Digital capacitance corner sensor calibrating system and calibrating method

An angle sensor, digital technology, applied in the direction of using electric/magnetic devices to transmit sensing components, general control systems, control/regulation systems, etc., to achieve the effect of improving quality indicators, good versatility, and satisfactory work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below according to the accompanying drawings and embodiments.

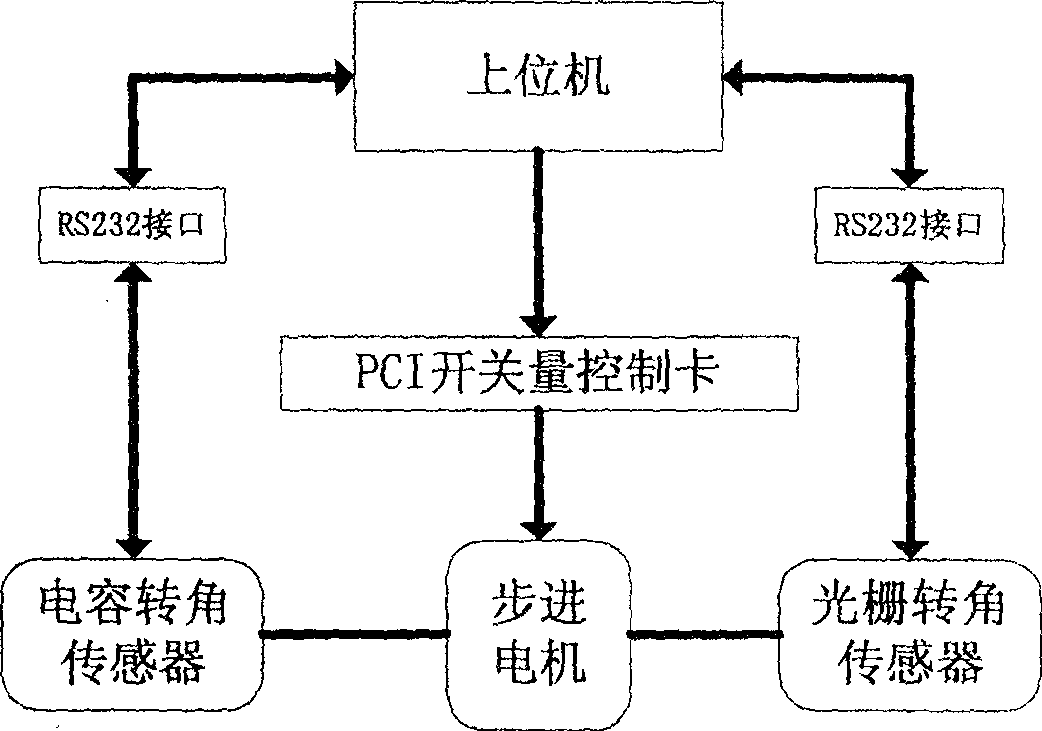

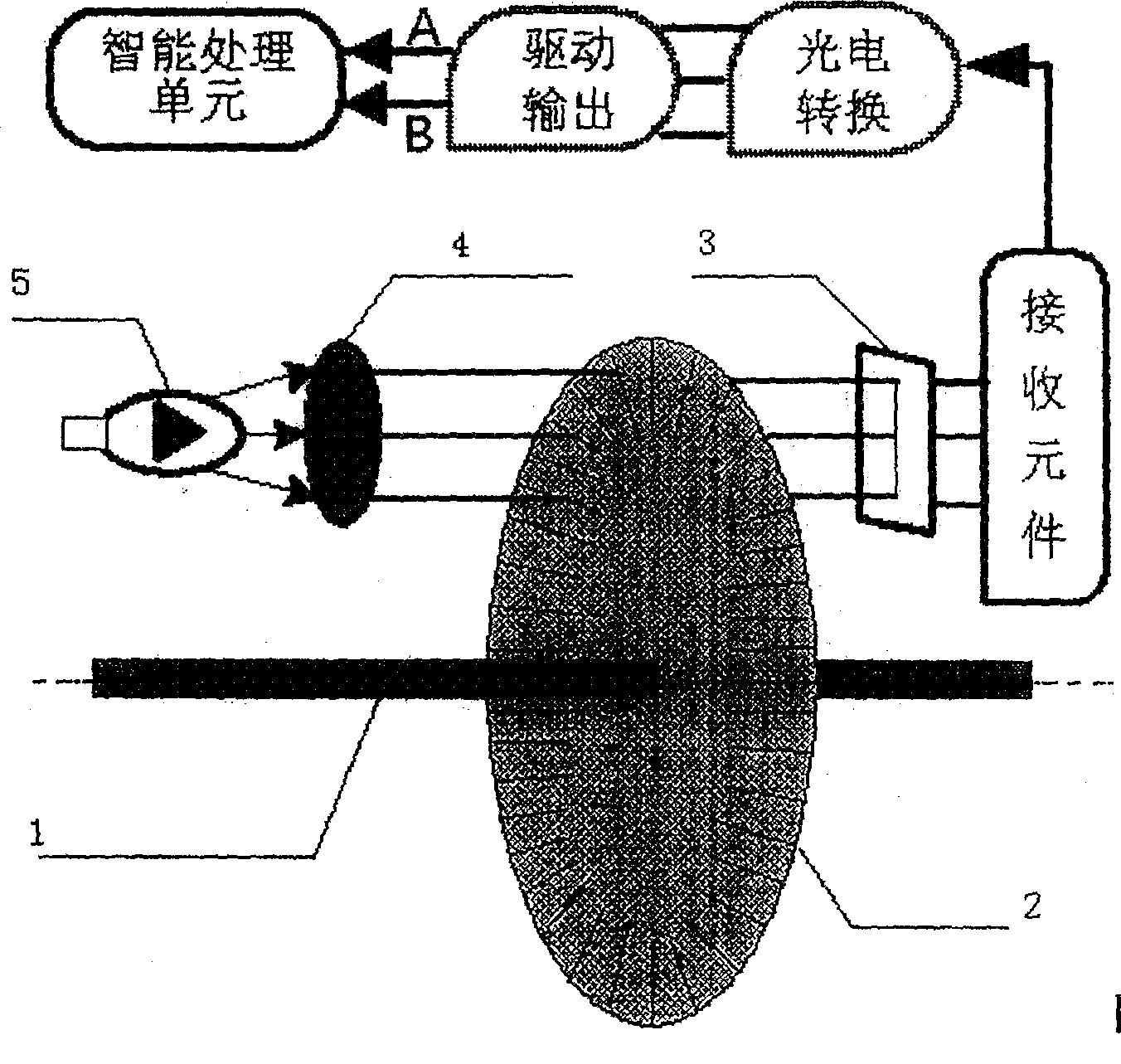

[0024] The overall design block diagram of the system is as follows figure 1 As shown, the sensor to be calibrated is the proportional capacitive angle sensor, the standard sensor is the high-precision grating angle sensor, and the power drive unit of the system is the stepping motor. The RS232 communication interface exchanges data with the upper computer; the start and stop of the stepping motor and the forward and reverse rotation are all realized by the upper computer software through the control of the PCI bus interface card as the interface component, and the output switch value is realized, and the upper computer simultaneously completes data acquisition, Data processing, database management, report output and other functions. In terms of structural layout, the stepper motor and the grating angle sensor are packaged in a stainless steel case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com