Accessory mounting structure

A technology of auxiliary equipment and installation structure, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve problems such as difficult alternator maintenance, reduced bolt hole accuracy, and inability to maintain alternator pulley coplanarity, etc. Achieve the effect of easy positioning, convenient positioning and fixed work, and stable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be explained in detail with reference to the drawings.

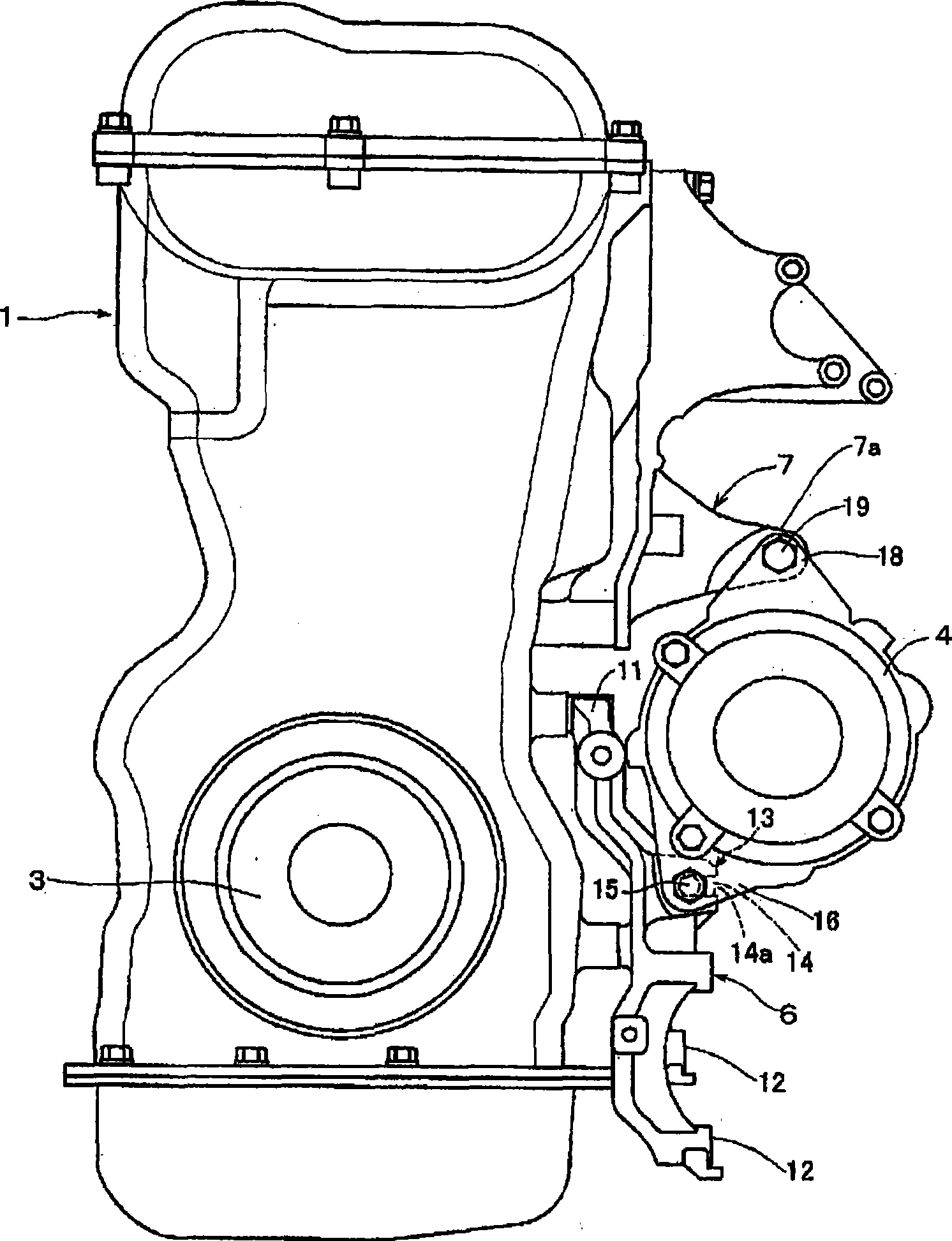

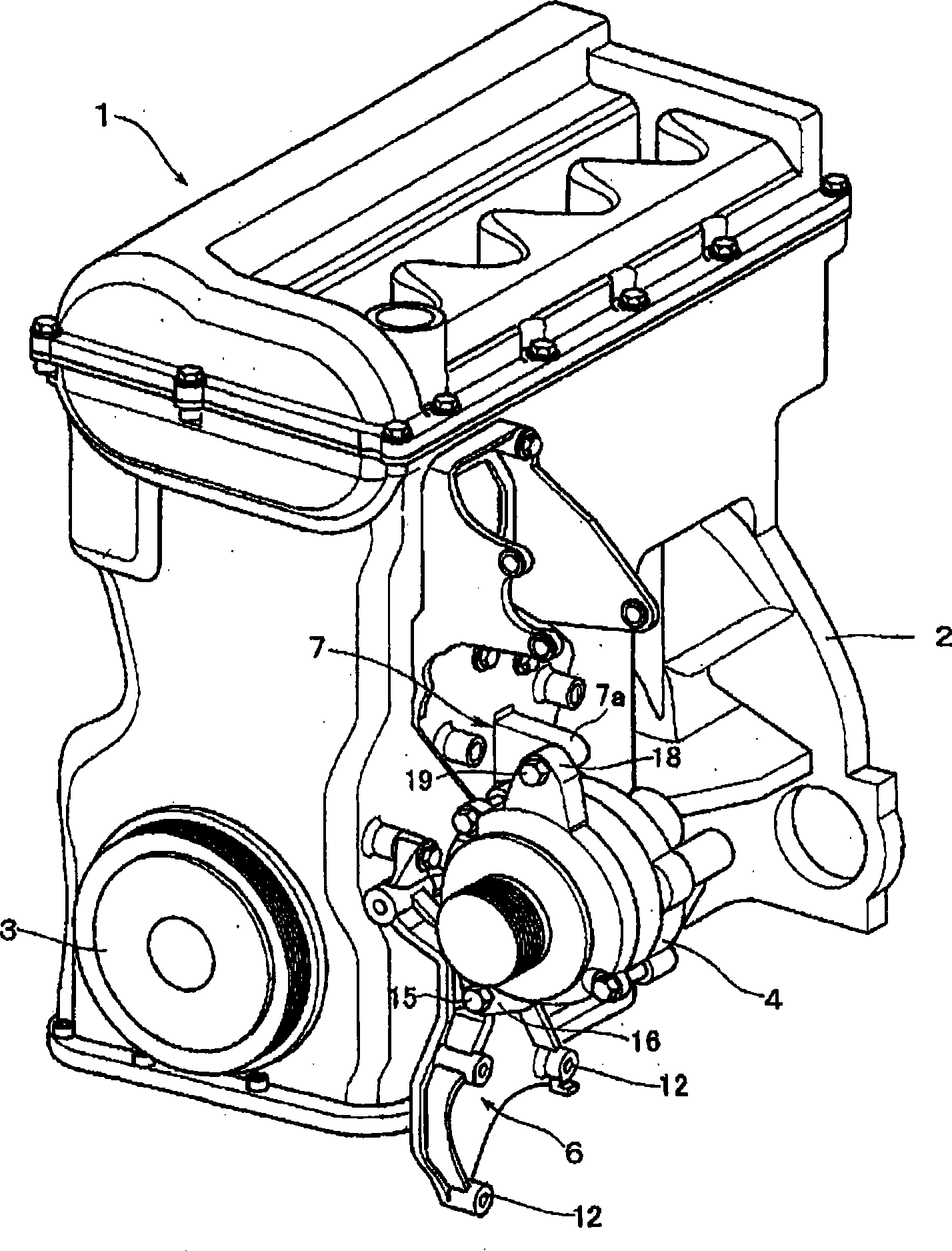

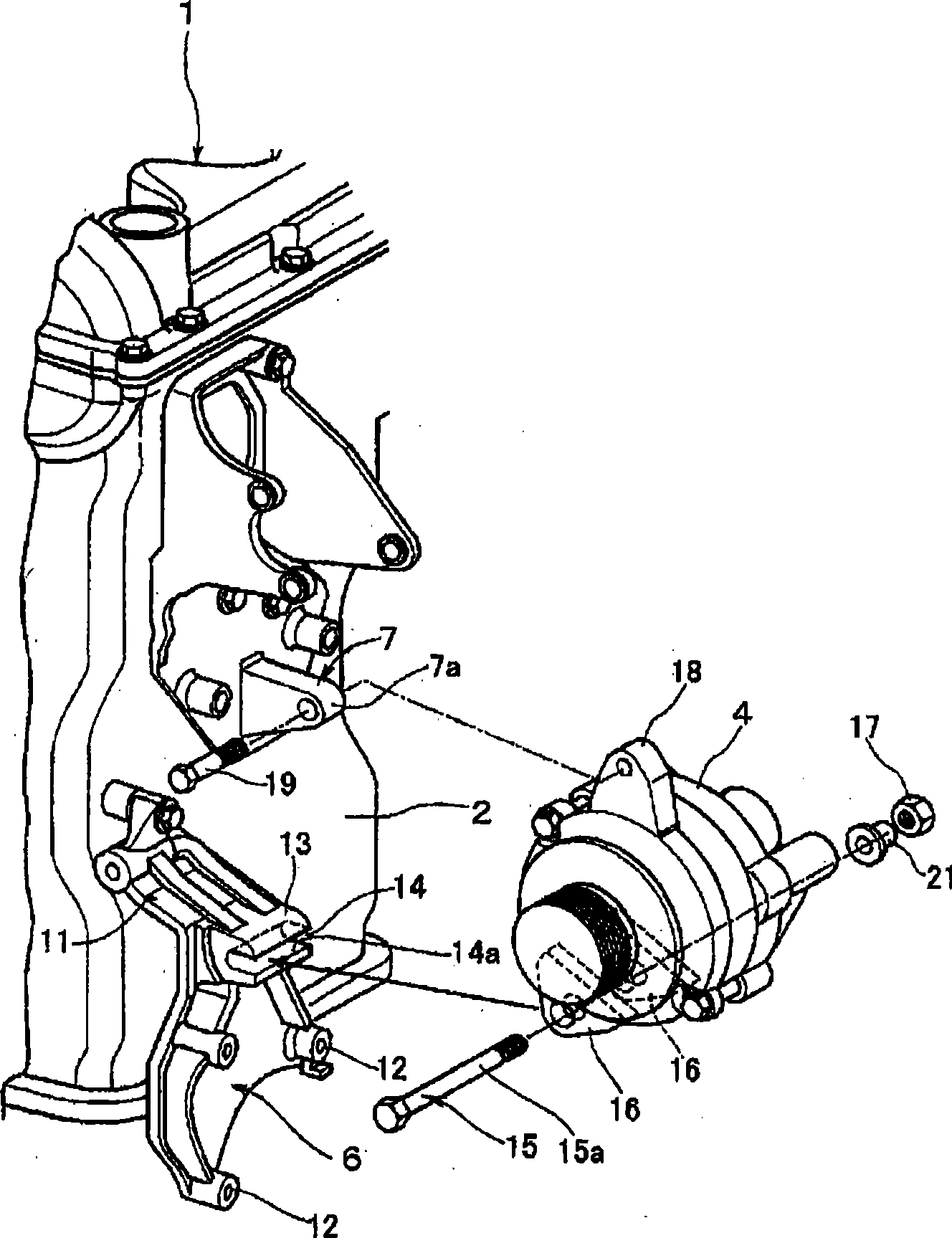

[0028] Such as figure 1 with 2 As shown, a vehicle engine (engine) 1 is an in-line multi-cylinder engine, and a crank pulley 3 connected to the crank is arranged on the front side of the cylinder block 2 of the engine 1. On the other hand, beside the side surface of the cylinder block 2, the alternator 4 as auxiliary equipment is held. In addition, the power steering pump and the air compressor are held beside the side surface of the cylinder block 2.

[0029] The pulley of auxiliary equipment such as the alternator 4 is arranged on the same plane as the crank pulley 3, and the belt is looped around the crank pulley 3 and the auxiliary equipment pulley through an idler pulley and a tension pulley. By doing so, the driving force of the crank of the engine 1 is transmitted to auxiliary equipment such as the alternator 4.

[0030] Such as Figure 1 to 5 As shown, an alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com