Formaldehyde purification plate and preparation method thereof

A technology for formaldehyde purification and sheet materials, applied in chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems of decorative paper visual distortion and other problems, and achieve the effect of realistic surface decoration, good effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

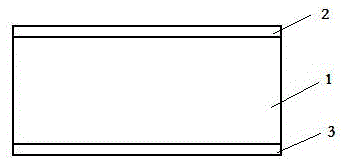

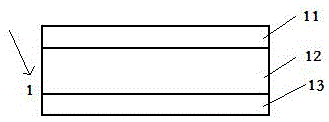

Image

Examples

Embodiment 1

[0056]a. Base material preparation: the base material layer is an oriented strand board layer, and the oriented strand board layer includes upper and lower surface layers in which the glue-mixed shavings are arranged longitudinally according to their fiber directions and a core layer of shavings in which the glue-mixed shavings are arranged horizontally according to their fiber directions;

[0057] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain the formaldehyde decomposition glue; the mass ratio of the formaldehyde decomposition active ingredients to the formaldehyde decomposition glue is 5%, and the stirring time is 5min; the formaldehyde decomposition is effective The ingredients include chitin, nano-silicon chips and tourmaline powder; tourmaline powder accounts for 1wt% of the mass of formaldehyde-decomposing active ingredients;

[0058] c. Manufacture of decorative adhesi...

Embodiment 2

[0065] a. Substrate preparation;

[0066] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain formaldehyde decomposition glue; the mass ratio of formaldehyde decomposition active ingredients to formaldehyde decomposition glue is 10%, and the stirring time is 10min; formaldehyde decomposition is effective The ingredients include chitin, nano-silicon chips and tourmaline powder; tourmaline powder accounts for 3wt% of the mass of formaldehyde-decomposing active ingredients;

[0067] c. Manufacture of decorative adhesive film paper: pass the decorative paper through amino resin glue and formaldehyde decomposition glue successively, and dry; the decorative paper is printed decorative paper with ash wood grain or maple wood pattern; the amino resin glue is Melamine-formaldehyde resin or melamine-modified urea-formaldehyde resin glue; the dipping amounts of the amino resin glue and the f...

Embodiment 3

[0074] a. Substrate preparation;

[0075] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain the formaldehyde decomposition glue; the mass ratio of the formaldehyde decomposition active ingredients to the formaldehyde decomposition glue is 6%, and the stirring time is 8 minutes; the formaldehyde decomposition is effective The ingredients include chitin, nano-silicon flakes and tourmaline powder; tourmaline powder accounts for 5wt% of the mass of formaldehyde-decomposing active ingredients; the mass ratio of chitin, nano-silicon flakes and tourmaline powder is 60:35:5;

[0076] c. Manufacture of decorative adhesive film paper: pass the decorative paper through amino resin glue and formaldehyde decomposition glue successively, and dry; the decorative paper is printed decorative paper with ash wood grain or maple wood pattern; the amino resin glue is Melamine-formaldehyde resin or m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com