Angle adjusting device and silk-screen printing device

An angle adjustment device and angle technology, applied in printing, printing machine, printing process and other directions, can solve the problems of complex linkage relationship, inability to realize fine control of printing screen frame, etc., to reduce energy consumption, improve transmission efficiency and precision, The effect of improving accuracy and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention can be further clearly understood through the specific examples of the present invention given below, but they are not intended to limit the present invention.

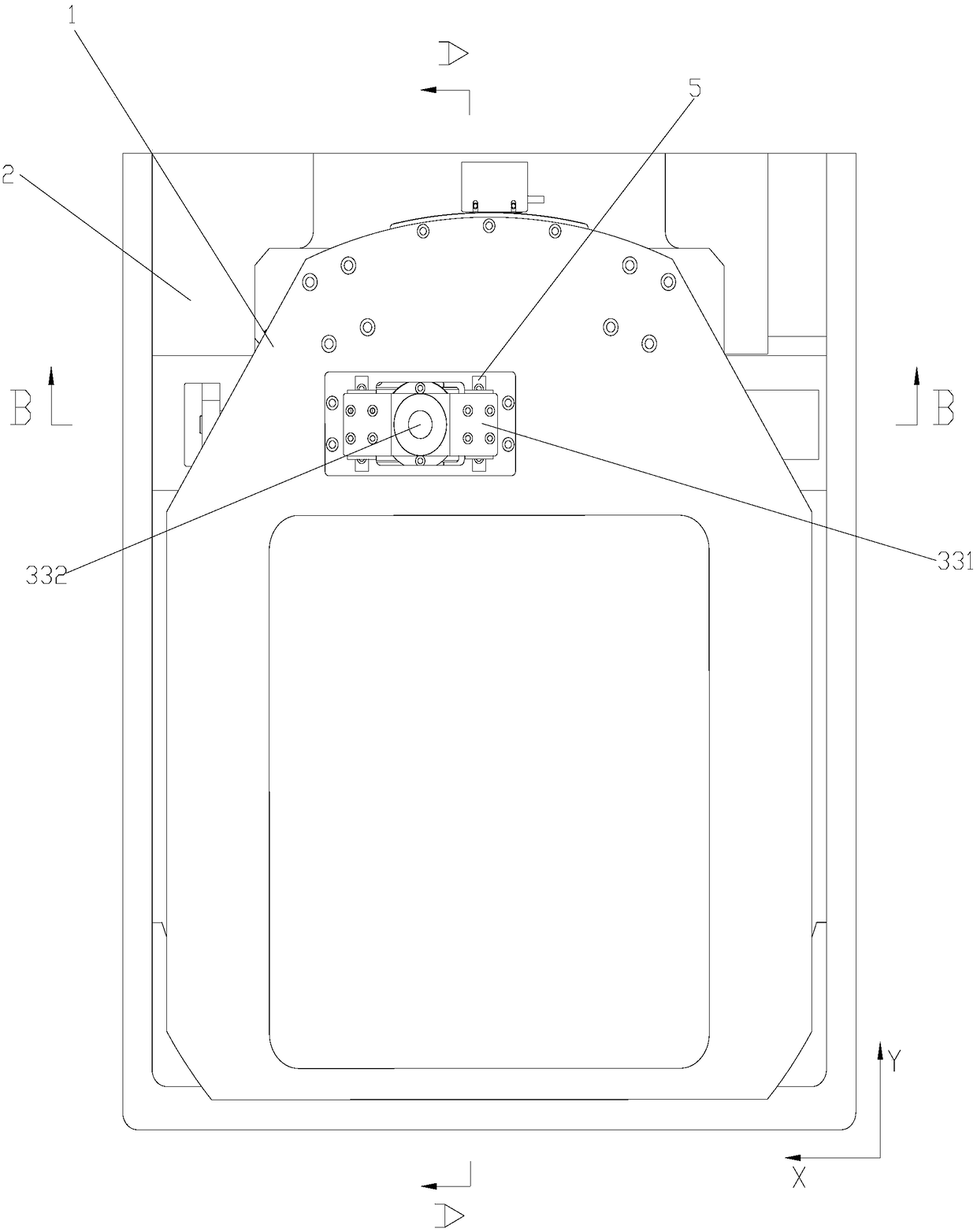

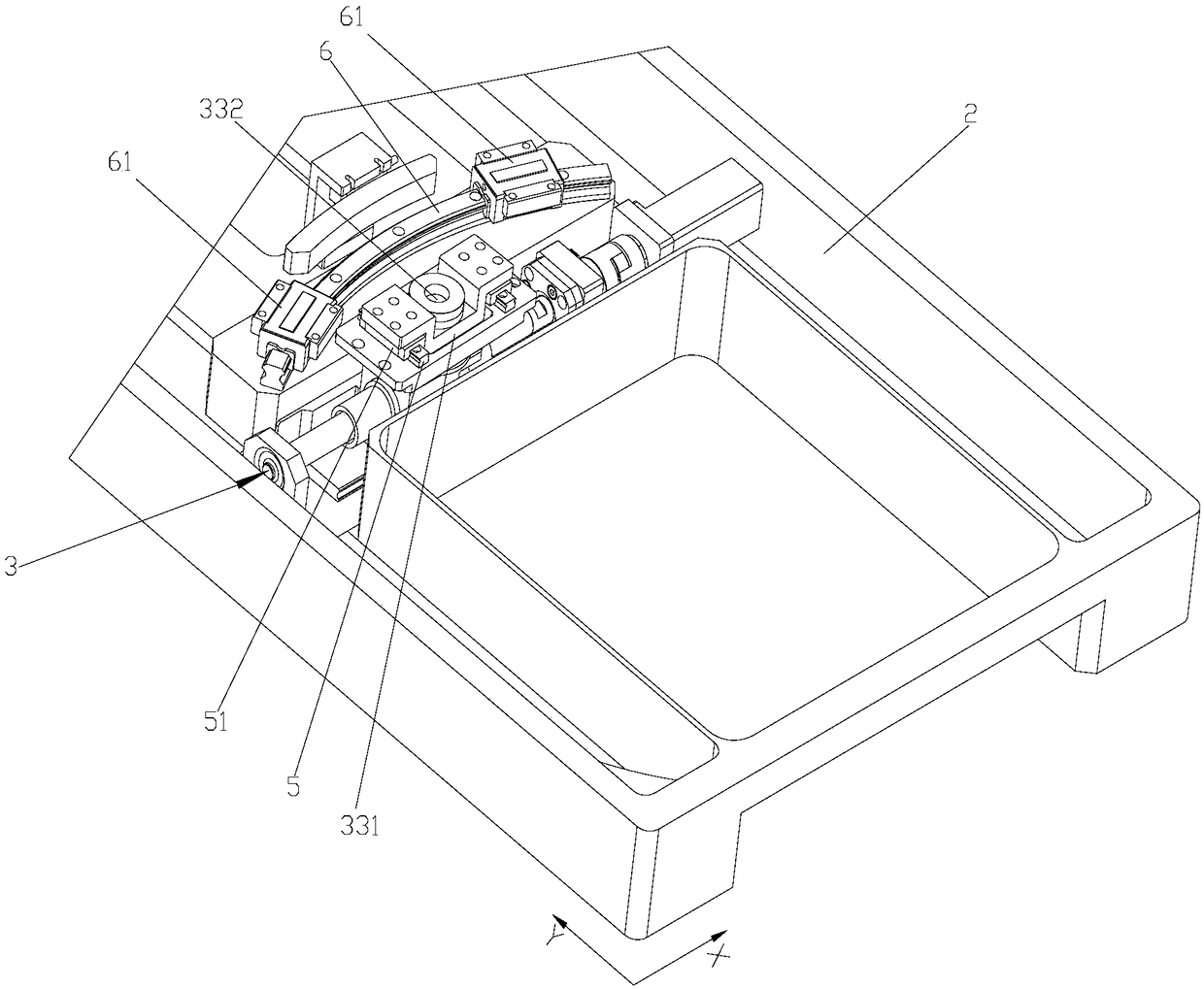

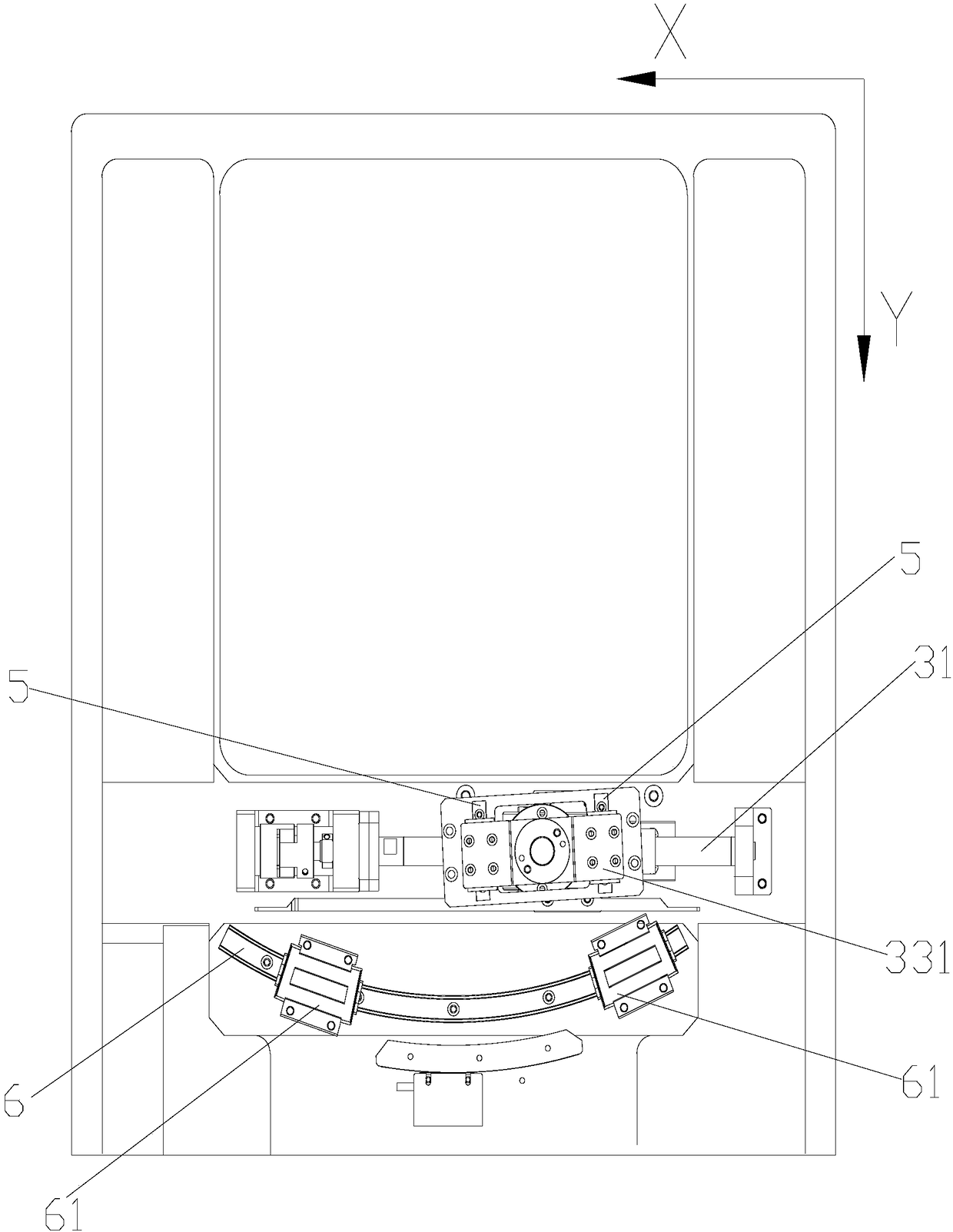

[0031] Such as Figure 1-6 As shown, this embodiment provides an angle adjustment device, which includes a base 2 and an angle running part 1. The base 2 is provided with an arc-shaped guide rail 6, and the angle running part 1 is slidably arranged on the On the arc-shaped guide rail 6, the drive mechanism includes a power device arranged on the base 2, a linear guide rod 31 arranged on the base 2, and a driver 32 slidingly arranged on the linear guide rod 31, the power device For driving the driving member 32 to move along the linear guide rod 31, the driving mechanism 3 also includes a driving connecting member 33, which is rotatably connected to the driving member 32, and the driving connecting member 33 is fixed on the angle running member 1 along the The linear guide device 5 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com