Preparation method of functional type engineered wood

A technical wood and functional technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood treatment, etc., can solve the problem of interfacial bonding of veneer interfaces with dyeing agents, poor compatibility of water-based adhesives, and environmental pollution in the bleaching and dyeing process and other problems, to achieve the effect of low formaldehyde and VOC release, good compatibility and good penetration function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of β-cyclodextrin peppermint oil micropowder is as follows: at 20°C, mix β-cyclodextrin and peppermint oil at a mass ratio of 8:65, and peppermint oil is embedded in the cavity of β-cyclodextrin in the form of molecules , forming β-cyclodextrin peppermint oil micropowder in clathrate form;

[0073] The extraction method of bamboo leaf flavonoids is as follows: select the dry leaves of the lower part of the bamboo that is more than six years old in Moganshan, Deqing, and grind them into 0.5mm bamboo leaf fine powder; Add 75wt% methanol solution to dissolve and filter, and take the filtrate as the liquid to be separated by column chromatography.

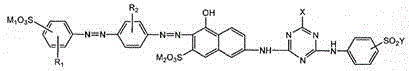

[0074] Three-component compound solution formula two

[0075] It is composed of biomass nanofiber solubilizer, flame retardant and acidic disazo dye compound solution according to the mass ratio of 1:40:100;

[0076] The configuration of biomass nanofiber solubilizer: by weight, 1 part of bamboo leaf fla...

Embodiment 1

[0085] The preparation method of modified MUF adhesive is:

[0086] A. 100 parts of formaldehyde aqueous solution, 0.1 part and 0.3 part of amino-terminated hyperbranched polymer PAMAM whose mass concentration is 36.5wt% are 100 parts by weight, and 0.3 part of amino-terminated hyperbranched polymer PAMAM is put into the reactor, and the stirring is started; The active substance is sodium hydroxide, potassium hydroxide, calcium hydroxide, barium hydroxide or ammonia water;

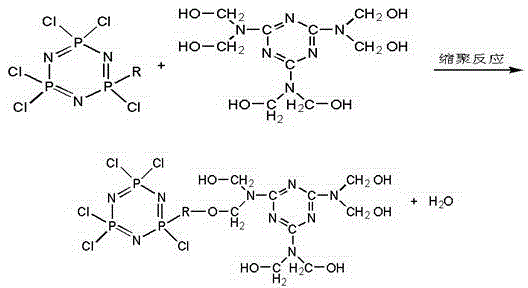

[0087] B. Add 1 part of hexachlorocyclotriphosphazene, heat up to 50°C, and when the temperature rises to 75°C by itself, add 35 parts of melamine, continue to heat up to 90°C, and react to obtain a preliminary polycondensate;

[0088] C. Add 40 parts of melamine to the above-mentioned preliminary polycondensate, and add 0.6 part of p-toluenesulfonamide to obtain the second polycondensate;

[0089] D. Add 20 parts of urea when the temperature of the second polycondensation product is lowered to 70°C, cont...

Embodiment 2

[0091] The preparation method of modified MUF adhesive is:

[0092] A. 100 parts of formaldehyde aqueous solution, 0.5 part and 0.6 part of amino-terminated hyperbranched polymer PAMAM whose mass concentration is 50wt% are 100 parts in formaldehyde aqueous solution and 0.6 part of amino-terminated hyperbranched polymer PAMAM by weight, and the mass concentration is put into the reactor, and the stirring is started; The active substance is sodium hydroxide, potassium hydroxide, calcium hydroxide, barium hydroxide or ammonia water;

[0093] B. Add 1 part of hexachlorocyclotriphosphazene, heat up to 55°C, and when the temperature rises to 85°C, add 55 parts of melamine, continue to heat up to 95°C, and react to obtain a preliminary polycondensate;

[0094] C. Add 45 parts of melamine in the above-mentioned preliminary polycondensate, and add 0.9 part of p-toluenesulfonamide to obtain the second polycondensate;

[0095] D. Add 30 parts of urea when the temperature of the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com