Gear chain type core rod for bending forming of rectangular pipe

A technology for bending and forming rectangular tubes, applied in the field of gear chain mandrels for bending and forming rectangular tubes, can solve the problems affecting the bending accuracy and low supporting accuracy of thin-walled tubes with large diameter-to-thickness ratio and small bending radius, and achieve tight fit , Improve the support accuracy, improve the effect of bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

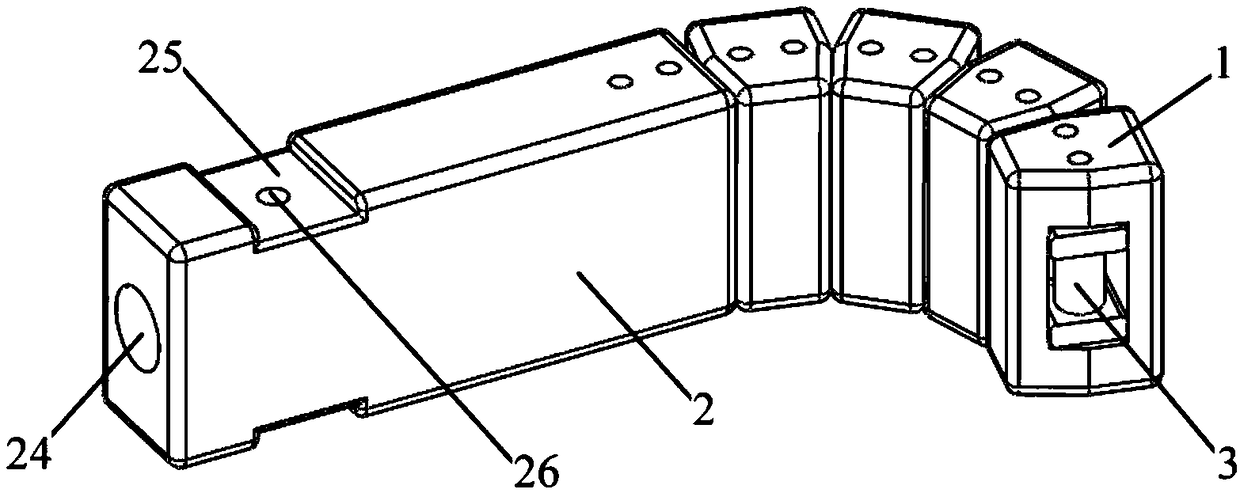

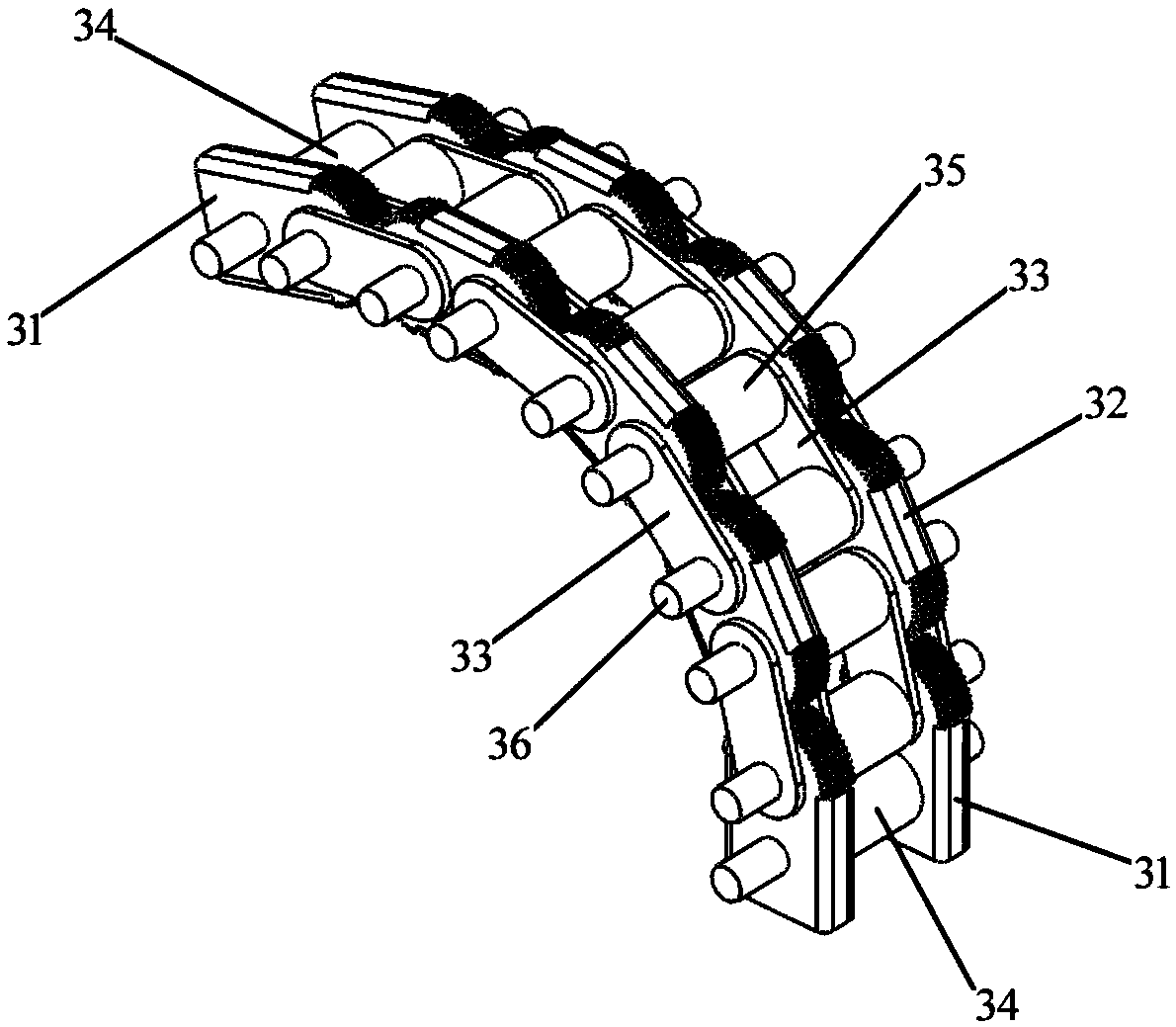

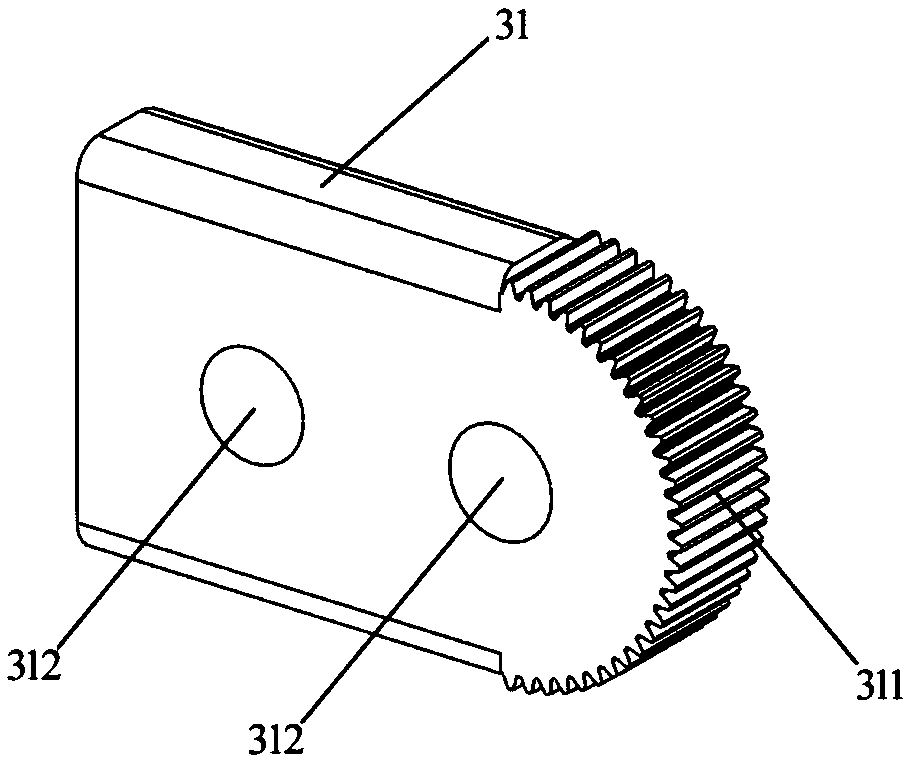

[0032] A kind of gear chain type mandrel for rectangular tube bending forming of the present embodiment, such as Figure 1-8 As shown, it includes more than one core ball 1 for supporting the curved section of the rectangular pipe, a mandrel 2 for supporting the straight section of the rectangular pipe, and a core ball 1 for connecting the core ball 1 and the core ball 1 and connecting the core ball 1 and the The gear chain connecting body 3 between the mandrels 2; wherein the gear chain connecting body 3 includes a single-sided gear plate 31, a double-sided gear plate 32, a connecting piece 33, a long limit ring 34, and a short limit ring 35 and shaft 36; the core ball 1 is a housing 14 with a cuboid structure, the housing 14 is provided with a first installation cavity 11, and the mandrel 2 is a mandrel with a cuboid structure;

[0033] The single-side gear plate 31 is divided into 2 pairs, each pair has 2 pieces, and the number of the core balls is the logarithm of the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com