Winding and method for producing a winding

A winding and carrier technology, applied in the field of winding manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

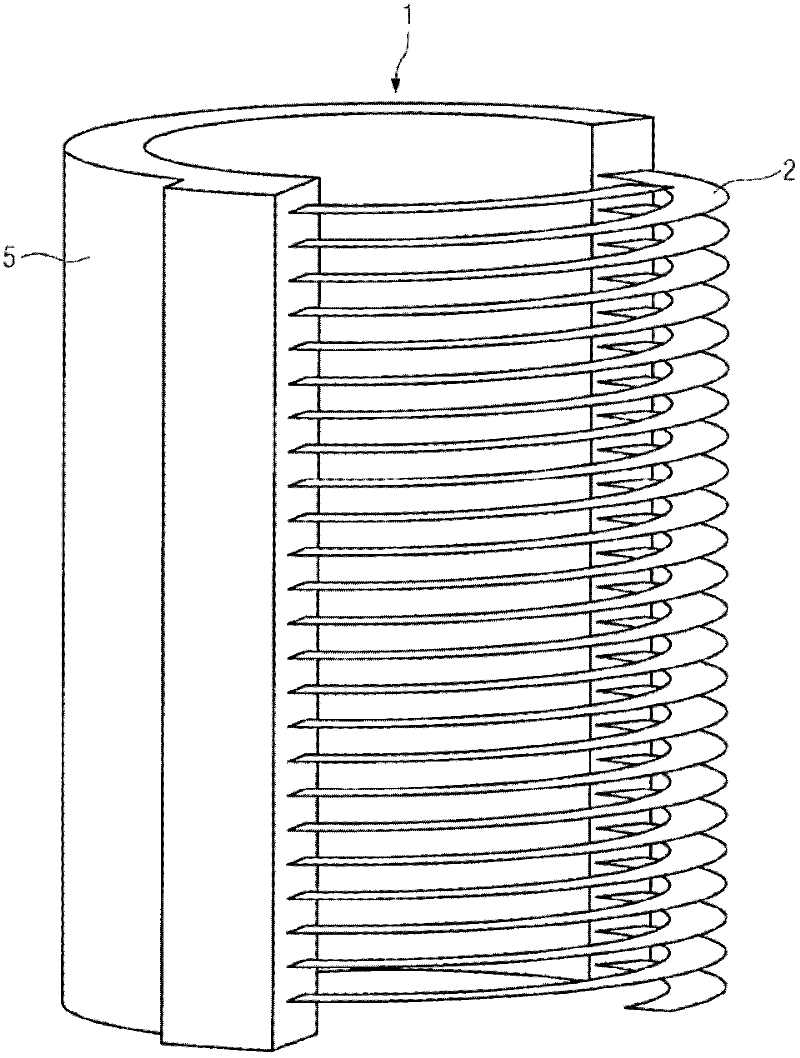

[0025] figure 1 A perspective view showing winding 1. exist figure 1 In the example shown, electrical conductors 3 a , 3 b , 3 c , 3 d (not shown) and at least partially electrically insulating layers 4 a , 4 b , 4 c are arranged on a carrier 2 . The carrier 2 has a curved shape which corresponds to the radius of the winding 1 . exist figure 1 In the example shown, the electrically insulating layers 4a, 4b, 4c are secured by a casing 5 of cast resin. This makes it possible to arrange the respective electrical conductors 3 a , 3 b , 3 c , 3 d on the carrier 2 and to have the respective potting resin jacket 5 completely surround the carrier 2 during subsequent processing. Based on the electrical insulation properties of the casting resin jacket 5, the casting resin jacket fulfills the function of the electrical insulating layers 4a, 4b, 4c.

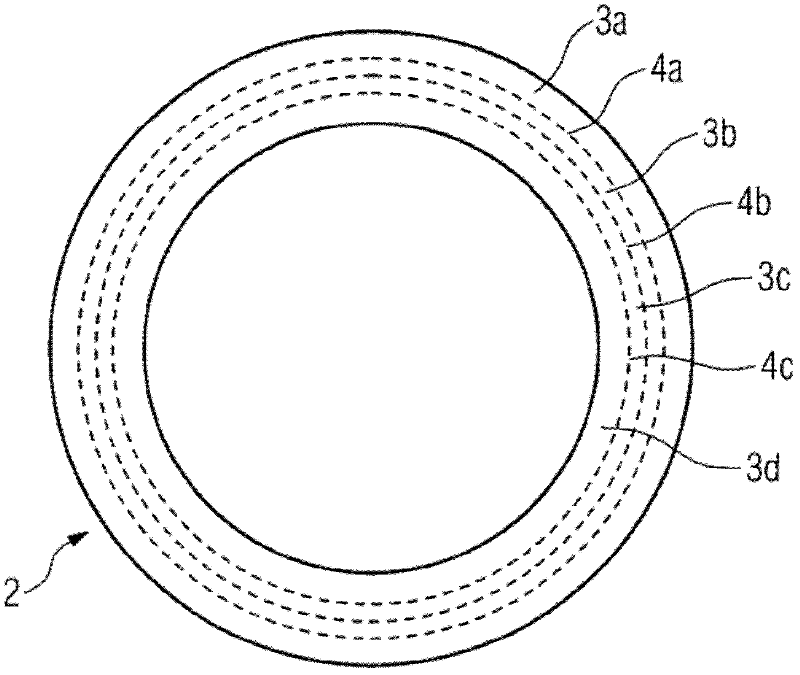

[0026] figure 2 A top view of a carrier 2 with four electrical conductors 3a, 3b, 3c, 3d is shown. Between the individual electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com