Detachable steel structure jig frame for building construction

A building construction and disassembly technology, applied in building construction, on-site preparation of building components, construction, etc., can solve the problems of reduced support effect and stability, poor height adjustability, tilting and collapse, etc., to improve disassembly and assembly. Efficiency, improving structural strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

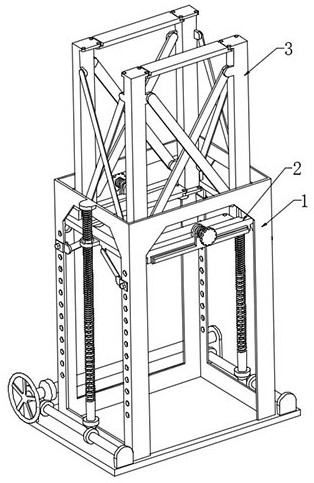

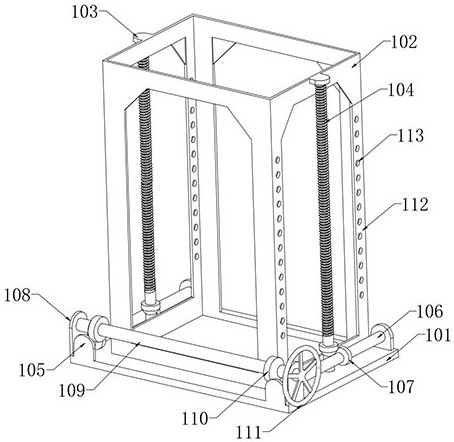

[0041] like Figure 1 to Figure 8 As shown, a detachable steel structure tire frame for building construction includes a support assembly 1, a lifting assembly 2 and a tire frame assembly 3. A lifting assembly 2 is arranged inside the support assembly 1, and a lifting assembly 2 is arranged above the lifting assembly 2. There is a tire frame assembly 3;

[0042] Support assembly 1, the support assembly 1 includes a support frame 101, the upper surface of the support frame 101 is provided with a support frame 102, the middle of both sides of the upper surface of the support frame 102 is provided with support plates 103, and the middle of the lower surface of the support plate 103 is movable through bearings A lifting screw 104 is connected, and the bottom end of the lifting screw 104 is movably connected to the upper surface of the support frame 101 through a bearing. The four corners of the upper surface of the support frame 101 are provided with fixing plates 105, and the fix...

no. 2 example

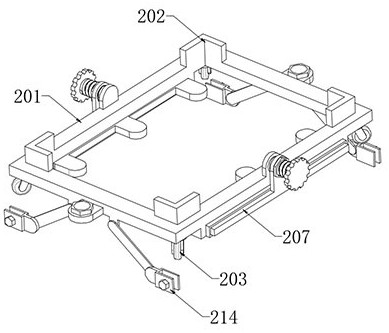

[0054] like Figure 9 As shown, when the tire frame assembly 3 is installed, especially when the splicing seat 303 at the top of the column 301 is not in contact with the top of the wall, it is necessary to adjust the movable frame 201 and then drive the tire frame assembly 3 at the bottom to perform first-order adjustment. The splicing seat 303 at the top of the column 301 is in contact with the top of the wall, and because there is a gap between the adjacent positioning holes 113, there is also a gap when adjusting the height of the movable frame 201, so it is impossible to accurately adjust the process. At the same time, when the inner top surface of the wall is an inclined wall, the horizontally arranged splicing seat 303 cannot be simultaneously set in an inclined state according to requirements, so the top splicing seat 303 is in line contact with the inner top surface of the wall, thereby reducing its supporting strength , can not meet the required support requirements,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com