Two-panel retractable internal mold flue gas channel vibration casting machine

A technology of vibration casting machine and inner mold, which is applied in molds, ceramic molding machines, manufacturing tools, etc., can solve the problems of unsealable outer mold side plate and outer mold lower plate, cracking of the finished flue gas channel, complex structure, etc., and achieve Improve directional stability and product quality, lower cost, and improve the effect of supporting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

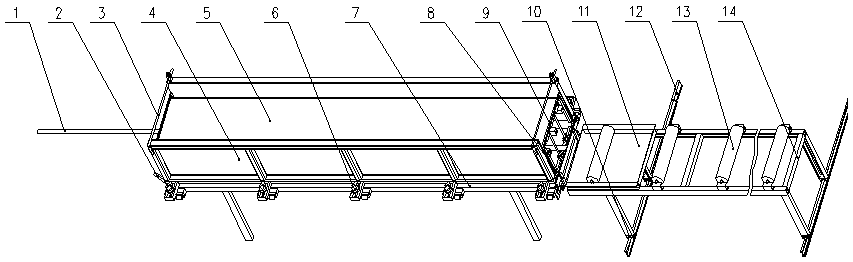

[0035] see figure 1 , the shock casting machine used to manufacture the flue gas duct of a building includes a handle, an inner mold mechanism, an outer mold mechanism, an outer mold frame 7, a mold ejection frame 14, a vibration pump, and an elastic support. The outer mold frame 7 supports the outer mold mechanism, the outer mold mechanism is placed outside the inner mold mechanism, and the flue gas channel is formed in the area clamped between the inner and outer mold mechanisms. The length of ejection frame 14 is identical with outer mold, is positioned at outer mold mechanism afterbody, and caster 10 and the guide rail 12 perpendicular to frame length direction are installed below it.

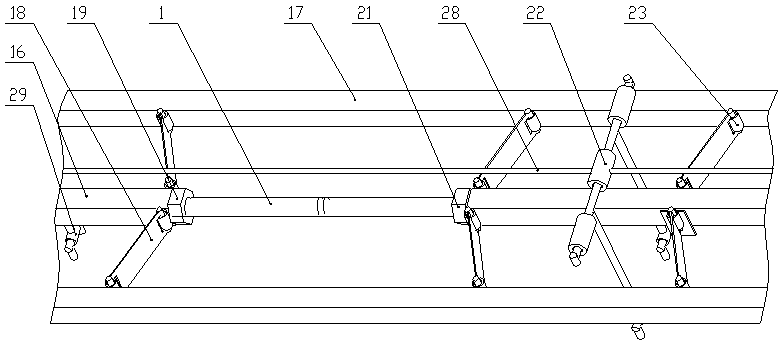

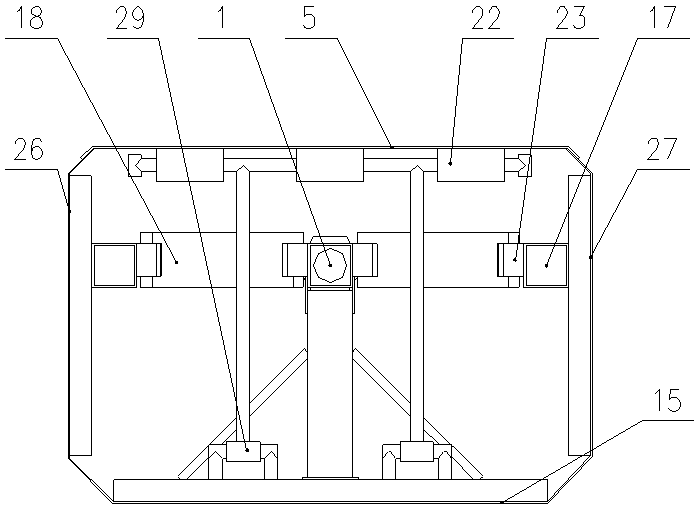

[0036] see figure 1 , figure 2 and Figure 4 , The length direction of the inner mold mechanism is consistent with the length direction of the shock casting machine, and the left and right ends are supported by the baffle plate 9 on the outer mold mechanism. The inner mold cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com