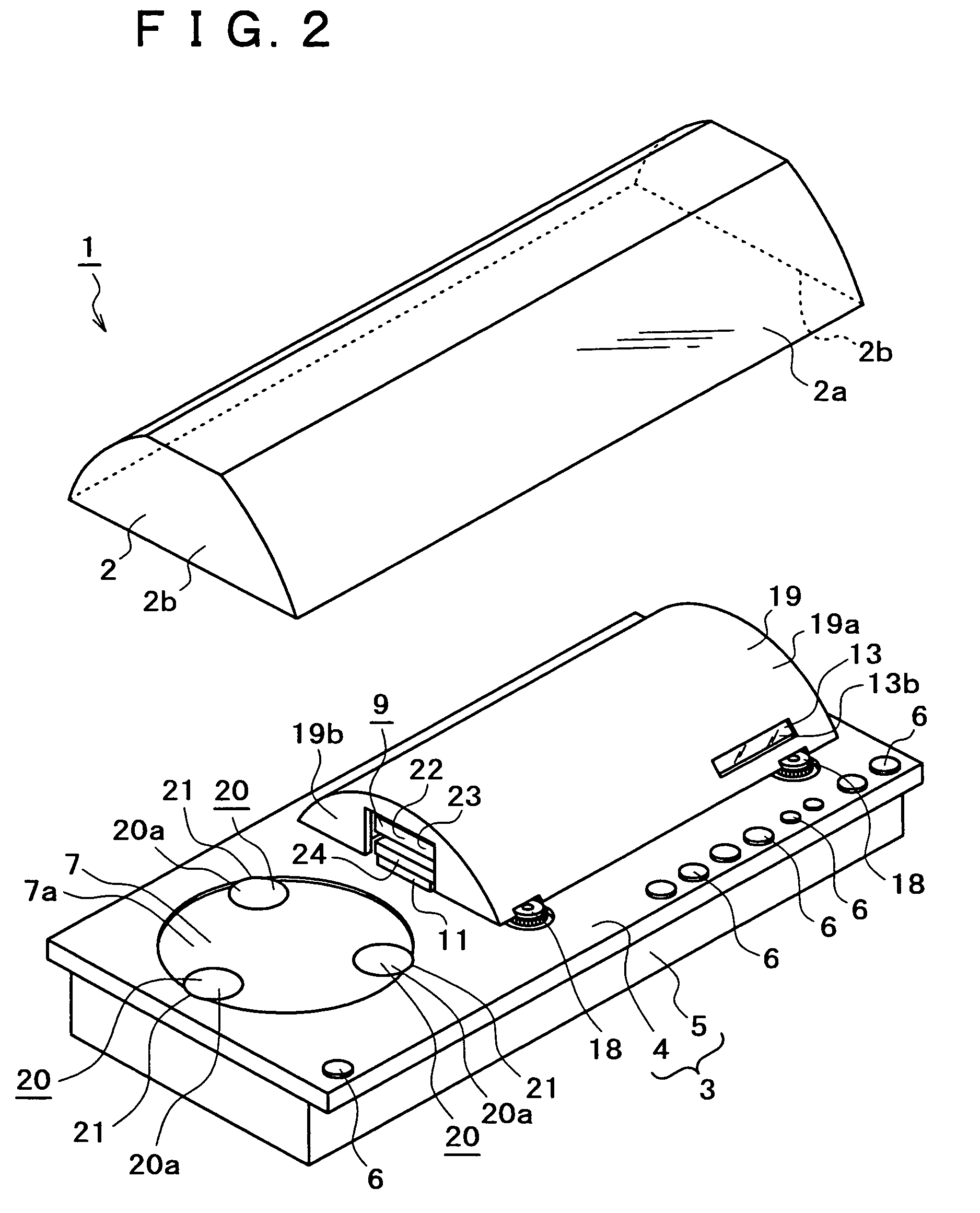

Image scanning device

InactiveUS20110176182A1Reduce component countSimple configurationPictoral communicationEngineeringChassis

An image scanning device includes a housing, a scanning carriage, and a first guide groove and a second guide groove. The housing includes a bottom chassis and a side wall member, and defines a document tray. A scanning carriage is movably arranged in the housing. The first guide groove and the second guide groove are arranged at the side wall members of the housing, and guide the scanning carriage in a scanning direction.

Owner:MURATA MASCH LTD

Universal disassembling and assembling rack for gun turret

ActiveCN105014363AHigh flatness of bearing surfaceImprove support accuracyMetal working apparatusSupporting systemTurret

The invention discloses a universal disassembling and assembling rack for a gun turret. The universal disassembling and assembling rack comprises a base, supporting systems and hexagonal reducing trays. The base comprises two bottom steel channels arranged in parallel and an adjusting steel channel for connecting the two bottom steel channels into an I shape. The adjusting steel channel comprises two sections which are fixedly connected with the opposite sides of the two bottom steel channels respectively. The opened ends of the two sections of the adjusting steel channel are connected through a bolt, and an adjusting oil cylinder is installed between the two sections of the adjusting steel channel. Each supporting system comprises a supporting oil cylinder and a supporting pillar which are vertically installed at the two ends of the corresponding bottom steel channel respectively. The universal disassembling and assembling rack further comprises supports which are installed on the upper surfaces of the bottom steel channels in a bias manner. The universal disassembling and assembling rack is used for carrying the gun turret and backwards drawing a barrel; corresponding checking, maintaining and repairing are convenient; barrel maintaining and replacing are achieved; and the universal disassembling and assembling rack is suitable for overhauling of various types of gun turrets, high in universality and capable of effectively reducing the research and equipment cost of troop tools.

Owner:NO 63908 TROOPS PLA

Hybrid vehicle driving apparatus

ActiveUS8808125B2Improve support accuracyIncrease the number ofHybrid vehiclesToothed gearingsHybrid vehiclePower transmission

Owner:TOYOTA JIDOSHA KK +1

Hybrid drive device and automobile with device mounted thereon

InactiveCN1701000AEasy to assembleIncrease carrying capacityHybrid vehiclesElectrodynamic brake systemsPower splitHybrid drive

Owner:TOYOTA JIDOSHA KK

Gear chain type core rod for bending forming of rectangular pipe

The invention discloses a gear chain type core rod for bending forming of a rectangular pipe. The gear chain type core rod for bending forming of the rectangular pipe comprises one or more core balls,a core shaft and a gear chain type connector. The core balls are used for supporting the bent pipe section of the rectangular pipe, the core shaft is used for supporting the linear section of the rectangular pipe, and the gear chain type connector is used for connecting the core balls and connecting the core balls and the core shaft. The gear chain type connector comprises single-side gear plates, double-side gear plates, connecting pieces, long limiting rings, short limiting rings and shafts. Each core ball is a shell which is of a cuboid structure, and a first installation cavity is formedinside each shell. The core shaft is of a cuboid structure. The gear chain type core rod for bending forming of the rectangular pipe has the certain universality, can be suitable for bending forming of the thin-wall pipe with the small bending radius, and is high in supporting accuracy.

Owner:ZHEJIANG KING MAZON MACHINERY

Angle adjusting device and silk-screen printing device

InactiveCN108357192AHigh precisionHigh control precisionScreen printersScreen printingScreen printingLinear motion

Owner:SUZHOU MAXWELL TECH CO LTD

Kitchen and bathroom water stop platform aluminum formwork construction structure

InactiveCN111379412APrecise positioningSolve the problem of eating moldForms/shuttering/falseworksArchitectural engineeringShear wall

The invention discloses a kitchen and bathroom water stop platform aluminum formwork construction structure, and belongs to the technical field of building construction. The construction structure ischaracterized by comprising split heads and reverse ridge formworks (7), wherein the lower sides of the split heads are connected with a top plate (1), the reverse ridge formworks (7) are arranged onthe upper sides of the split heads, positioning parts for positioning the reverse ridge formworks (7) are arranged on the two sides of the tops of the split heads, and the split heads are arranged along the reverse ridge formworks (7) at intervals. According to the kitchen and bathroom water stop platform aluminum formwork construction structure, the reverse ridge formworks are supported on the split heads, the lower sides of the split heads are connected with the top plate, and the positioning parts for positioning the reverse ridge formworks are arranged on the two sides of the top of the split heads, so that reliable positioning of the reverse ridge formworks are guaranteed, and the problems of vertical post return settlement and reverse ridge deflection caused by formwork reinforcing deformation are avoided; the anti-ridge axis displacement can be avoided, the problem of slab staggering between the anti-ridge and a shear wall due to pouring deformation of the anti-ridge is solved;the problem of formwork engagement due to sinking of the anti-ridge formwork during concrete pouring is also solved; and the anti-ridge formwork is high in supporting speed and supporting precision.

Owner:山东天齐置业集团股份有限公司

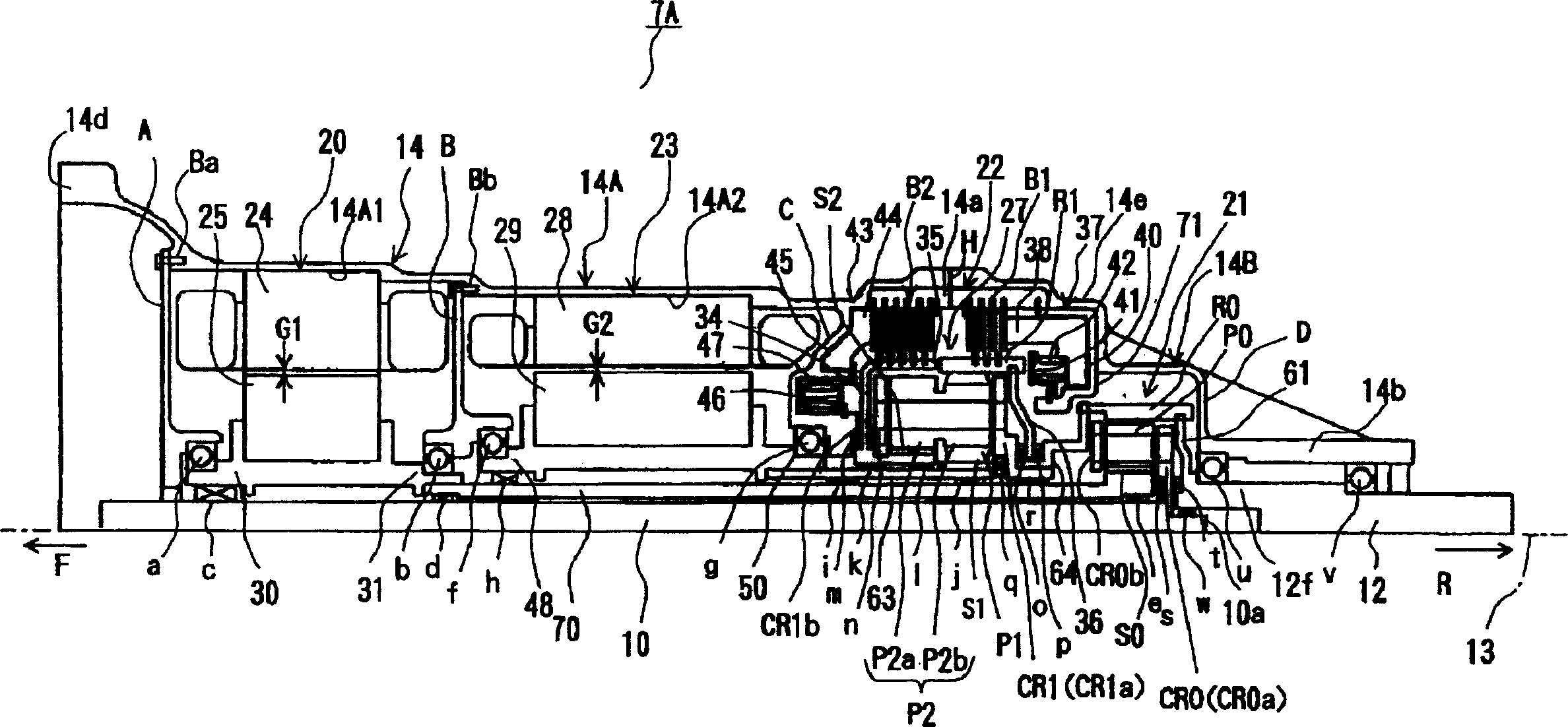

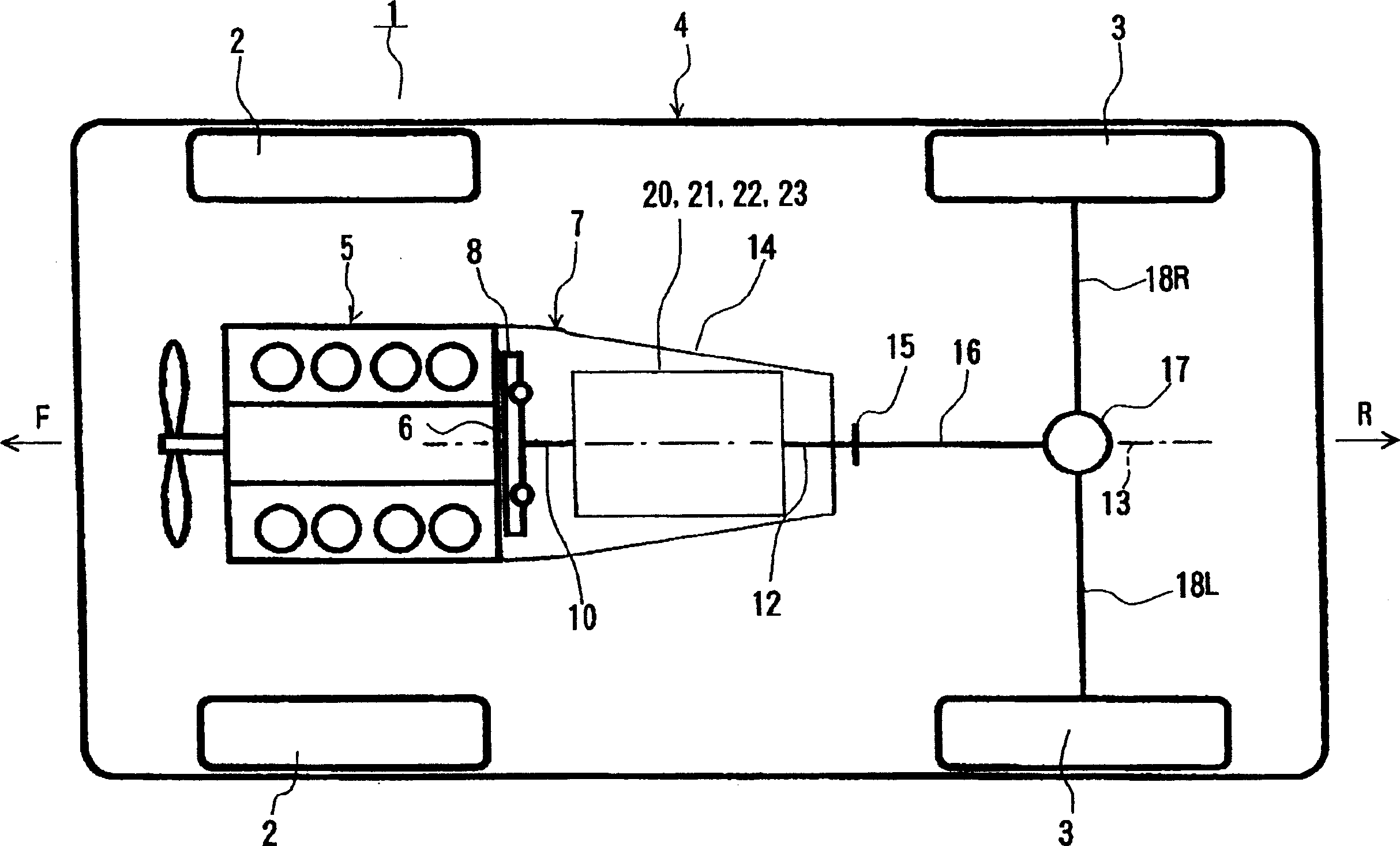

Hybrid drive device and automobile mounted with device

ActiveCN1700999AStable supportInhibition of oversizingElectric propulsion mountingPropulsion using engine-driven generatorsHybrid driveElectric motor

A connection portion (14d) at a front end portion of a case member (14) is connected to an internal combustion engine, and the case member is mounted on a portion (4a) of a vehicle body using a mount portion (installation portion) (14c) at a rear end portion of the case member (14). Further, a second electric motor (23), a heavy object, is disposed at the rearmost end portion of a line where a first electric motor (20), a planetary gear (21) for power distribution, a second electric motor (23), and a speed changer (22) are arranged on one shaft (13) of the case member (14). This suppresses vibration occurring in the case member (14).

Owner:TOYOTA JIDOSHA KK

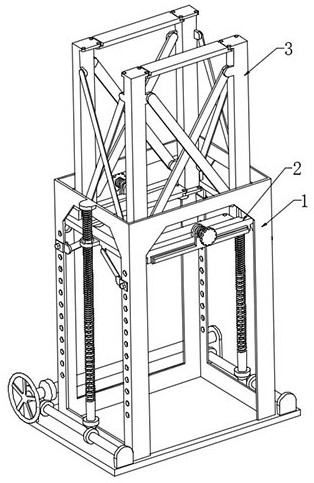

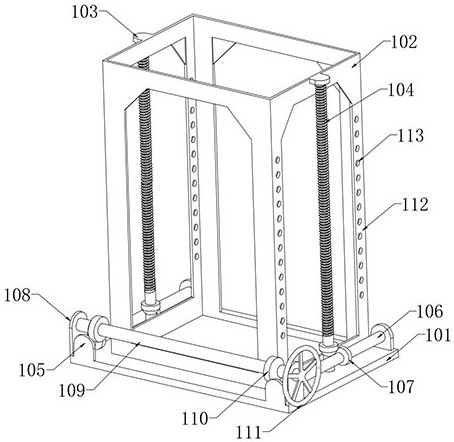

Detachable steel structure jig frame for building construction

The invention discloses a detachable steel structure jig frame for building construction, and relates to the technical field of building construction auxiliary equipment.The detachable steel structure jig frame comprises a supporting assembly, a lifting assembly and a jig frame assembly, the lifting assembly is arranged in the supporting assembly, the jig frame assembly is arranged above the lifting assembly, and the supporting assembly comprises a supporting frame; a supporting frame is arranged on the upper surface of the supporting frame. By arranging the supporting assembly, the lifting assembly and the jig frame assembly, the lifting assembly can move up and down in the supporting assembly, the lifting assembly can drive the jig frame assembly to move up and down, and therefore the height of the jig frame assembly can be adjusted, and the multiple jig frame assemblies are spliced through the splicing bases; according to the assembly jig, the assembly jig assembly can be rapidly spliced, it is guaranteed that the assembly needing to be supported in building construction is manufactured, meanwhile, the disassembly and assembly efficiency of the assembly jig is improved, use of the assembly jig is facilitated, the construction progress is accelerated, adaptability is higher, and the damping and buffering effect is better.

Owner:SHANXI INSTALLATION GRP CO LTD

Construction method of arc-shaped outer wall of basement based on one-sided support formwork of stereotyped support

The invention relates to a construction method for a basement arc-shaped outer wall based on a stereo-type bracket single side formwork. The construction method for the basement arc-shaped outer wallbased on the stereo-type bracket single side formwork is characterized in that anchor backing plates are preinstalled in a basement base plate, horizontal sliding grooves are formed in the lower portions of the anchor backing plates; a bracket base plate is arranged on the upper surface of the basement base plate, an arc-shaped formwork guide slot is formed in the position, corresponding to an outer wall internal mold, of the bracket base plate, a stand column is arranged on the upper surface of the basement base plate, a column top beam is arranged at the top of the stand column; a first hanging beam is connected with a second hanging beam through a hanging beam poisoning frame; a steel bar cage gripper is arranged at a cantilever end of the first hanging beam; a connecting protruding falcon and a connecting groove are formed in the joint position of an assembly type outer mold, a waterproof layer and a vertical-directional supporting rod are arranged on the outside of the assembly type outer mold; a protective layer control strip is arranged between the assembly type outer mold and an outer wall inner mold and a wall body steel bar cage; and an assembly type outer mold limiting groove and a supporting rod limiting groove are formed in the foundation of the wall bottom in a pre-installation mode. The construction method for the basement arc-shaped outer wall based on the stereo-type bracket unilateral mode branch not only can improve the construction efficiency of the arc-shaped outer wall and the formwork bracing quality, but also can reduce the difficulties of lifting and positioning of the wall body steel cage, and further can improve the use ratio of materials.

Owner:核工业西南建设集团有限公司

Radial support mechanism of primary mirror of large aperture telescope for eliminating temperature stress

The invention provides a radial support mechanism of a primary mirror of a large aperture telescope for eliminating the temperature stress, which consists of a radial support base, a lever bracket, clump weights, a lever, a lower pair slider bar, rolling bearings and an indium steel sleeve. The indium steel sleeve is sleeved on the radial support base which is located in the middle of the indium steel sleeve. Silica gel is dotted at a gap fit position between the radial support base and indium steel sleeve so that the indium steel sleeve is fixed on the radial support base. The lever is connected to the radial support base via two mounting screws. The pivot end of the lever is connected to the lever bracket by two rolling bearings through the lower pair slider bar. The clump weights are screwed in the lower end part of the lever in threaded connection. Two bearing cover plates cover the bearing holes on the lever bracket. When the radial support mechanism of the primary mirror works, the radial support mechanism is connected to and fixed on the primary mirror base by means of two mounting screws via the lever bracket, and the radial support base extends to the radial support holesof the primary mirror to be mounted.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Disk chucking mechanism and disk drive device with increased positional accuracy

InactiveUS7249362B2High positioning accuracyLow-profile structureRecord information storageRecording on magnetic disksEngineeringPulley

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com