Construction method of arc-shaped outer wall of basement based on one-sided support formwork of stereotyped support

A technology for basement exterior walls and shaped brackets, applied in wine cellars, buildings, building components, etc., can solve the difficult problems of accurate positioning of curved exterior wall formwork, rapid hoisting of steel cages, rapid hoisting of protective layers, effective control of protective layer thickness, etc., to avoid protective layer Insufficient thickness, improved accuracy, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Technical requirements for bolt fastening construction, external wall internal formwork hoisting construction technical requirements, steel cage binding and hoisting construction technical requirements, site welding construction technical requirements, concrete pouring construction technical requirements, wall filling body construction technical requirements, etc., in this embodiment No more details will be given, and the embodiments of the methods involved in the present invention will be explained emphatically.

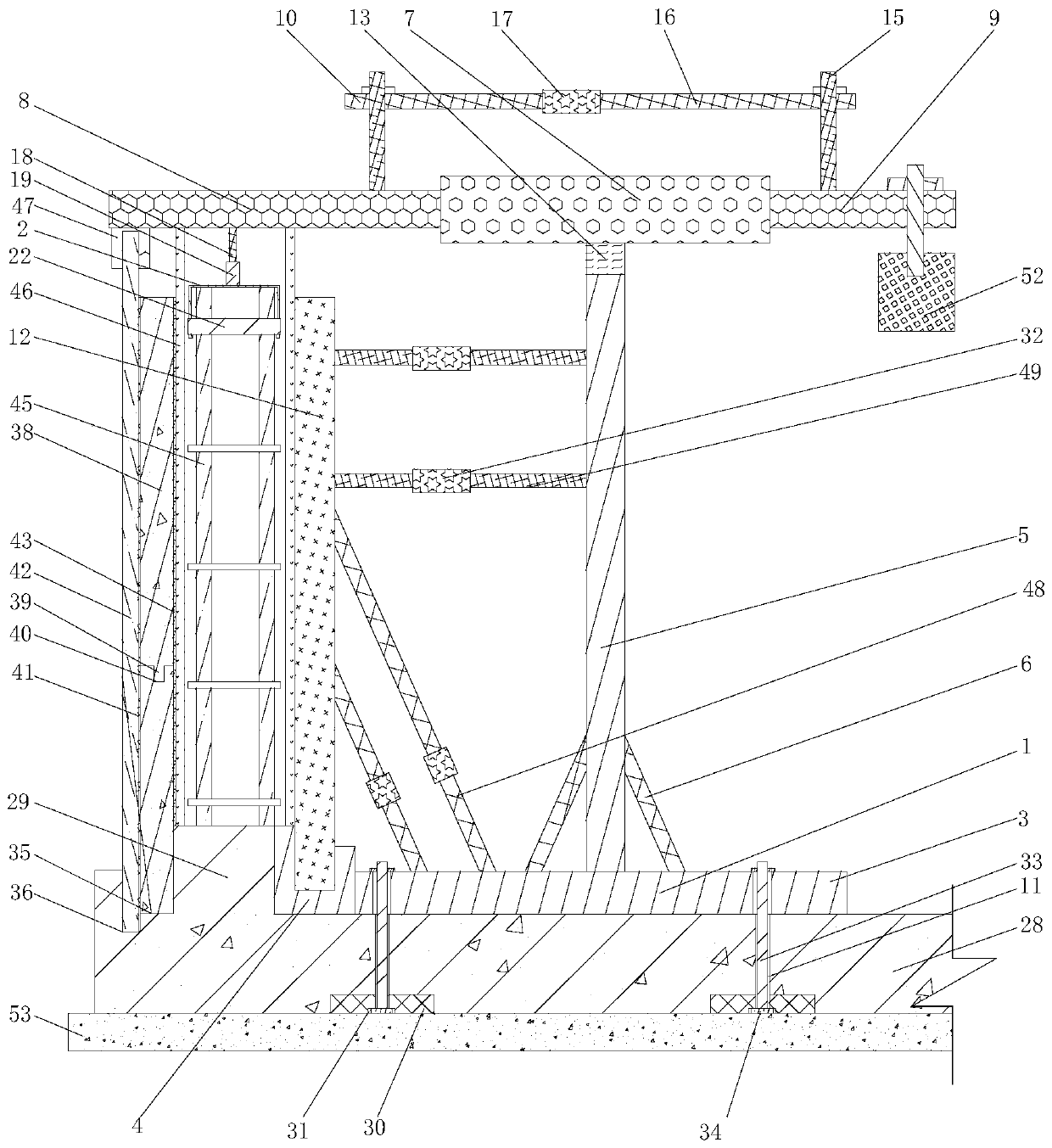

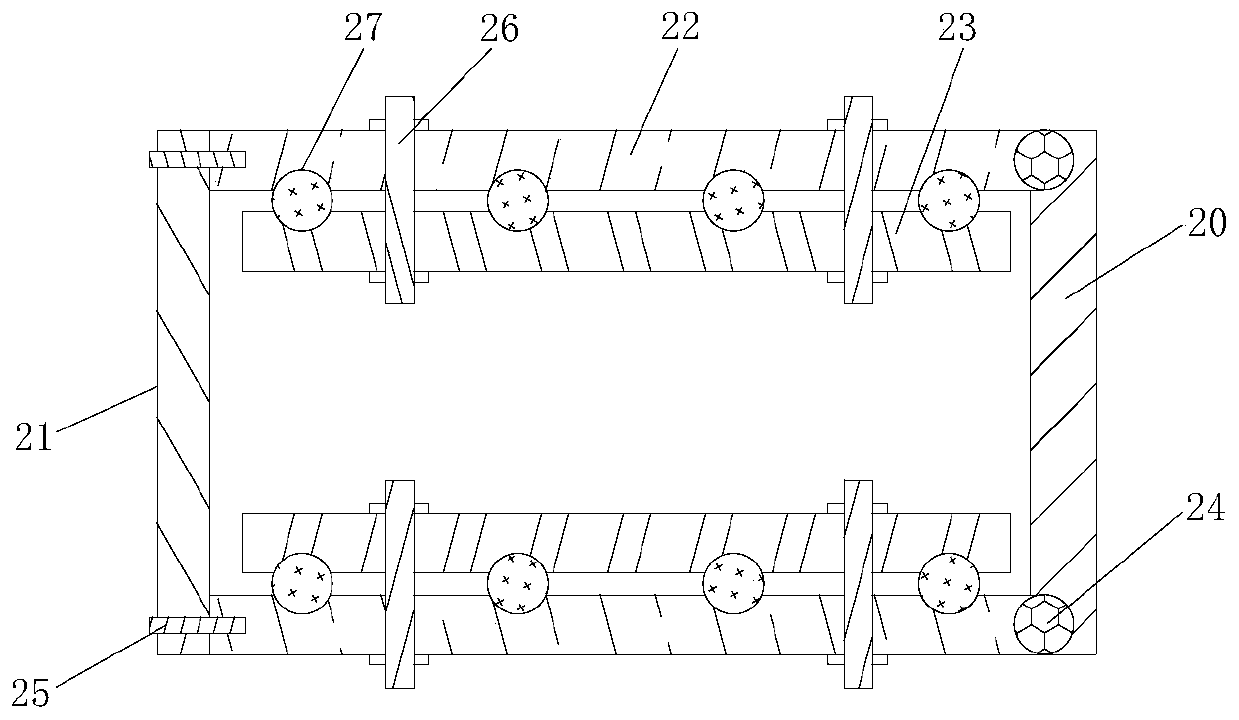

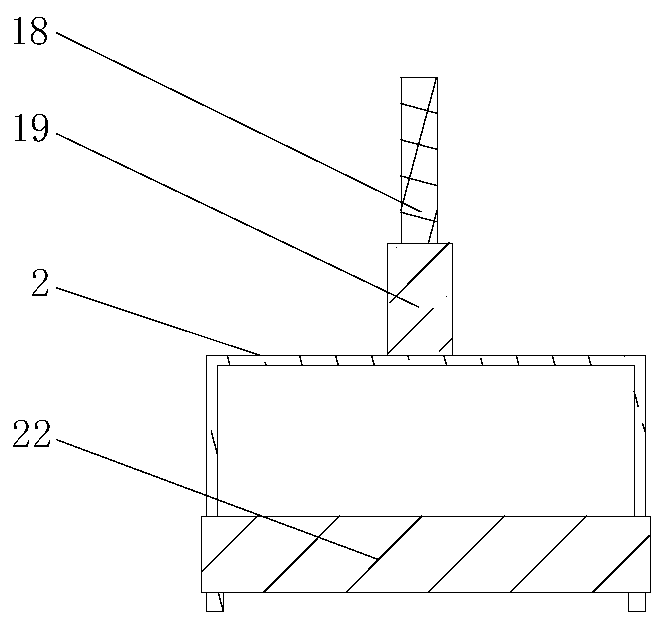

[0036] figure 1 It is a schematic diagram of the construction structure of the arc-shaped outer wall of the basement based on the unilateral formwork of the stereotyped bracket in the present invention, figure 2 yes figure 1 Schematic diagram of the cross-section of the steel cage gripper, image 3 yes figure 2 Reinforcement Cage Grab Elevation, Figure 4 yes figure 1 Schematic diagram of the cross-section of the beam at the top of the column, Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com